Anti-explosion solar all glass vacuum heat collecting tubes

A technology of vacuum heat pipe and glass heat pipe, applied in the direction of solar heat collector, solar thermal energy, solar thermal power generation, etc., can solve the problems of bursting, heat pipe pressure rise, low product reliability, etc., and achieve moderate manufacturing cost and reliable work. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

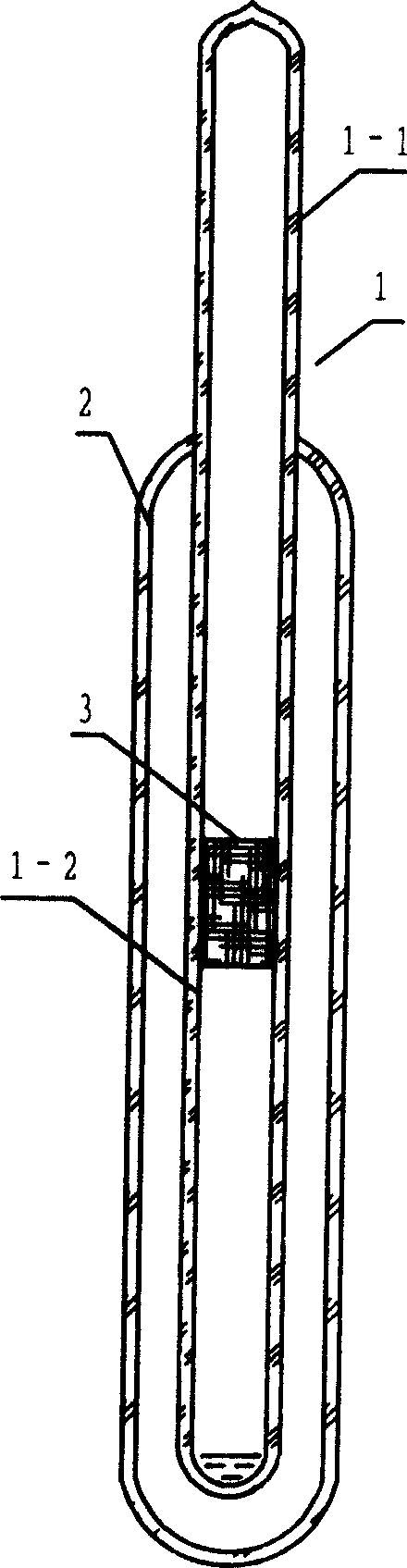

[0011] see figure 1 , the utility model is composed of a glass heat pipe 1 and a glass outer pipe 2, wherein the heat pipe is composed of an evaporation section 1-2 and a condensation section 1-1, the evaporation section is set in the outer pipe, the condensation section is located outside the outer pipe, and the outer pipe and the heat pipe are two are melted. Vacuum is drawn between the heat pipe and the outer pipe as well as in the heat pipe, and the outer wall of the heat pipe is attached with a high-temperature selective heat-absorbing coating, which can make the heat pipe have a higher absorption rate and a lower emissivity, and the heat pipe is filled with working fluid. The gist of the invention is: to change the state of the working fluid so that it can be converted into a vapor phase when it reaches a certain critical temperature. In this way, when the temperature continues to rise, the pressure rises according to the law of the vapor phase, not the law of the vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com