Lightweight sound insulation composite wall plate

A composite panel and wall technology, applied in the direction of sound insulation, building components, layered products, etc., can solve the problems of thermal insulation, heat insulation, sound insulation, moisture-proof and other poor performance, inconvenient installation, etc., to achieve a reasonable and smooth structural strength design High-strength, easy-to-process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

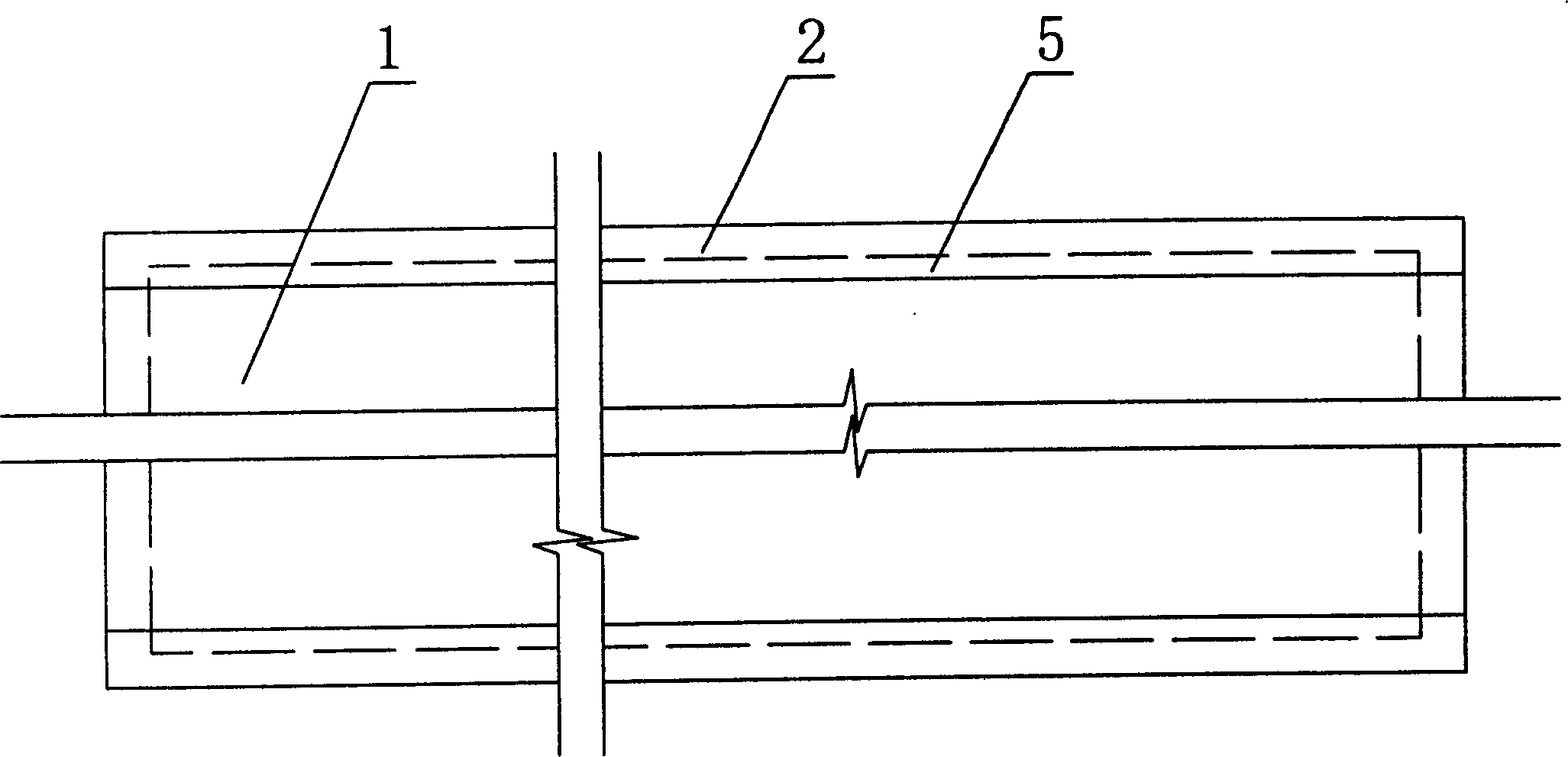

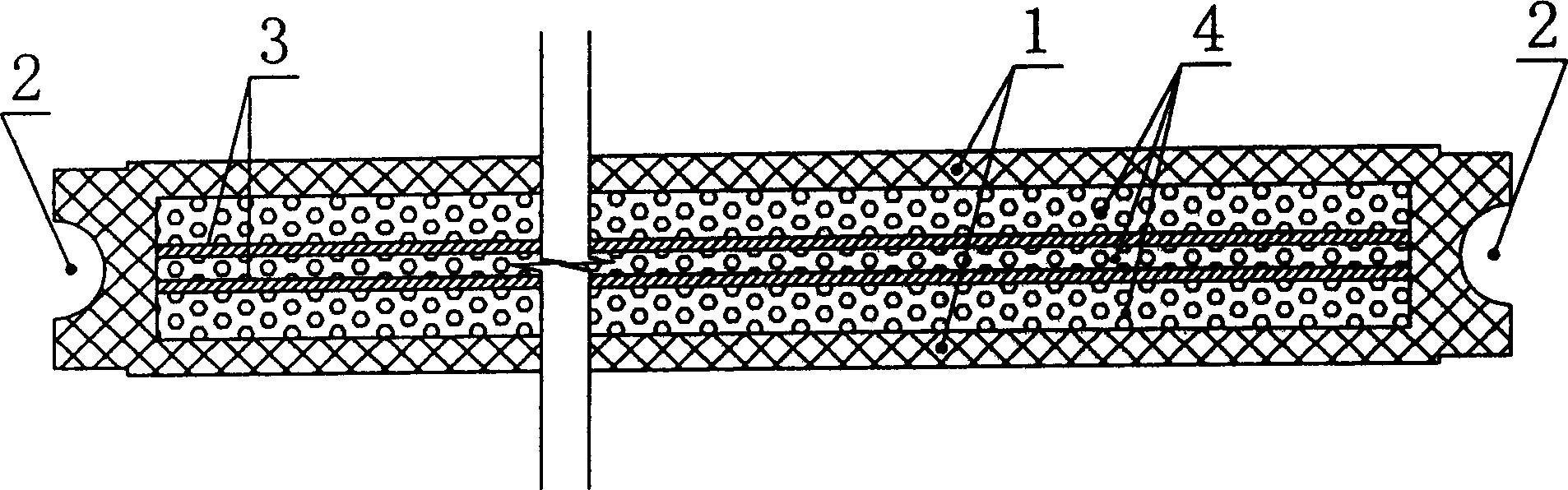

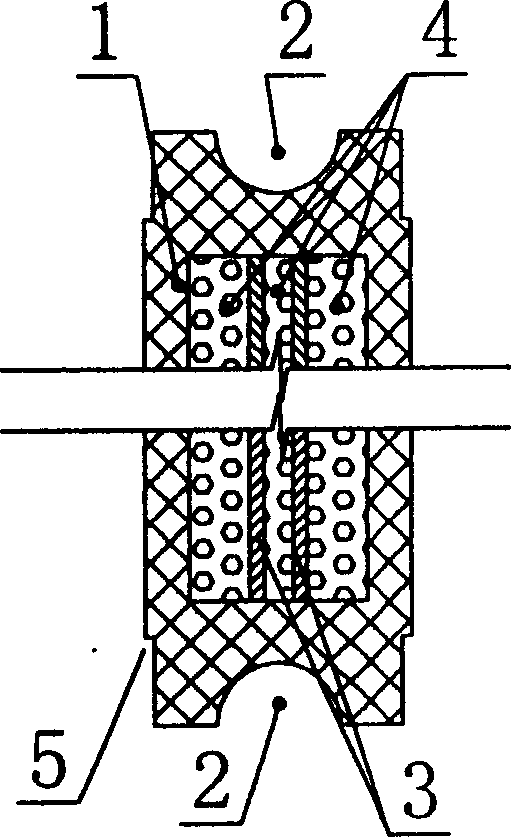

[0019] Figure 1-3 and Figure 4-6 Respectively represent two preferred embodiments of the present invention.

[0020] According to the light weight sound insulation wall composite board of the present invention, comprise wall surface layer 1 and by as in Figure 4 Or the core layer made of honeycomb cardboard or polystyrene foam as seen in partial section in 8. Wherein, the wall surface layer is the front and rear wall surface layers 1 of the front and rear two layers, and two layers of reinforcement boards 3 are arranged in the middle of them, and between the reinforcement board layer 3 and the front and rear wall surface layers 1 The core layer 4 is respectively arranged in between.

[0021] At the same time, semicircular grouting installation interfaces 2 are respectively arranged on the opposite side edges of the lightweight sound insulation wall composite board of the present invention, such as figure 2 , Structure shown in 3. Optionally, this grouting installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com