Planetary gear train single input/double output reduction clutch

A single-input, double-output, deceleration clutch technology, applied in the field of clutches, can solve the problems of high machining precision, difficult and complex machining technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

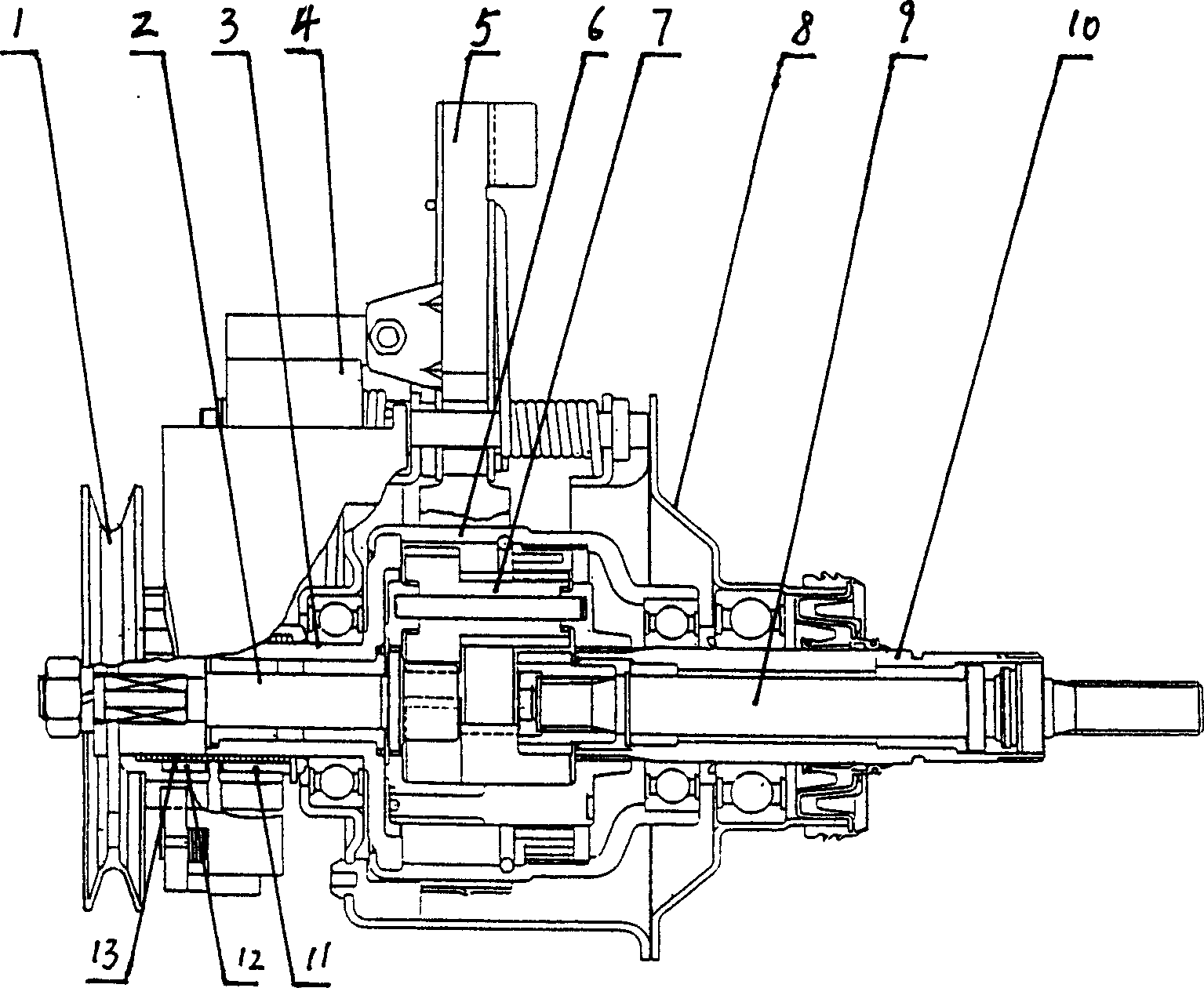

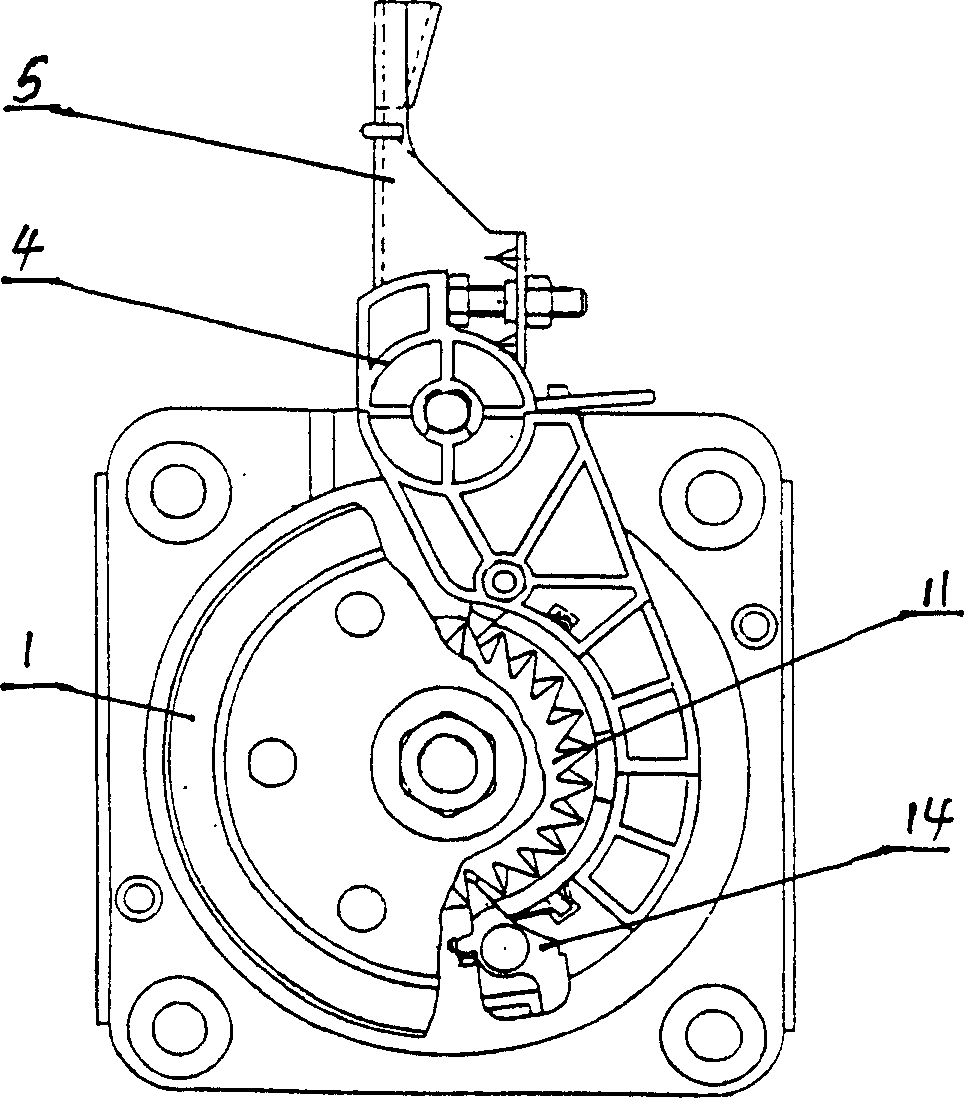

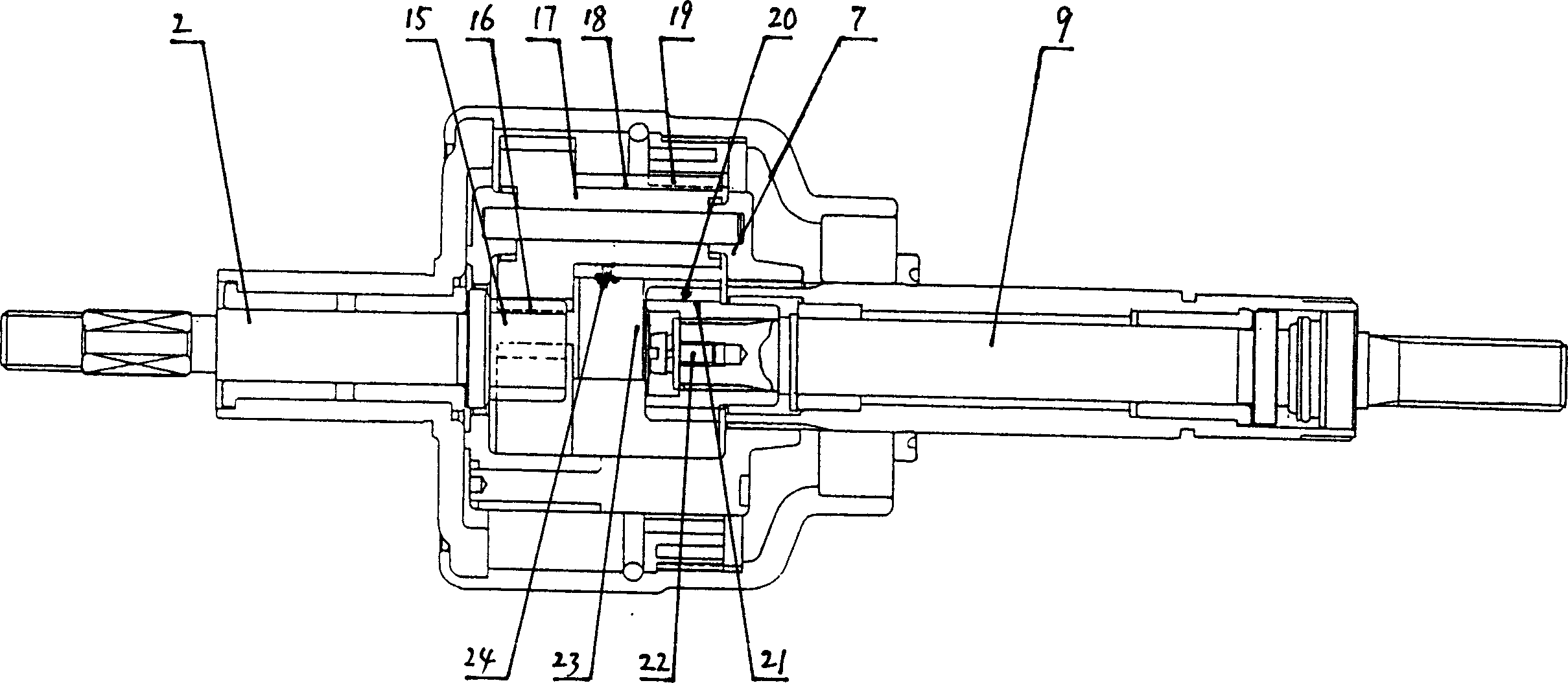

[0012] The present invention comprises input shaft 2, output shaft 9, dehydration shaft 10, brake arm 5, ratchet arm 4, ratchet 11,12, belt pulley 1, input shaft shell 3, core shell 6 and output shaft used as the brake hub Housing 8, pulley 1 is set on the left end of input shaft 2 through splines, the motor is connected with pulley 1 through a belt, ratchets 11, 12 and square wire spring 13 are set on the outer wall of input shaft housing 3, and fixed on the right end of output shaft 9 There is a pulsator, a dehydration bucket is fixed on the right end of the dehydration shaft 10, an input shaft external gear 15 is processed on the right end of the input shaft 2, and a passing pin is set on the primary transmission bracket 17 of the cylindrical swing arm frame body 7. The first-stage transmission left gear 16 and the one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com