Detecting soot during real time operation in diesel engine lubricant

一种柴油发动机、实时运行的技术,应用在润滑零部件、润滑指示装置、测量装置等方向,能够解决无法监测柴油发动机润滑剂炭黑等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

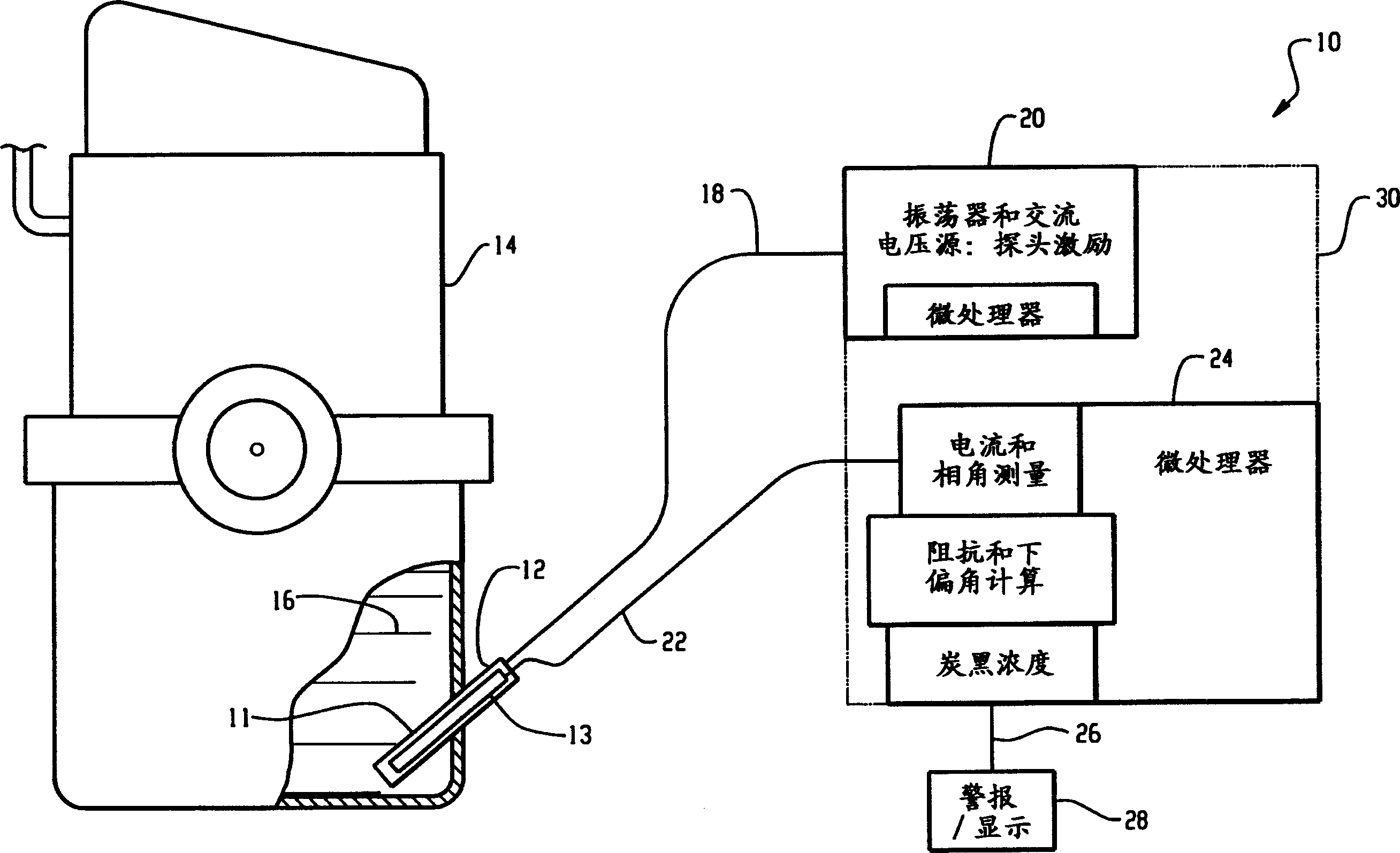

[0011] The system of the present invention, generally designated 10, includes a probe 12 inserted into the crankcase or oil pan of a diesel engine 14, indicated generally at 16, at the oil level. The electrodes of the probe can be of any suitable configuration; but in the present invention a pair of figure 1 Concentric tubular electrodes of concentric tubular structures represented by reference numbers 11 and 13. For the structure of the probe, see the application date assigned to the applicant as January 31, 2002, entitled "Probe Assembly For Fluid Condition Monitor And Method Of Making Same (probe assembly for fluid state monitoring and its manufacturing method)" Pending Publication No. 10 / 060,107.

[0012] One electrode of probe 12 is supplied with a lower voltage AC current via lead 18 from a controller 20 which may include an oscillator and microprocessor to provide the lower voltage AC current to the probe. The measured probe current is transmitted to an electrical sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com