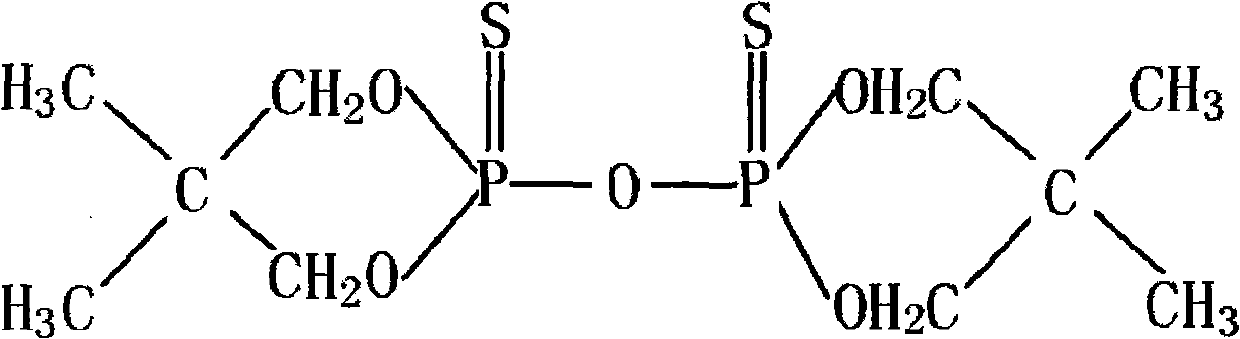

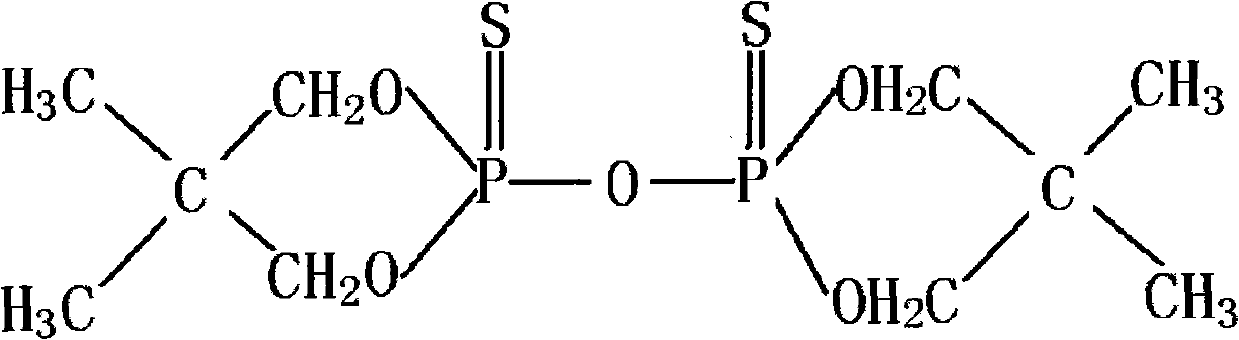

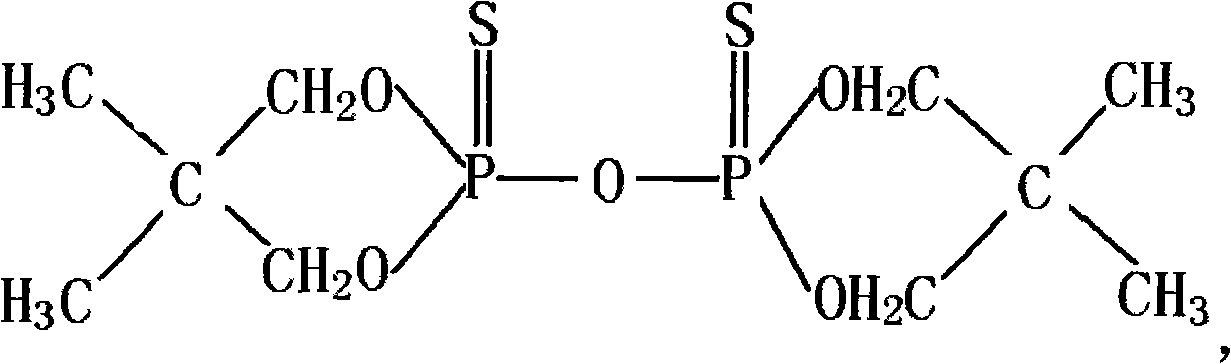

Method for synthesizing dithio dineopentyl phosphate fire retardant

A technique for the synthesis of neopentyldithiophosphoric acid ester, which is applied in the fields of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problem of using toxic solvents, high cost and technical process Long-term problems, to achieve the effect of low price, low toxicity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 180g of cyclohexane into a 1500ml round bottom flask, add 25g of neopentyl glycol and stir evenly, then add 45g of phosphorus trichloride, fully dissolve at 52°C, then add 80g of triethylamine dropwise, heat up to 58°C and keep After 2 hours, add 25 g of triethylamine and 1.3 g of water, raise the temperature to 71° C. and keep for 10 hours to obtain the product of the present invention, the phosphorothioate flame retardant, with a molecular formula of C10Hz0O5P2S2 and a yield of 81.1%. After filtering and grinding, the product of the present invention is obtained. The phosphorothioate flame retardant suspension has a particle size of 0.82 μm as detected by a particle size tester.

Embodiment 2

[0034] Add 250g of cyclohexane into a 1500ml round bottom flask, add 25g of neopentyl glycol and stir evenly, then add 38g of phosphorus trichloride, fully dissolve at 40°C, then add 85g of triethylamine dropwise, heat up to 50°C and keep After 2.5 hours, add 40 g of triethylamine and 13 g of water, raise the temperature to 60° C. and keep for 12 hours to obtain the product sulfur phosphoric acid ester flame retardant of the present invention, the molecular formula is C10H20O5P2S2, and the yield is 81.3%. The phosphate ester flame retardant suspension has a particle size of 0.81 μm as detected by a particle size tester.

Embodiment 3

[0036] Add 115g of cyclohexane into a 1500m] round bottom flask, add 25g of neopentyl glycol and stir evenly, then add 62g of phosphorus trichloride, fully dissolve at a temperature of 55°C, then add 70g of triethylamine dropwise, and heat up to 65°C Keep at ℃ for 1.5 hours, then add 15g of triethylamine and 2g of water, raise the temperature to 75℃ and keep for 8 hours to obtain the product of the present invention, the sulfur phosphoric acid ester flame retardant, the molecular formula is C10H20O5P2S2, and the yield is 81.3%. After filtering and grinding, the present invention is obtained. The product phosphorothioate flame retardant suspension has a particle size of 0.79 μm as detected by a particle size tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com