Electron beam processing apparatus

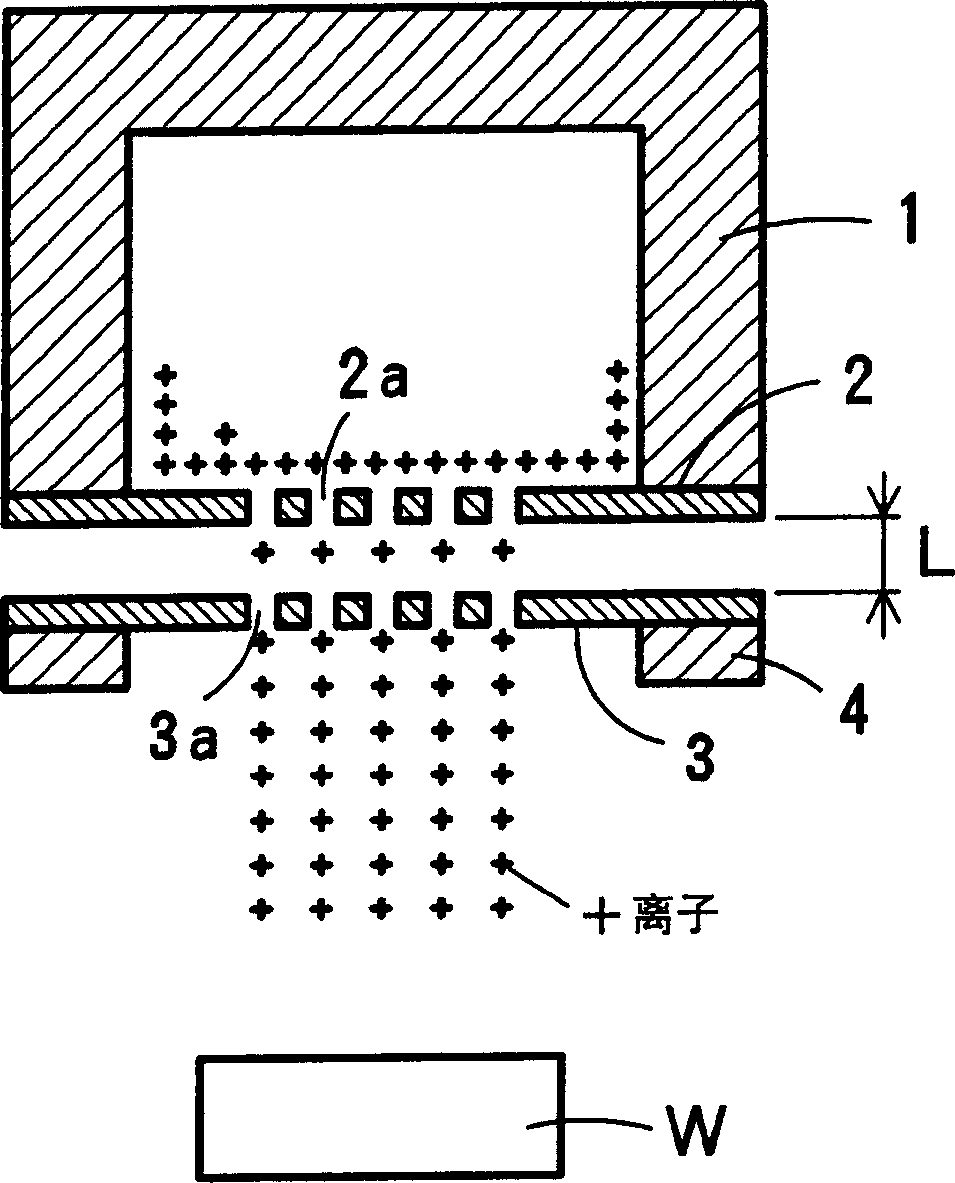

An electron beam processing, positive ion technology, applied in the directions of irradiation devices, ion beam tubes, circuits, etc., can solve the problems of reducing the cooling effect, the acceleration grid 3 cannot obtain sufficient cooling effect, and the contact area is reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, specific embodiments of the present invention will be described with reference to examples.

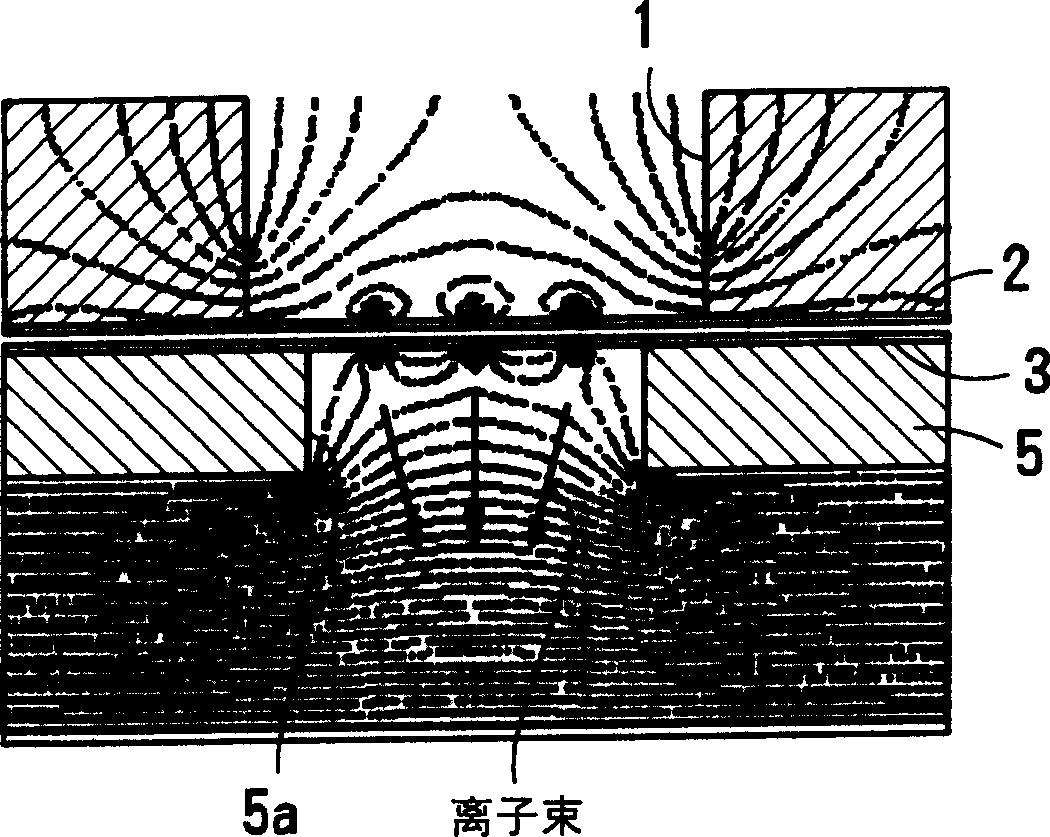

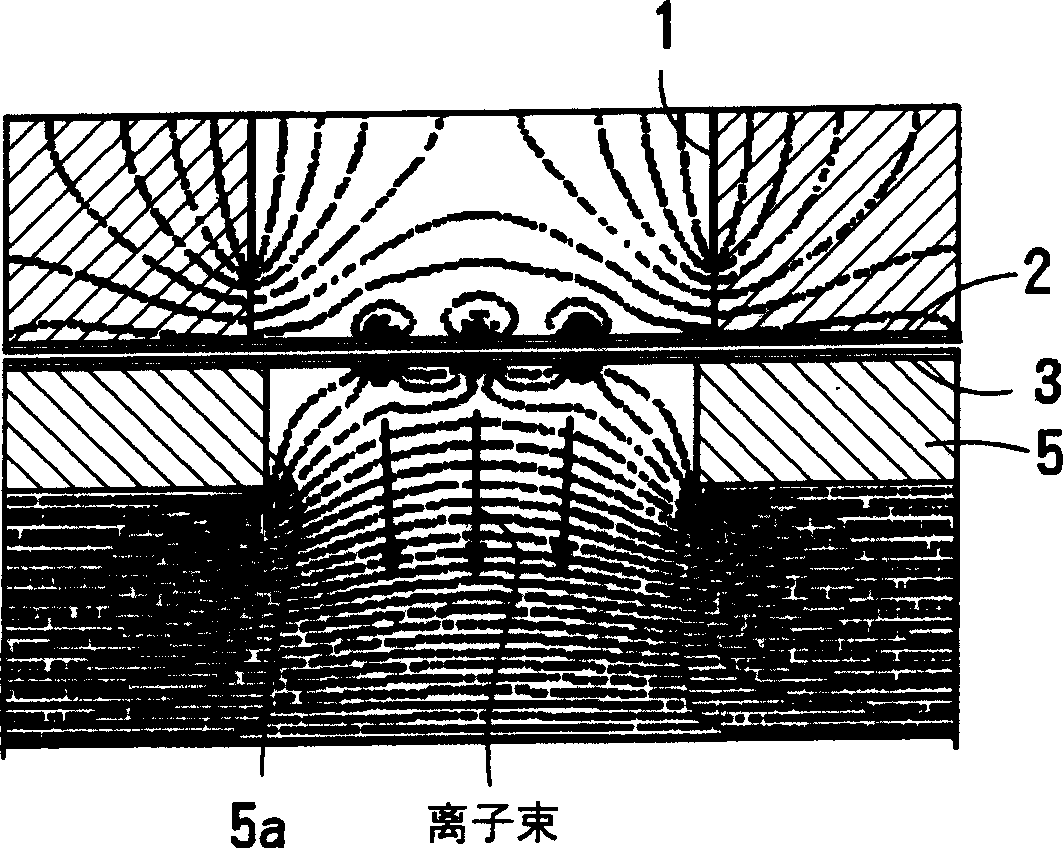

[0032] Figure 4 , Figure 5 An example of the electron beam processing apparatus of the present invention is shown. Figure 4 versus figure 1 The same parts are represented by the same symbols and will not be repeated.

[0033] In this processing device, the cooling jacket 5 on the front side of the acceleration grid 3 is tightly fixed by screws or the like. A cooling water channel 5b is formed inside the cooling jacket 5, which has the function of absorbing the heat conducted from the acceleration grid 3 to the cooling jacket 5 and removing it to the outside.

[0034] The cooling jacket 5 is formed with an opening 5a wider than the range in which the fine hole 3a of the acceleration grid 3 is provided. The opening 5a, such as Figure 5 As shown, the pores 3a of the acceleration grid 3 arranged in a rectangular shape correspond to the pores 3a, and are elliptical, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com