Device and method for nondestructive inspection on semiconductor device

A non-destructive, semiconductor technology, applied in semiconductor/solid-state device testing/measurement, electrical components, non-contact circuit testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0101] Embodiment A contains various examples designed for non-destructive inspection in accordance with the present invention.

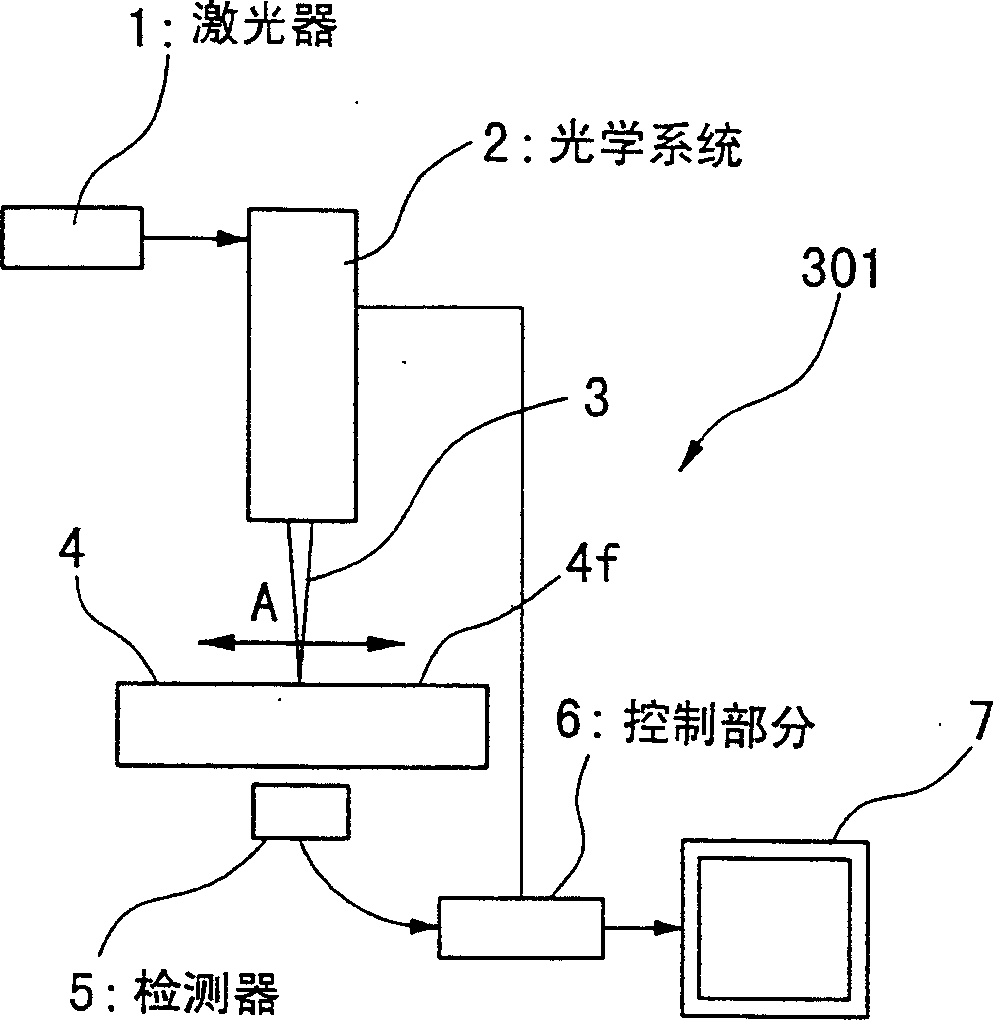

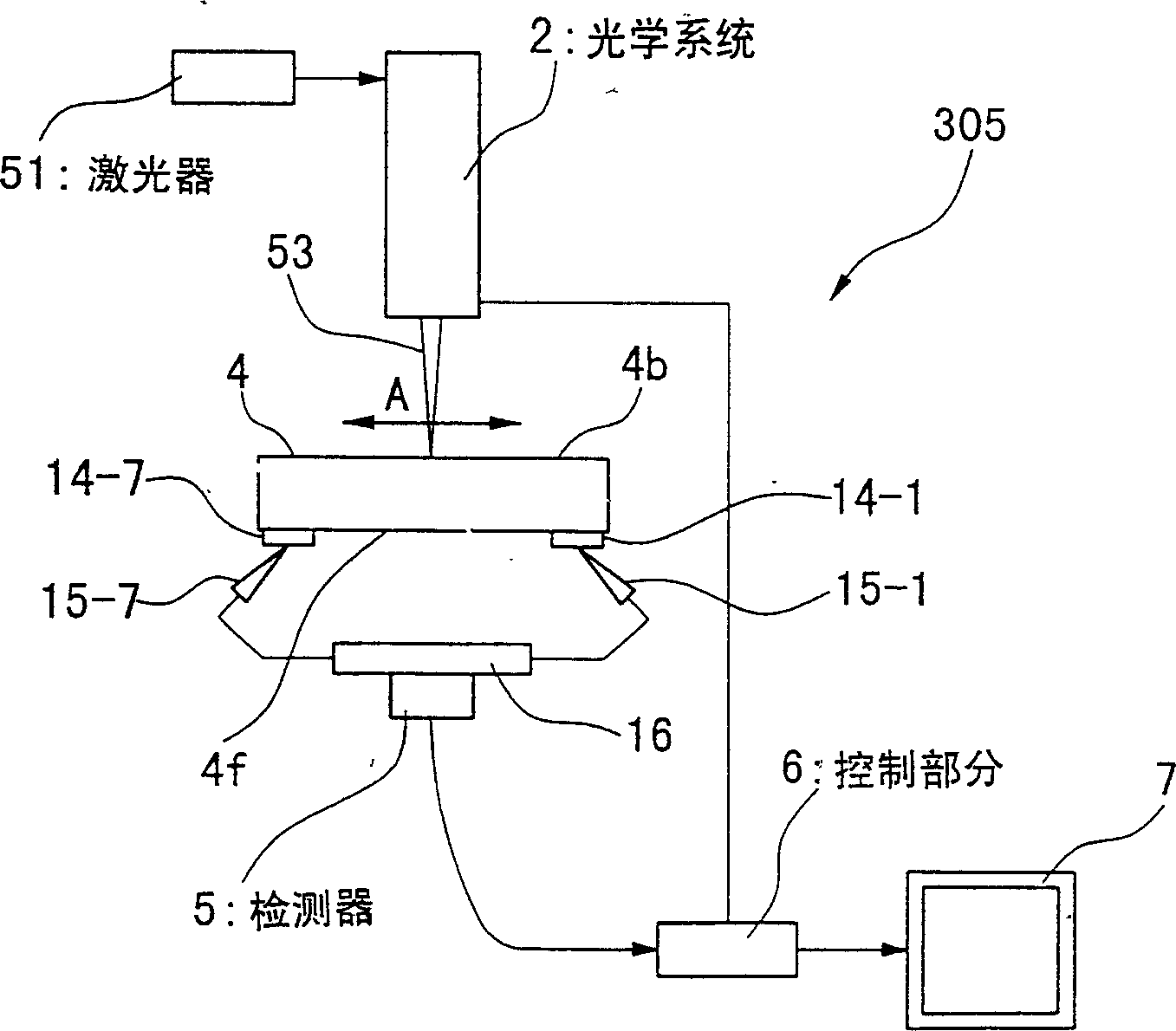

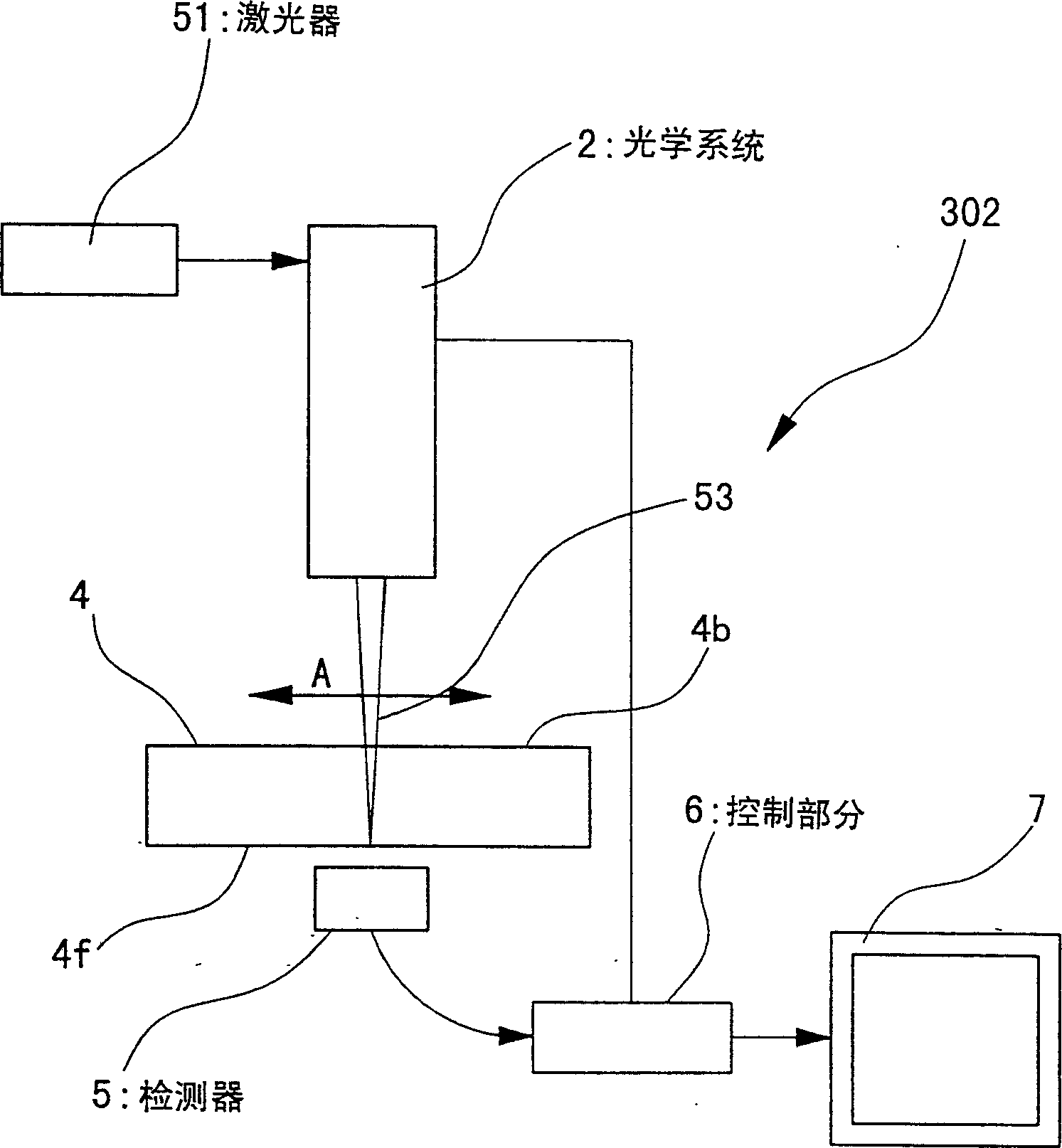

[0102] Figure 1A , 1B , 2, 3 and 4 are five examples showing the non-destructive inspection apparatus according to Embodiment A of the invention, which are similar to those shown in Figure 8 and 9 Equivalent and identical parts are assigned the same reference numerals.

[0103] Now, refer to Figure 1A , 2 , 3 and 4 describe examples 1, 2, 3 and 4 of the non-destructive inspection device in sequence. Here, the structures of those examples will be described first, and then, the operation procedures will be described.

[0104] exist Figure 1A The non-destructive inspection device 301 of the illustrated example 1 is configured as follows:

[0105] Laser 1 produces a laser beam, which is narrowed in irradiation size by optical system 2 to produce laser beam 3 . The laser beam 3 is irradiated on the upper surface 4f of the semiconductor device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com