Optical mask, method for making figure and method for making semiconductor device

A mask pattern and photomask technology, which is applied in the field of photolithography, can solve the problems that it is difficult to set up dummy patterns, it is difficult to planarize the interlayer dielectric film, and it is impossible to form photoresist patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below with reference to the drawings. Note that throughout the drawings, the same or similar reference numerals denote the same or similar parts and units, and descriptions of the same or similar parts and units will be omitted or simplified.

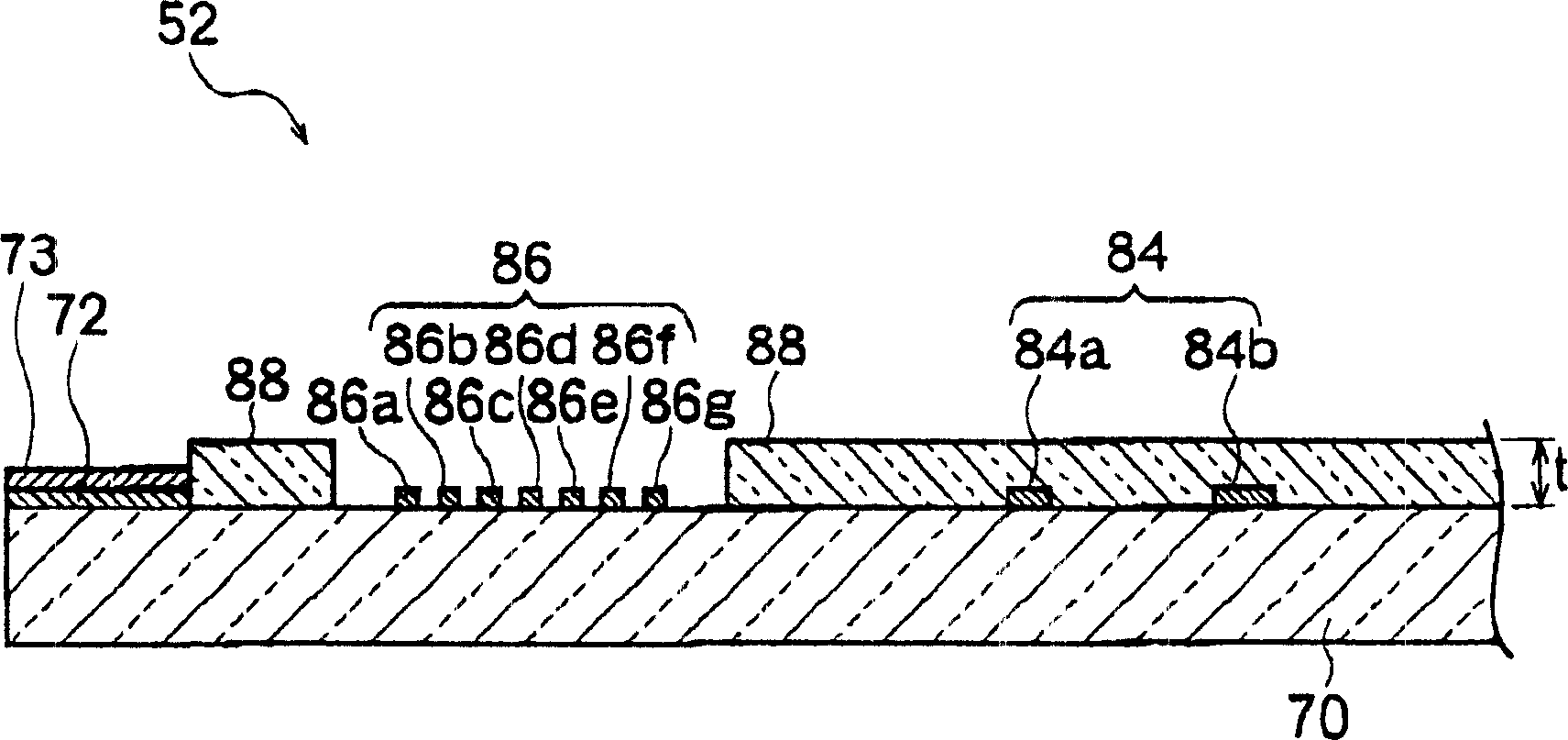

[0024] Such as figure 1 As shown, a photomask 52 according to an embodiment of the present invention includes a transparent substrate 70 , a first mask pattern 84 , a second mask pattern 86 and a transparent film 88 . First and second mask patterns 84, 86 are provided on the transparent substrate 70, and a transparent film 88 having an actual film thickness t is located in the pattern area including the mask pattern 84 provided therein. For the first mask pattern 84, in figure 1 The cross-sectional view of the first mask portion 84a, 84b is shown, and for the second mask pattern 86, in figure 1 The second mask portions 86a to 86g are shown in the cross-sectional view of . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com