Extraction process for removal of impurities from mother liquor in the synthesis of carboxylic acid

A technology of mother liquor and carboxylic acid, which is applied in the separation/purification of carboxylic acid compounds, preparation of carboxylate salts, chemical instruments and methods, etc., can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

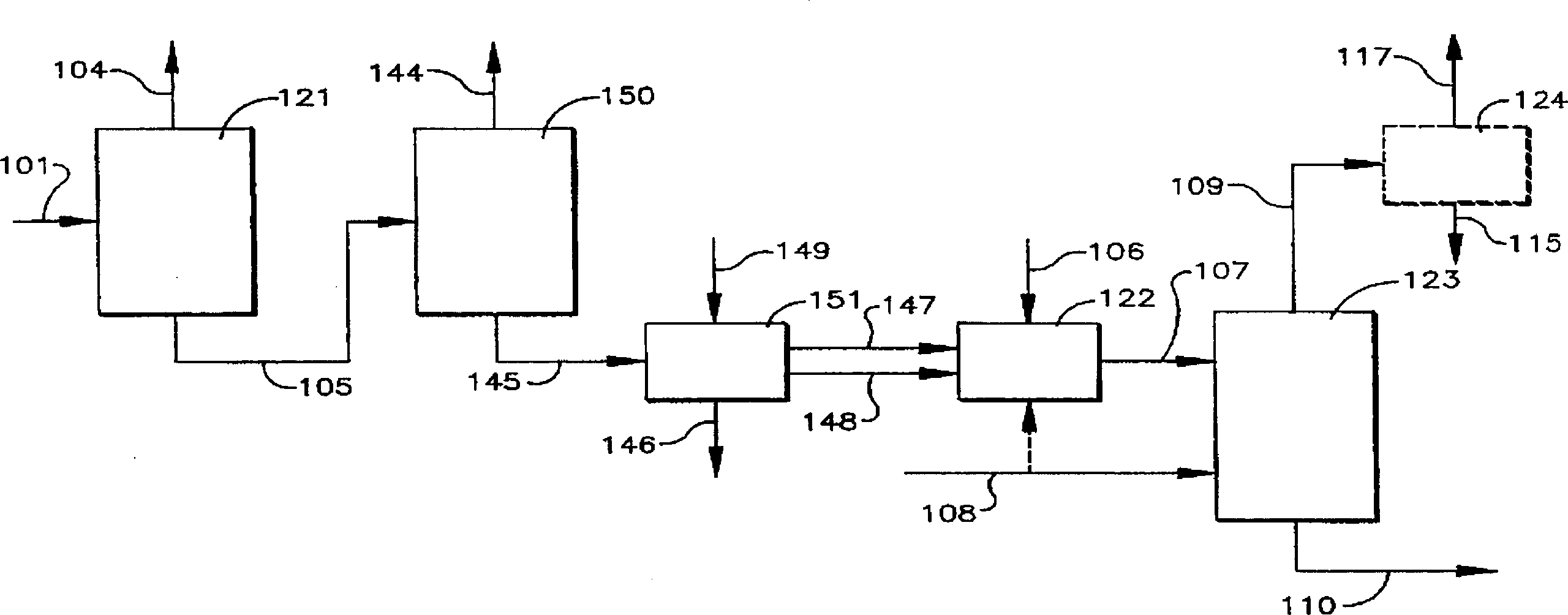

[0036] In one embodiment of the invention, as figure 1 As shown, a method for recovering metal catalysts from mother liquor 101 is provided. The method includes the following steps.

[0037] Step (a) comprises evaporating mother liquor 101 containing carboxylic acid, said metal catalyst, impurities, water and solvent in first evaporation zone 121 to produce vapor stream 104 and concentrated mother liquor stream 105 .

[0038] The mother liquor 101 is discharged from the carboxylic acid oxidation synthesis process. The mother liquor 101 is used as a feed stream in the process of the present invention. The mother liquor contains carboxylic acid, water, solvent, said metal catalyst and impurities. The impurities include organic bromides and corrosion metals. The organic bromide is used as a cocatalyst for the oxidation reaction. Examples of corrosive metals are iron and chromium compounds which inhibit, reduce or completely destroy the activity of metal catalysts.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com