Energy-saving environment protective lubricating oil

An energy-saving and environmental-friendly lubricating oil technology, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., to achieve the effect of low friction coefficient and high synergistic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The base oil of lubricating oil is synthetic fat and any mixed oil selected from API classification II, III and IV, and its weight percentage is 80-90%; add additives including: detergent, ashless dispersant, antioxidant Anti-corrosion and anti-rust agent, auxiliary antioxidant, viscosity index improver, pour point depressant, defoamer, friction modifier, extreme pressure agent and anti-friction and anti-wear synergist, the total additives account for 10-20% of the total weight of the composition %. Among them, the friction modifier is composed of sulfurized dihydrocarbyl dithiophosphate (S-MDTP) or dihydrocarbyl dithiophosphate (MDTP) and molybdenum dihydrocarbyl dithiocarbamate (MoDTC) with a hydrocarbon group of 2-ethylhexyl ) compound, its composite ratio is S-MDTP or MDTP:MoDTC=(1~4):(4~1), and its content accounts for 0.001~0.5% (by molybdenum weight) of the total composition; S- MDTP or the metal constituting the salt in MDTP is molybdenum (Mo) or tungsten (W). ...

Embodiment 2

[0011] Add the base oil into the blending kettle according to the metered quantity, start stirring, and raise the temperature to 65-70 degrees Celsius, and add the quantities of each component in Table-1 to the base oil in the following order, first add the pour point depressant, the second Add viscosity index improver first, then add auxiliary antioxidant, anti-oxidant and anti-corrosion agent, detergent, dispersant, defoamer, friction modifier compound, extreme pressure agent, anti-friction and anti-wear synergist in turn. After adding all the components, keep the original temperature and continue to stir for 30 minutes. After all the components are mixed evenly, cool down to room temperature to obtain a homogeneous, light brown, clear and transparent lubricating oil.

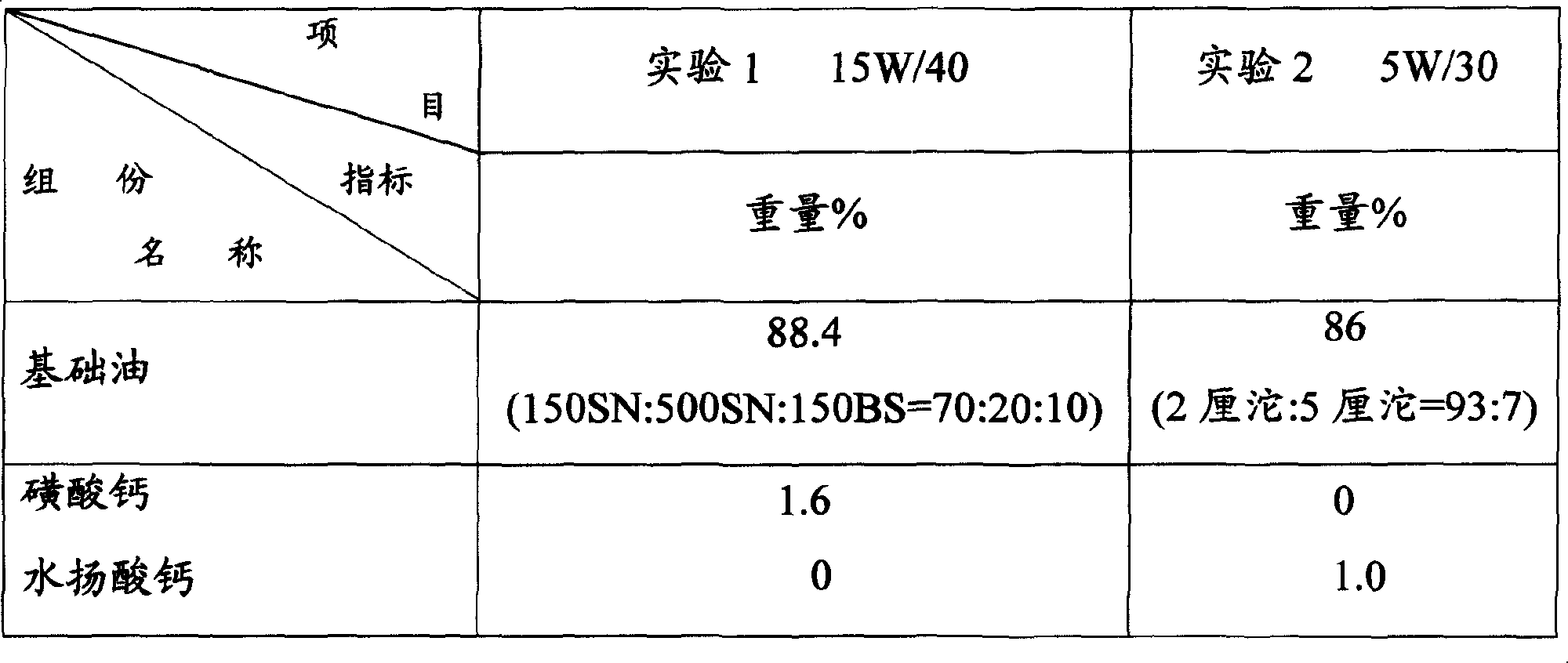

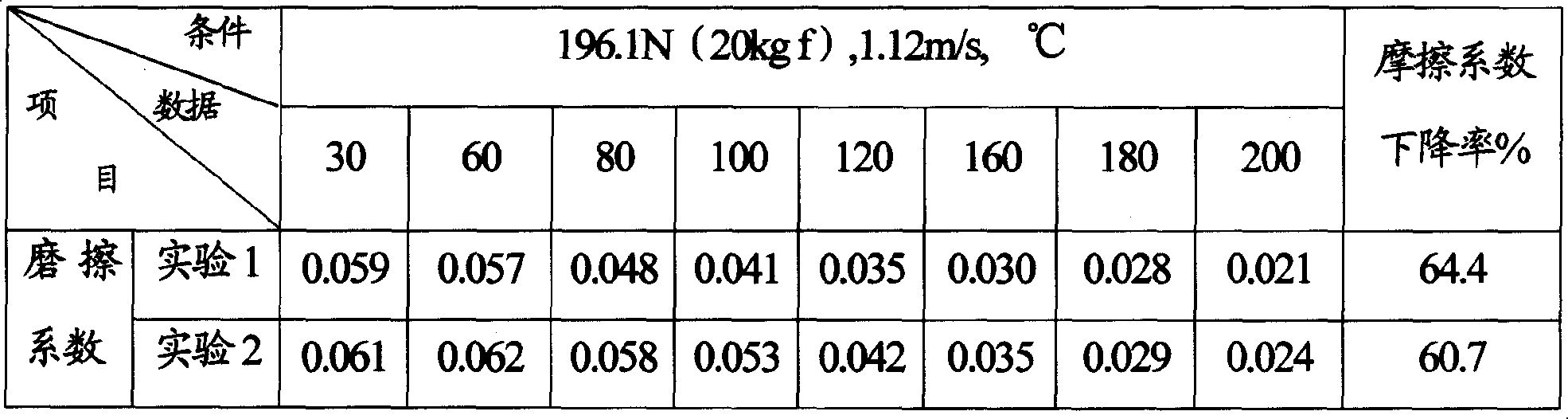

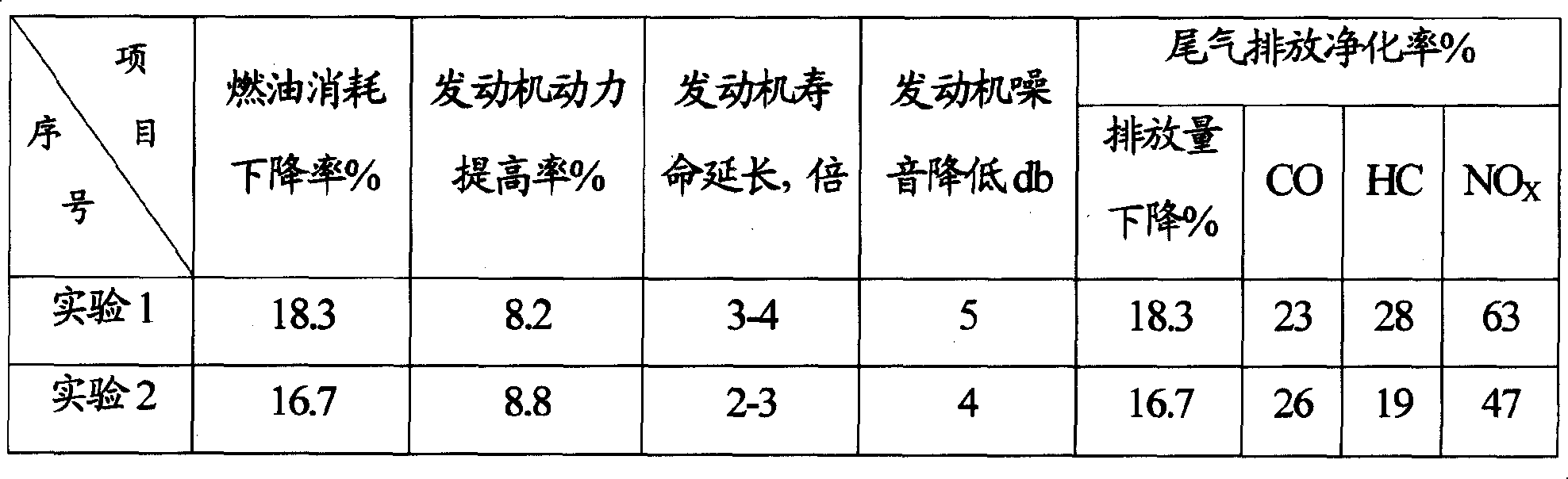

[0012] Table-1 List of components of lubricating oil composition

[0013]

[0014] Polyisobutenylsuccinimide

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com