Parallel optical array assembly with standard MPO interface

An optical fiber array, a standard technology, applied in the field of parallel optical fiber array components, can solve the problem that the positioning accuracy of optical fibers is not very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

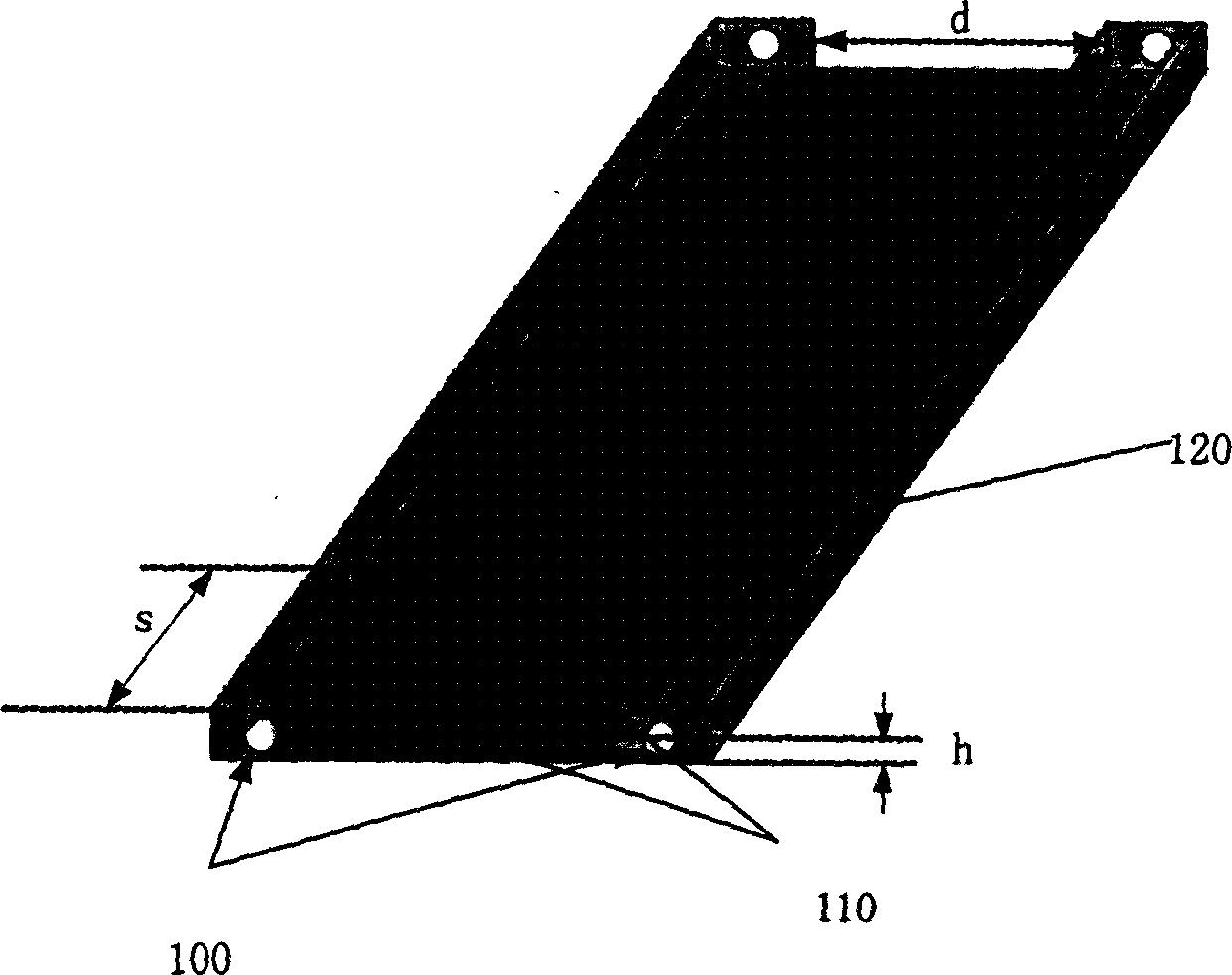

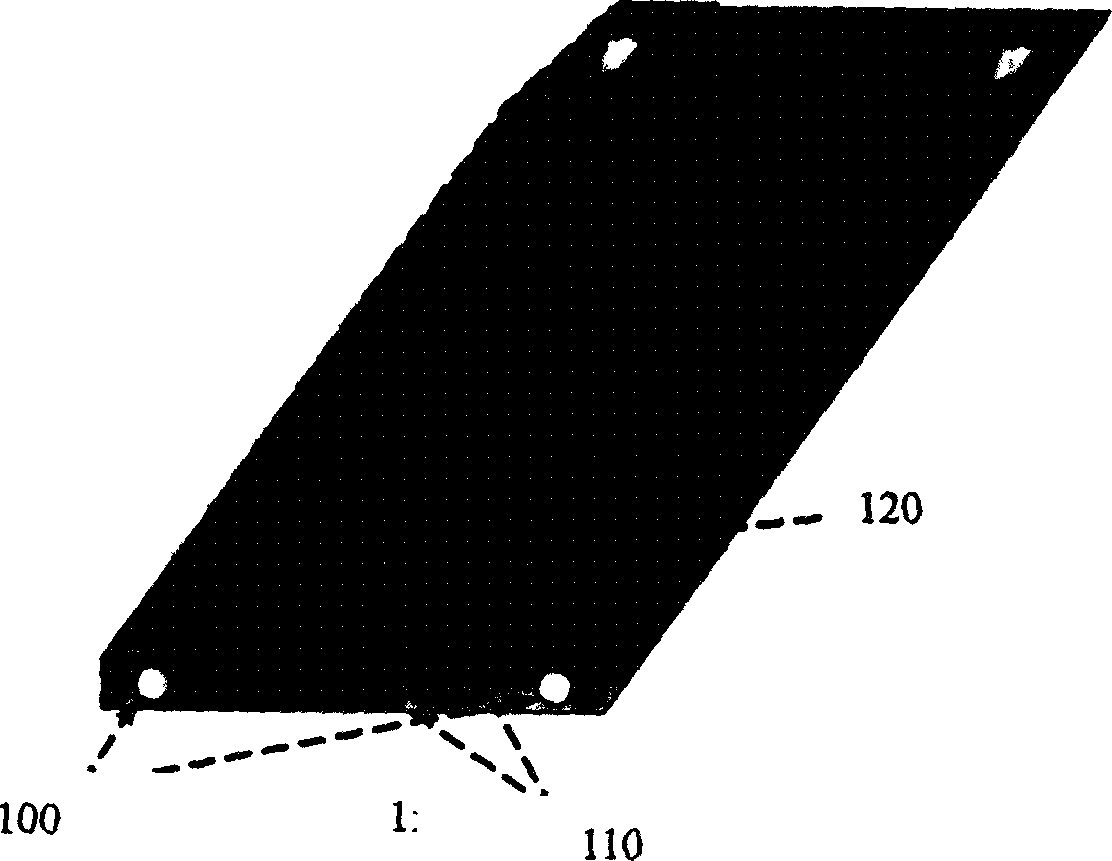

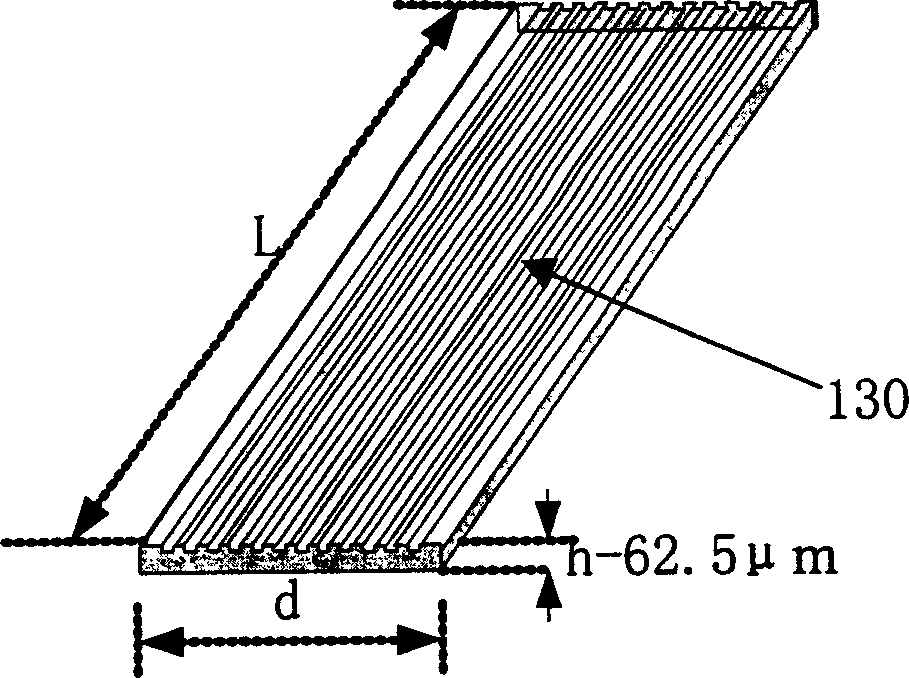

[0015] First, using traditional standard compression molding techniques to make such as figure 1 The traditional 1×N standard MPO socket component shown in the figure has the following three key functions: First, there are two positioning pin holes 100 that penetrate the entire device on both sides, which are used when two opposite devices are docked. , so that all optical channels in the two devices are fully coupled; second, there is a 1×N core fiber positioning hole 110 at one end, which is used for the strict positioning of 1×N optical fibers; third, after the 1×N positioning hole , there is a 1×N core optical fiber positioning V-shaped groove 120, its height and horizontal position are strictly the same as the previous optical fiber positioning holes, when it is used to discharge optical fibers, guide each optical fiber into each positioning hole, and at the same time, for each Fiber optics play a supporting role. The traditional standard 1×N MPO socket component can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com