Elevated platform type automatic processing center of lathe and milling machine of five shafts

An automatic processing, overhead technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., to achieve the effect of low processing cost, guaranteed processing accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

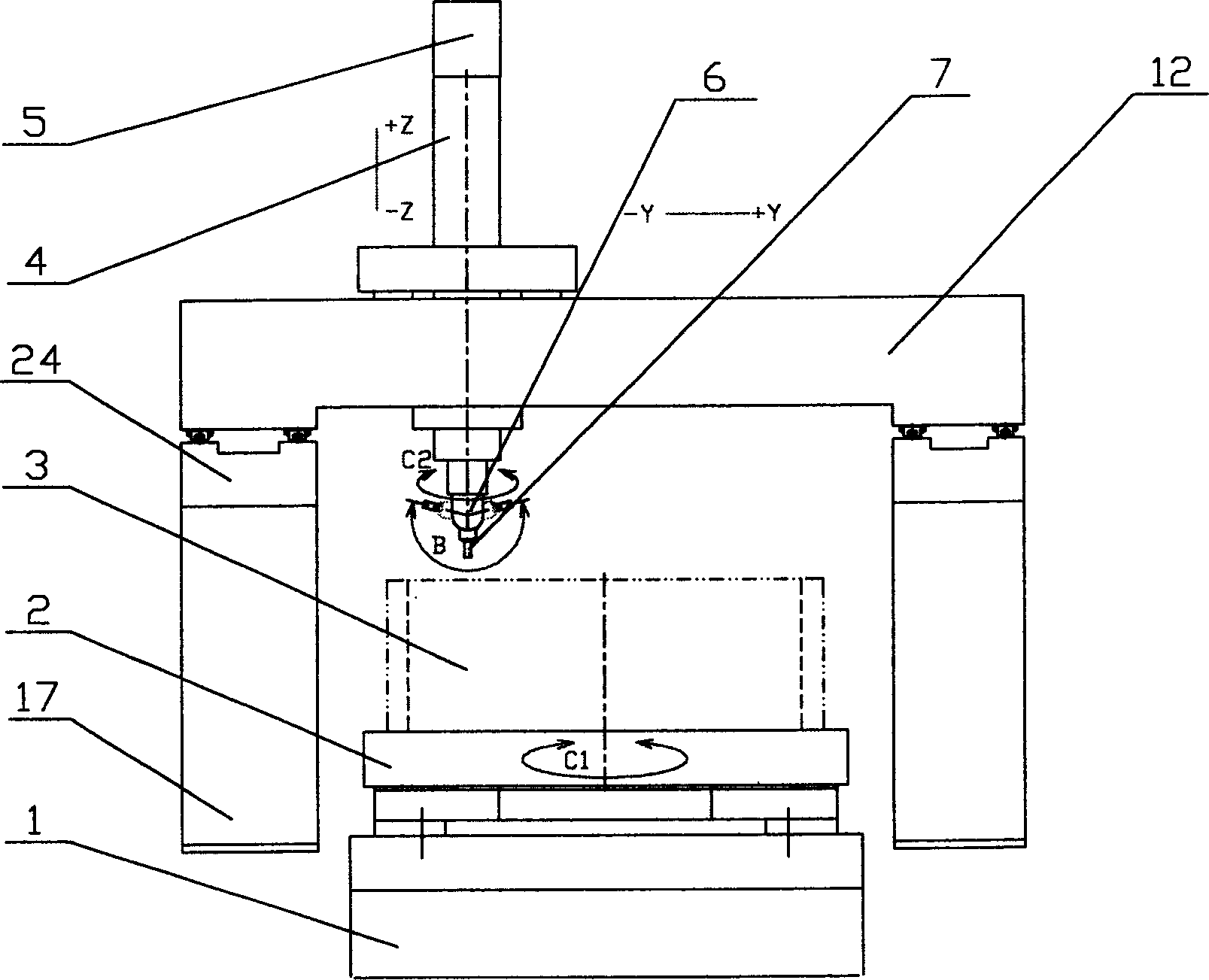

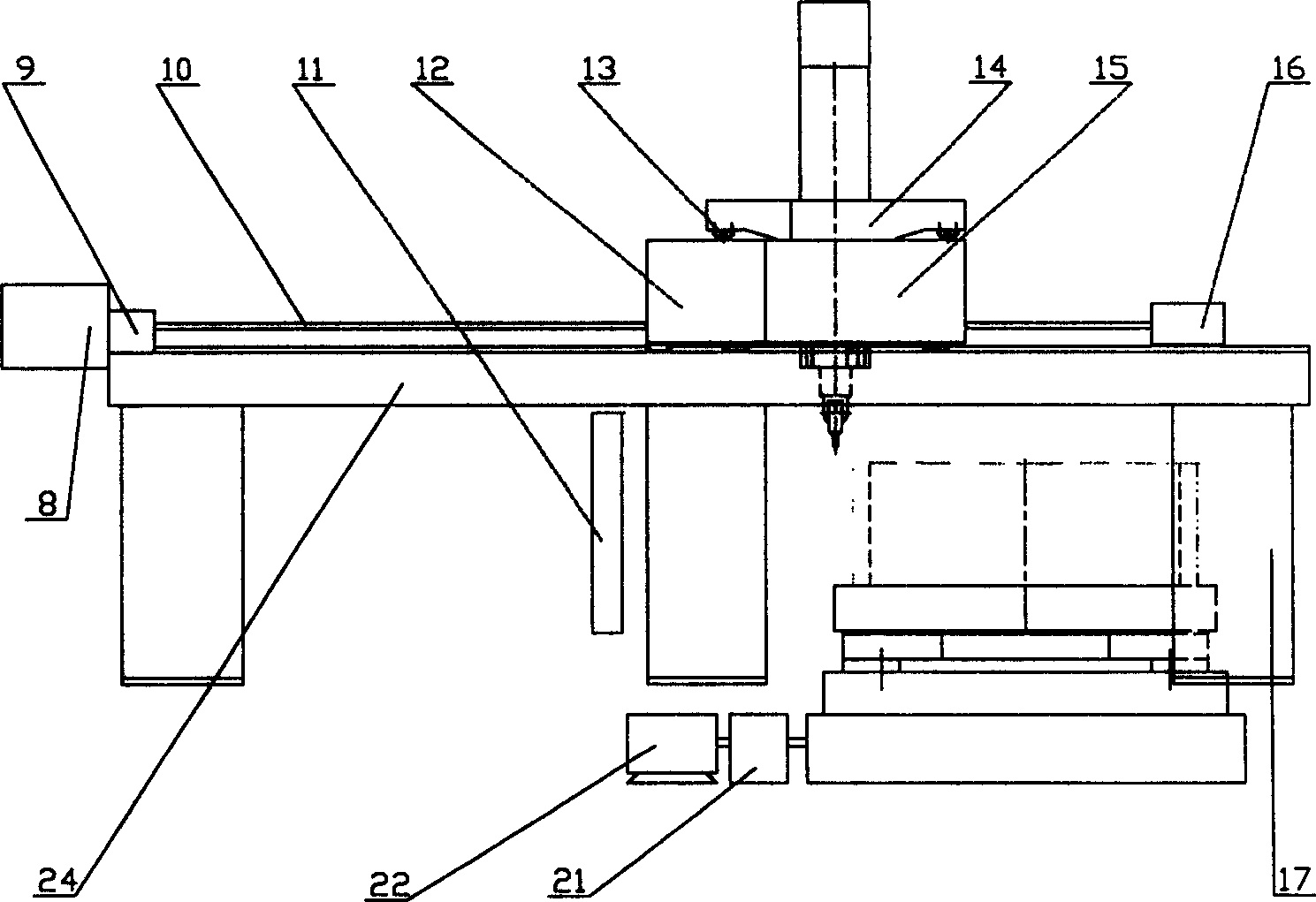

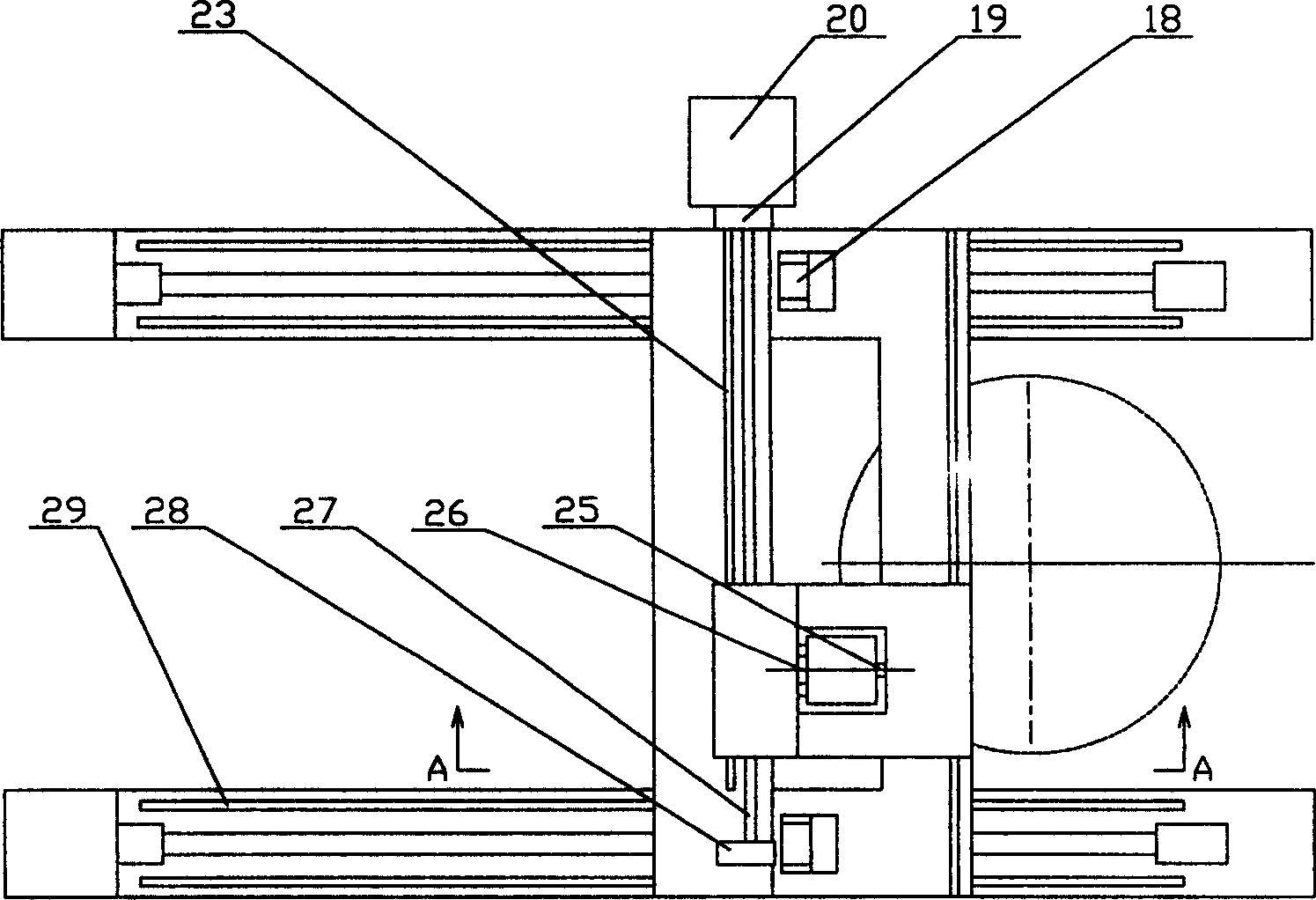

[0012] As shown in the figure, the technical scheme and working process of the present invention are further described in conjunction with examples.

[0013] Such as figure 1 As shown, an elevated five-axis turning and milling automatic machining center, the machine includes a table base 1, a rotary table 2, X-axis double beams, double swing compound turning and milling electric spindle 6, Y-axis saddle parts, Z-axis Ram components and electrical control systems. The rotary workbench 2 is arranged on the workbench base 1, driven by a DC speed regulating motor 22 and a gear box 21, and its rotating speed is 0.4-40 rpm. The X-axis double beam is fixedly connected by the X-axis main beam 12 and the X-axis auxiliary beam 15 through connecting bolts, and is respectively arranged on two support beams 24 through two pairs of X-axis rolling guide rails 29, and the support beams 24 are respectively fixed on two beds. On the bed column 17, each bed column 17 has three columns, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com