Method for preparing organic electroluminescent device of copper (I) phosphorescence material

A phosphorescent material and electroluminescent technology, applied in electroluminescent light sources, luminescent materials, chemical instruments and methods, etc., can solve the problem of not showing the superiority of electrophosphorescent materials, and achieve the effect of high device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

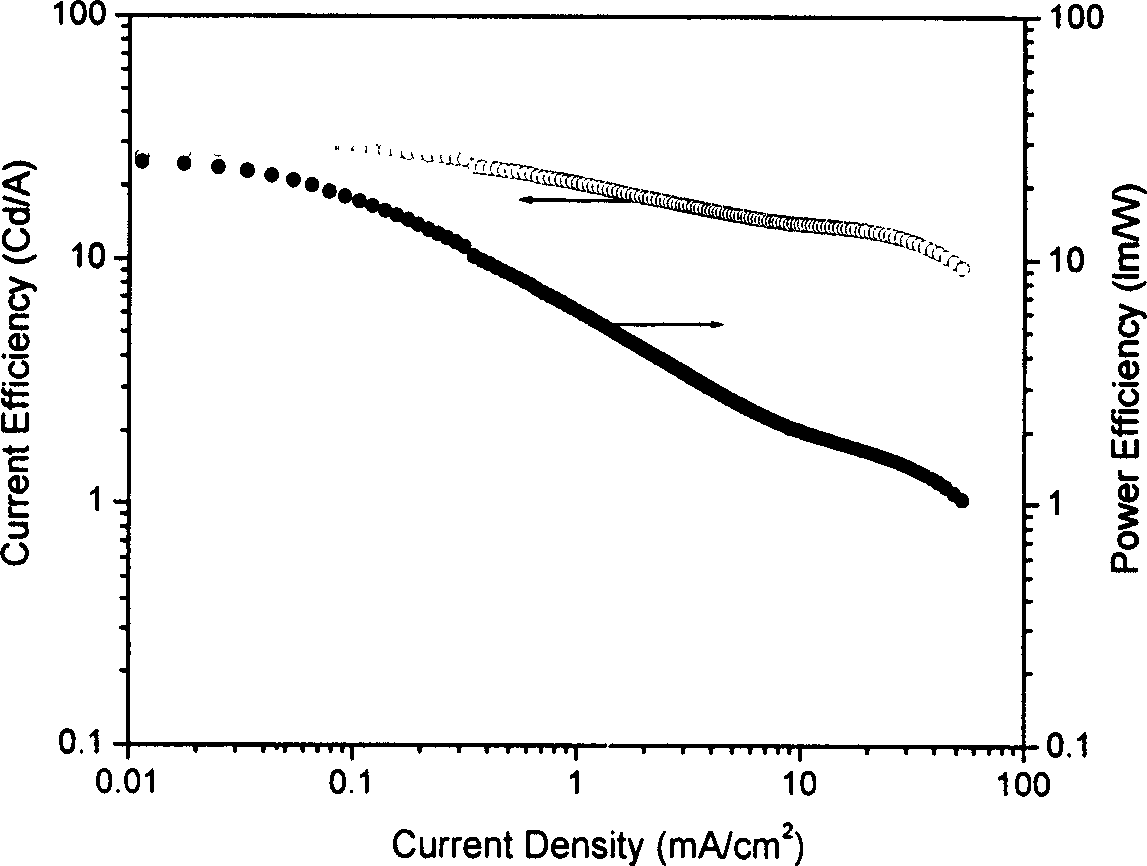

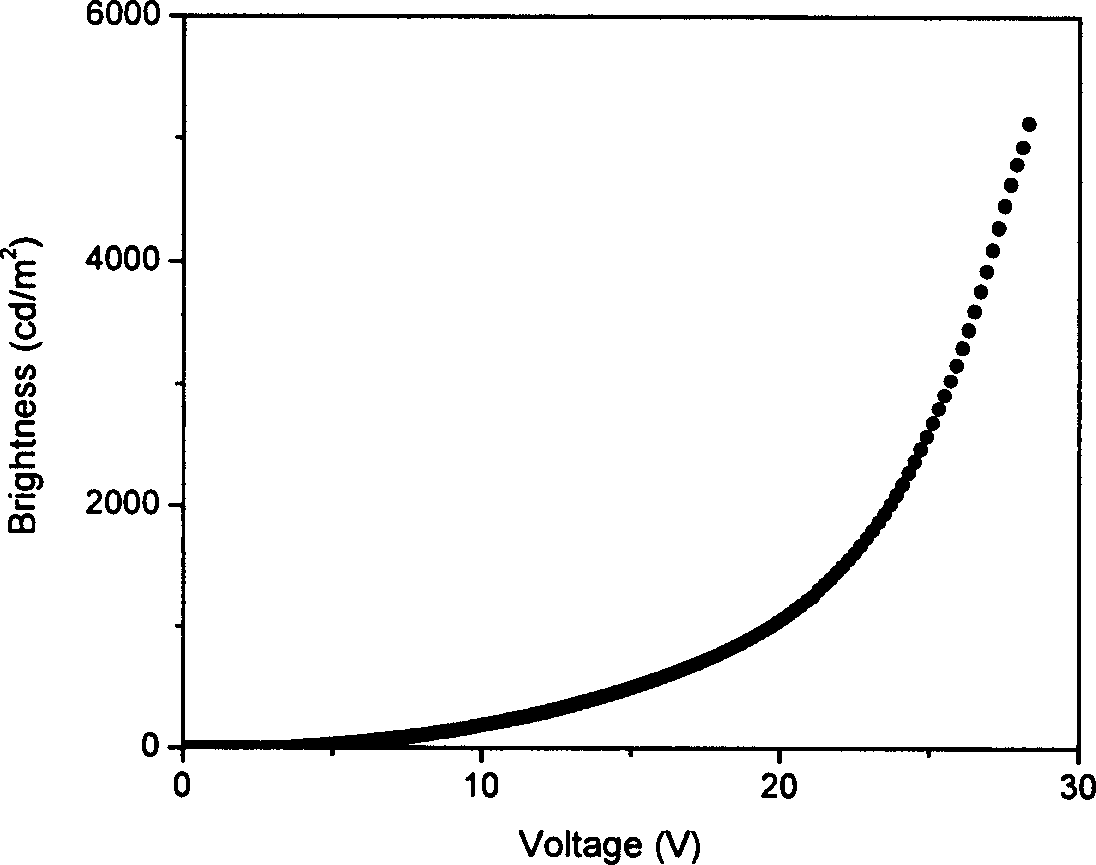

[0033] Embodiment 1: multilayer device with complex 1 / PVK as light-emitting layer

[0034] The device structure is: ITO / PEDOT / luminescent layer / BCP / Alq 3 / LiF / Al. The assembly conditions are as follows: a layer of conductive polymer-polythiophene derivative (PEDOT) is spin-coated on the clean ITO glass surface at a rotational speed of 3000 rpm, and then dried at 120°C for 30 minutes. Put PVK (polyvinyl carbazole) and complex 1 in CH 2 Cl 2 The solution is formulated into a solution with a weight ratio of 100 / 1, and spin-coated on the surface of the glass electrode modified by PEDOT under the condition of a rotating speed of 1500 rpm. After drying for 2 hours under high vacuum conditions, 10nm of BCP (2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline) and 50nm of Alq 3 (8-hydroxyquinoline aluminum), 1nm LiF and 100nm aluminum metal. The performance of the multilayer device is as follows: starting voltage 10V, maximum brightness 1000cd / m 2 , the maximum current efficiency is 2...

Embodiment 2

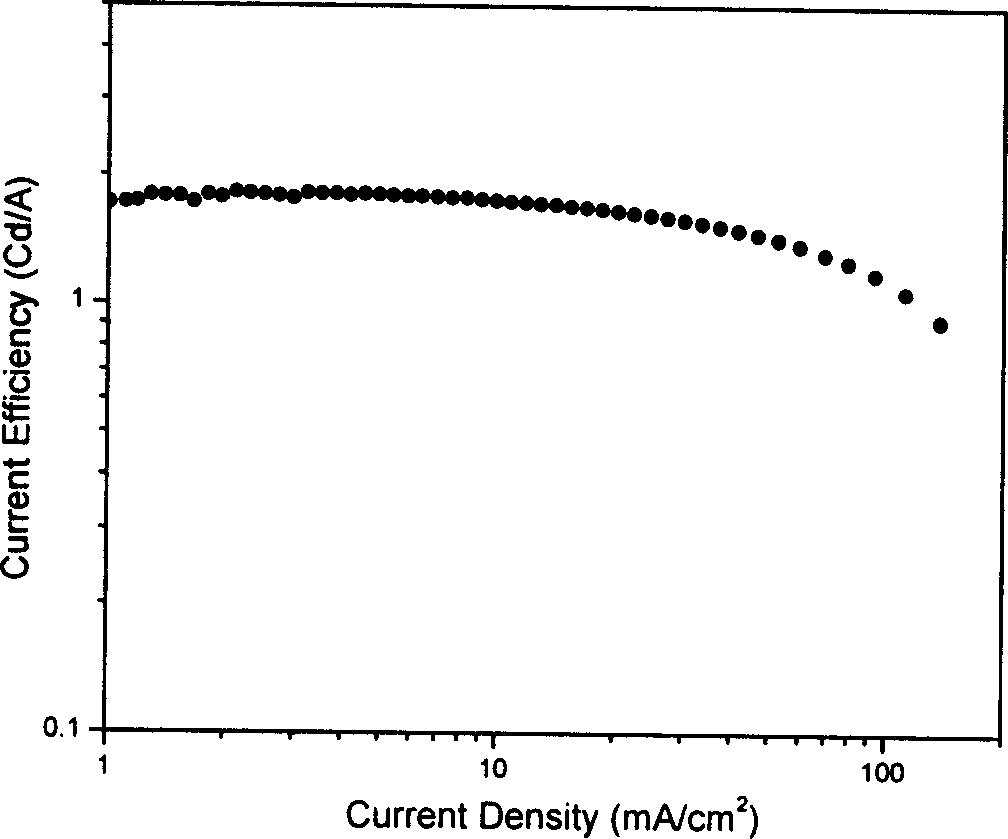

[0035] Example 2: Single-layer device with complex 2 / PVK / PBD as light-emitting layer

[0036] The device structure is: ITO / PEDOT / luminescent layer / Ca / Al. The assembly conditions are: PVK, PBD (2-(4-diphenyl)-5-(4-tert-butylphenyl)-1,3,4-oxadiazole) and complex 2 in CH 2 Cl 2 The solution is formulated with a weight ratio of 100 / 40 / 2, and spin-coated on the surface of the ITO glass electrode modified by PEDOT under the condition of a rotating speed of 1500 rpm. After drying under high vacuum conditions for 2 hours, 1 nm of metallic calcium and 100 nm of metallic aluminum were vapor-deposited. The performance of a single-layer device is as follows: start-up voltage 10V, maximum brightness 1200cd / m 2 , the maximum current efficiency is 2.8cd / A, and the maximum luminous peak is 555nm.

Embodiment 3

[0037] Embodiment 3: multilayer device with complex 3 / PVK as light-emitting layer

[0038] The weight ratio of PVK to compound 2 in the light-emitting layer of the multilayer device is 100 / 2, and other assembly conditions are the same as in Example 1. The performance of multi-layer devices is as follows: start-up voltage 11V, maximum brightness 1400cd / m 2 , the maximum current efficiency is 3.2cd / A, and the maximum luminous peak is 525nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com