A method for improving electrochemical and shock-proofing performance of power-driven lithium ion battery

A lithium-ion battery and power-type technology, applied in the field of lithium-ion batteries, can solve the problems of low utilization rate of battery active materials, poor high-current discharge capacity, large thermal effect, etc., and achieve consistent and concentrated distribution of battery capacity and internal resistance. Effects of improved discharge performance and increased rate of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Take the 12Ah lithium-ion power battery as an example:

[0042] The electrode materials are composite positive electrode materials for power lithium-ion batteries and high-rate nanocomposite carbon negative electrode materials. The positive electrode current collector is 0.02mm thick aluminum foil, and the negative electrode current collector is 0.02mm copper foil.

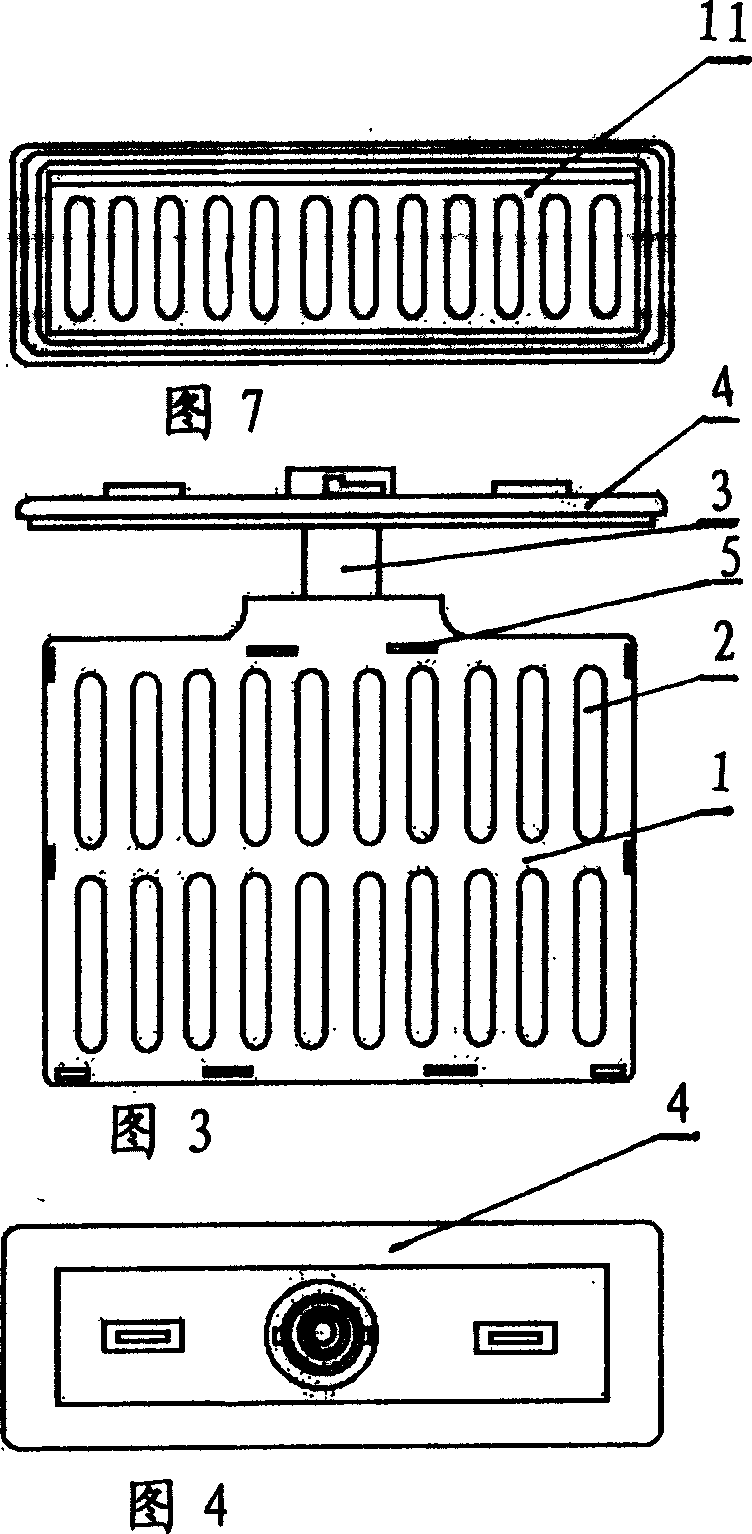

[0043] The thickness of the positive electrode sheet of the battery is 150 μm; the thickness of the separator is 40 μm, and the separator and the positive electrode sheet form a bag-like coating structure.

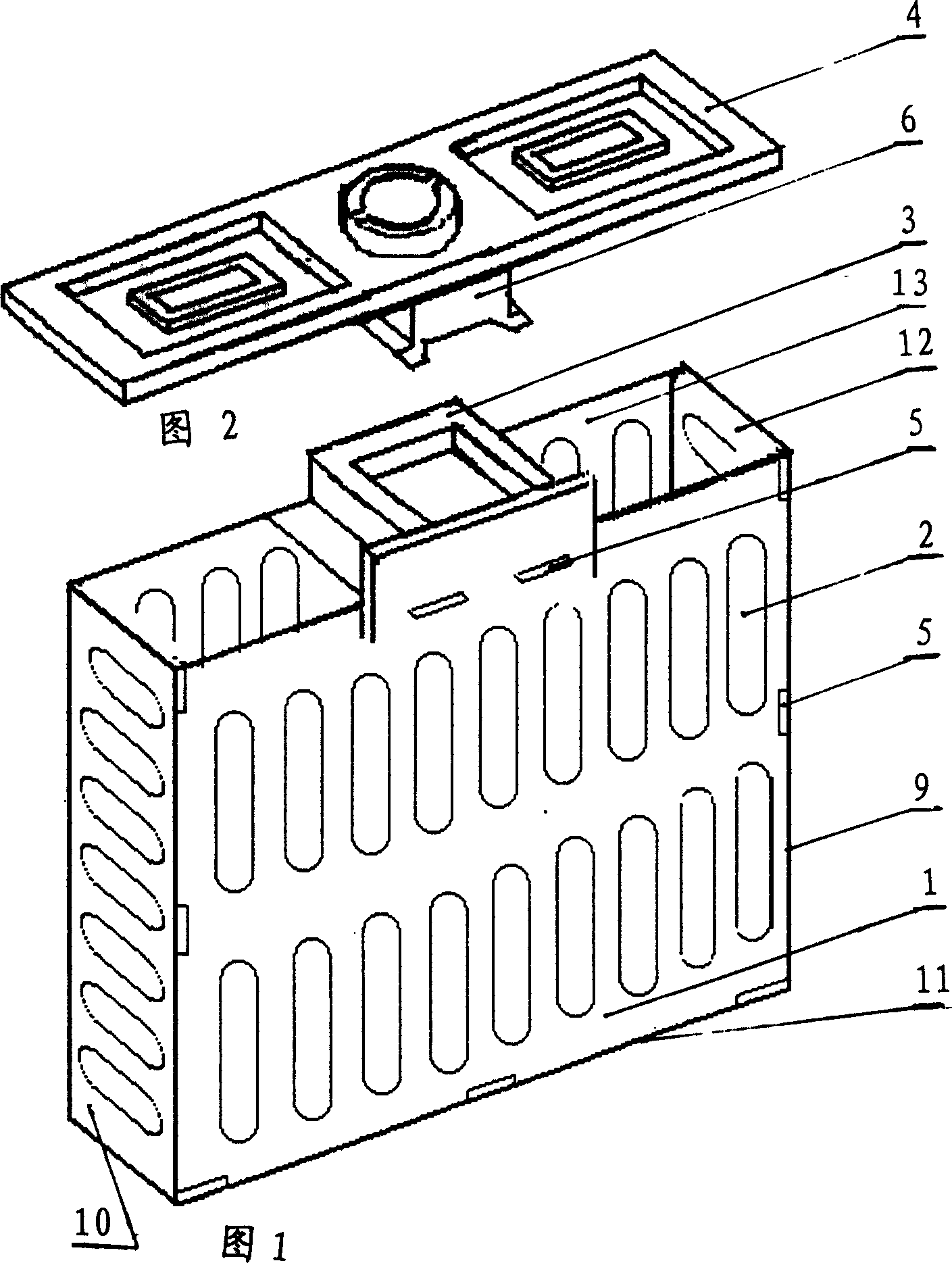

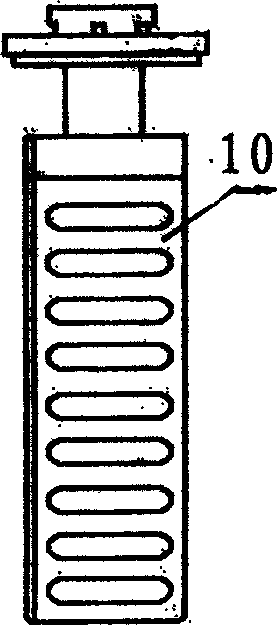

[0044] The battery pole piece, the pole piece box 9, the pole piece box cover 1, and the battery case cover 4 are assembled as follows: firstly, the connection key 6 below the battery case cover 4 is inserted into the connection slot 3 of the pole piece box 9 to realize The connection between the battery case cover 4 and the pole piece box 9; then stack 51 battery negative pole pieces and 50 bag-type ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com