Patents

Literature

34results about "Electrographic processes using thermoplastic layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

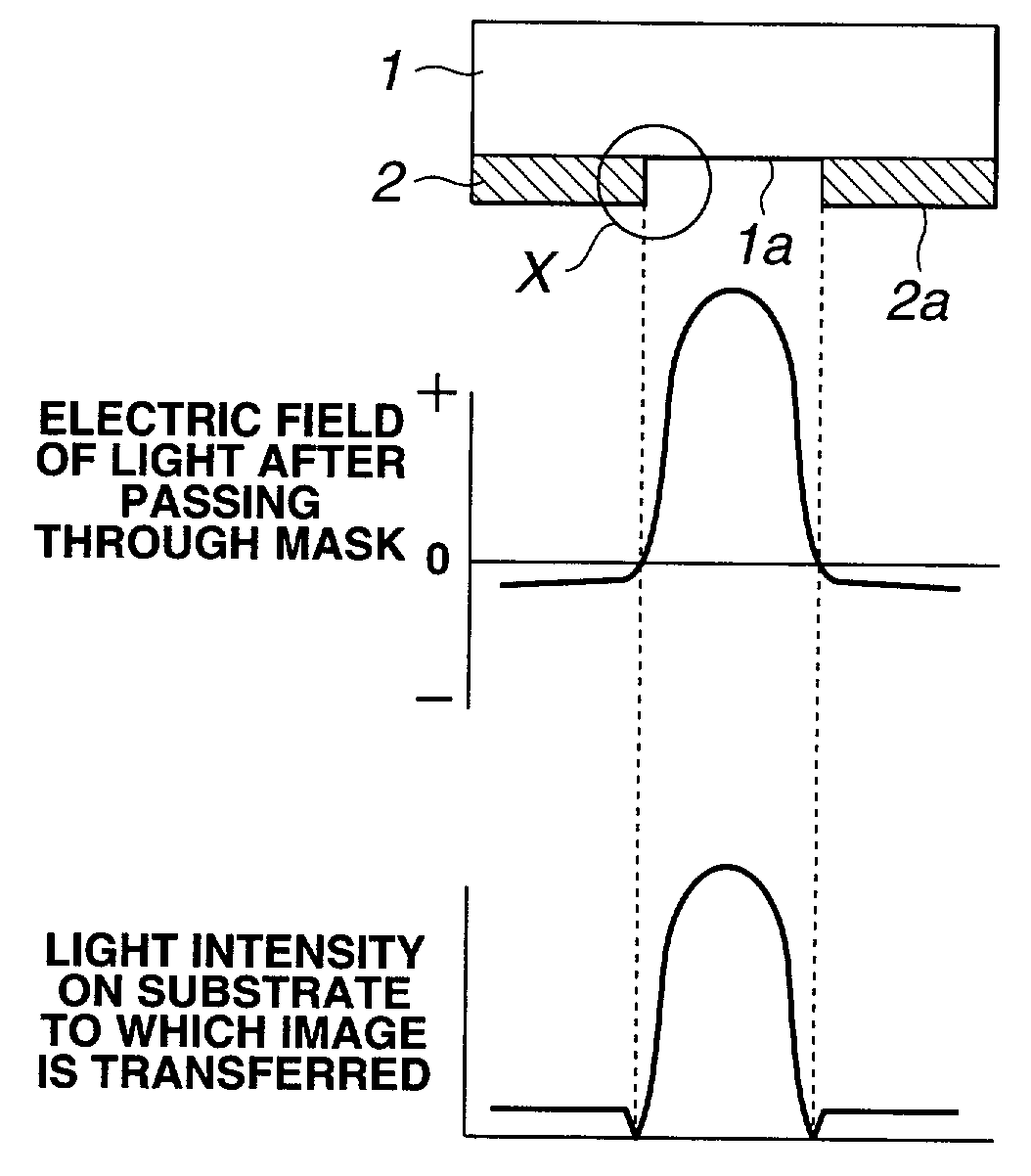

Phase shift mask and design method therefor

InactiveUS20020177050A1Shorten the timeAvoid deformationPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistEngineering

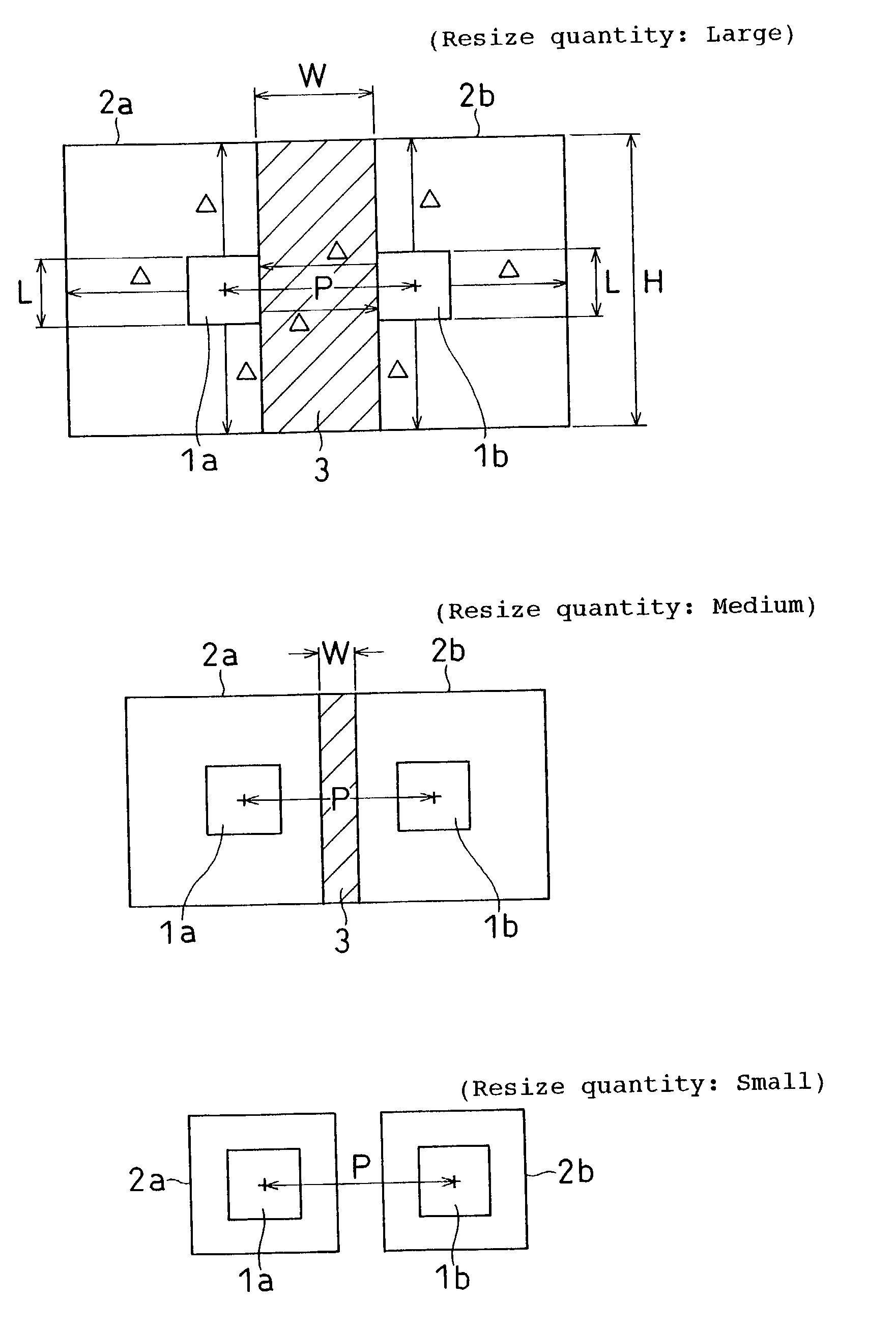

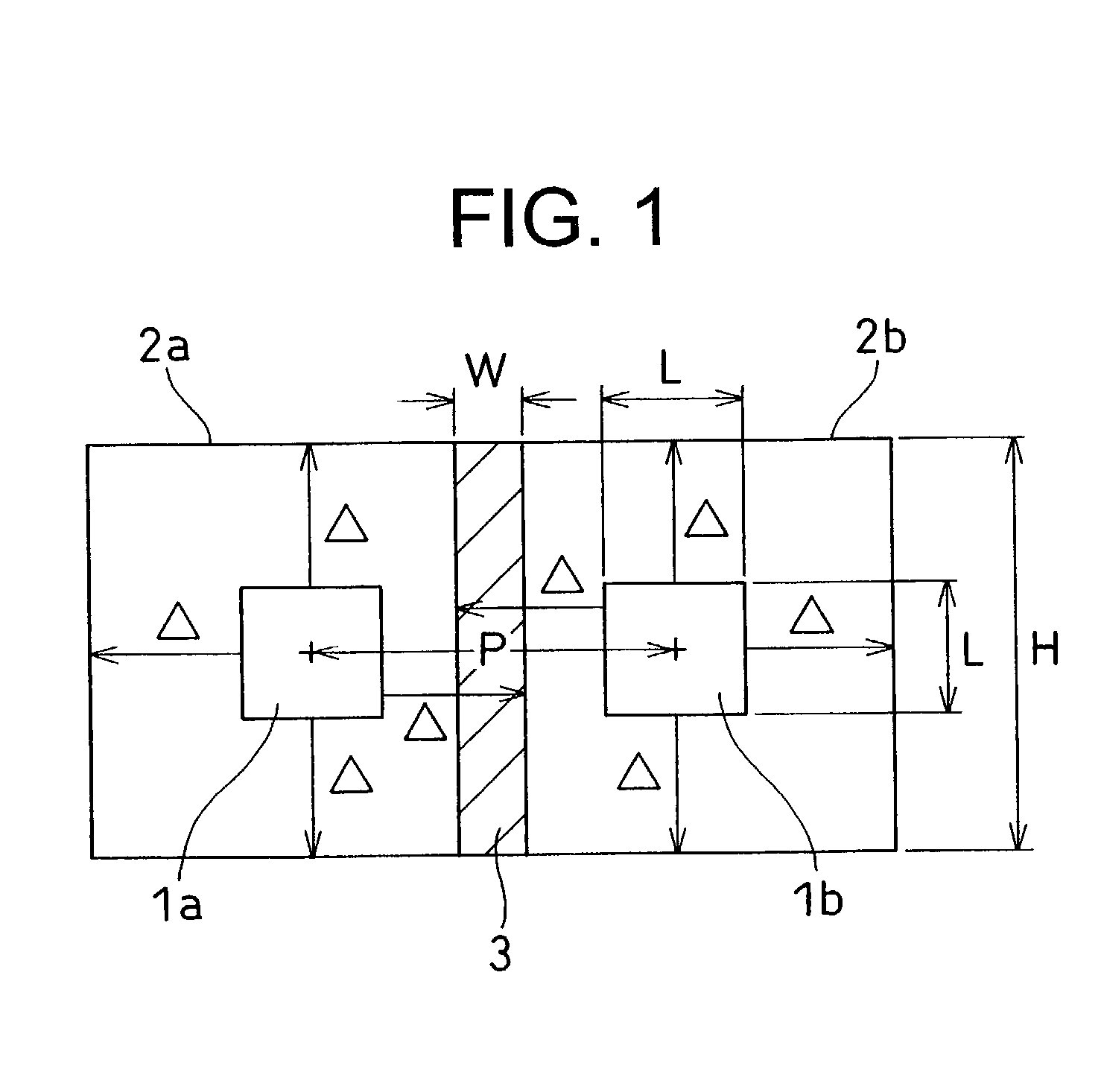

After a plurality of main patterns are placed at a predetermined pitch P, the individual main patterns are extended by a predetermined resize quantity DELTA to form virtual regions. When the virtual regions have an overlapped part, the overlapped part is placed between the virtual regions, and is set as a halftone region forming part having a predetermined transmission factor T with respect to exposure light. The resize quantity DELTA and the transmission factor T are set such that a transferred size of the main patterns on a predetermined resist film is settled within a desired range according to the change of the pitch P under a predetermined exposure condition.

Owner:NEC ELECTRONICS CORP

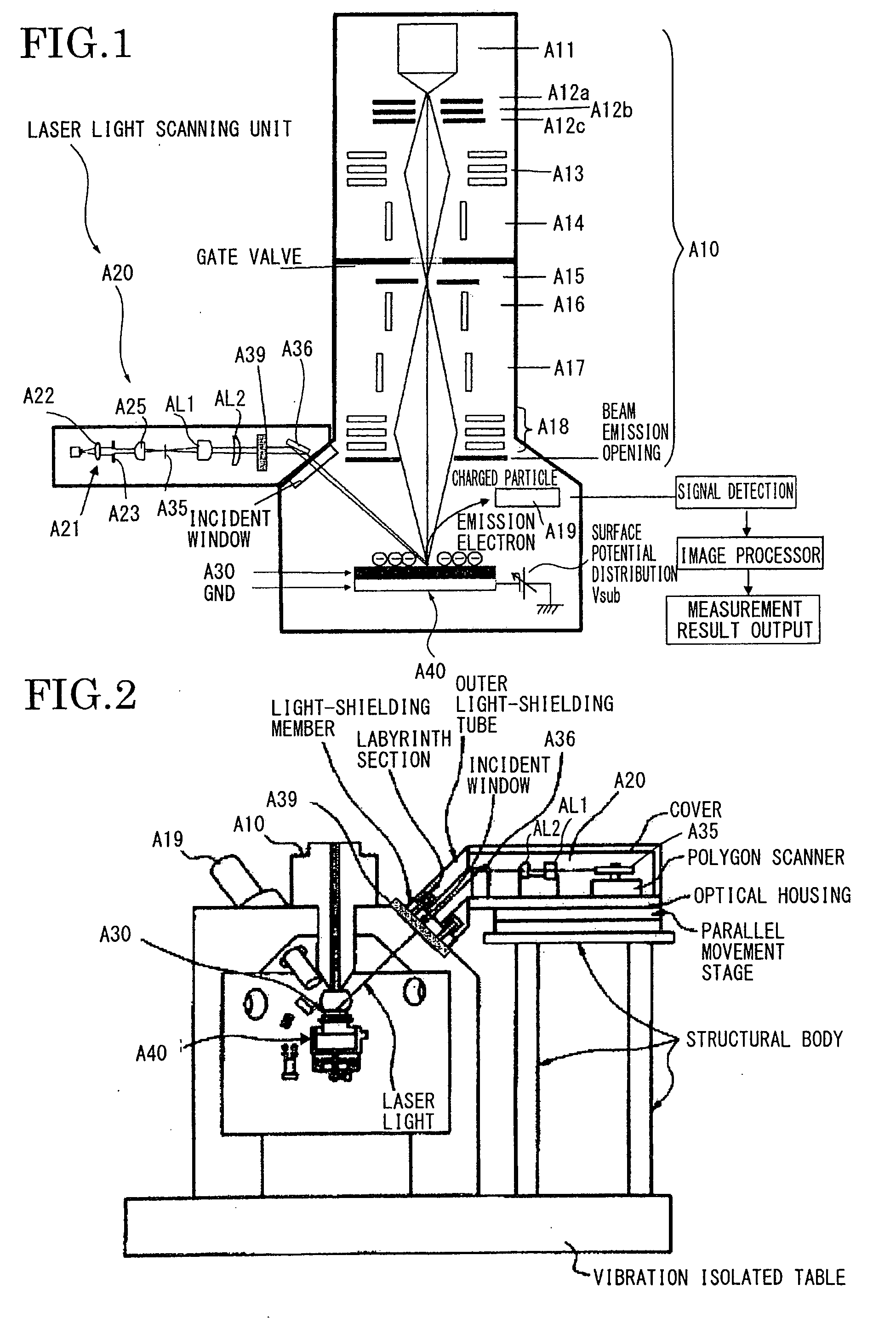

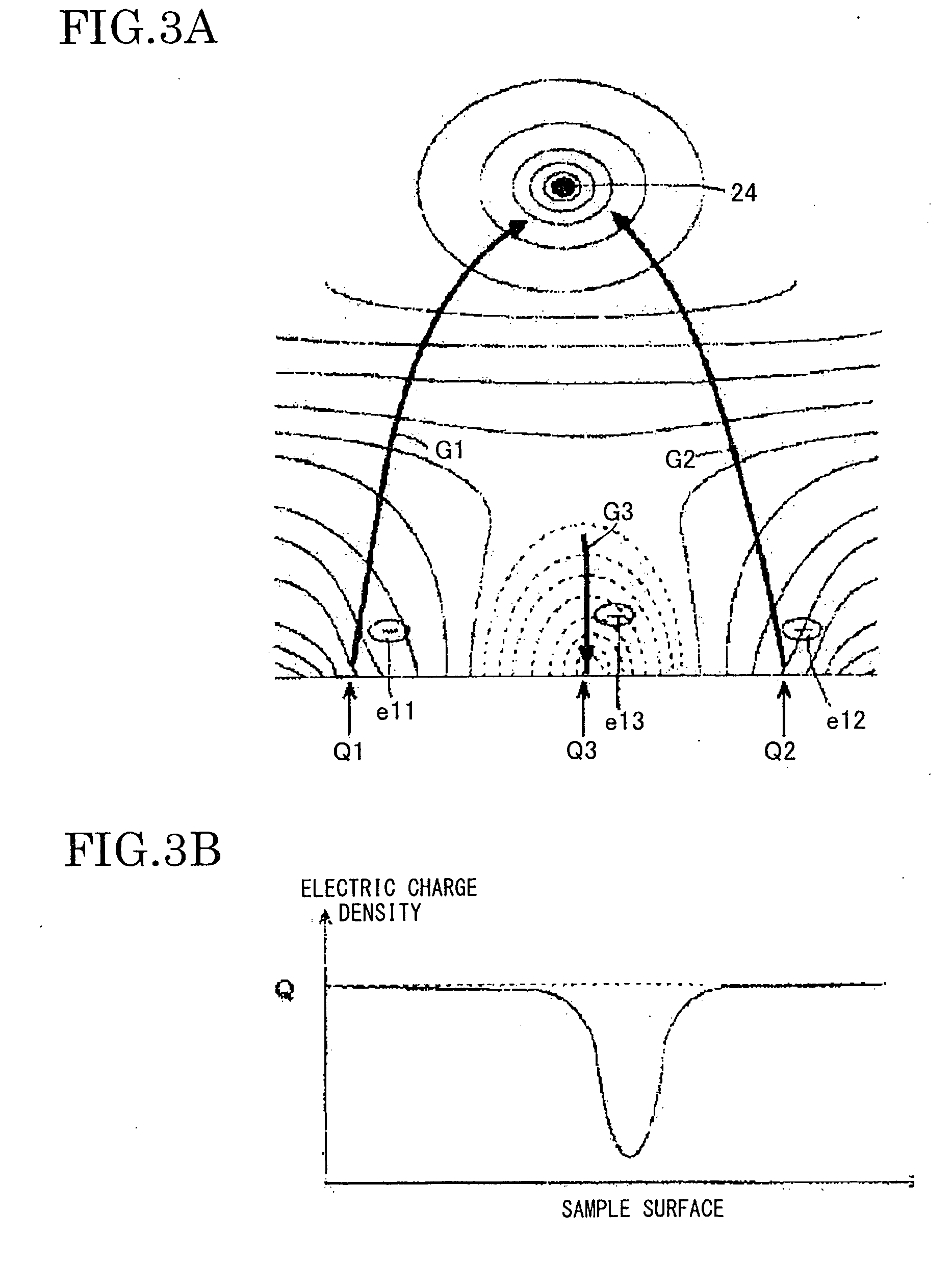

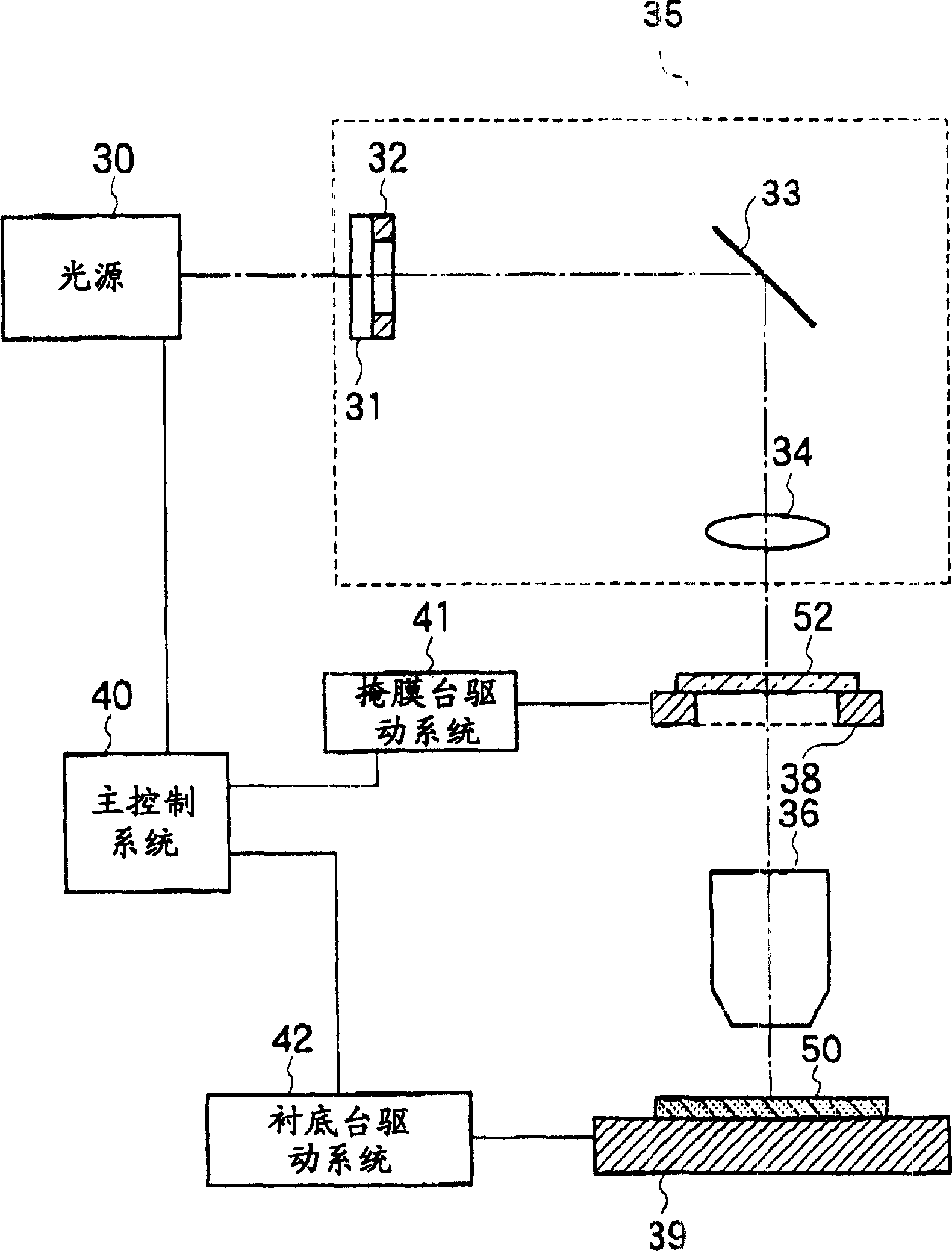

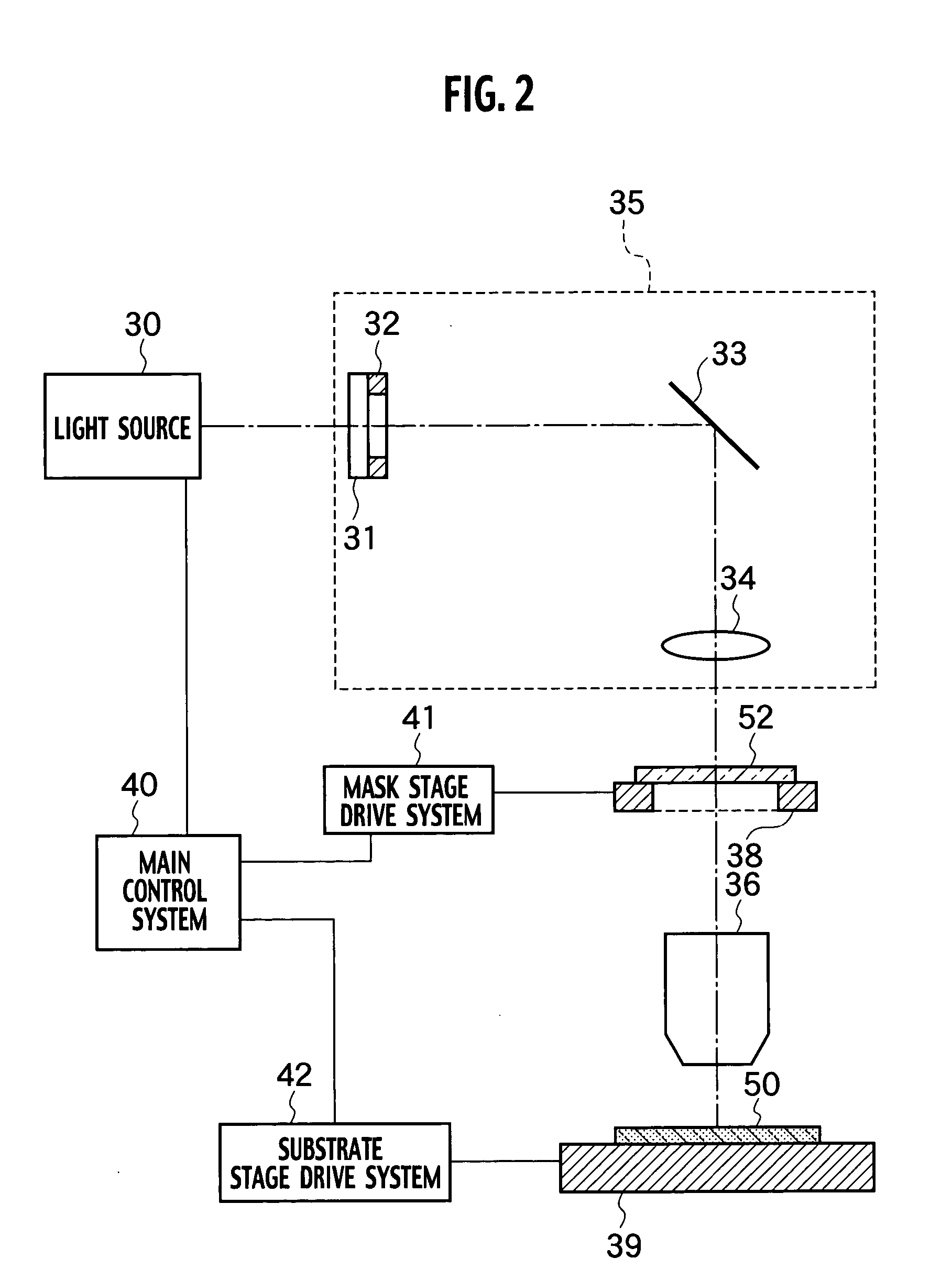

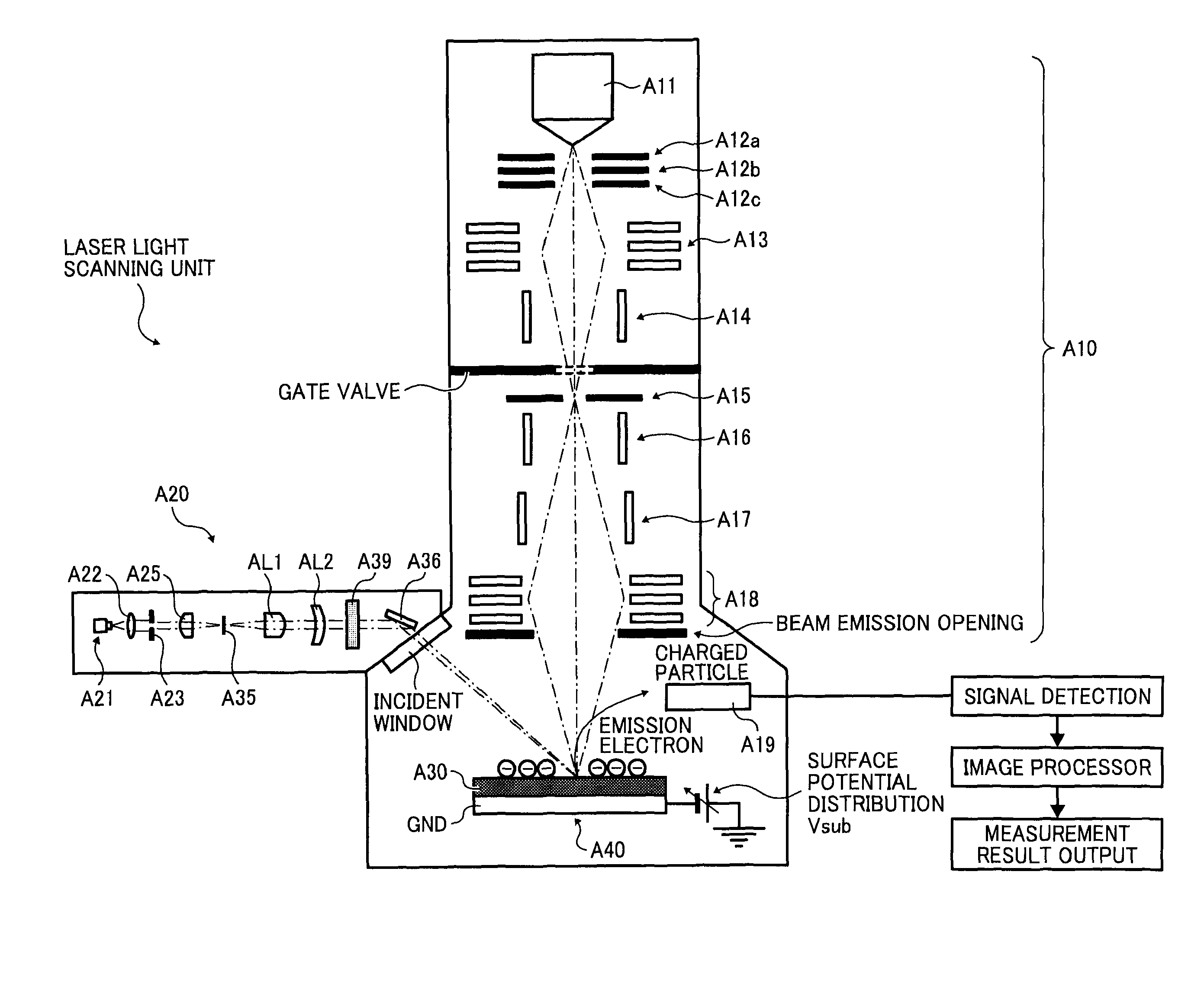

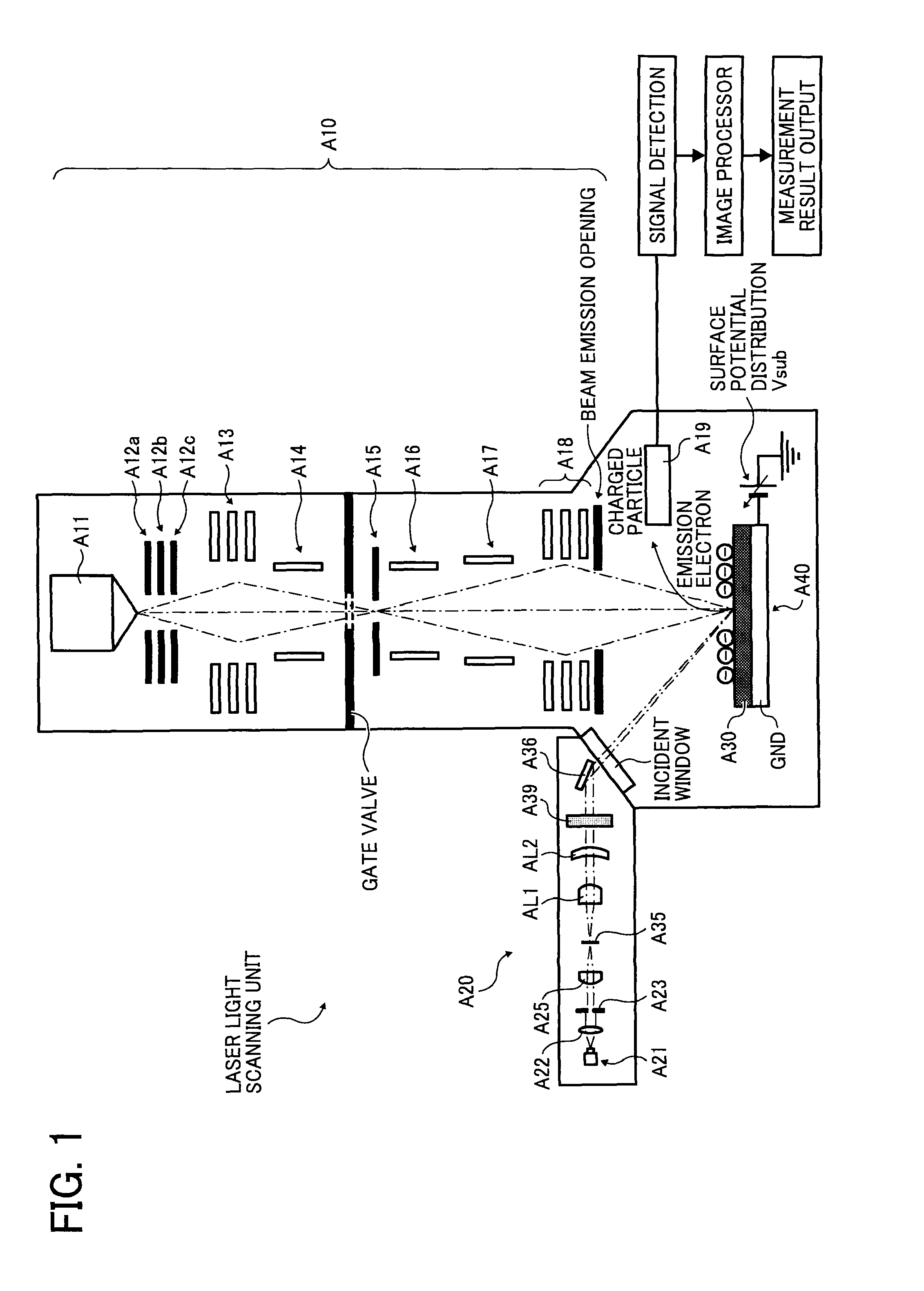

Electrostatic latent image measuring device

ActiveUS20090220256A1Improve accuracyHigh precision measurementThermometer detailsBeam/ray focussing/reflecting arrangementsElectrical conductorLatent image

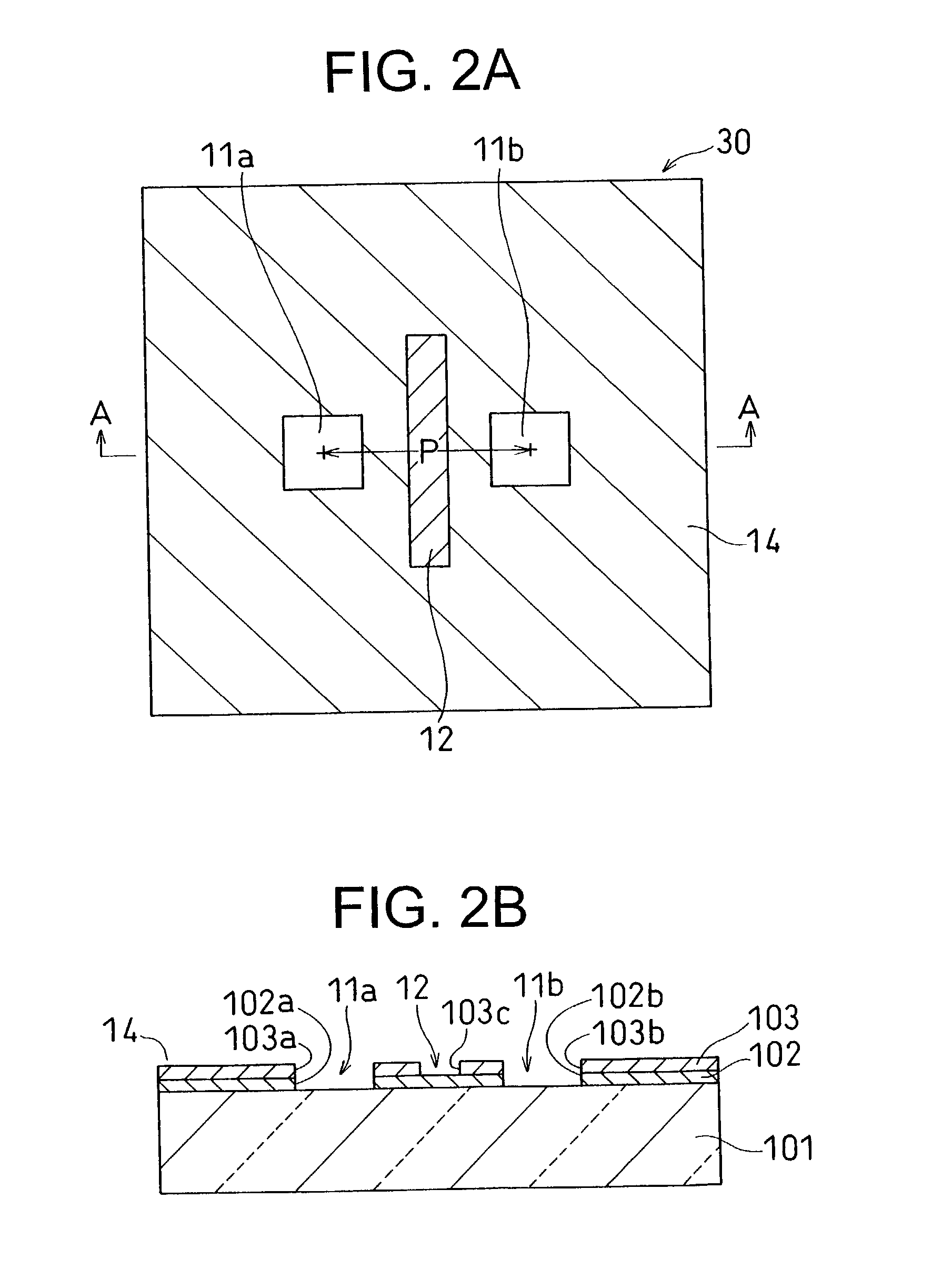

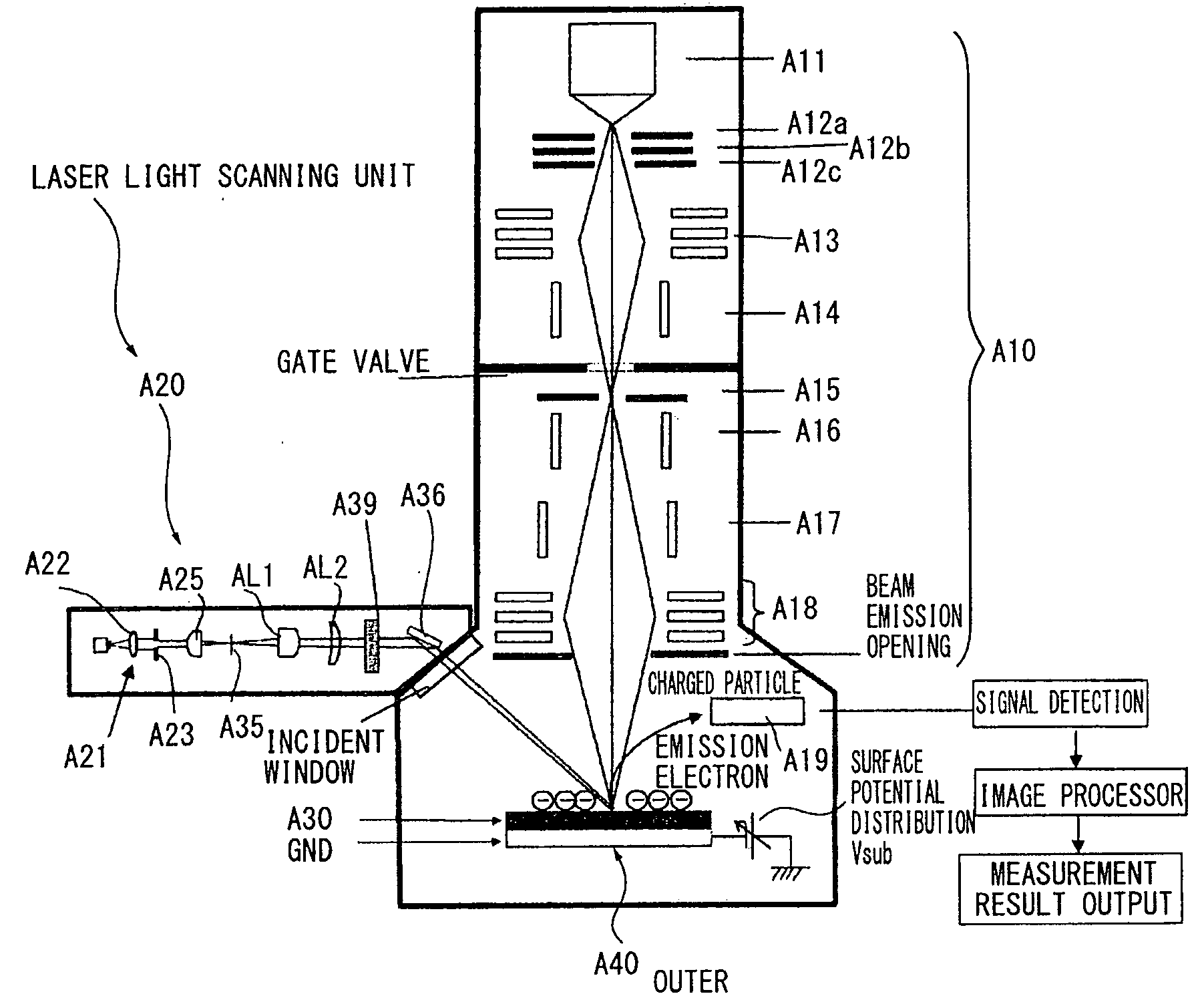

An electrostatic latent image measuring device includes a charged particle optical system which irradiates an electron beam and charges a photoconductor sample, an exposure optical system which forms an electrostatic latent image on a surface of the photoconductor sample, and a scanning unit which scans the surface of the photoconductor sample by the electron beam, a distribution of the electrostatic latent image on the surface of the sample being measured by a signal detected by the scanning.

Owner:RICOH KK

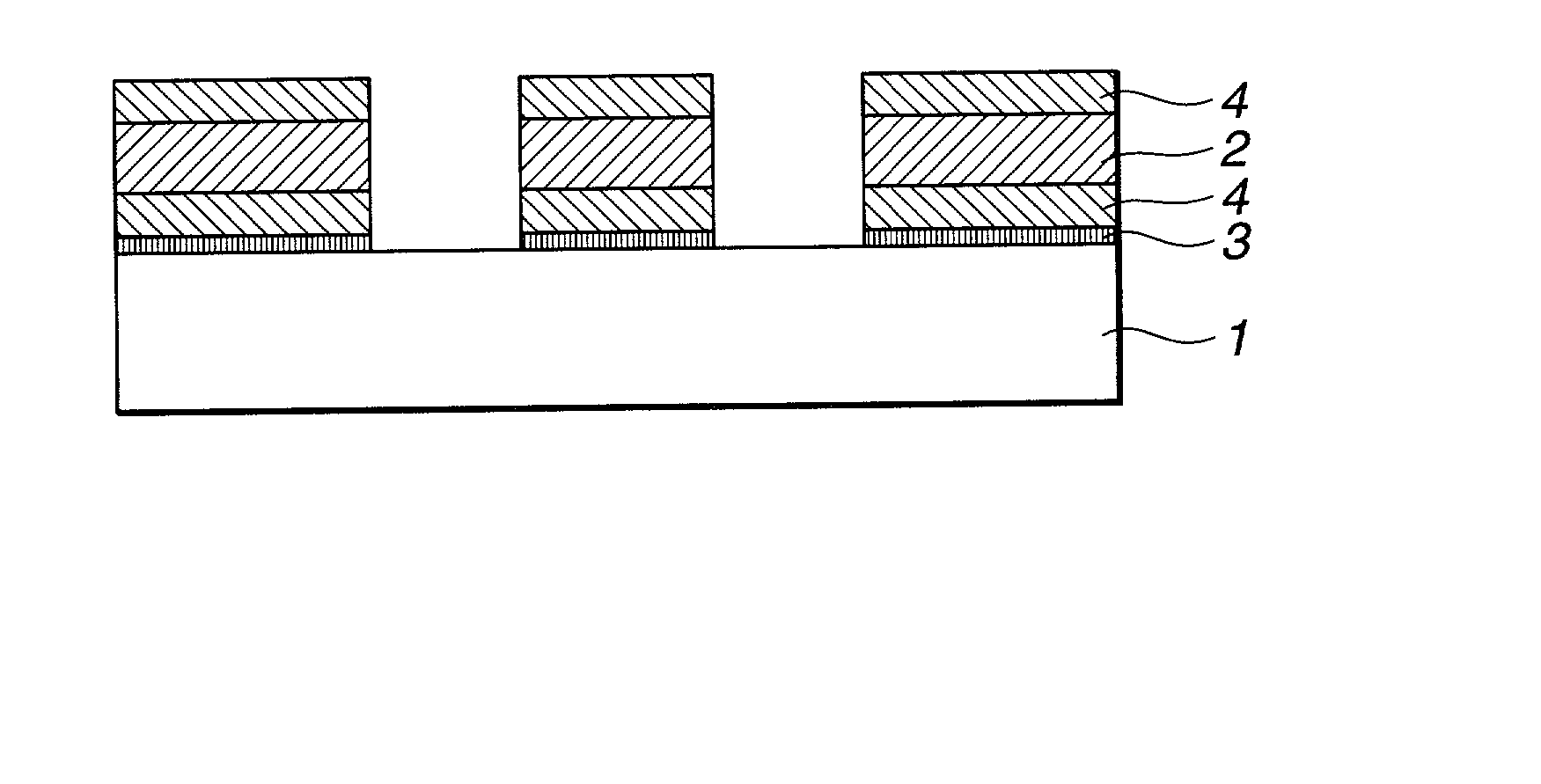

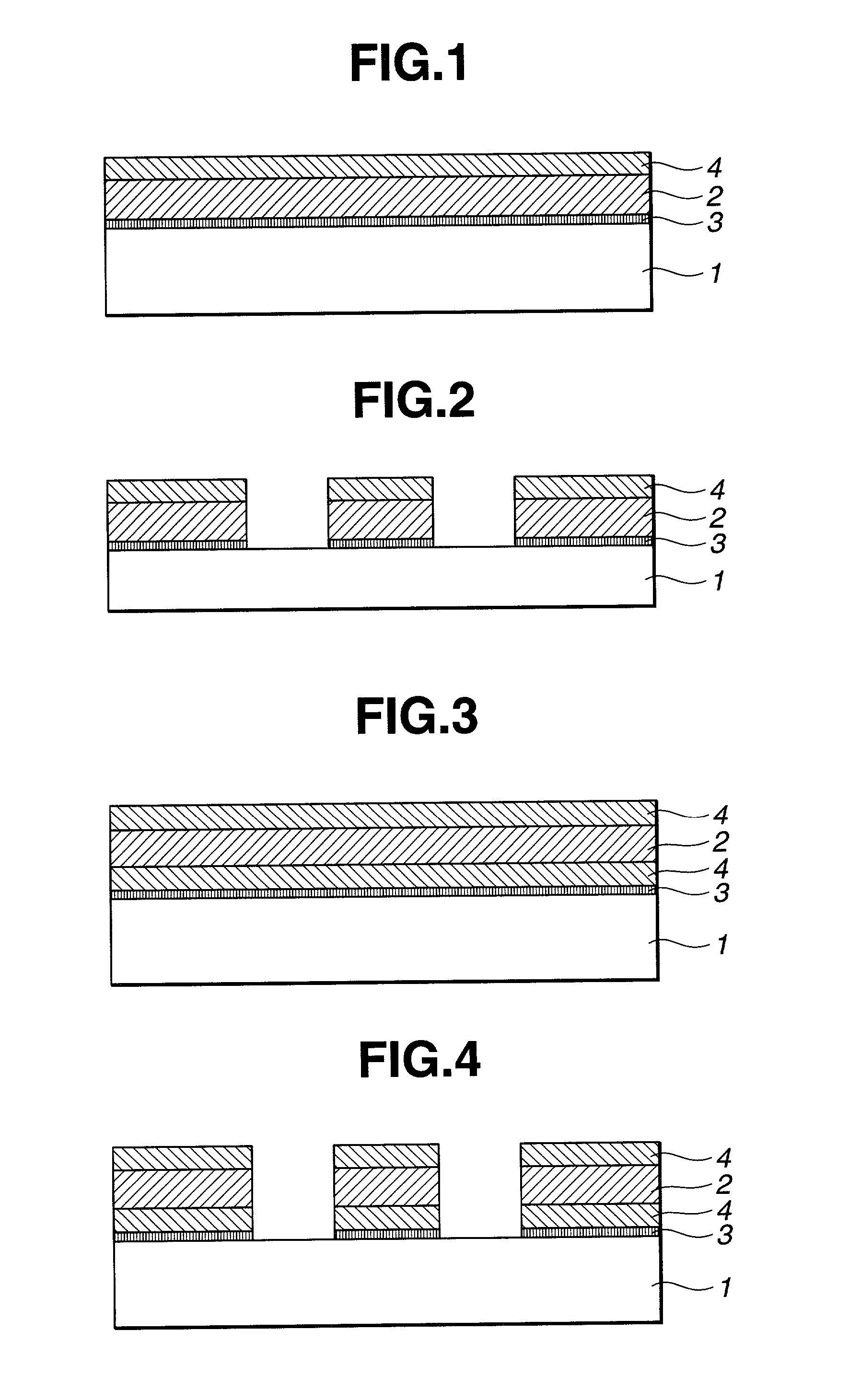

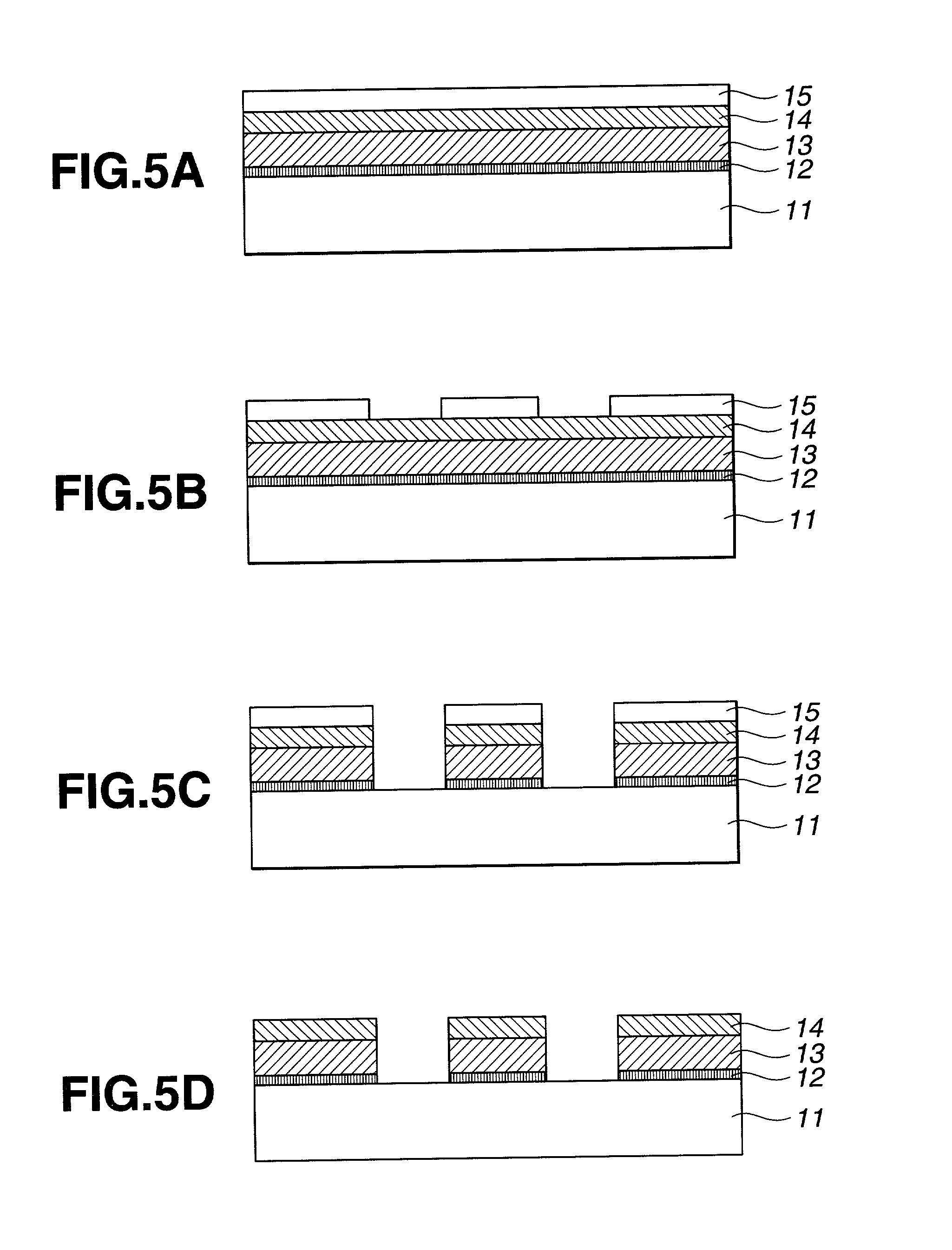

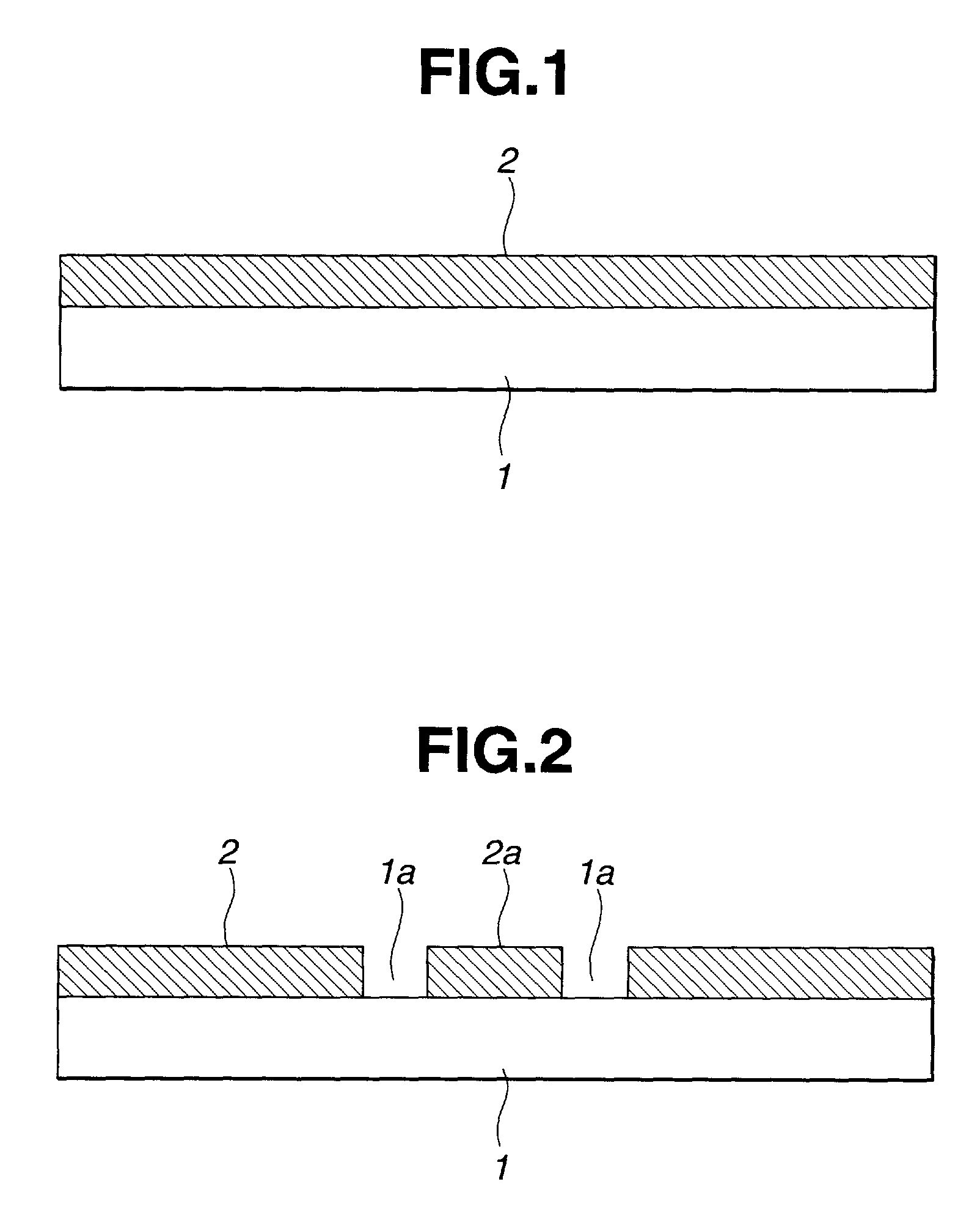

Photomask blank and photomask

InactiveUS20020115003A1Uniform film qualityReduce surface roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSurface roughnessNitrogen

In the manufacture of a photomask blank, a seed layer of a chromium material containing oxygen, nitrogen and / or carbon is formed on a transparent substrate before a light-shielding film and an antireflective film are deposited thereon. Any film on the seed layer builds up in accordance with fine granular growth, and so the resulting photomask blank has an improved surface roughness, which enables high-sensitivity detection in the process of defect inspection and circuit pattern inspection. By lithographically patterning the photomask blank, a photomask is fabricated.

Owner:SHIN ETSU CHEM IND CO LTD

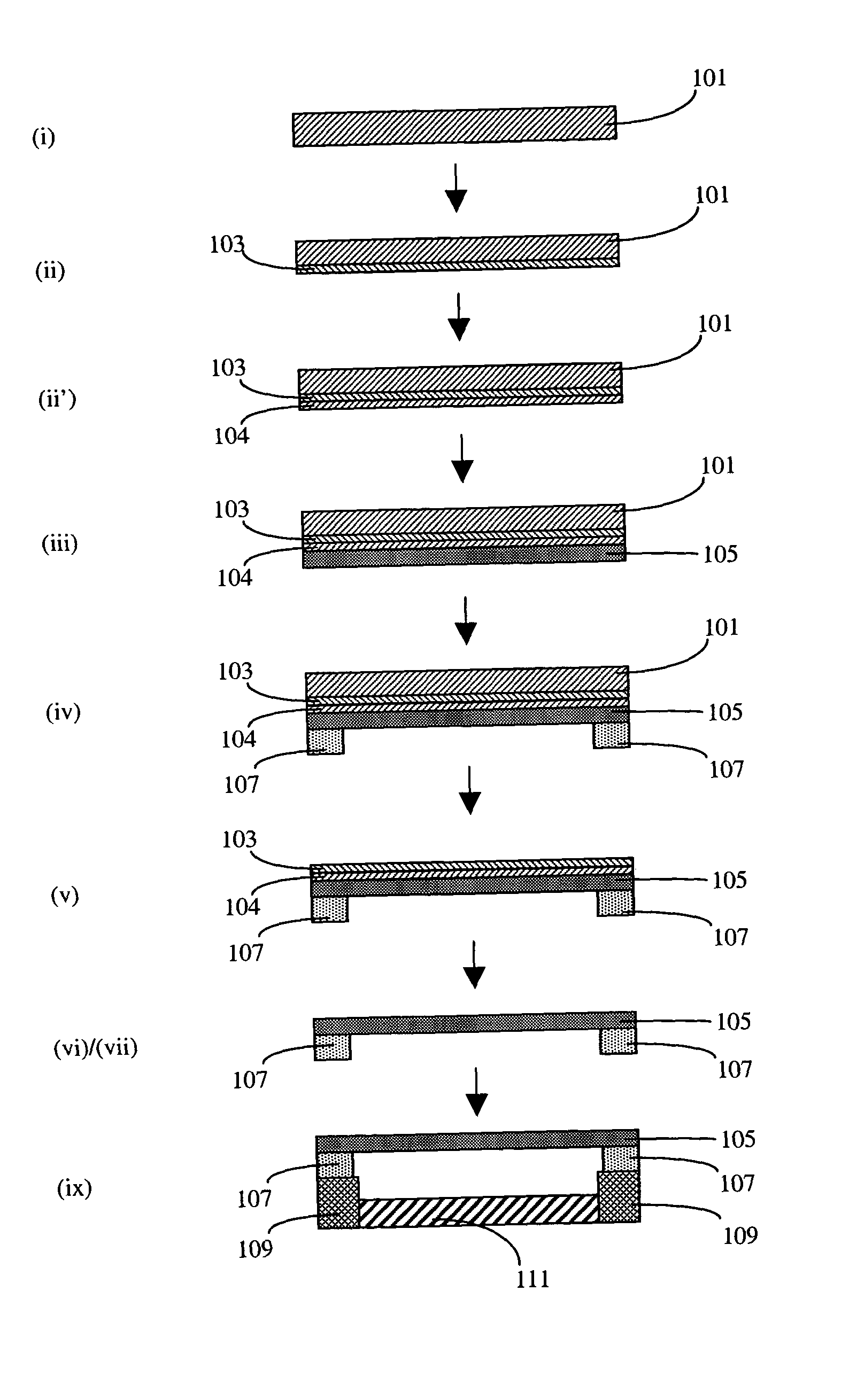

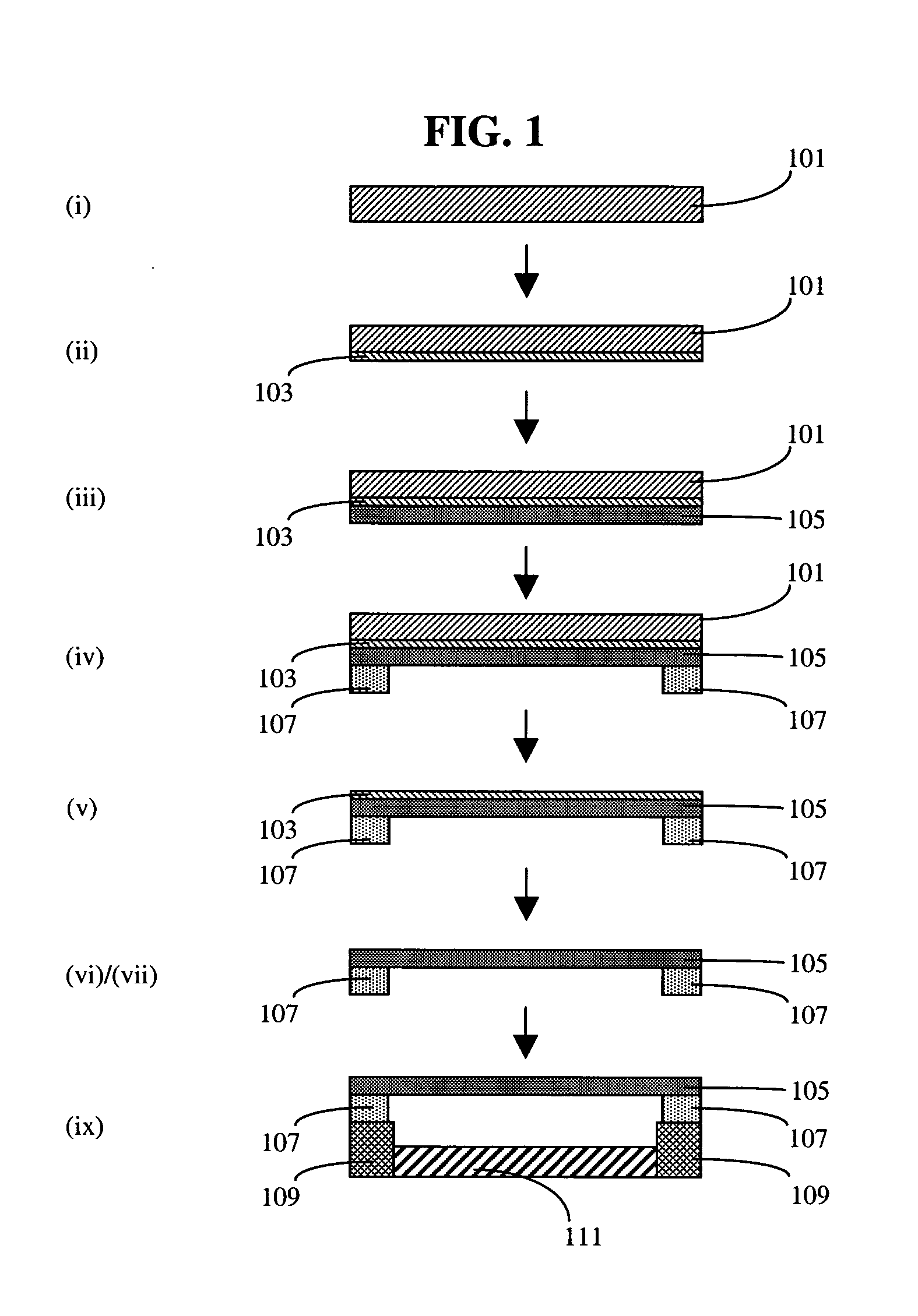

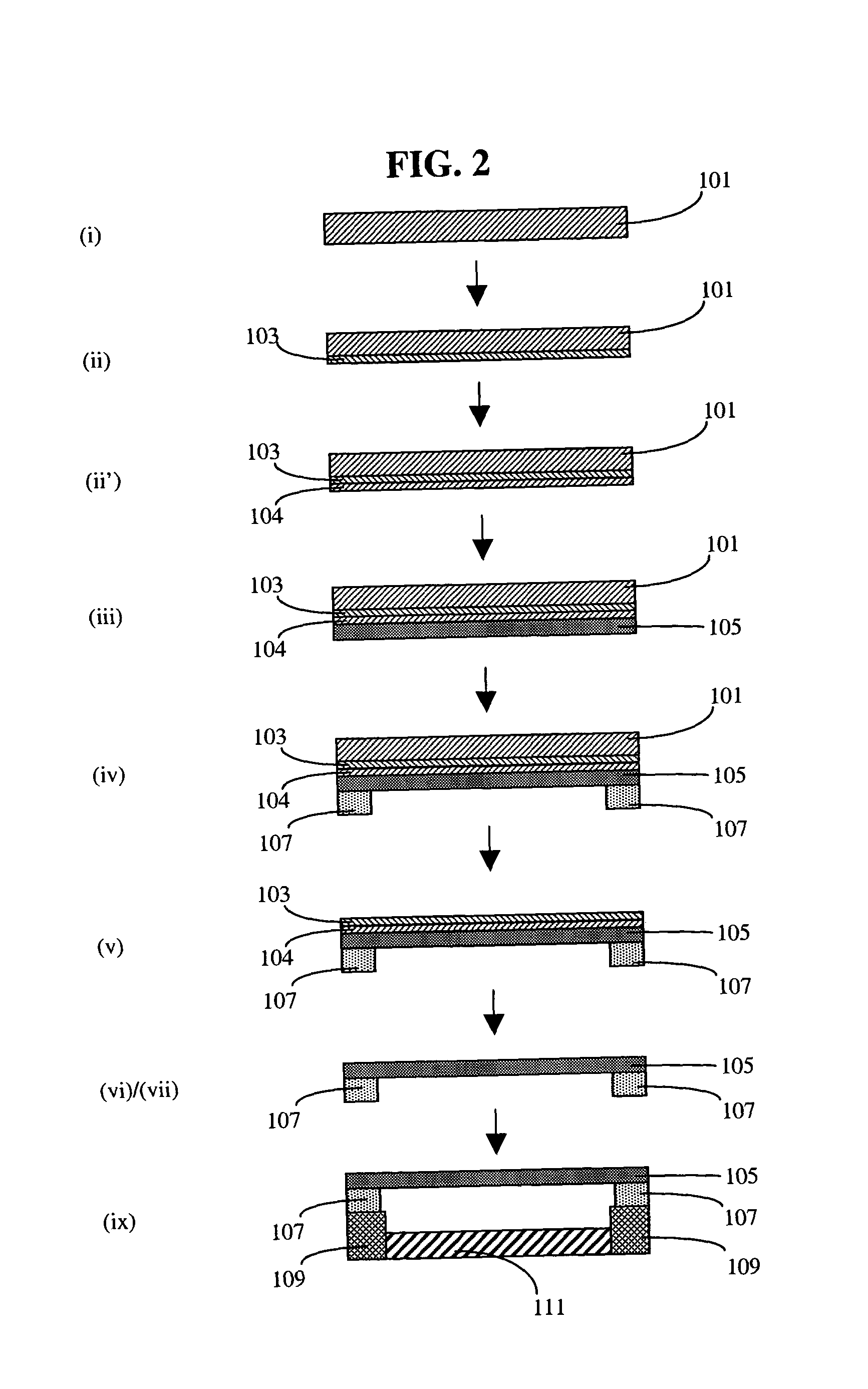

Process for making hard pellicles

Disclosed is a process for making thin hard pellicle for photomasks used in projection photolithography. The process can be used for making thin hard pellicles comprising a pellicle layer having a thickness in the range of about 5 to 120 μm and a mount frame attached to the peripheral area of a surface of the pellicle layer. The pellicle layer can consist essentially of a material selected from silica, fluorine doped silica, aluminum doped silica, methylated silica, fluorinated and methylated silica, fluorinated aluminum doped silica, CaF2, MgF2, BaF2 and SiC. The mount frame is preferred to have substantially the same CTE of the pellicle layer to minimize stress caused by temperature change. The mount frame is preferred to be porous to the purging gas. The process for making the hard pellicle involves deposition of an intermediate layer comprising a hydrogenated amorphous silicon layer on a flat substrate, deposition of the pellicle layer on the intermediate layer, mounting the frame to the pellicle layer and the separation of the pellicle from the substrate by heat treatment.

Owner:CORNING INC

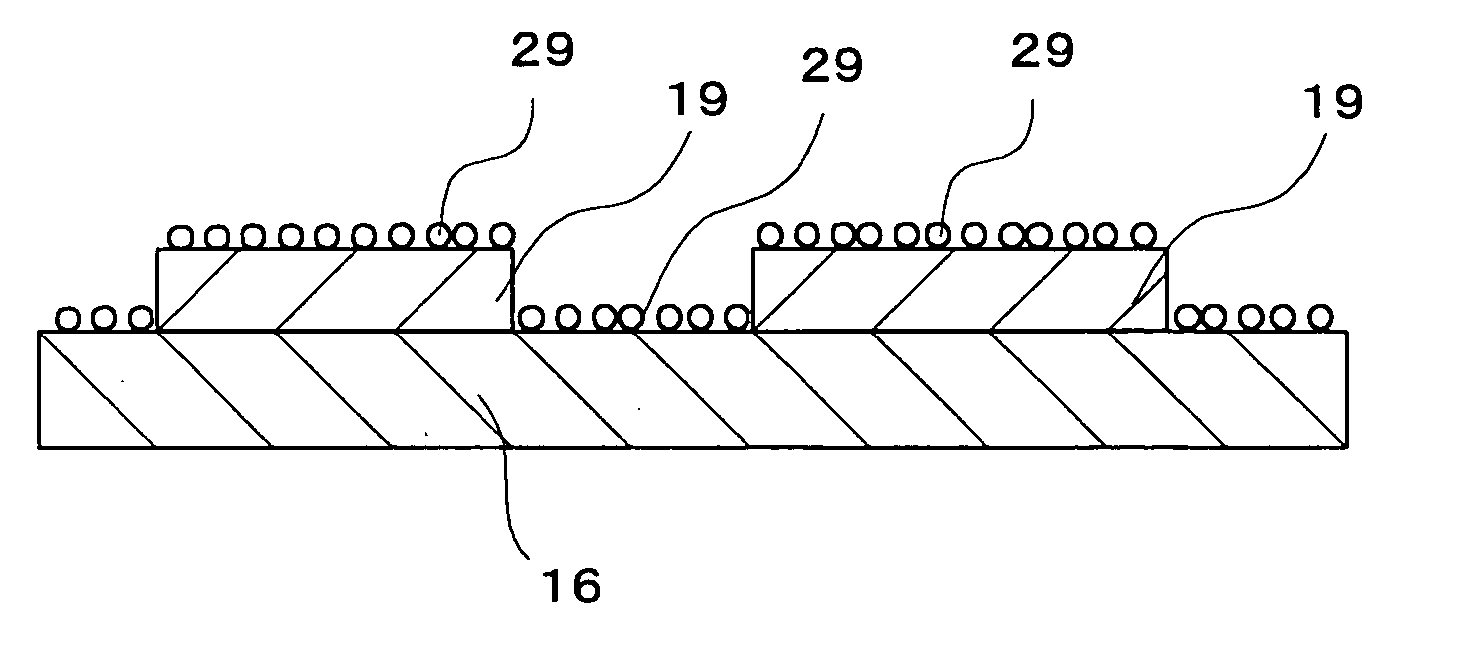

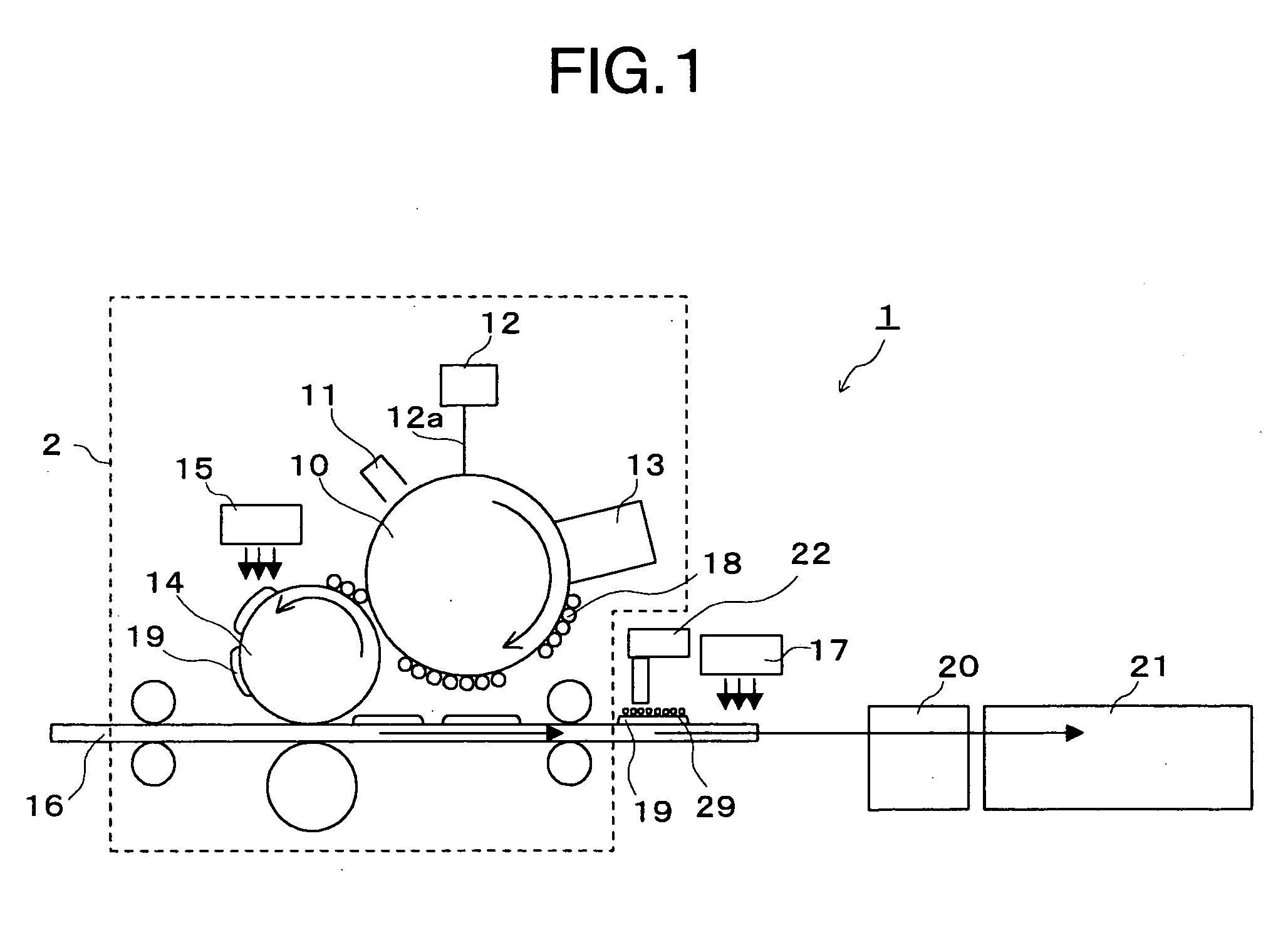

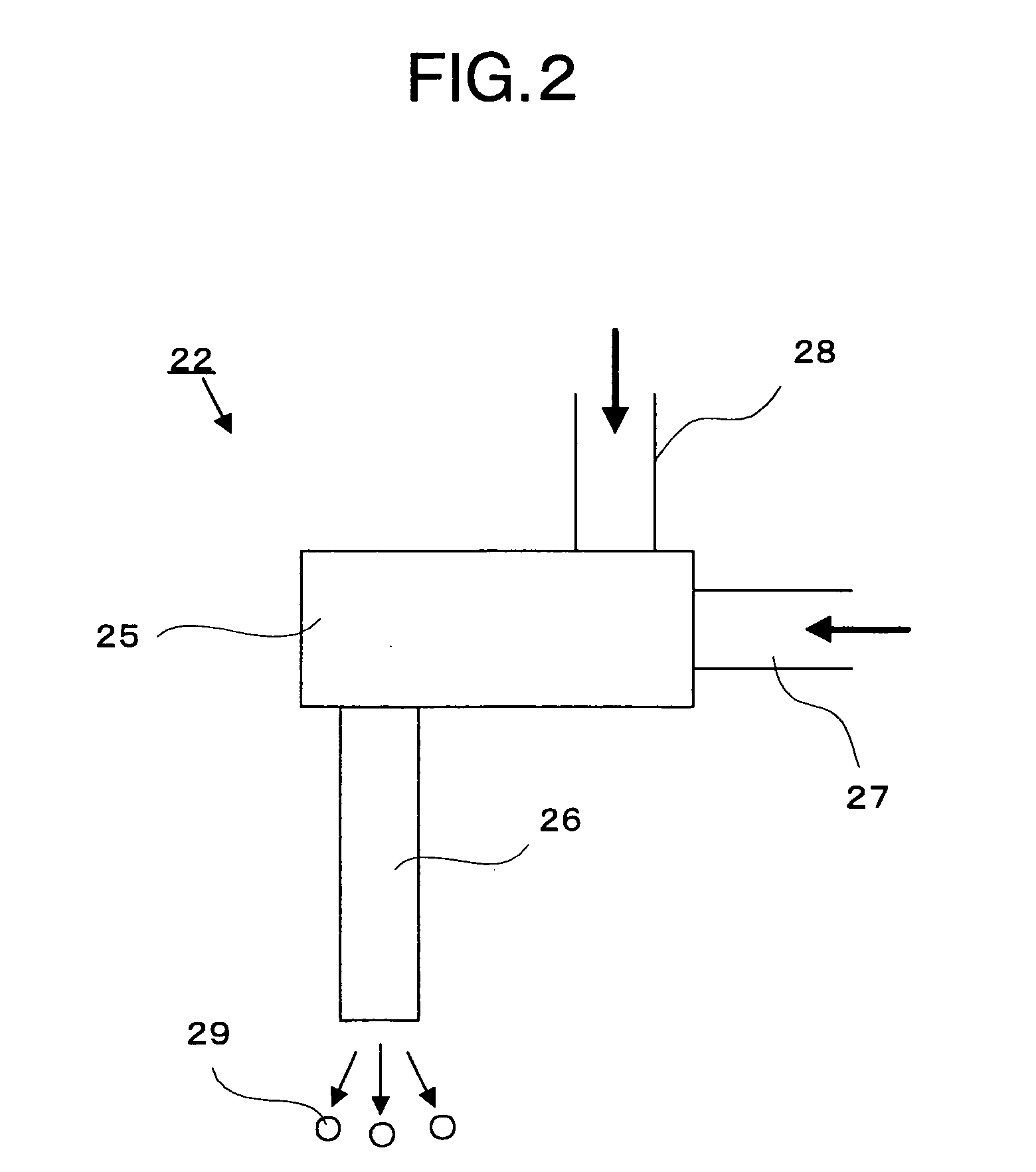

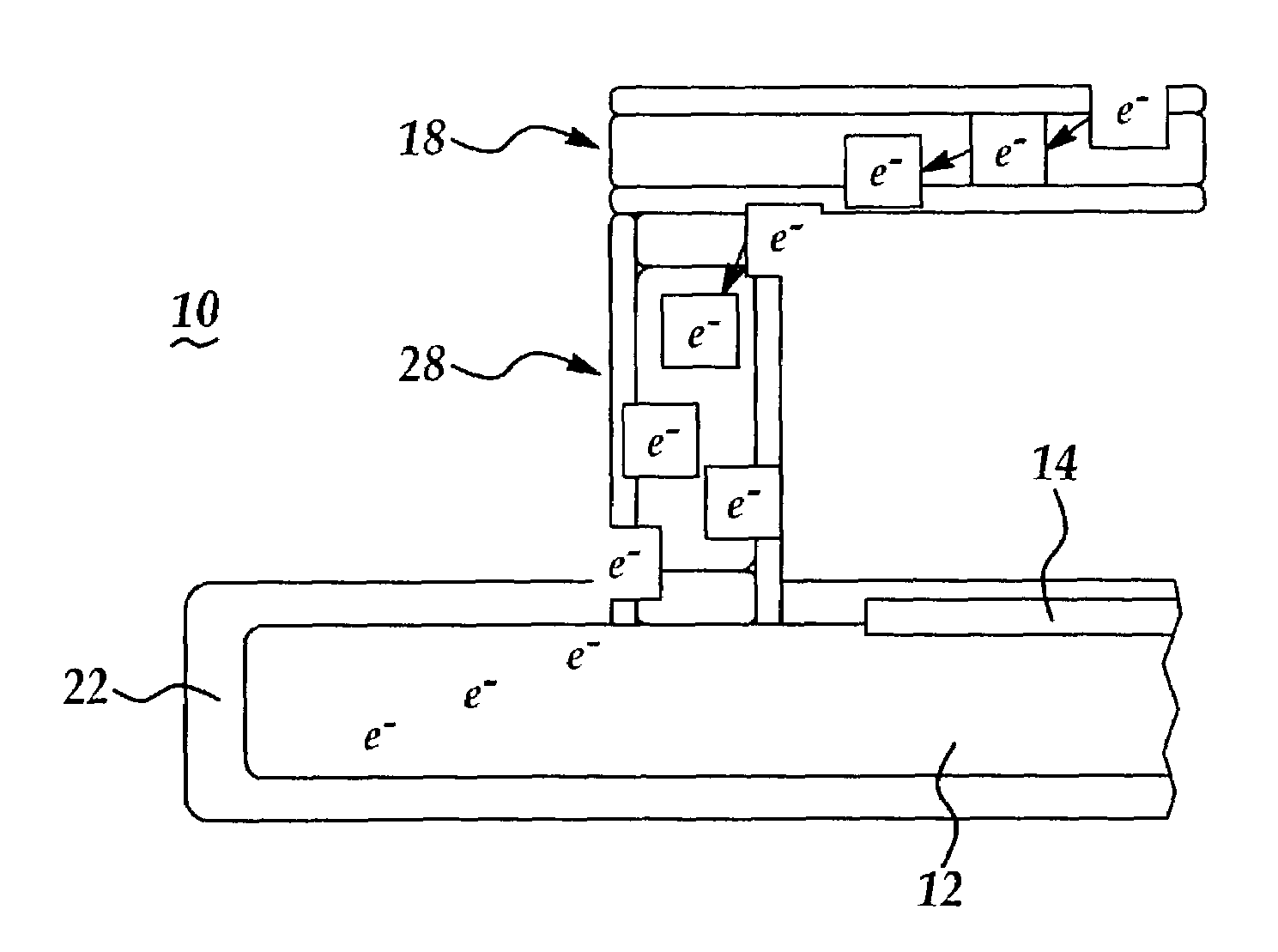

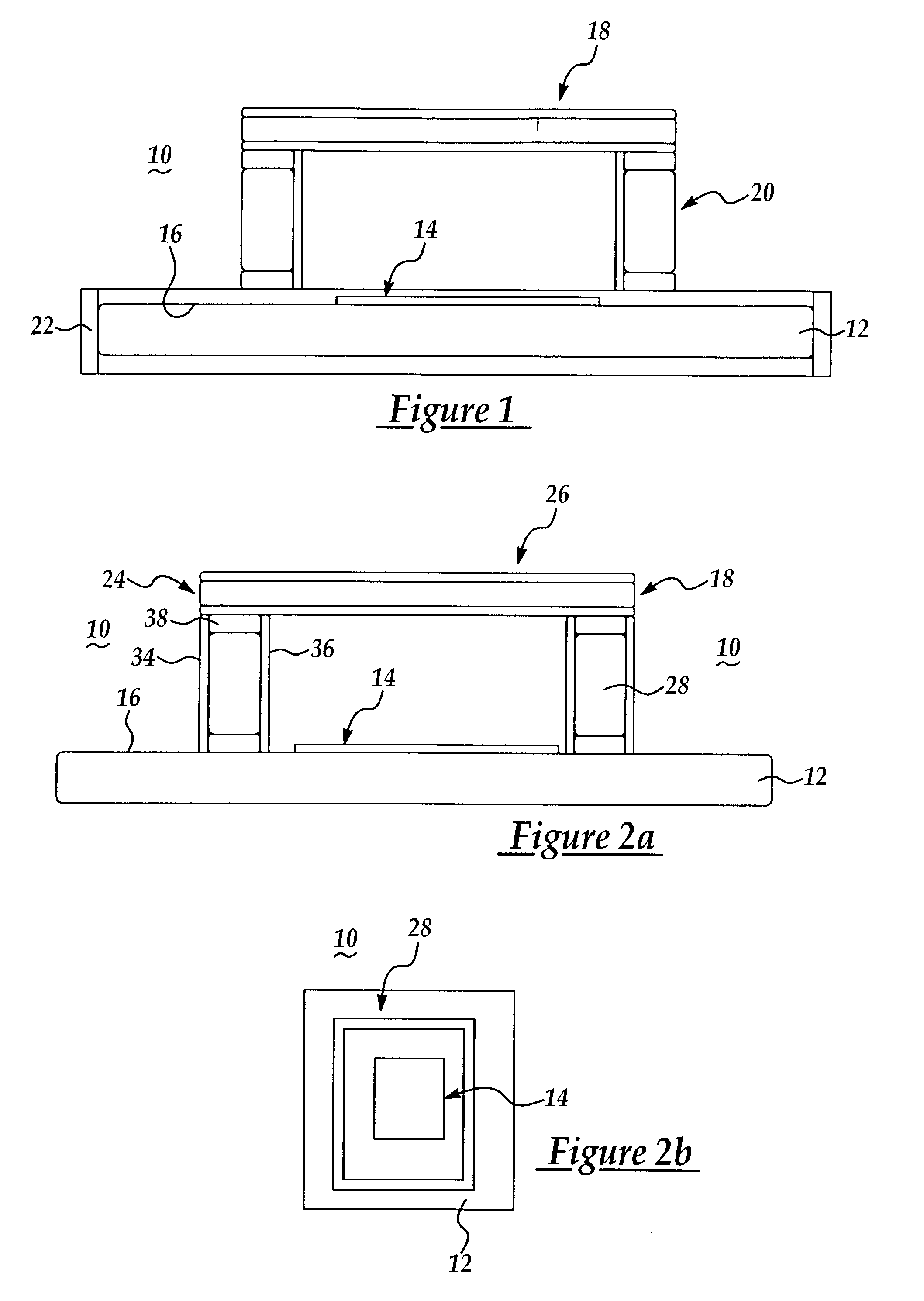

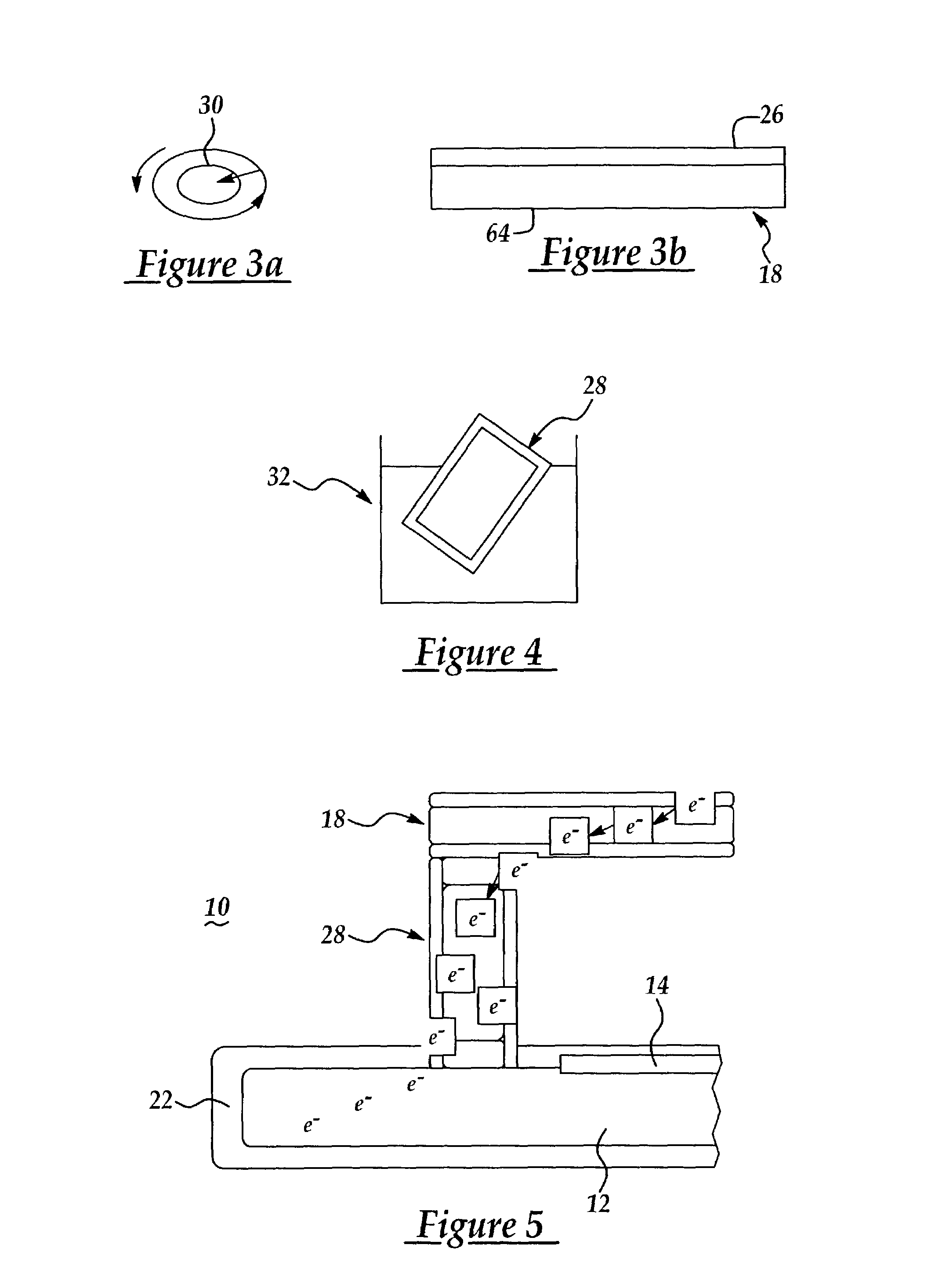

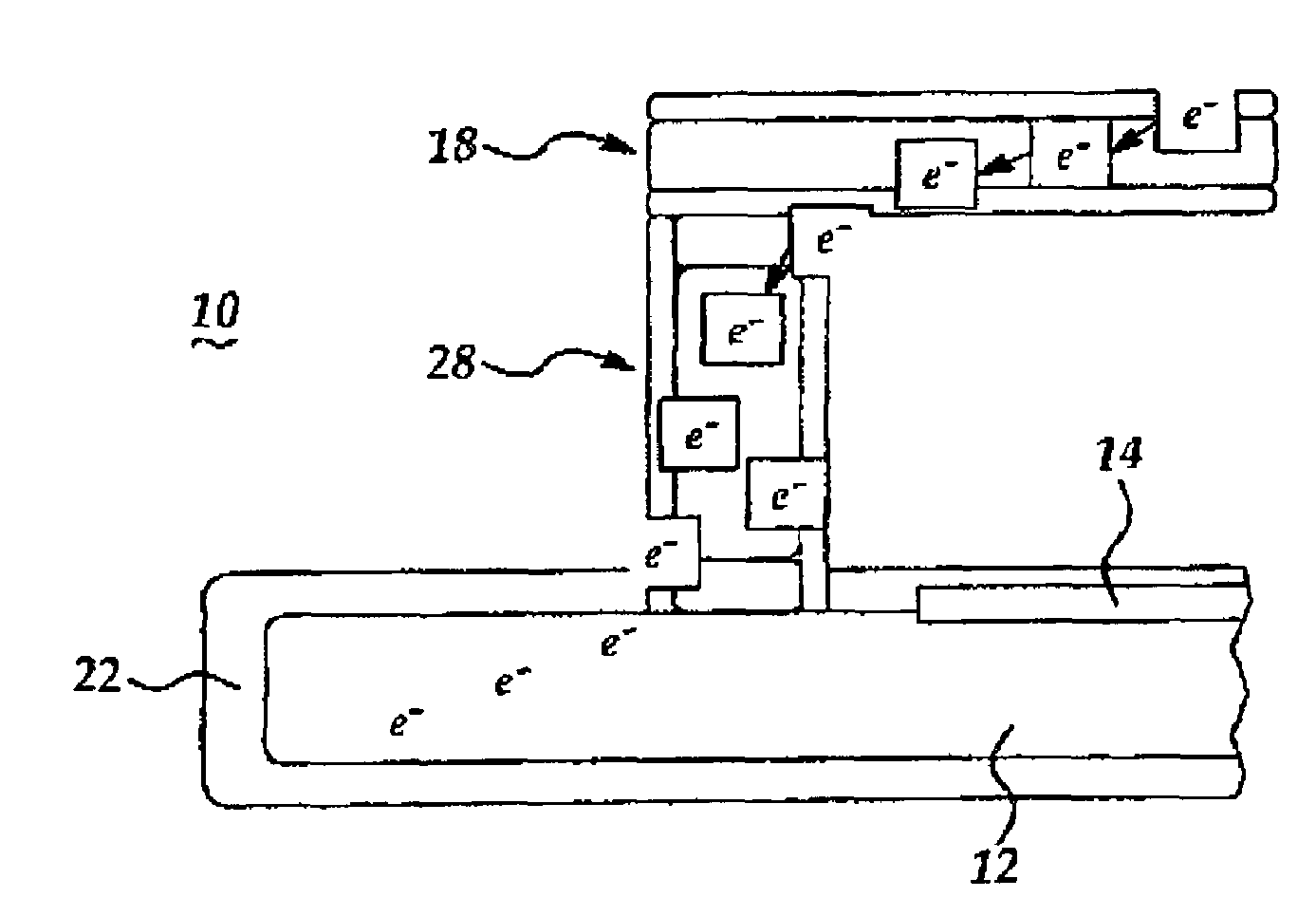

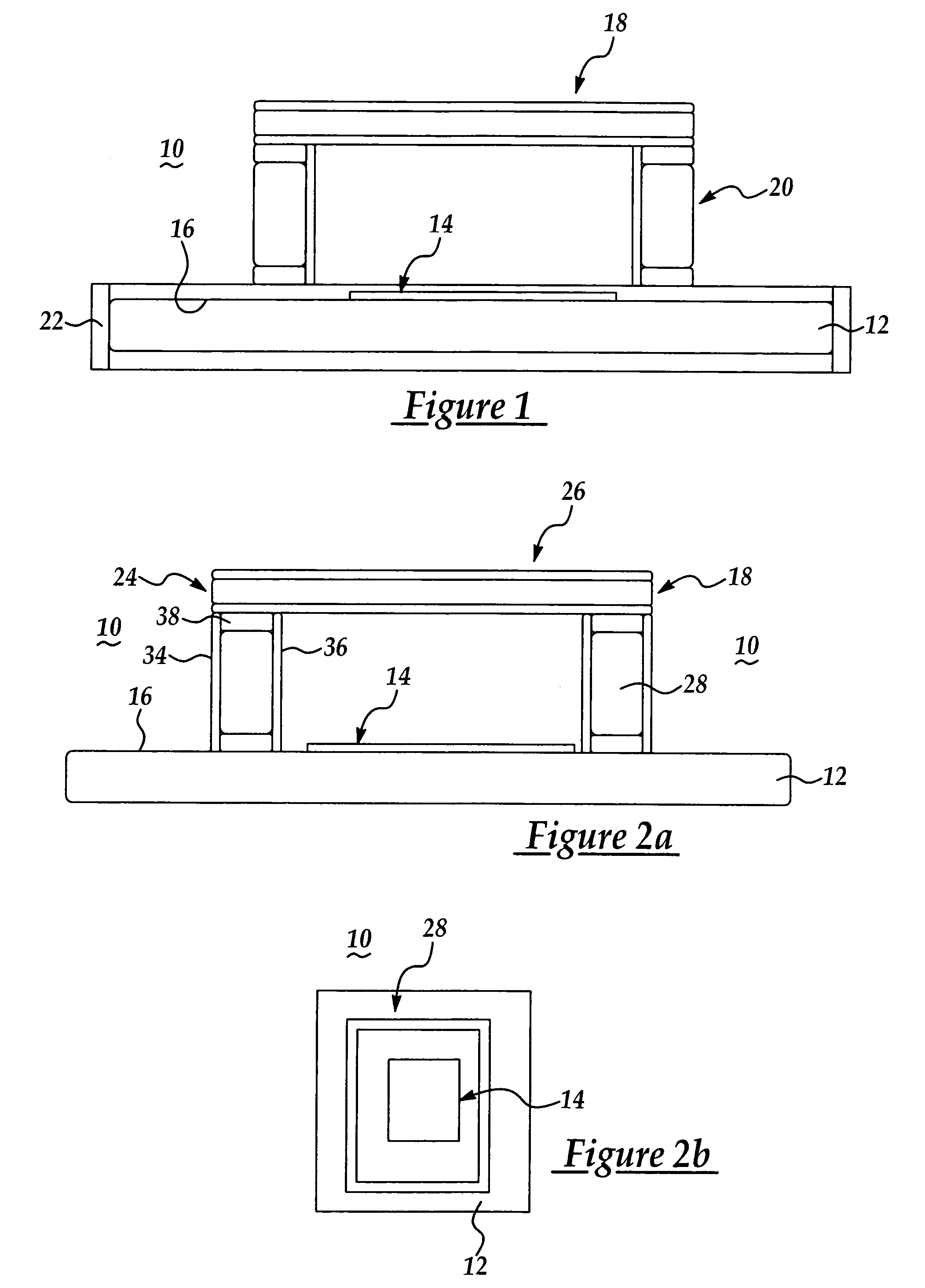

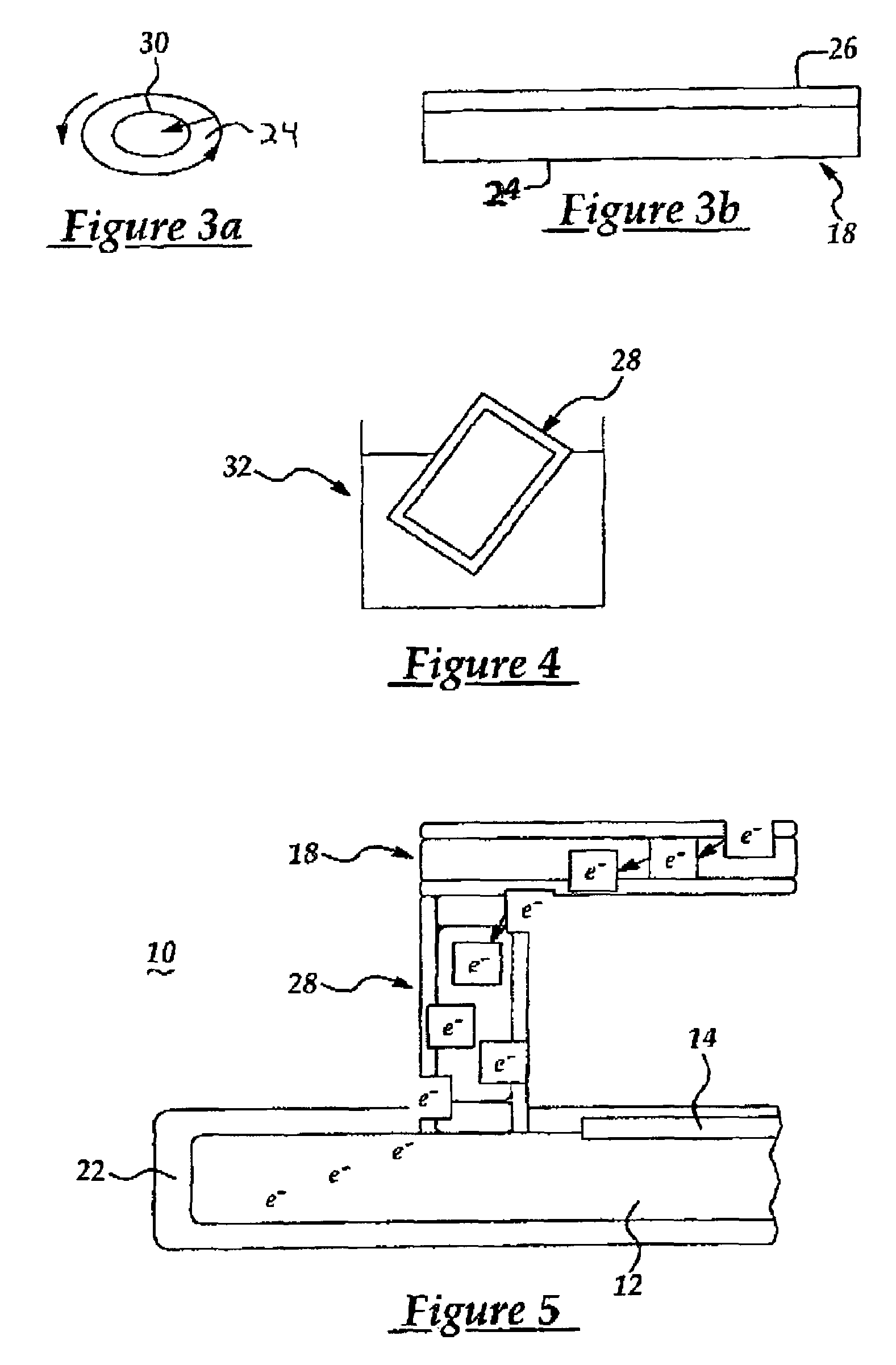

Electronic component manufacturing apparatus, electronic component manufacturing method, and electronic component

InactiveUS20050153249A1Photomechanical apparatusSemiconductor/solid-state device manufacturingParticulatesManufactured apparatus

There are provided a metal particulate spraying step to spray metal particulates over a substrate having an insulating pattern formed of thermosetting resin, a heating step to heat and dissolve the resin pattern and fix the metal particulates on the resin pattern, and a metal particulate eliminating step to eliminate metal particulates attached on the surface of the substrate excluding the resin pattern.

Owner:KK TOSHIBA

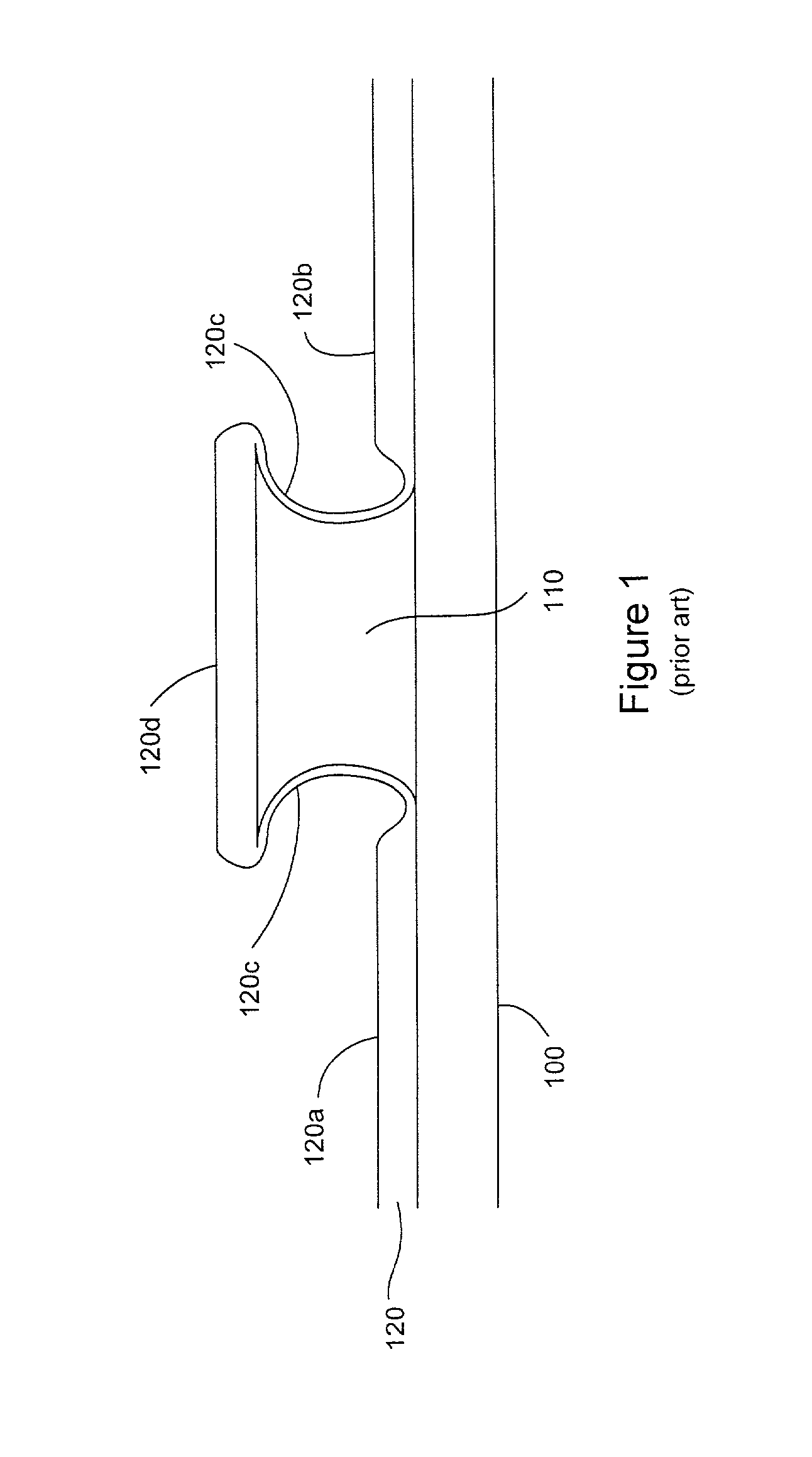

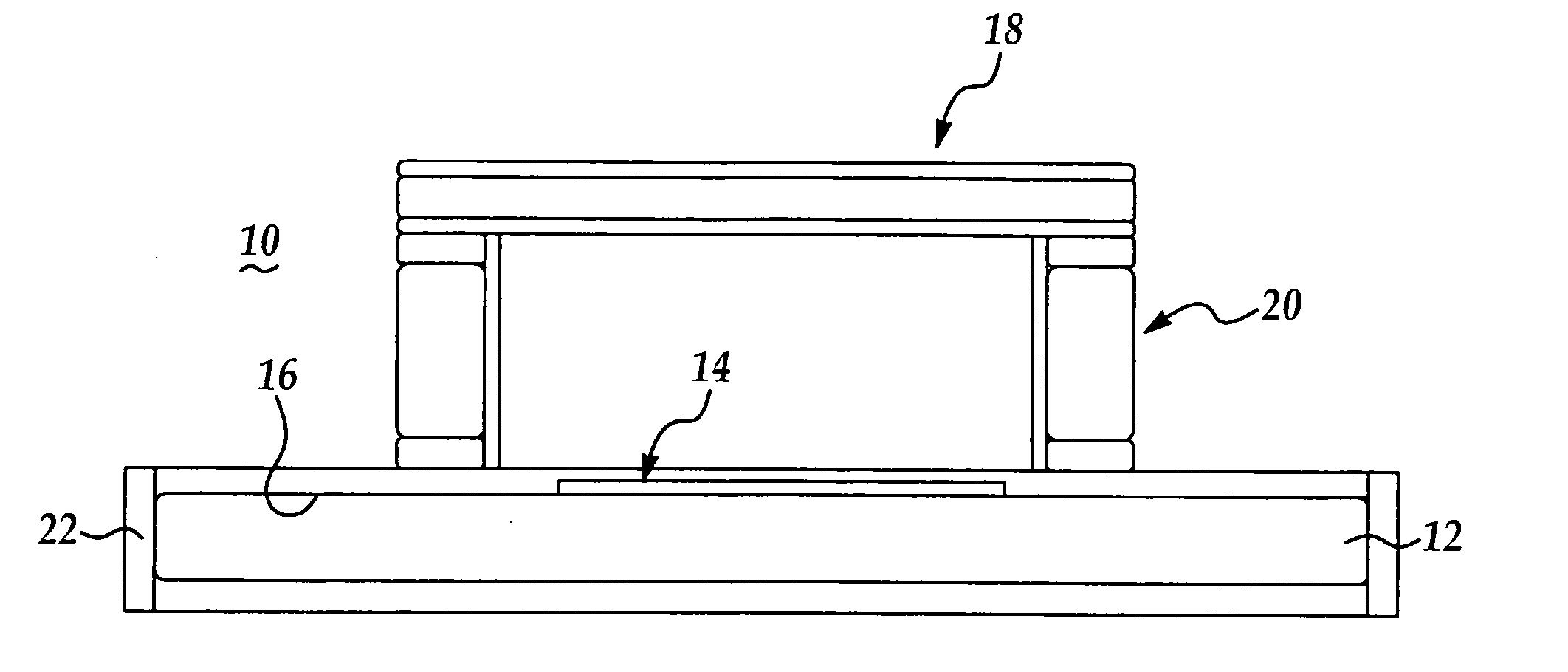

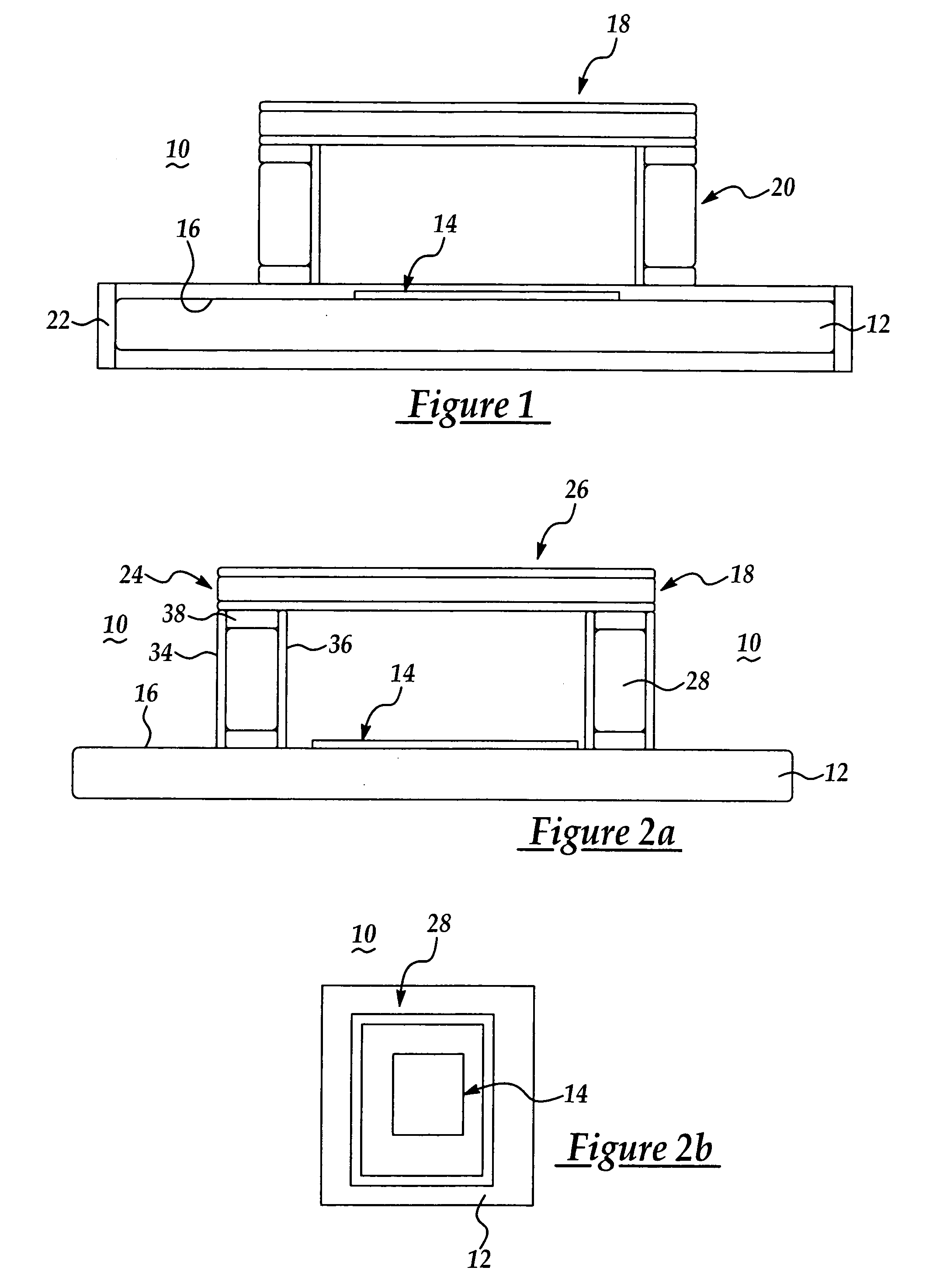

Method for patterning devices

A photoresist mask is provided, having a central region fabricated on an underlying layer. An overhang supported by the central region is separated from the underlying layer by a recessed area. The recessed area has an aspect ratio of at least about 1.5. The mask may be advantageously used to pattern electrodes deposited through the mask by chemical vapor deposition or sputtering, such that there is no significant conductivity across the mask between the patterned electrodes.

Owner:UNIVERSAL DISPLAY

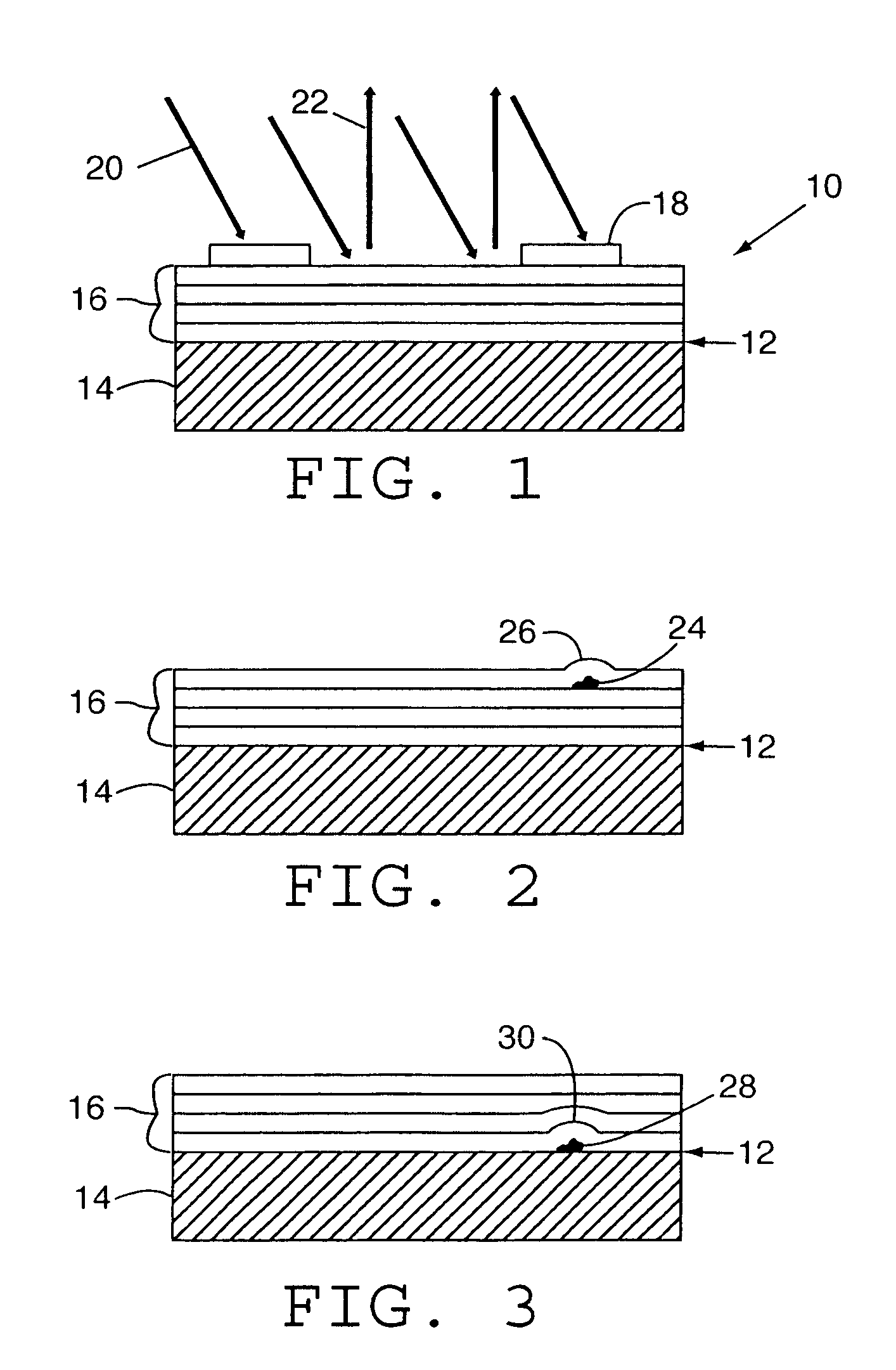

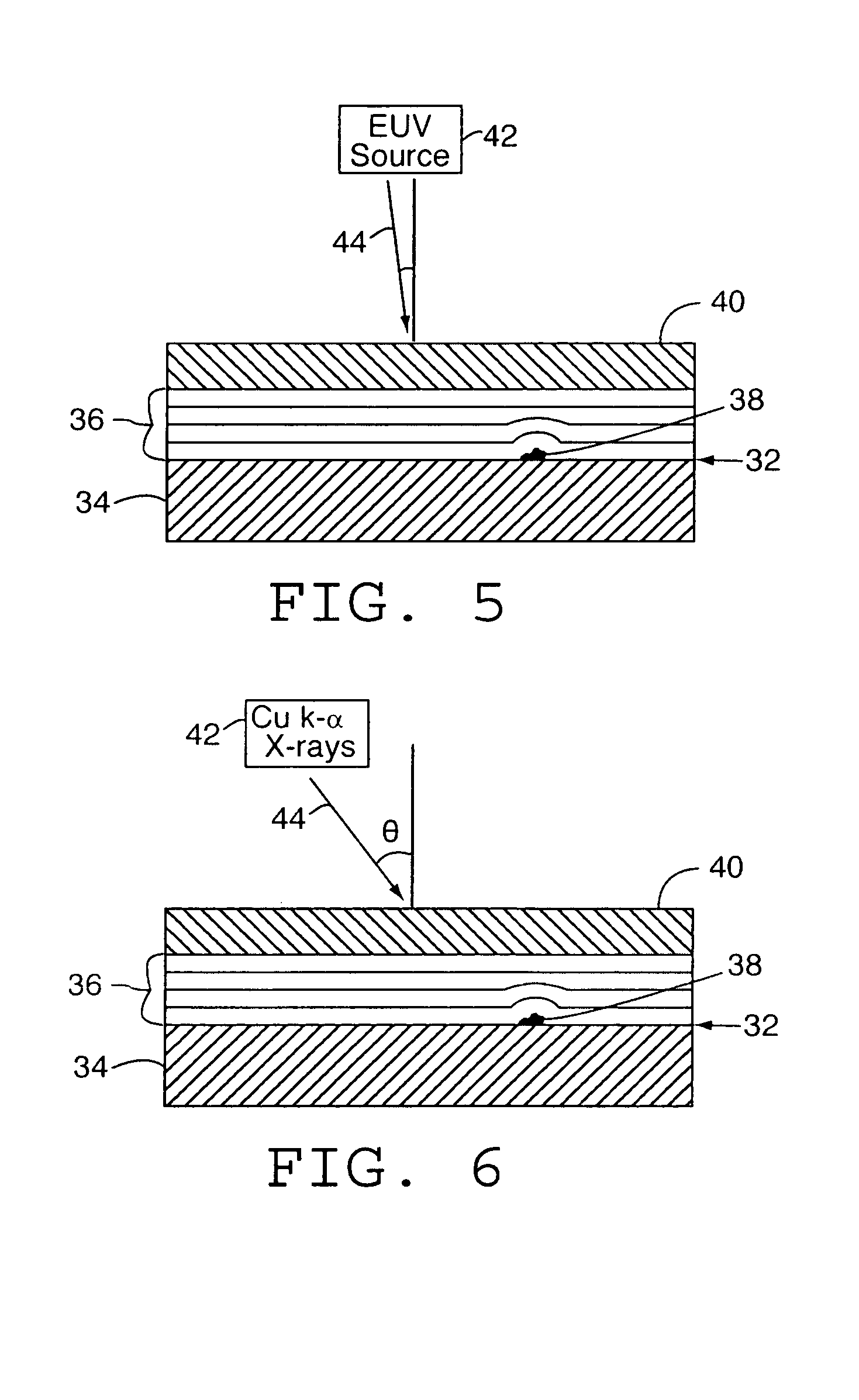

Defect inspection of extreme ultraviolet lithography masks and the like

InactiveUS7179568B2Reduce exposureQuickly and effectively revealImage enhancementImage analysisResistSoft x ray

A dark-field imaging method for detecting defects in reflective lithography masks (e.g., extreme ultraviolet (EUV) masks) used, e.g., in processes for the fabrication of microelectronic devices. A mask blank is coated with a photoresist layer having a fluorescent dye incorporated therein. The photoresist layer is exposed to a source of radiation (e.g., EUV radiation or glancing soft X-rays). In areas of the mask blank having defects the combined direct and reflected radiation will be insufficient fully to expose the photoresist layer. After development, photoresist will remain on the mask blank surface in areas corresponding to defects. Illumination with the excitation wavelength of the fluorescent dye reveals the location of any remaining photoresist, which can be detected using an optical microscope, thereby to detect defects in the mask blank.

Owner:WISCONSIN ALUMNI RES FOUND

Reticle with antistatic coating

InactiveUS7029800B2Potential damageEliminate potential differencePicture framesLight effect designsEngineeringReticle

A static resistant reticle comprises a substrate and a patterning layer and is covered by an antistatic conductive film of quaternary amine (R4N)+Cl−. A pellicle structure comprising an optically transparent membrane tightly stretched on a frame is also coated by an antistatic electro conductive film of a similar material. The reticle with the pellicle form a shielded structure isolating the reticle from ESD.

Owner:TAIWAN SEMICON MFG CO LTD

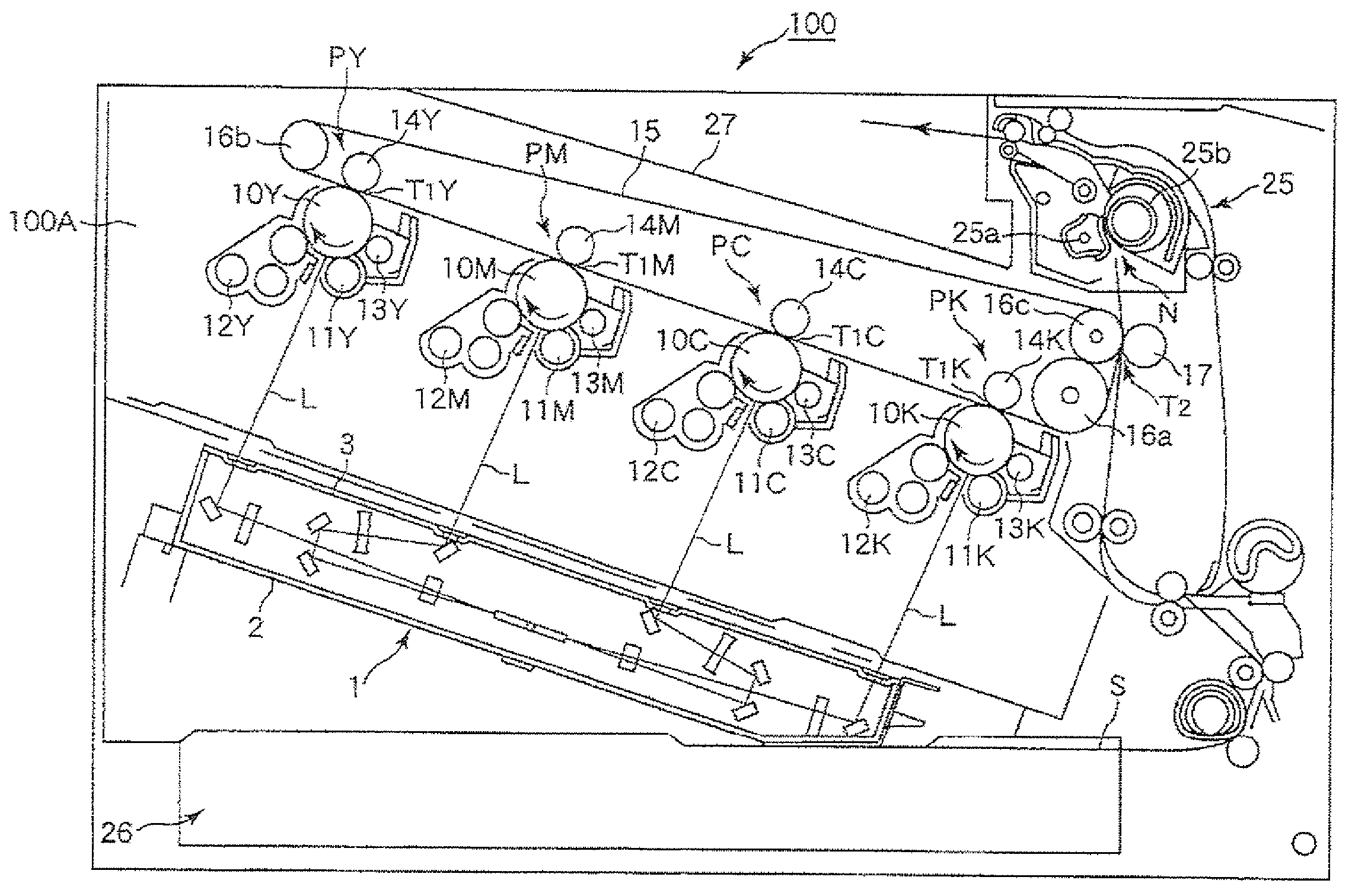

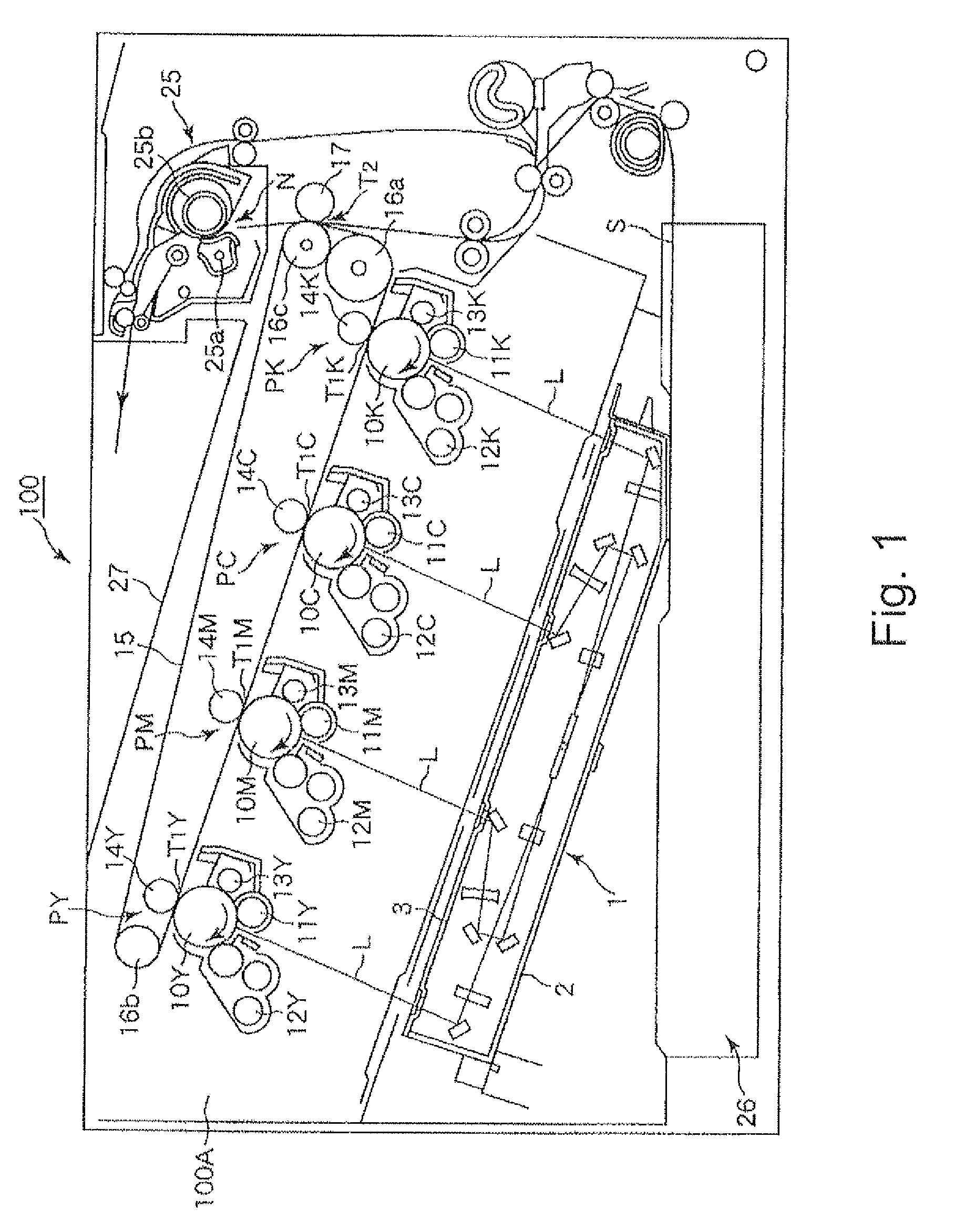

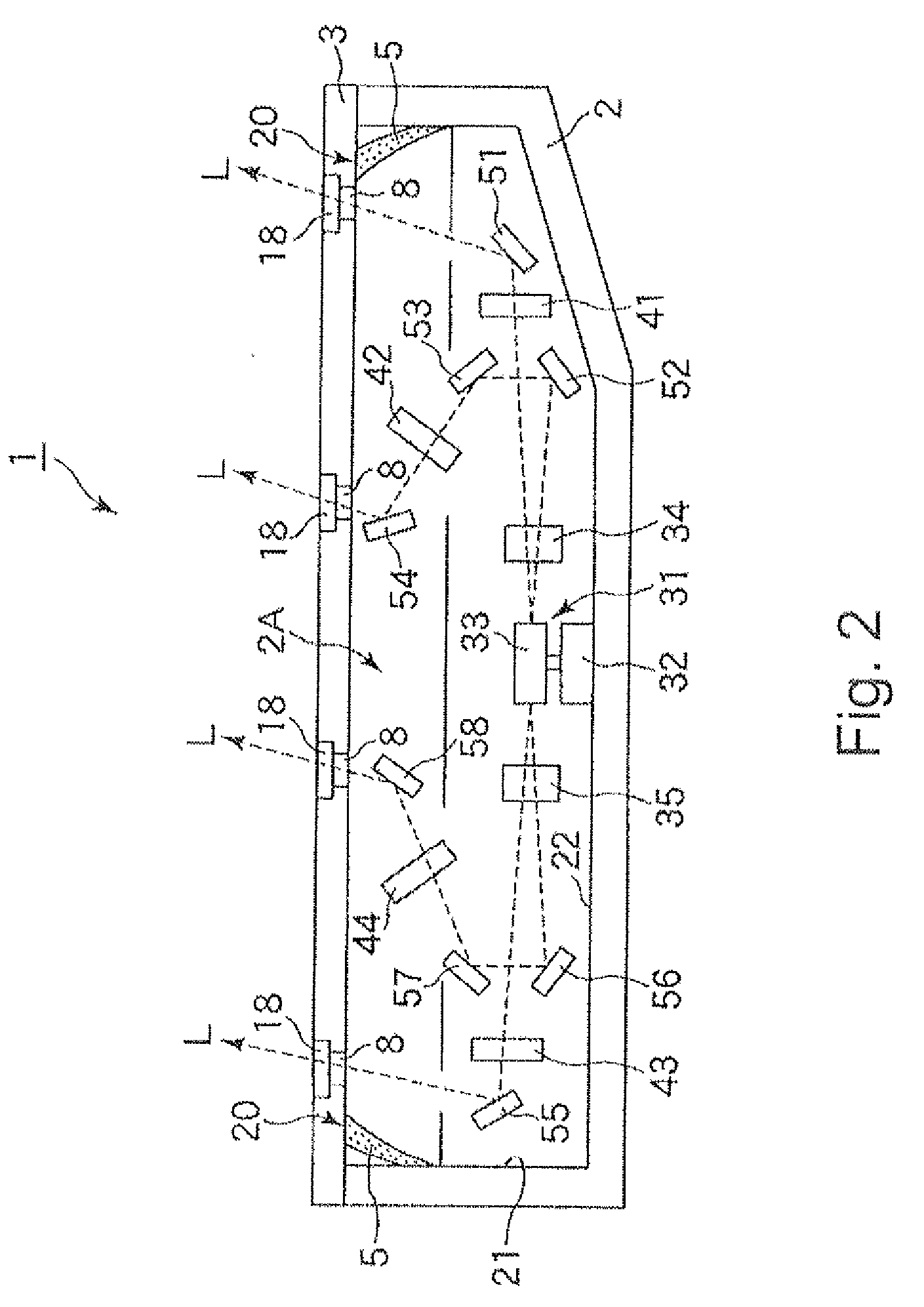

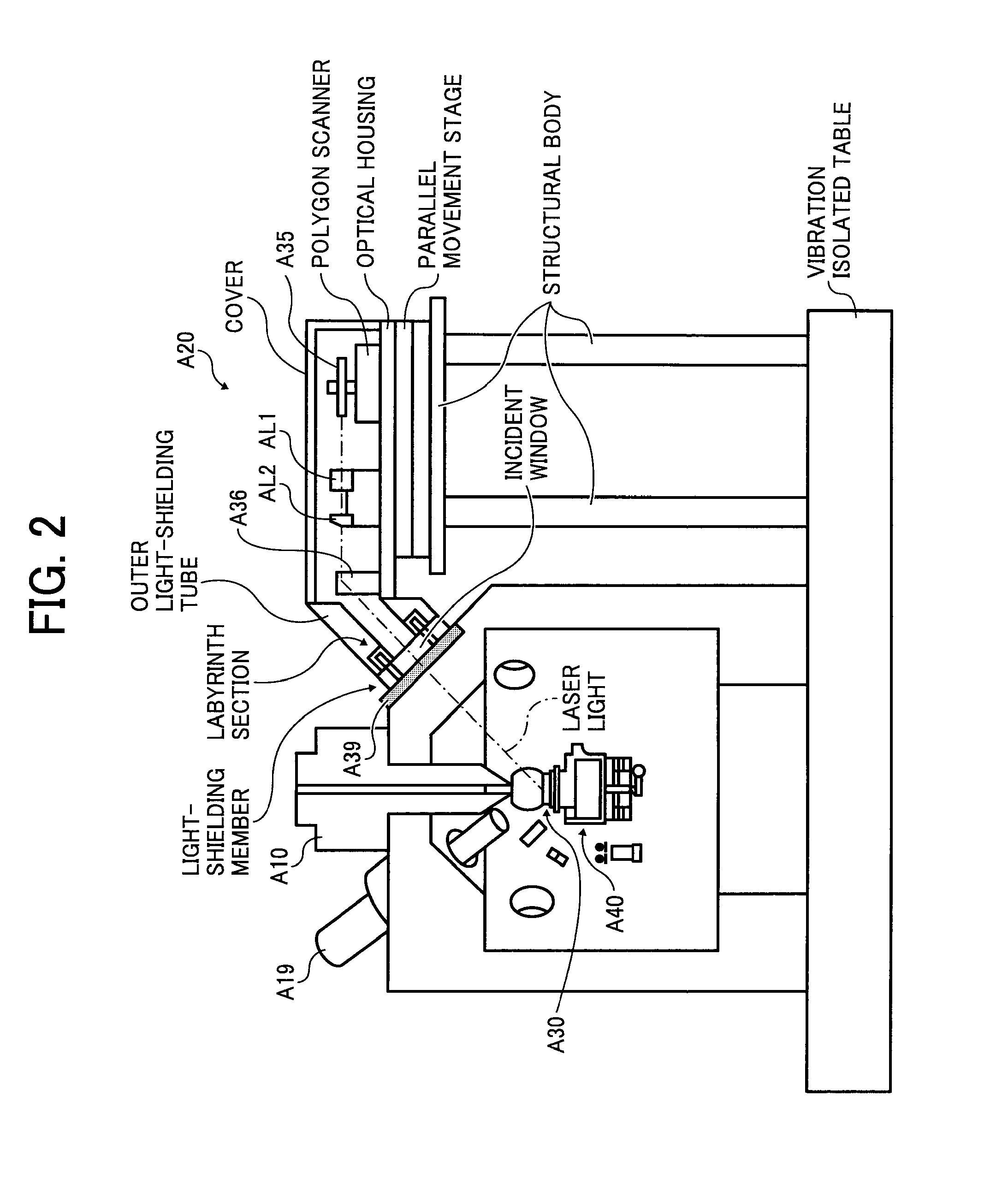

Optical scanning apparatus

InactiveUS20090226213A1Electrographic process apparatusElectrographic processes using thermoplastic layersLaser beam guideOptoelectronics

A scanning optical apparatus includes an optical box accommodating a deflection device for scanningly deflecting a laser beam emitted by a light source and an optical part for directing the laser beam toward a member-to-be-scanned; a cap mounted to the optical box; a sealing member extending from the cap, wherein the sealing member is made of a material exhibiting easier deformation than the cap, and is contacted to a wall of the optical box in a deformed state.

Owner:CANON KK

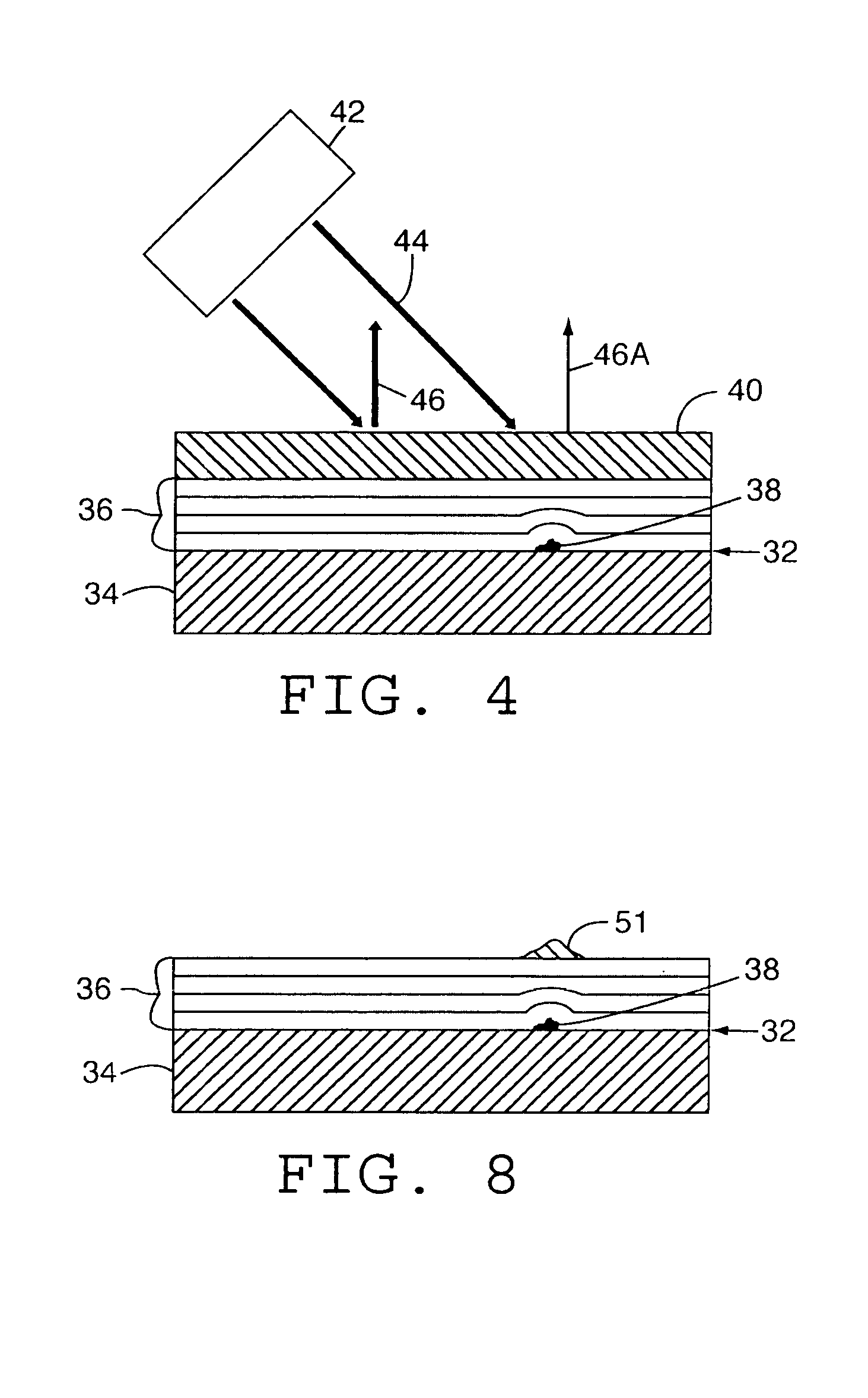

Optical mask, method for making figure and method for making semiconductor device

InactiveCN1581437ASemiconductor/solid-state device manufacturingPhotomechanical coating apparatusFocal positionSemiconductor

A photomask includes a transparent substrate; a first mask pattern disposed on a first region of the transparent substrate; a second mask pattern disposed on a second region different from the first region of the transparent substrate; and a transparent film provided on the first mask pattern, having an optical thickness configured to make a focal position of the first mask pattern deeper than a focal position of the second mask pattern.

Owner:KK TOSHIBA

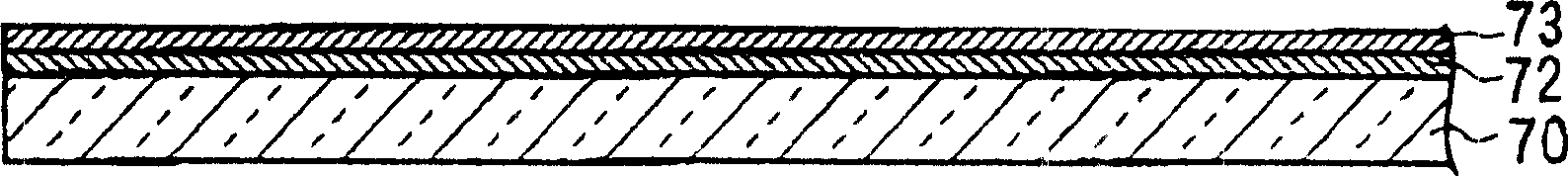

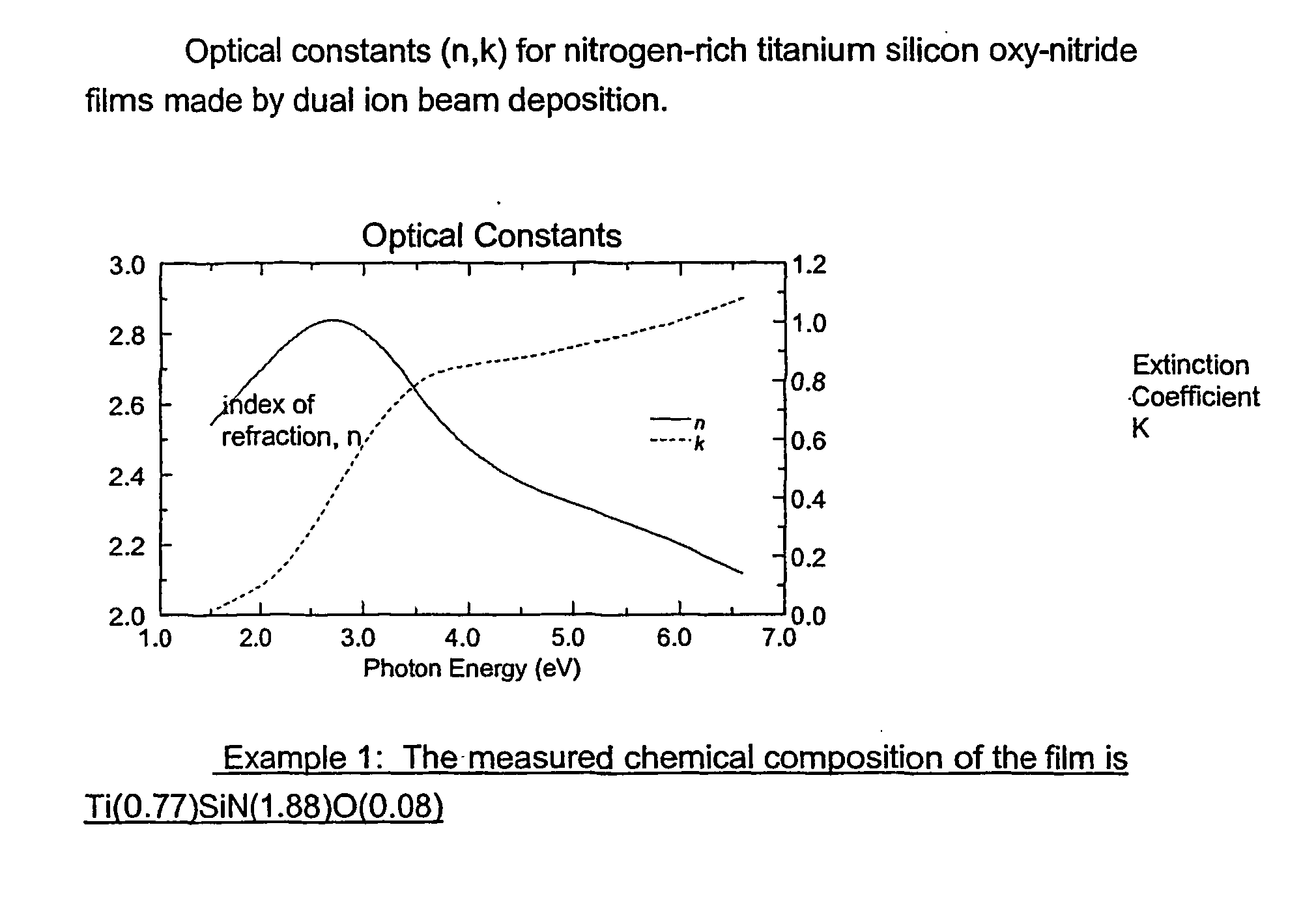

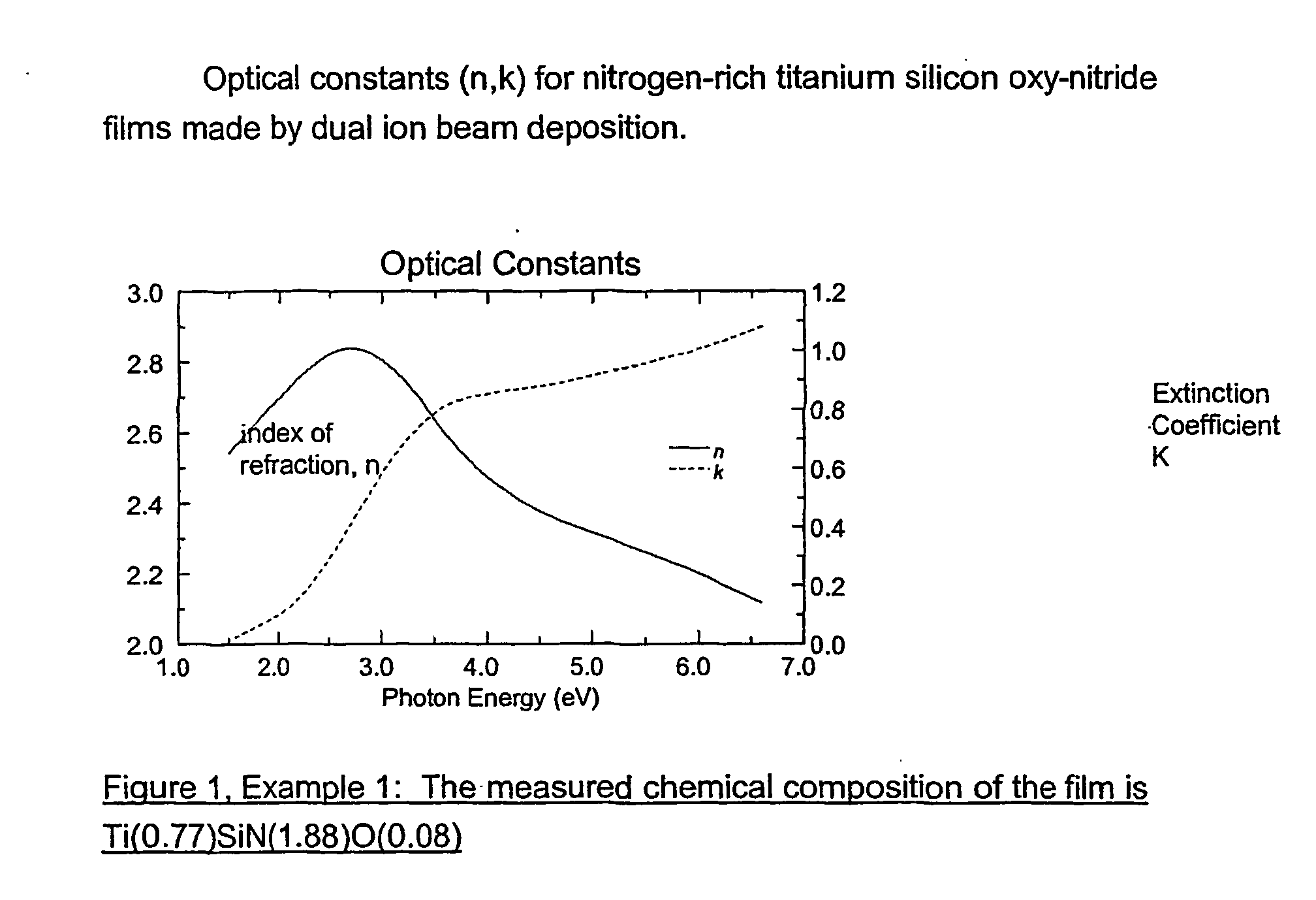

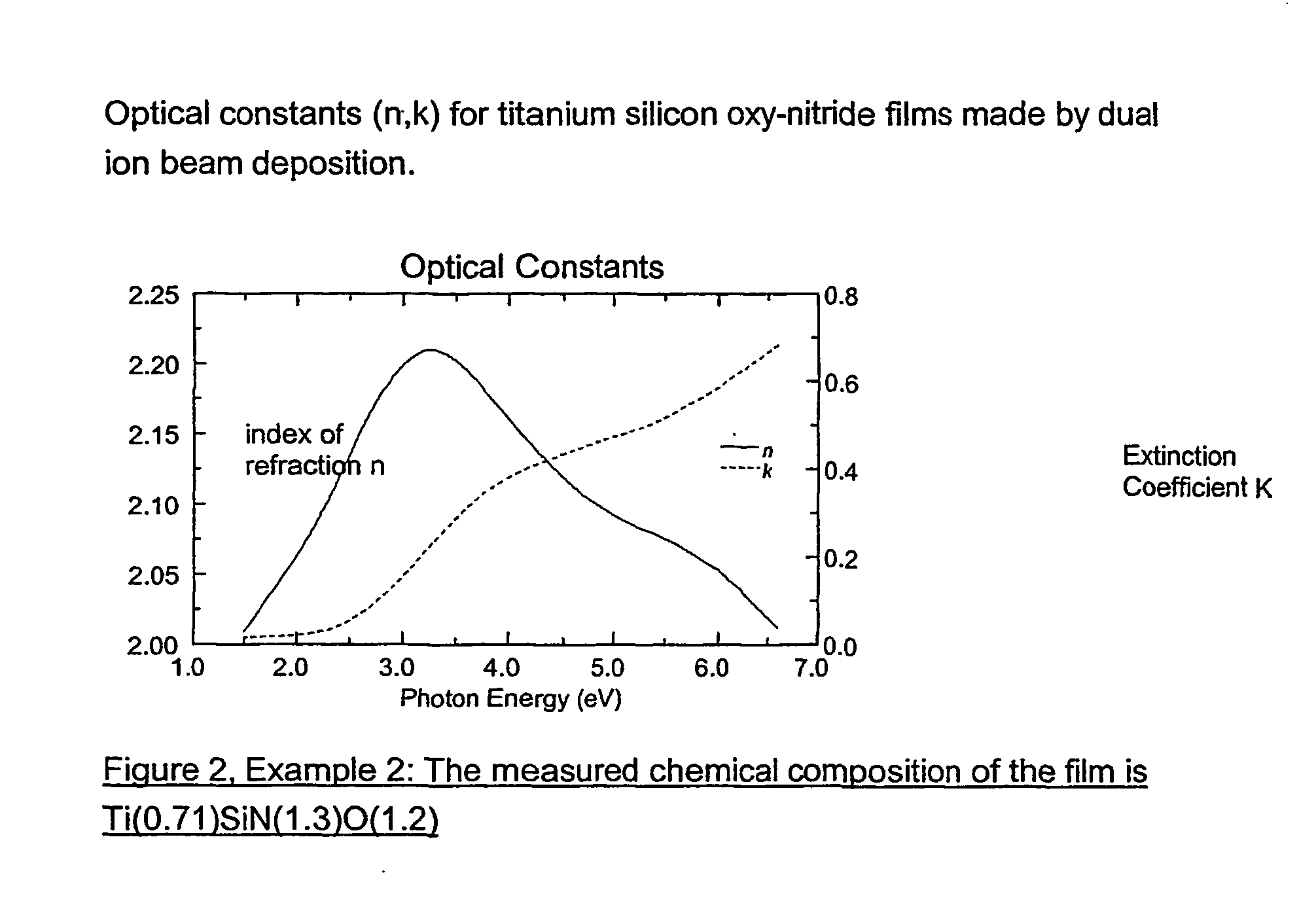

Ion-beam deposition process for manufacturing attenuated phase shift photomask blanks

An ion-beam deposition process for fabricating attenuating phase shift photomask blanks, capable of producing a phase shift of 180°, and which can provide tunable optical transmission at selected lithographic wavelengths<400 nm, comprising at least one layer of material of general formulae MzSiOxNy or MzAlOxNy, is described.

Owner:EI DU PONT DE NEMOURS & CO

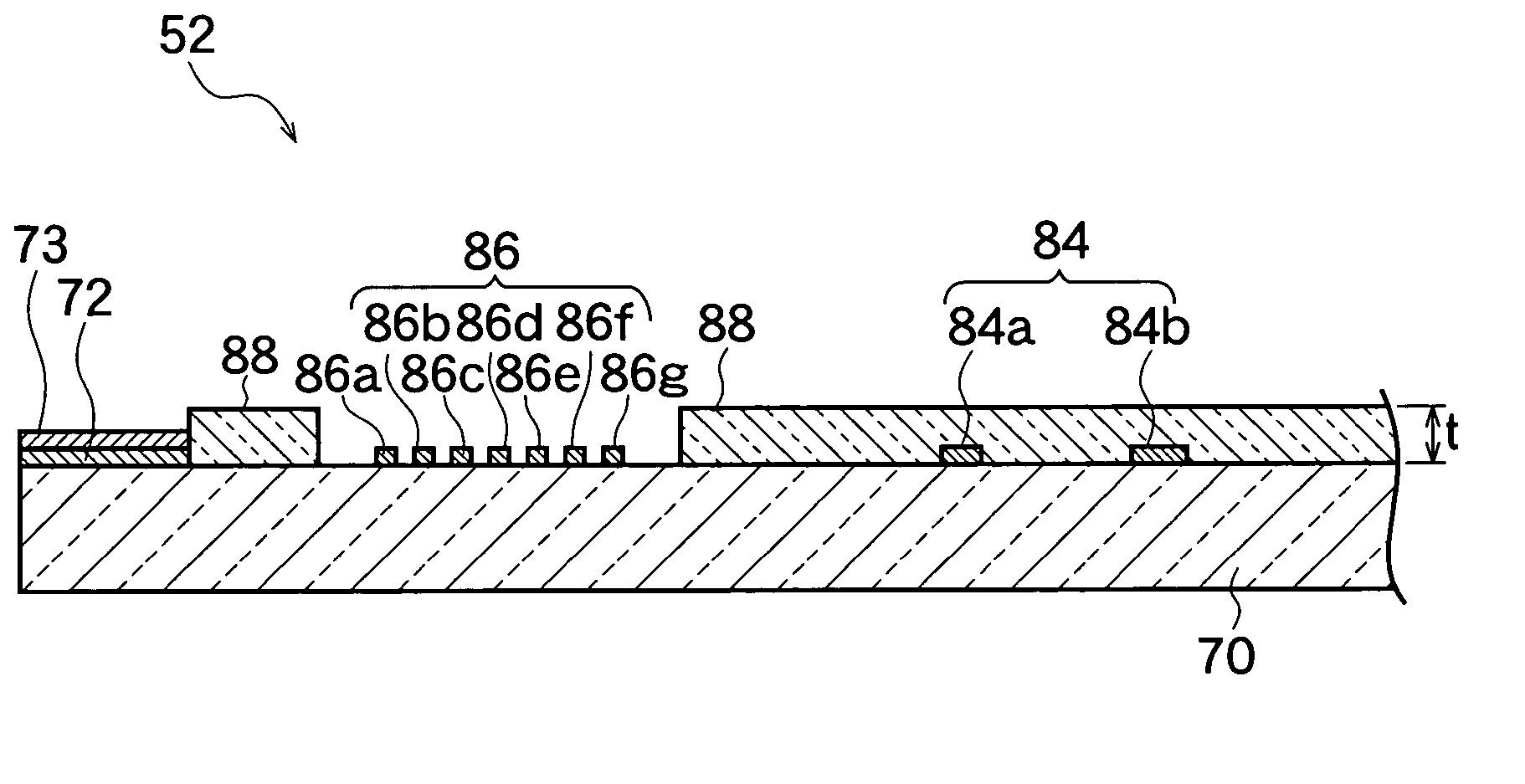

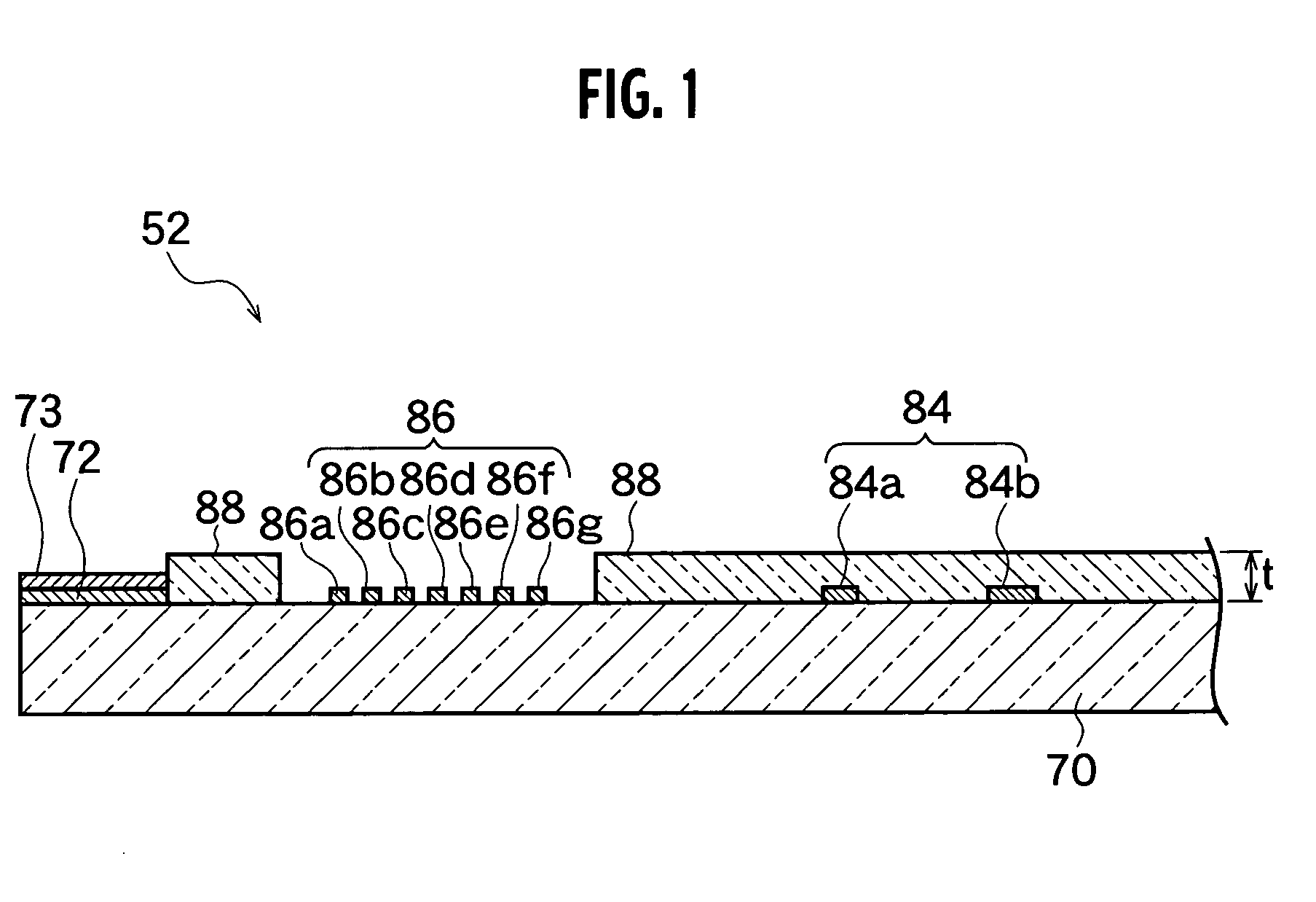

Photomask, method for fabricating a pattern and method for manufacturing a semiconductor device

InactiveUS20050031967A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusDevice materialOptoelectronics

A photomask includes a transparent substrate; a first mask pattern disposed on a first region of the transparent substrate; a second mask pattern disposed on a second region different from the first region of the transparent substrate; and a transparent film provided on the first mask pattern, having an optical thickness configured to make a focal position of the first mask pattern deeper than a focal position of the second mask pattern.

Owner:KK TOSHIBA

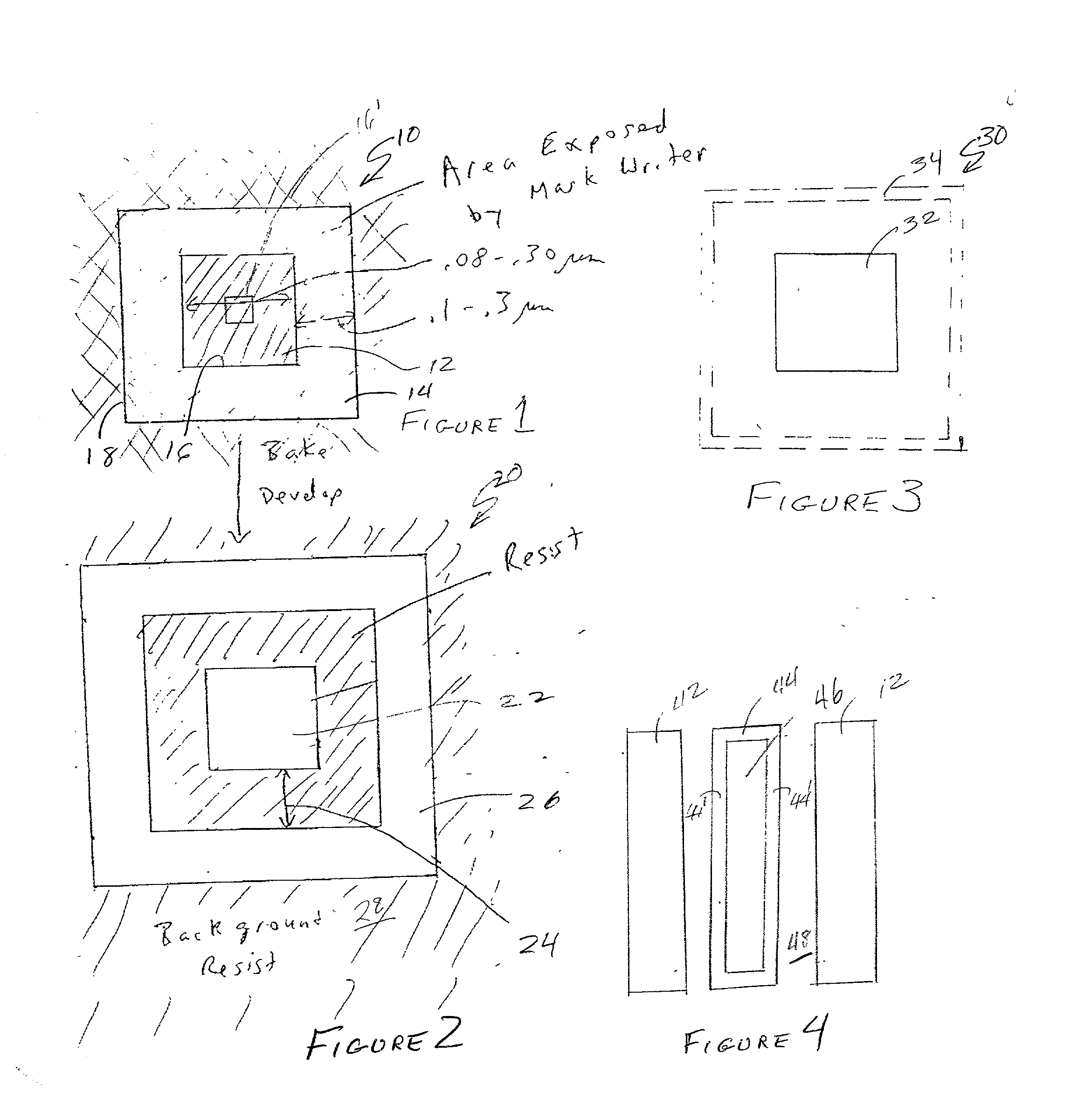

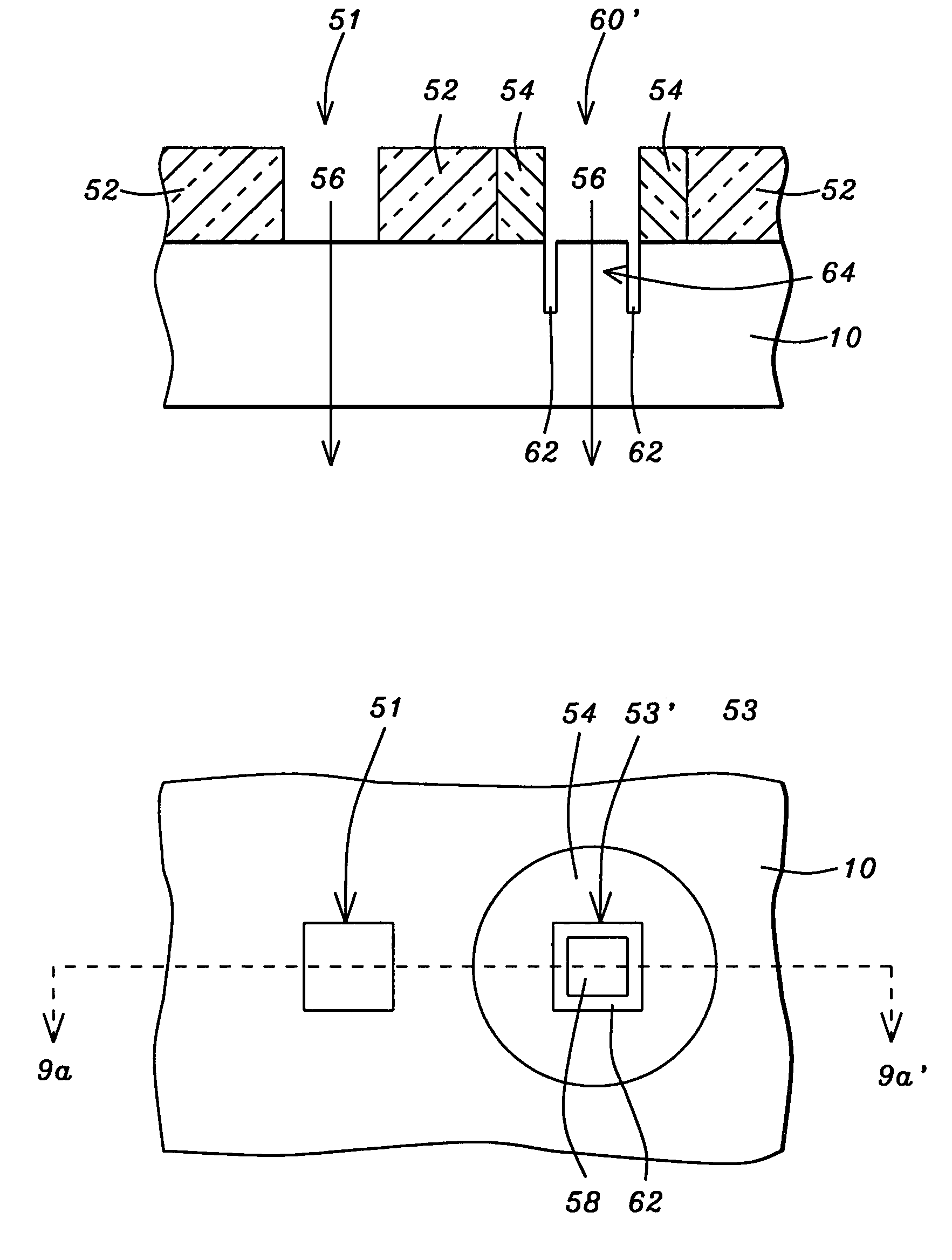

Assist features for contact hole mask patterns

InactiveUS20030008216A1Reduced footprintIncrease exposurePhoto-taking processesPhotomechanical apparatusPattern recognitionResist

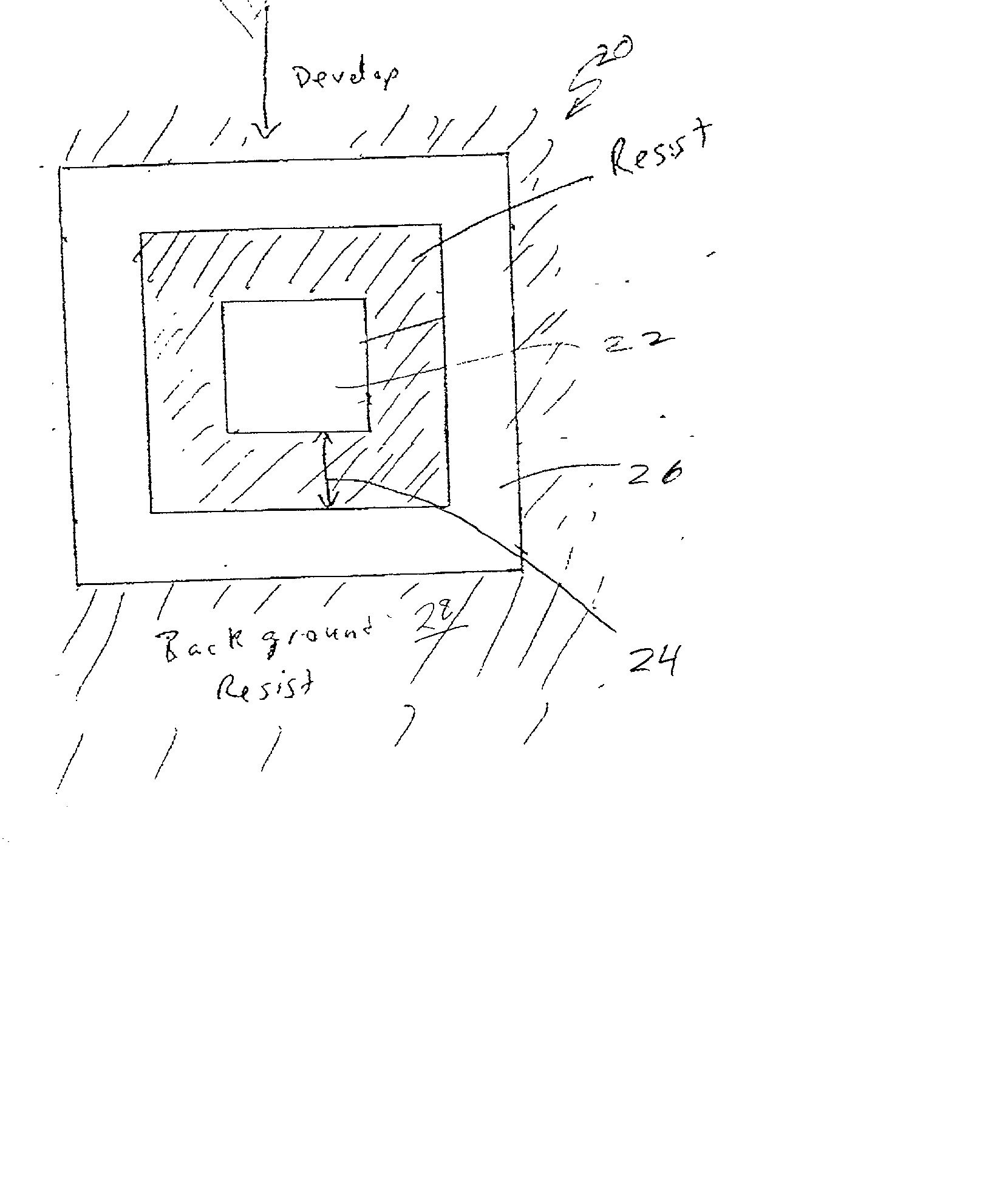

An assist feature is formed on a lithographic reticle or mask using a hybrid resist and an exposure dose such that only an annular area is effectively exposed having a width that is potentially less than the minimum feature size that can be resolved by the mask exposure tool to simultaneously or sequentially form both a feature of interest and an assist feature for enhancing imaging of the feature of interest when the feature is printed to a wafer. Since the assist feature can be imaged simultaneously with the feature of interest or multiple assist features imaged concurrently, possibly between closely spaced features, data volume and mask writing time are greatly reduced. The invention is particularly applicable to the scaling of contact holes for connections to active devices in extremely high density integrated circuits.

Owner:GOOGLE LLC

Reticle with antistatic coating

Owner:TAIWAN SEMICON MFG CO LTD

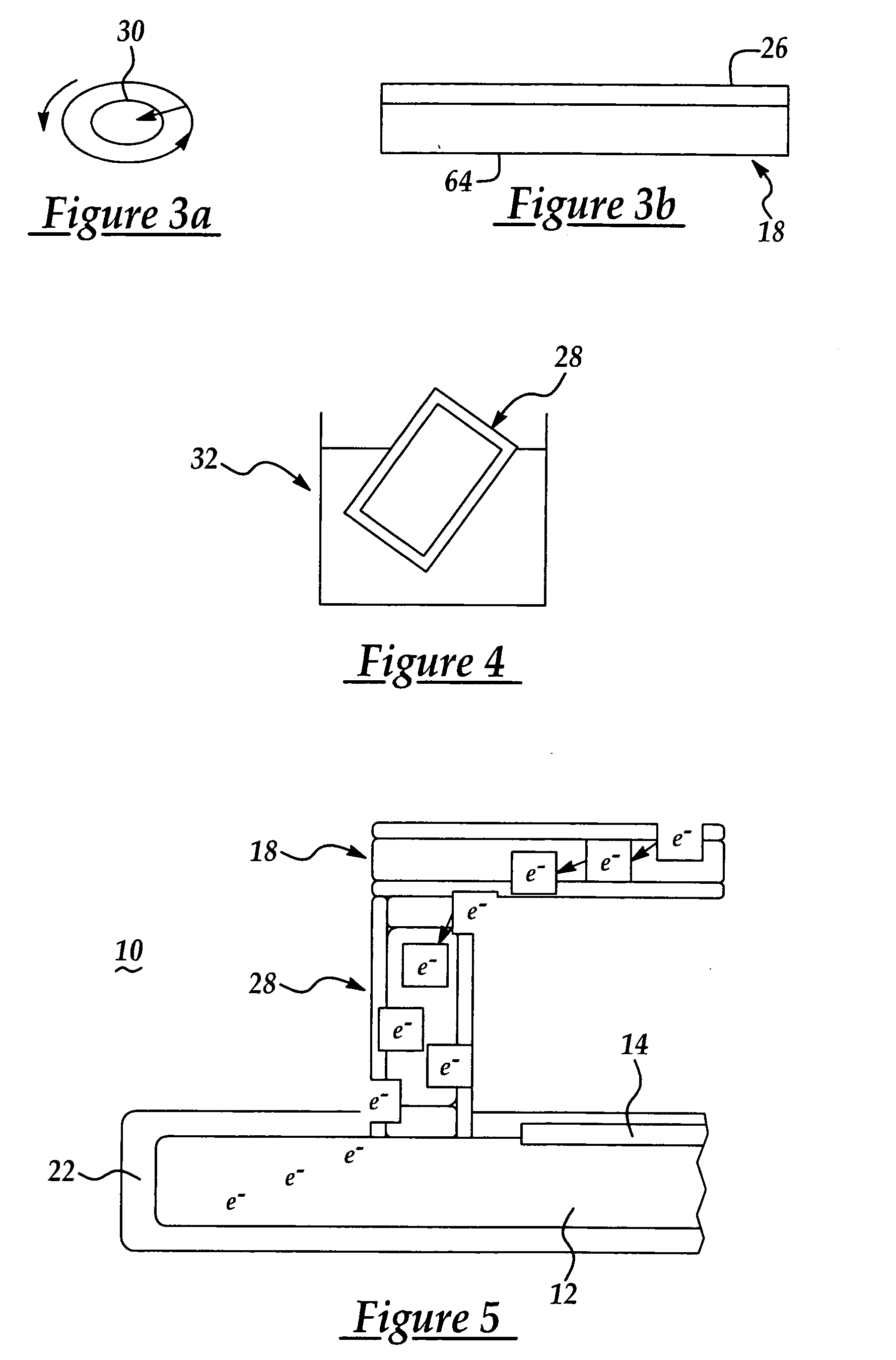

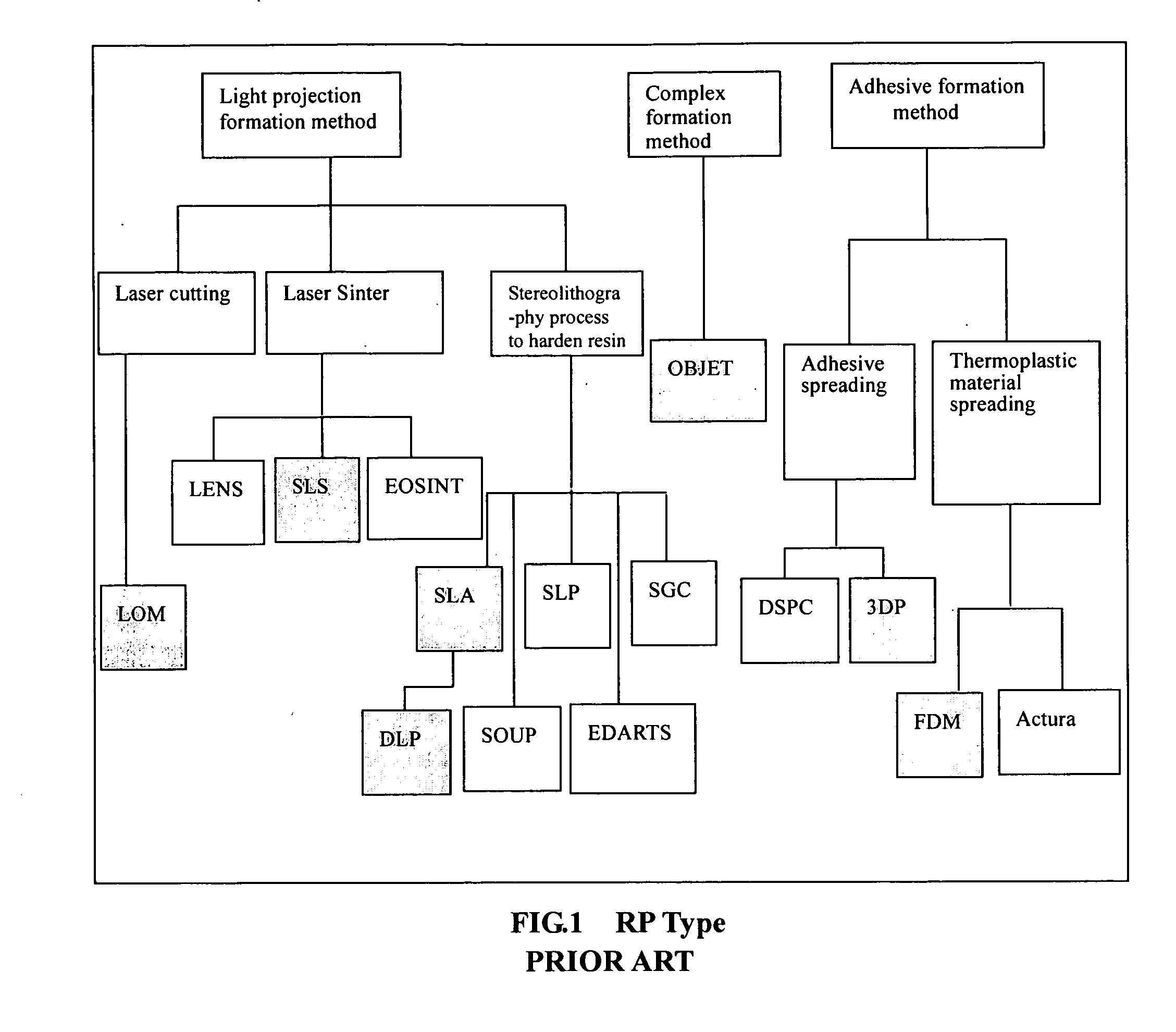

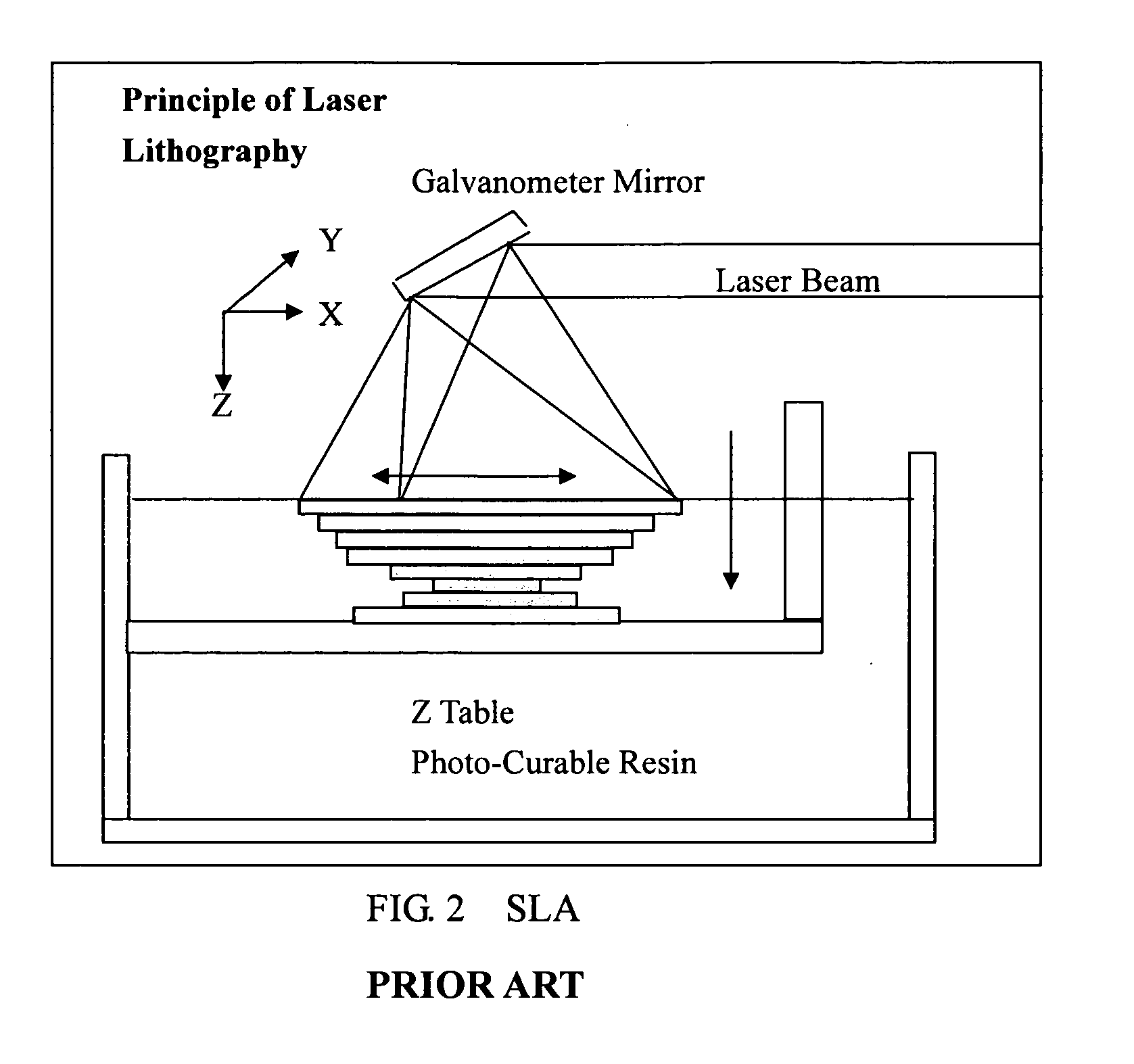

Method of manufacturing rapid prototyping workpiece by using laser transfer printing technology

InactiveUS20060290772A1Facilitate next loopSaving work hourRecording apparatus3D object support structuresRapid prototypingLaser beams

The invention discloses a method of manufacturing rapid prototyping workpiece by projecting a laser beam or other light onto the photo-conductive drum to attach powder materials to form a thin layer, and then coat the thin-layer material on a working platform. A point, line or plane light source of stronger intensity is used to go with the DMD (Digital Micromirror Device) or LCD (Liquid Crystal Display) to produce a physical change or a chemical change in the selected projecting region and combine the materials to become an acceptable property. The method comprises three stages of a process and repeats the process to complete a physical workpiece. The first stage refers to evenly spreading electric charges on a photo-conductive drum, and then projects a laser beam or a visible light onto the photo-conductive drum to electically conduct the electric charges and lower the electric potiential. By that time, the photo-conductive drum rotated in a high speed passes through a cartridge containing powder, the material will be attached onto the photo-conductive drum, since there is a potential difference between the photo-conductive drum and the material. Then, an appropriate method is used to flatly coat the material disposed on the photo-conductive drum onto the working platform, and thus a very thin even material layer is formed. The second stage refers to using a point, line or plane light source of stronger intensity for a selected region to go with a DMD or LCD to project or scan the selected region and produce a physical or chemical change, so that the materials are combined with each other to form an acceptable property. The third stage refers to removing the material remained on the photo-conductive drum and eliminating the static charges on the photo-conductive drum, so that the electric potential at the surface of the photo-conductive drum resumes its initial state to facilitate the next loop of actions. The whole manufacturing process uses this method to stack layer by layer to build a complete three-dimensional physical workpiece, so as to achieve the effect of saving work hours, materials and costs as well as enhancing the precision of the workpiece. The invention is definitely a very valuable manufacturing method.

Owner:NAT CHENG KUNG UNIV

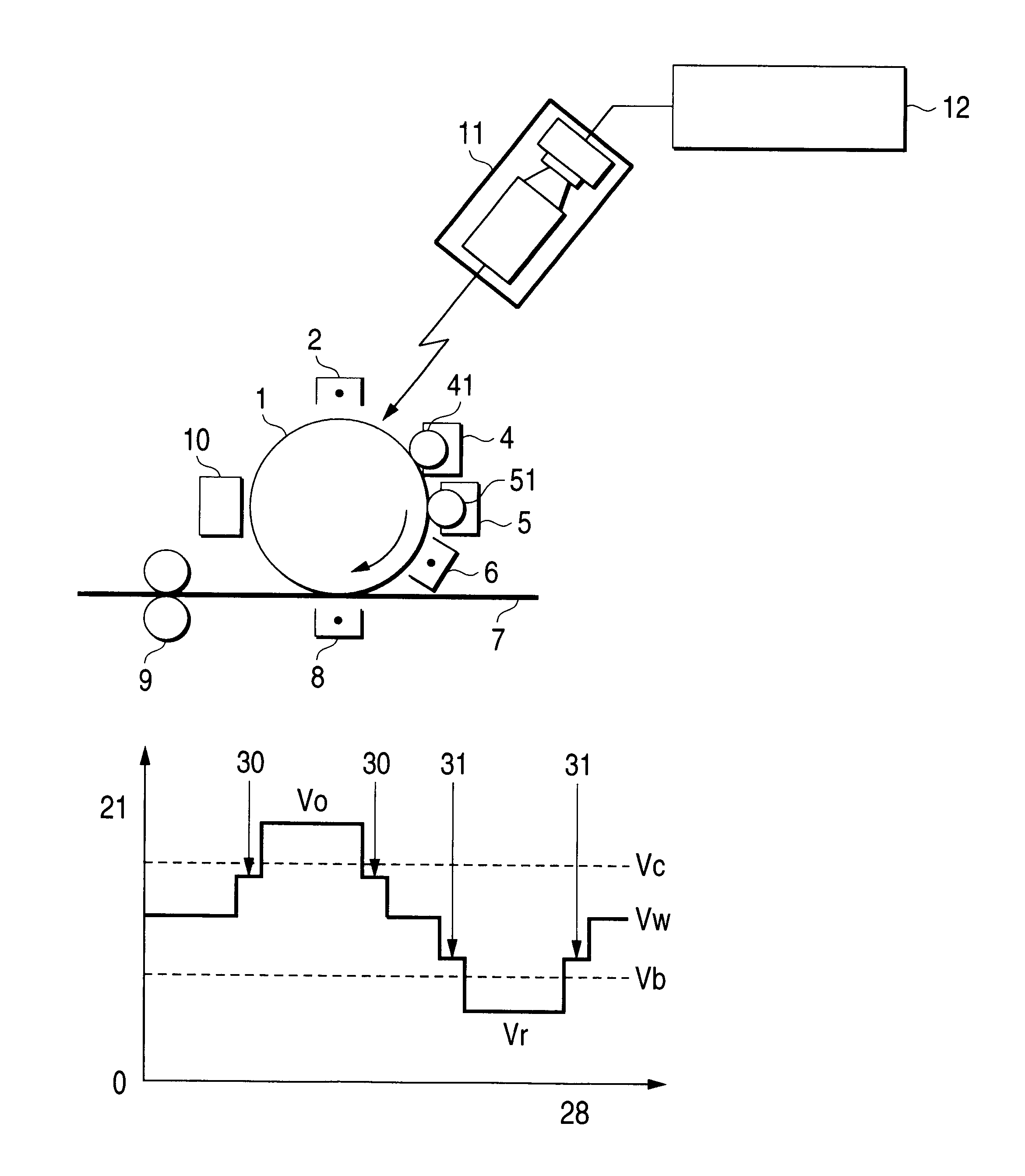

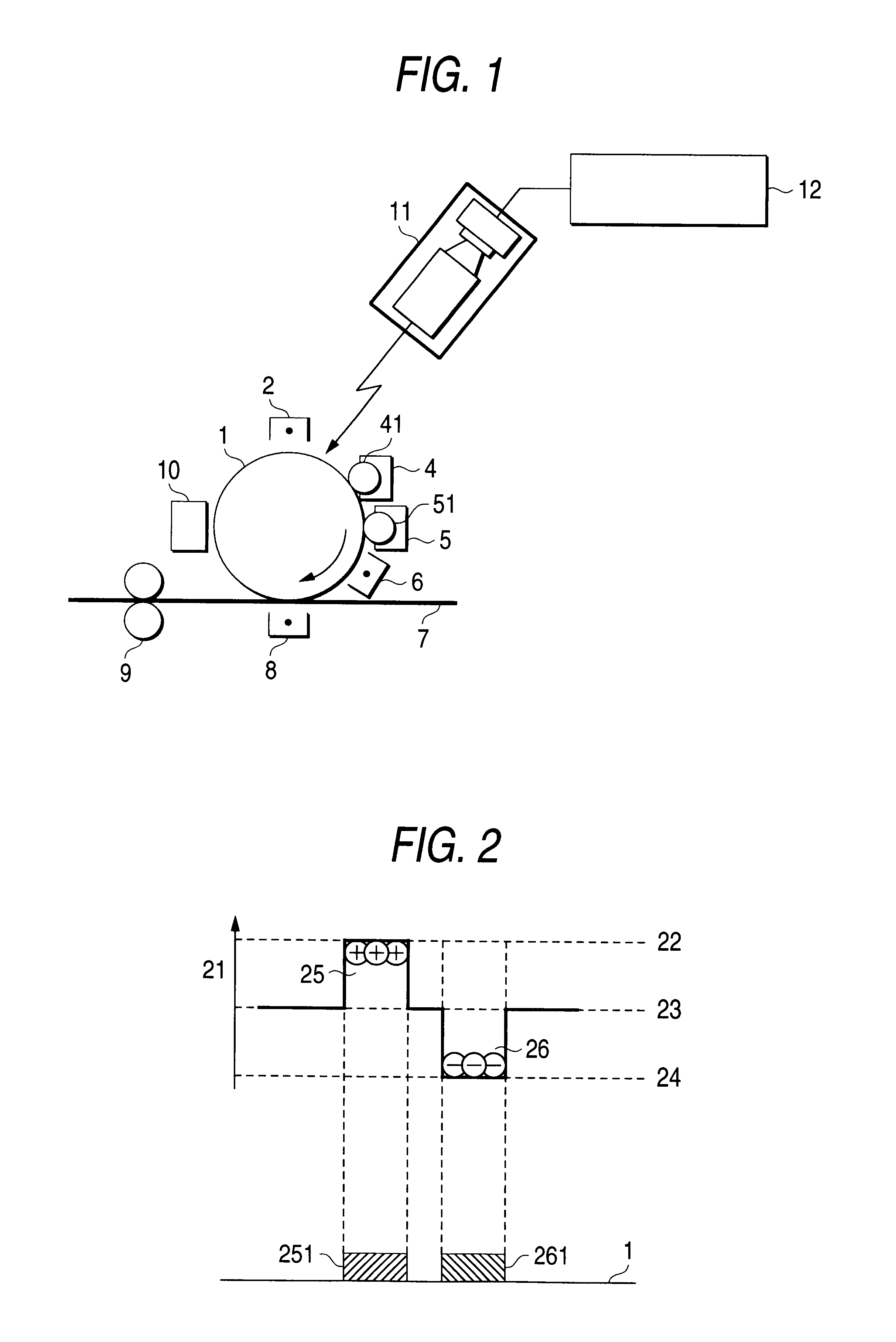

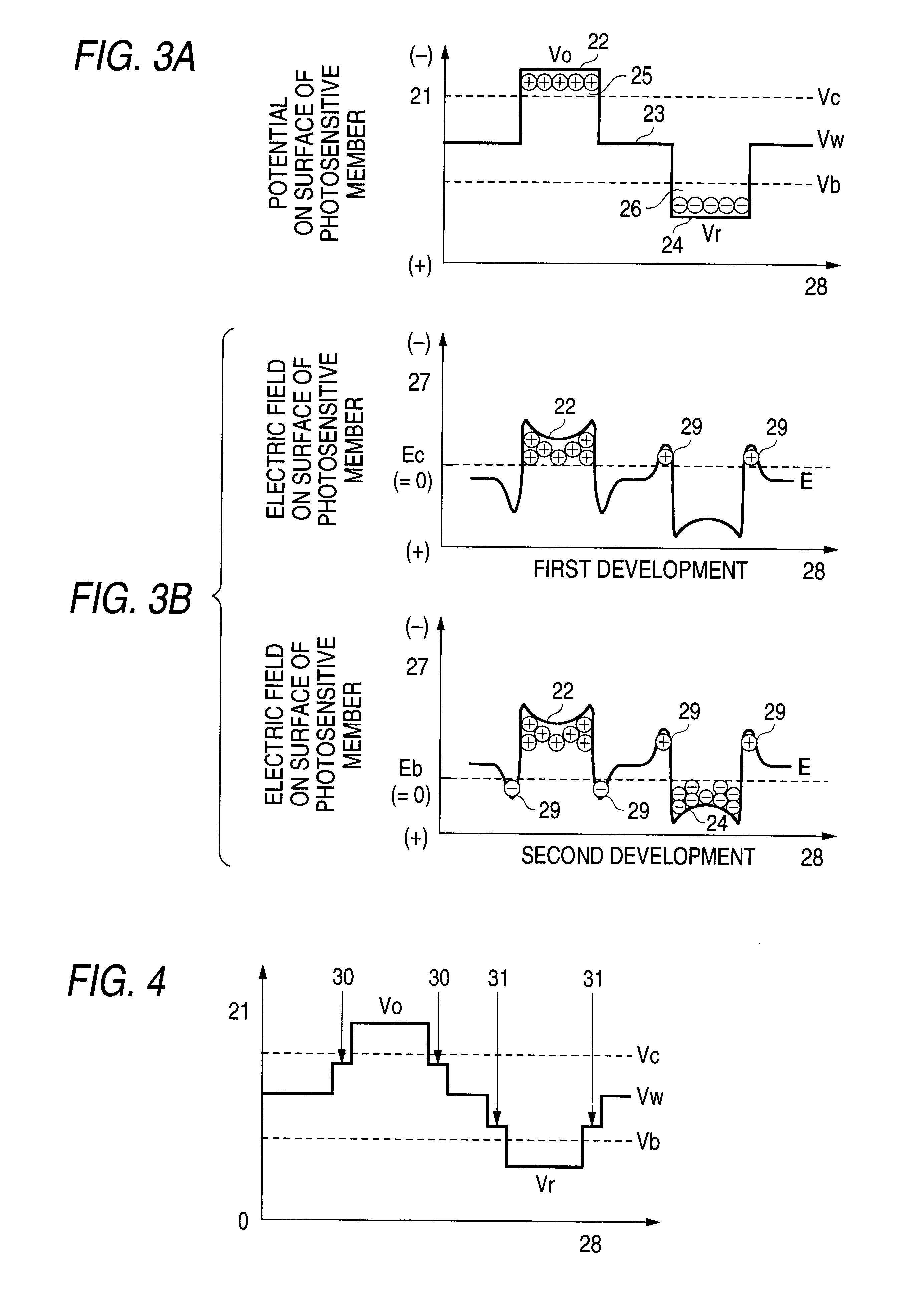

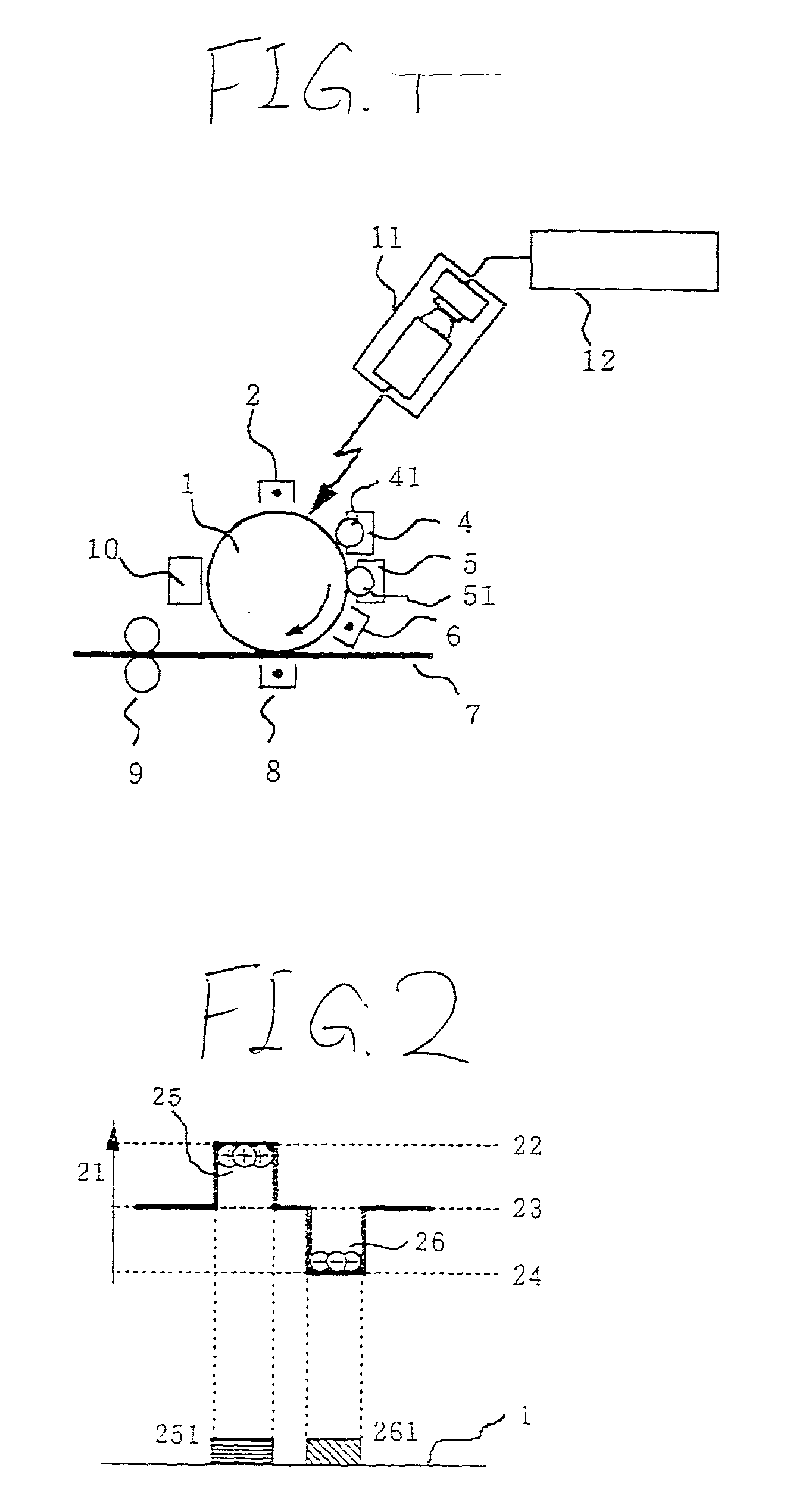

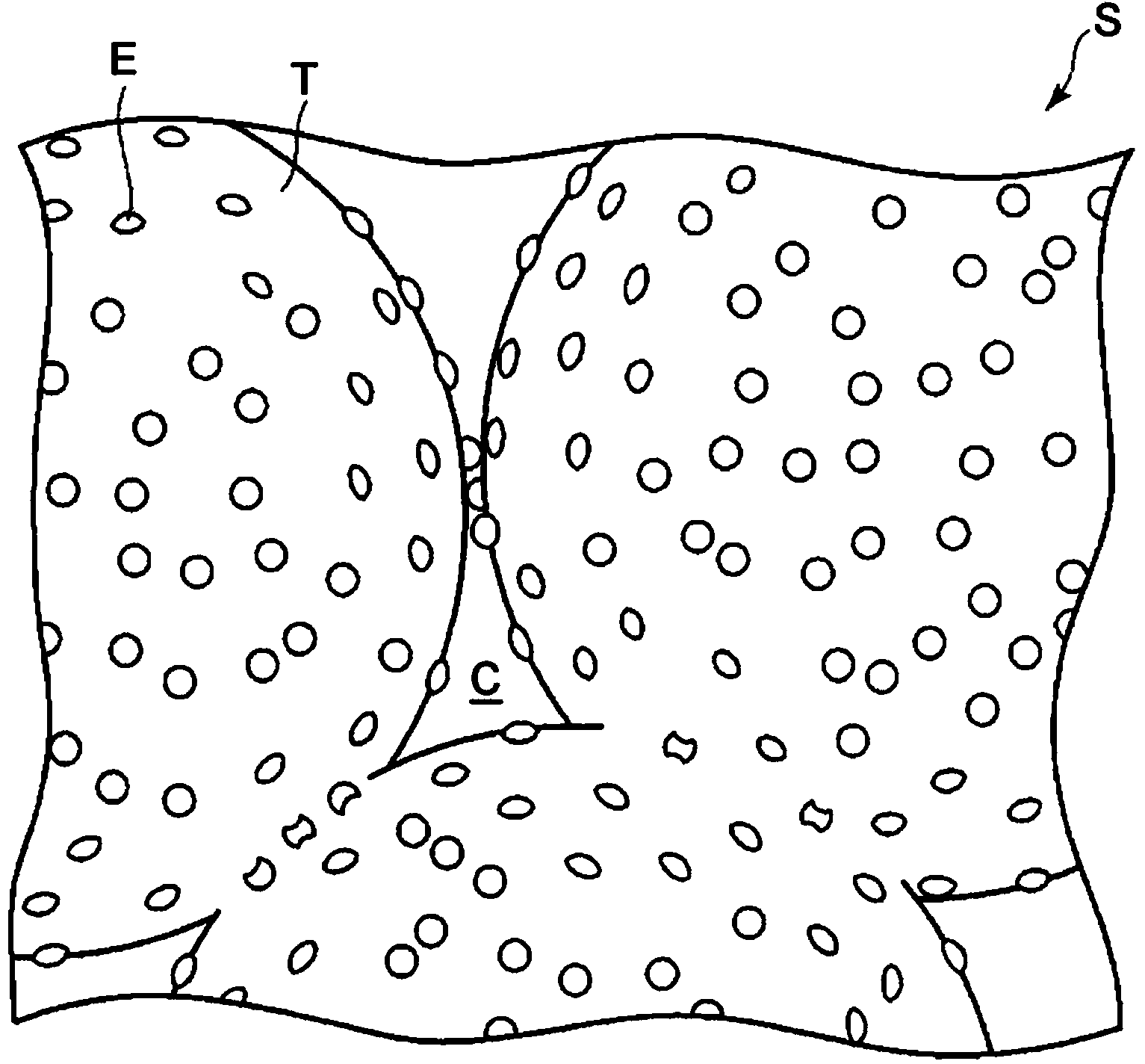

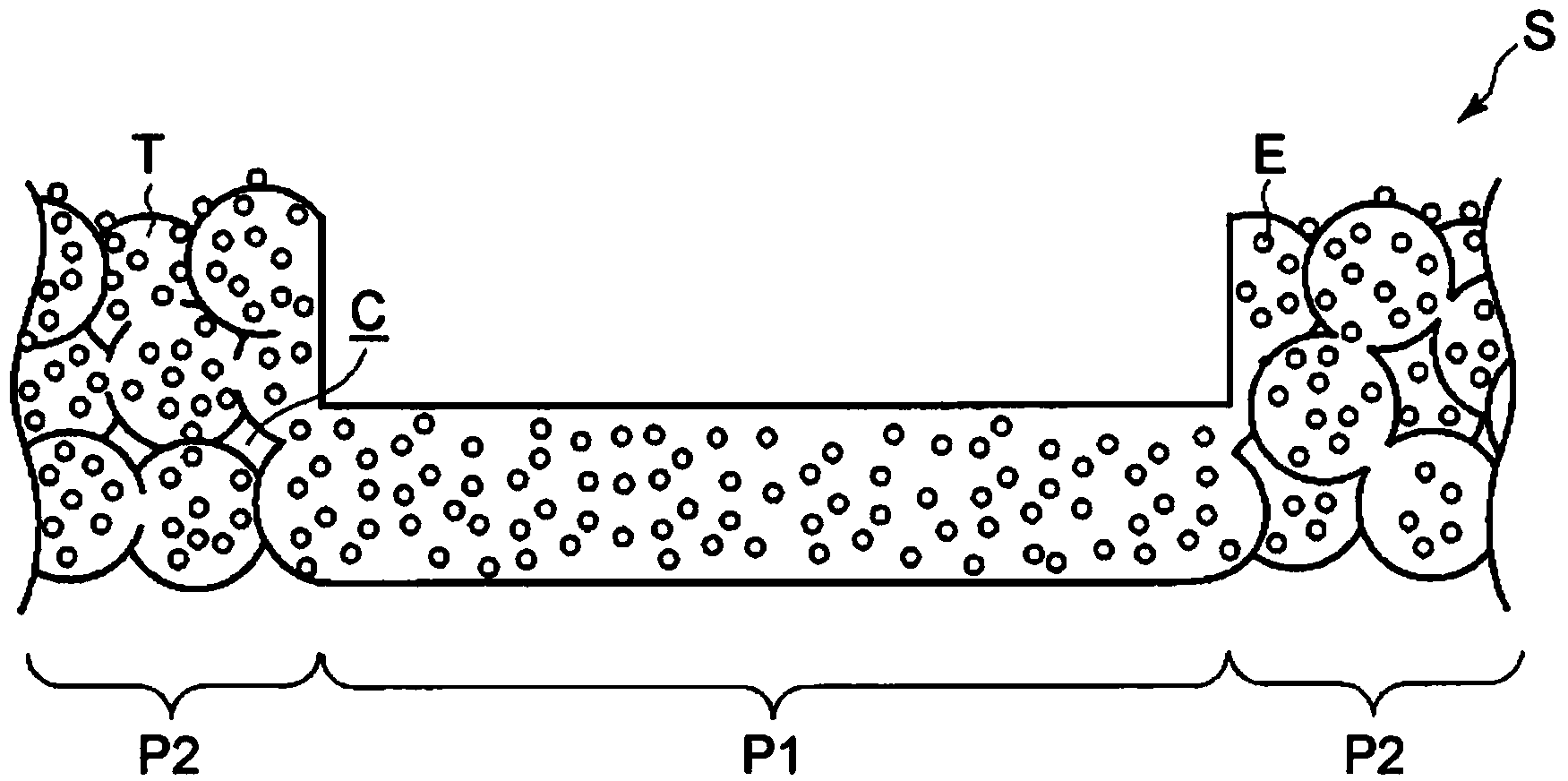

Electrophotographic apparatus having a fringe development preventing mechanism

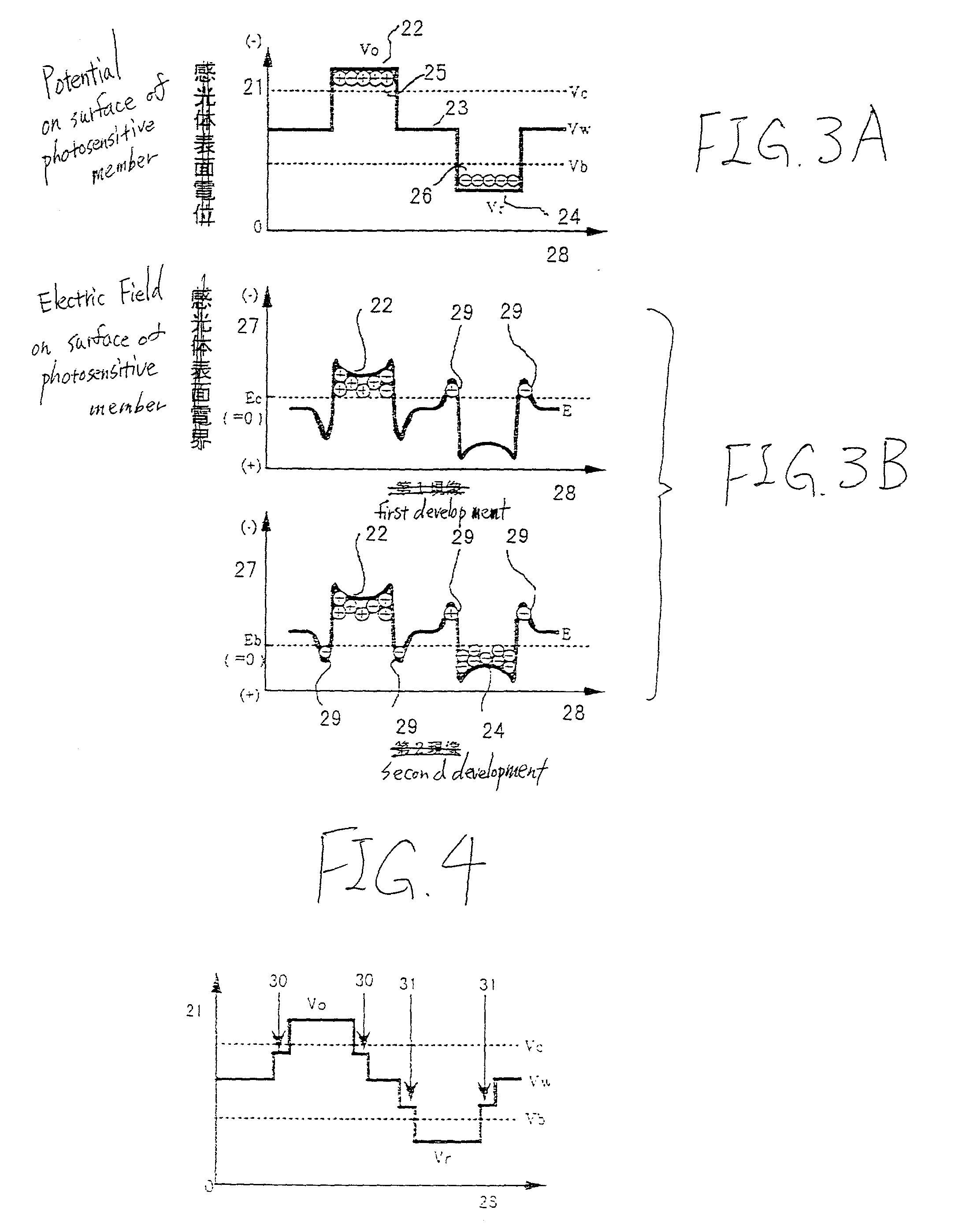

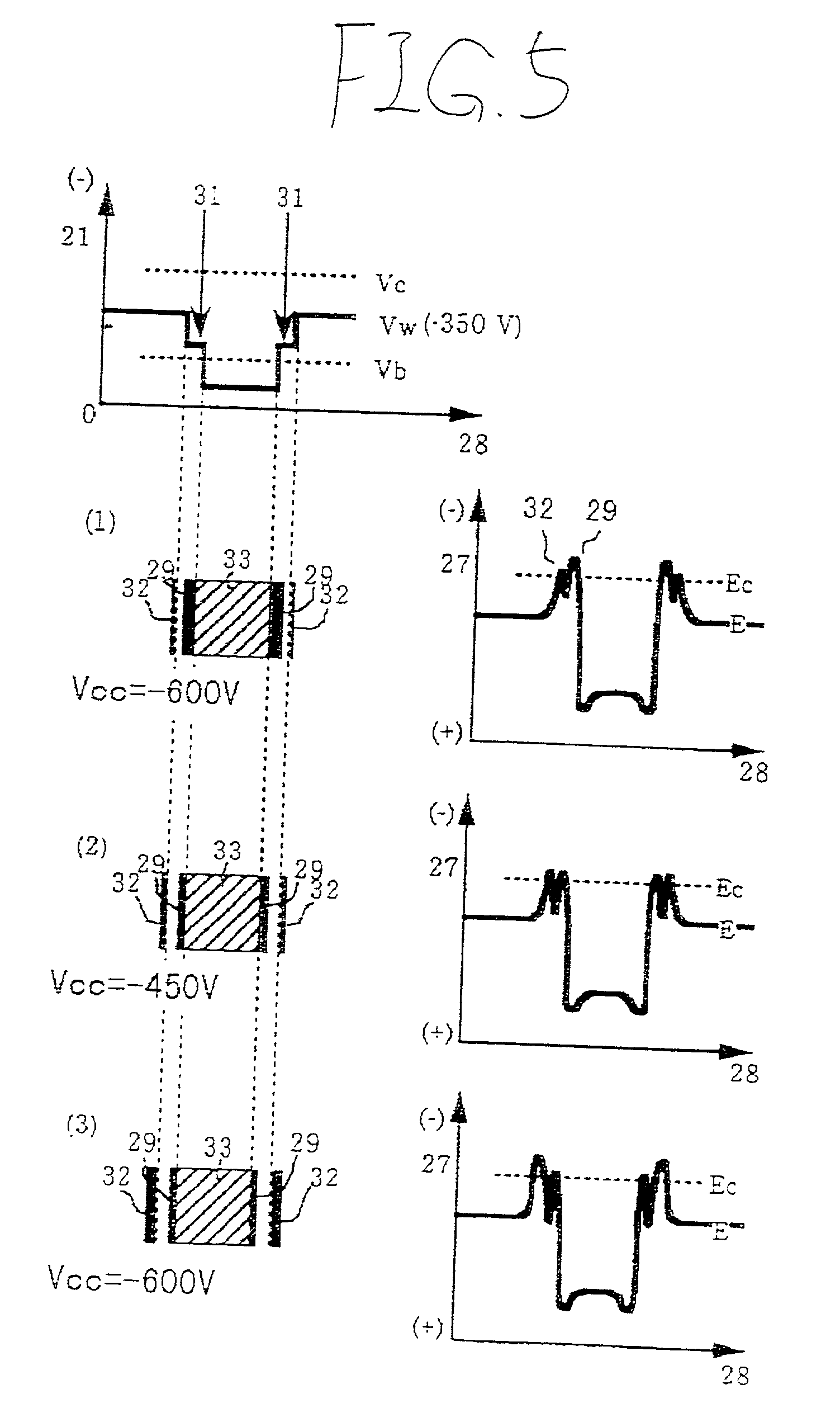

In an electrophotographic apparatus, regions having at least three different potential levels Vc, Vw, and Vr are formed on a photosensitive member by using an exposing device, and developing processes respectively using colored particles of different kinds are performed by normal development and reversal development on two potential levels Vc and Vr excluding the intermediate potential level Vw. The apparatus has an auxiliary exposing unit for forming a fringe development preventing potential in an edge of an image forming region in order to prevent fringe development from occurring. The auxiliary exposing unit sets an auxiliary exposure amount by performing pulse-width modulation on a laser driver.

Owner:HITACHI PRINTING SOLUTIONS LTD

Electrophotographic apparatus

InactiveUS20010030680A1Recording apparatusElectrographic process apparatusImage formationEngineering

In an electrophotographic apparatus, regions having at least three different potential levels Vc, Vw, and Vr are formed on a photosensitive member by using an exposing device, and developing processes respectively using colored particles of different kinds are performed by normal development and reversal development on two potential levels Vc and Vr excluding the intermediate potential level Vw. The apparatus has an auxiliary exposing unit for forming a fringe development preventing potential in an edge of an image forming region in order to prevent fringe development from occurring. The auxiliary exposing unit sets an auxiliary exposure amount by performing pulse-width modulation on a laser driver.

Owner:HITACHI PRINTING SOLUTIONS LTD

Process for preparing a polyester resin

InactiveUS20060128906A1High molecular weightReduce the amount requiredDevelopersElectrographic processes using thermoplastic layersContinuous reactorVitrification

The present invention relates to a process for preparing a polyester resin having a gel content of less than 0.45 wt %, based on the total weight of the polyester resin, and a glass transition temperature of between 40 and 70° C., comprising the step of reacting a polyester resin precursor with a chain extender which is different from the building blocks of the polyester precursor resin, optionally in the presence of a catalyst, at a temperature between 170 and 300° C. in a continuous reactor, wherein the polyester resin precursor comprises a functional group present as end group selected from hydroxyl or carboxyl, and optionally a functional group in the polyester resin precursor backbone selected from hydroxyl, carboxyl, amine, and carbonate, and the molar ratio of the functional group in the polyester resin precursor backbone to the functional group present as end group is at most 10:1. The invention further pertains to a polyester resin having a gel content of less than 0.45 wt %, based on the total weight of the polyester resin, and a glass transition temperature of between 40 and 70° C., which is prepared from a polyester resin precursor and a chain extender which is different from the building blocks of the polyester precursor resin.

Owner:HEXION SPECIALTY CHEM INC

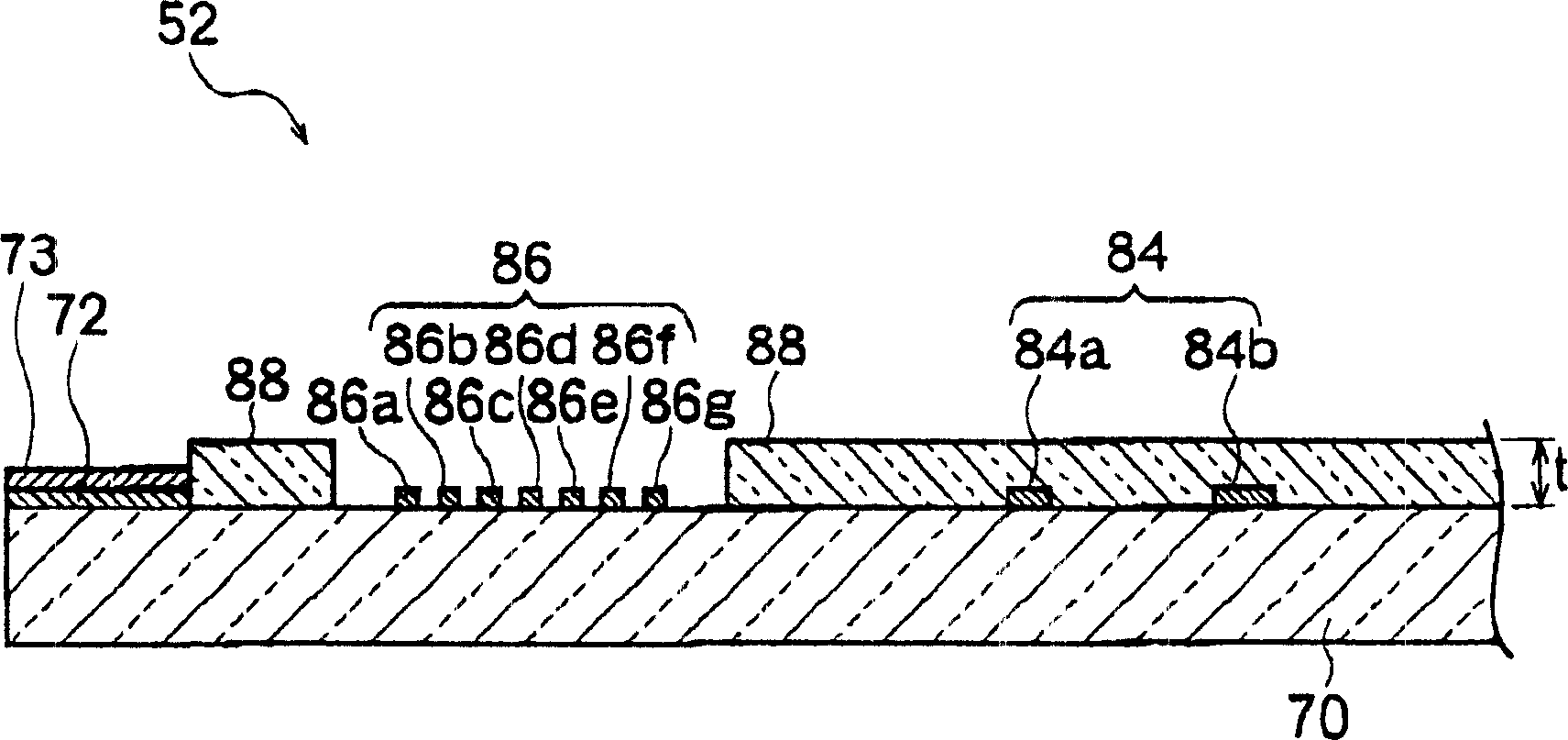

Electrostatic latent image measuring device

ActiveUS8143603B2Improve accuracyHigh precision measurementThermometer detailsBeam/ray focussing/reflecting arrangementsElectrical conductorLatent image

An electrostatic latent image measuring device includes a charged particle optical system which irradiates an electron beam and charges a photoconductor sample, an exposure optical system which forms an electrostatic latent image on a surface of the photoconductor sample, and a scanning unit which scans the surface of the photoconductor sample by the electron beam, a distribution of the electrostatic latent image on the surface of the sample being measured by a signal detected by the scanning.

Owner:RICOH KK

Phase shift mask blank, phase shift mask, and methods of manufacture

A phase shift mask blank includes a transparent substrate and a phase shift film thereon. The phase shift film is composed primarily of a metal and silicon, typically molybdenum silicide oxide carbide or molybdenum silicide oxide nitride carbide, and has a film stress no higher than 100 MPa. The low stress makes it possible to maintain a good substrate flatness when the phase shift film is formed during production of the phase shift mask blank, and when the phase shift film is patterned during production of a phase shift mask from the blank.

Owner:SHIN ETSU CHEM IND CO LTD

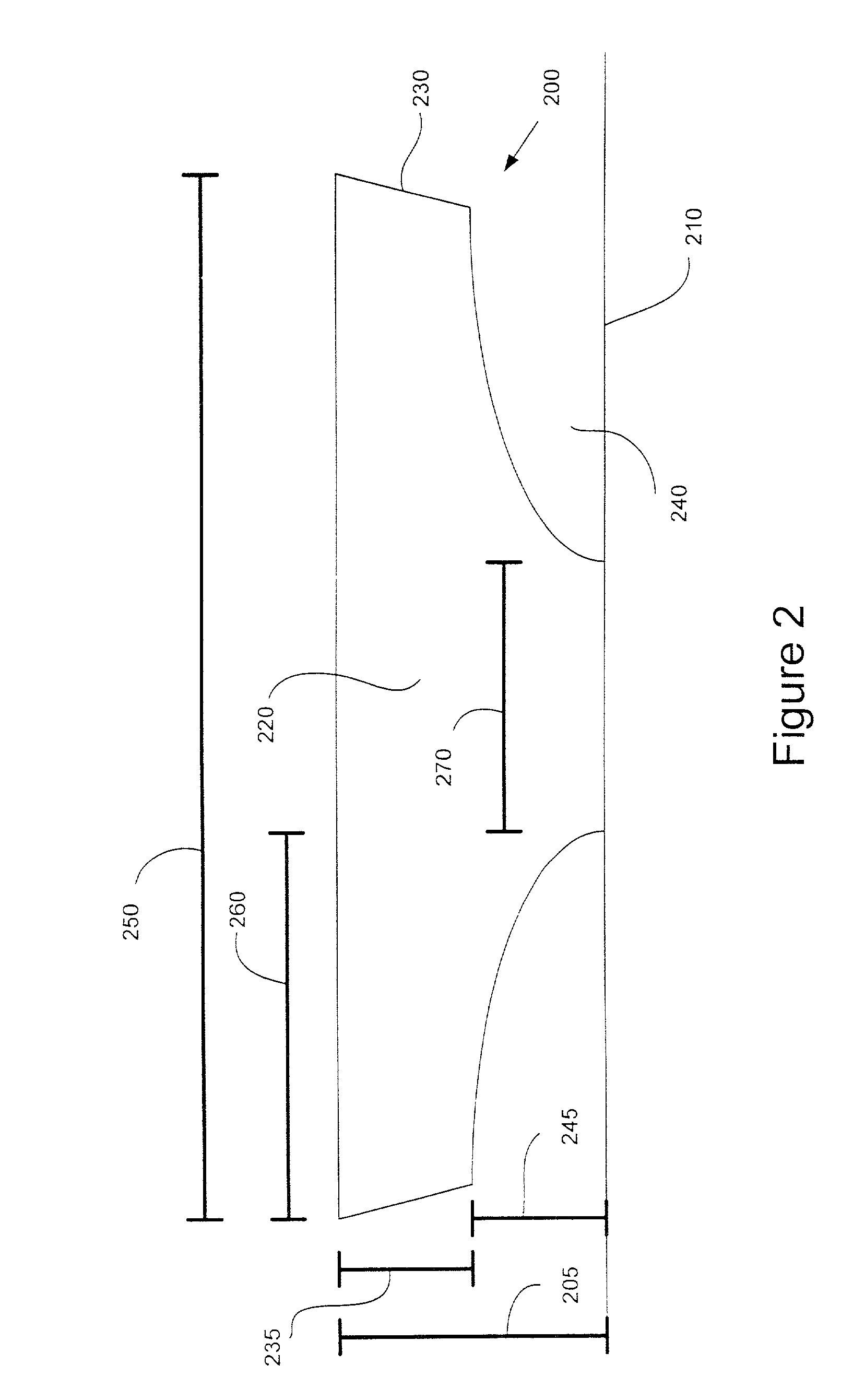

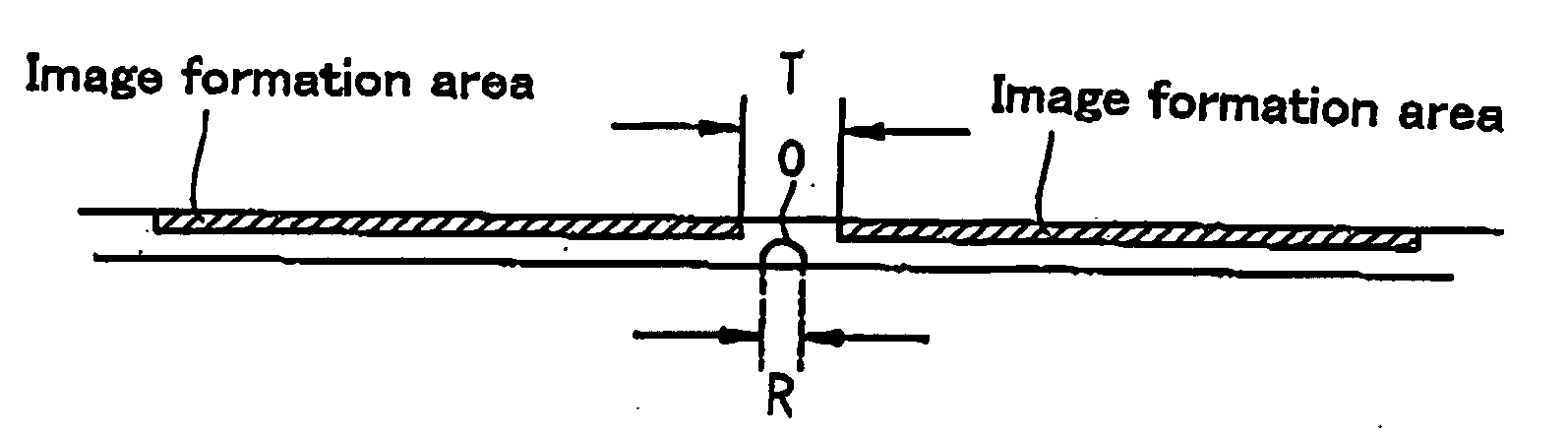

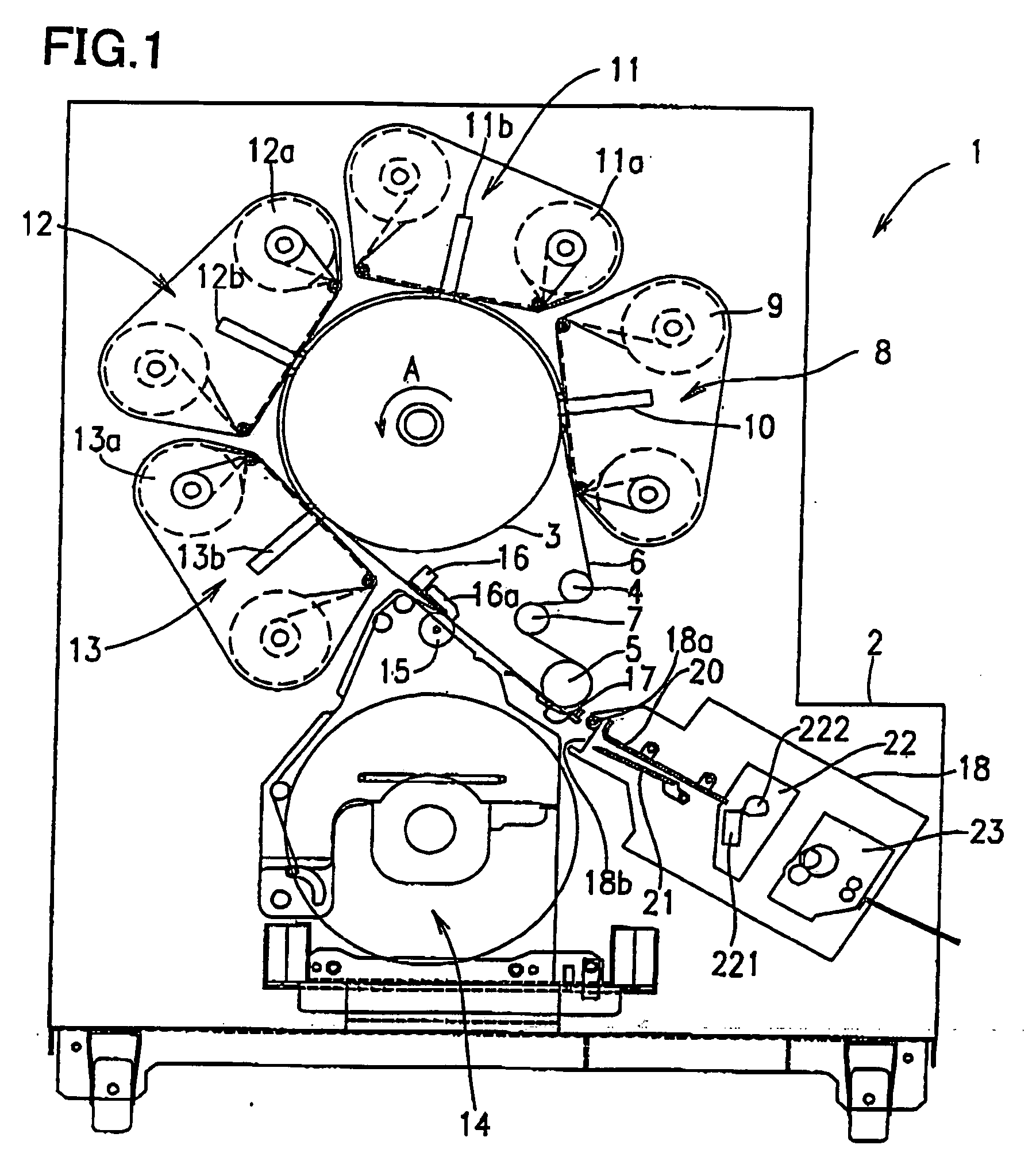

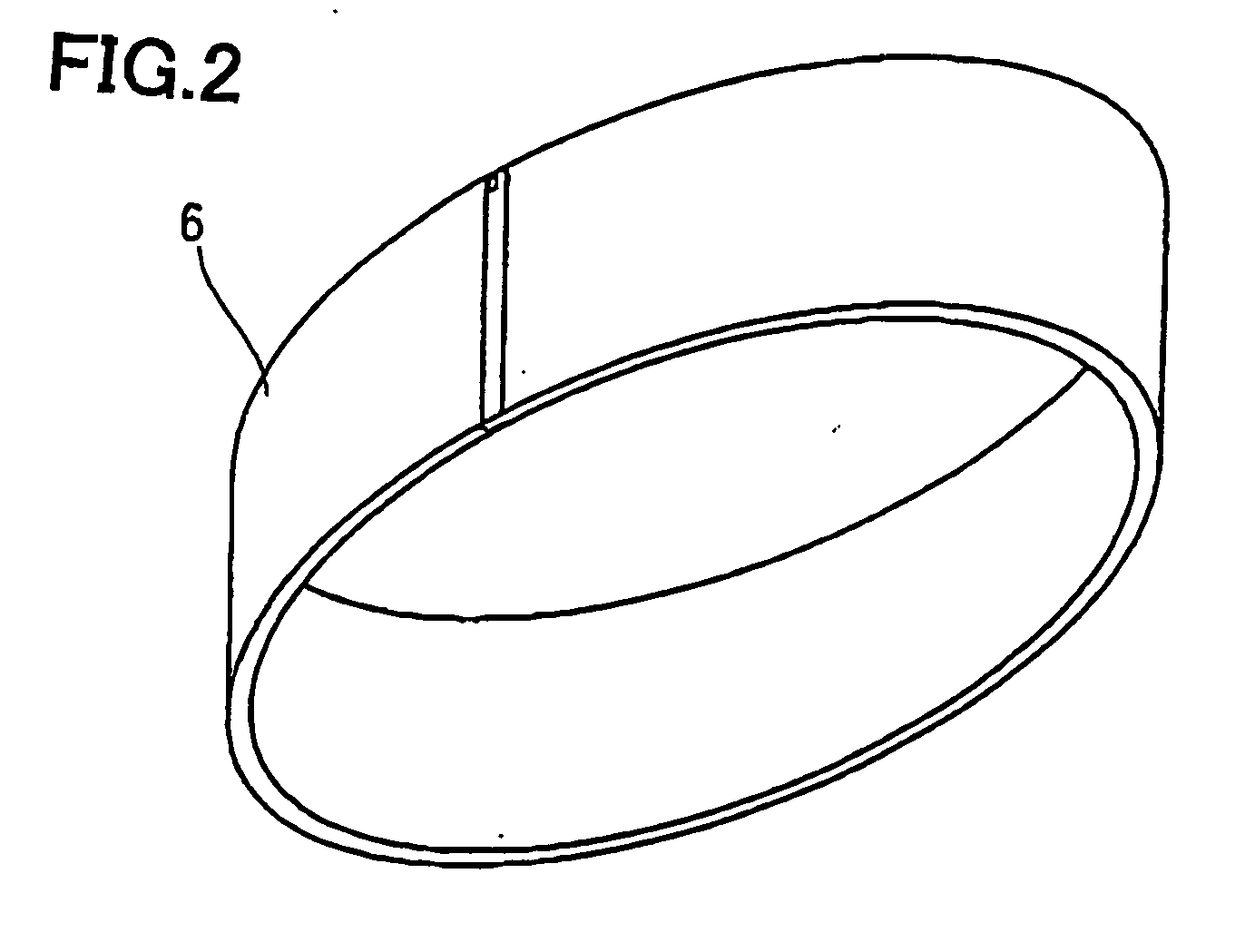

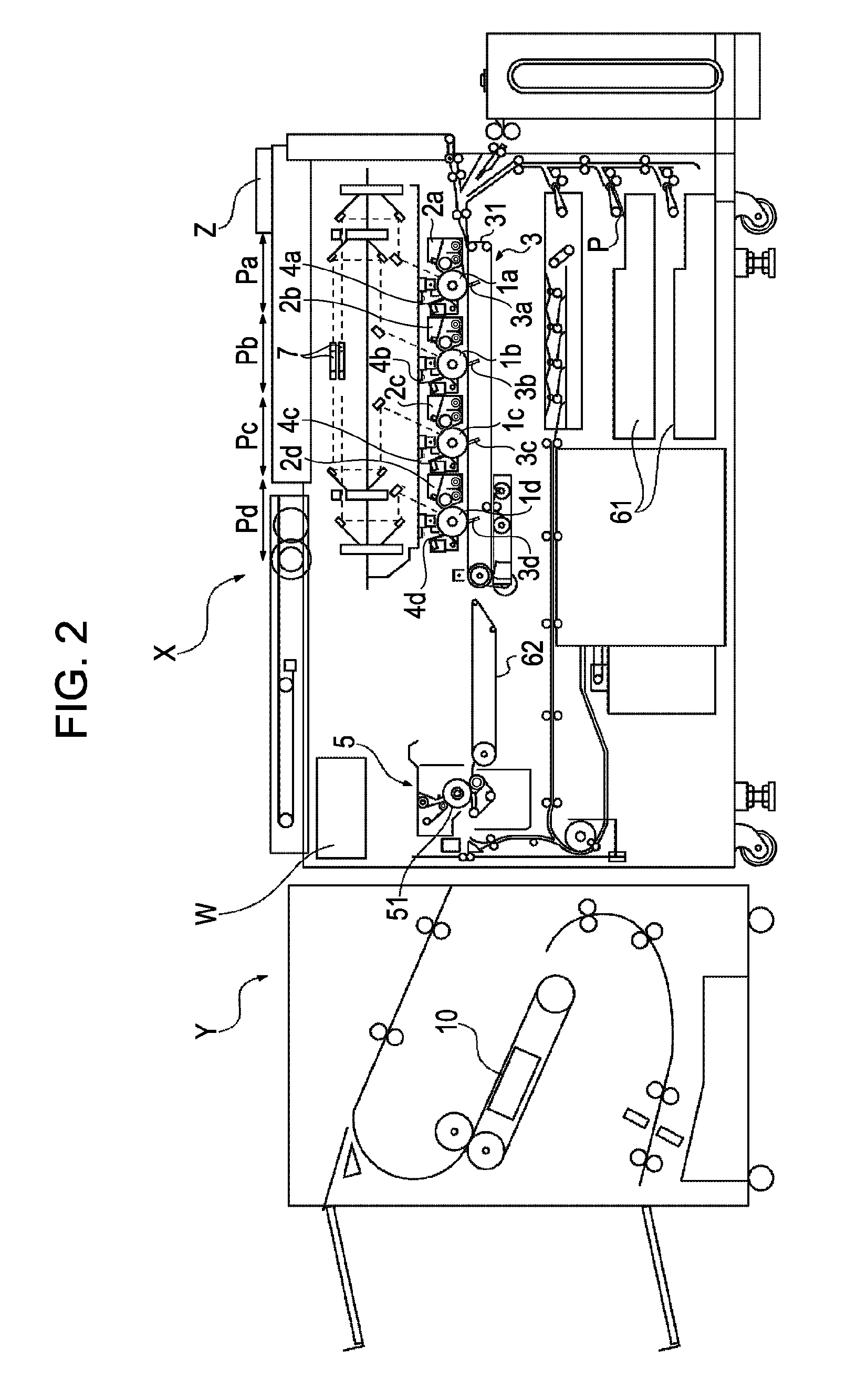

Image formation device and image formation method

In order to avoid a load change which occurs when seam O passes by the heads affect image information, a dyeing layer transfer head and recording heads are located in equal intervals having length P, which is obtained by equally dividing an entire circumference K of a recording intermediate belt by n (n is integer), and, given that the position of the seam of the recording Intermediate belt, which does not have an end obtained by coupling two ends of a belt body of a band shape, is origin O, images are formed in portions except for portions at origin O, or at a distance of 1×P, 2×P, . . . (n−1)×P from origin O. In this way, it is possible to prevent deterioration in the image quality, such as a stripe line in an image formed by an image forming apparatus.

Owner:PANASONIC CORP

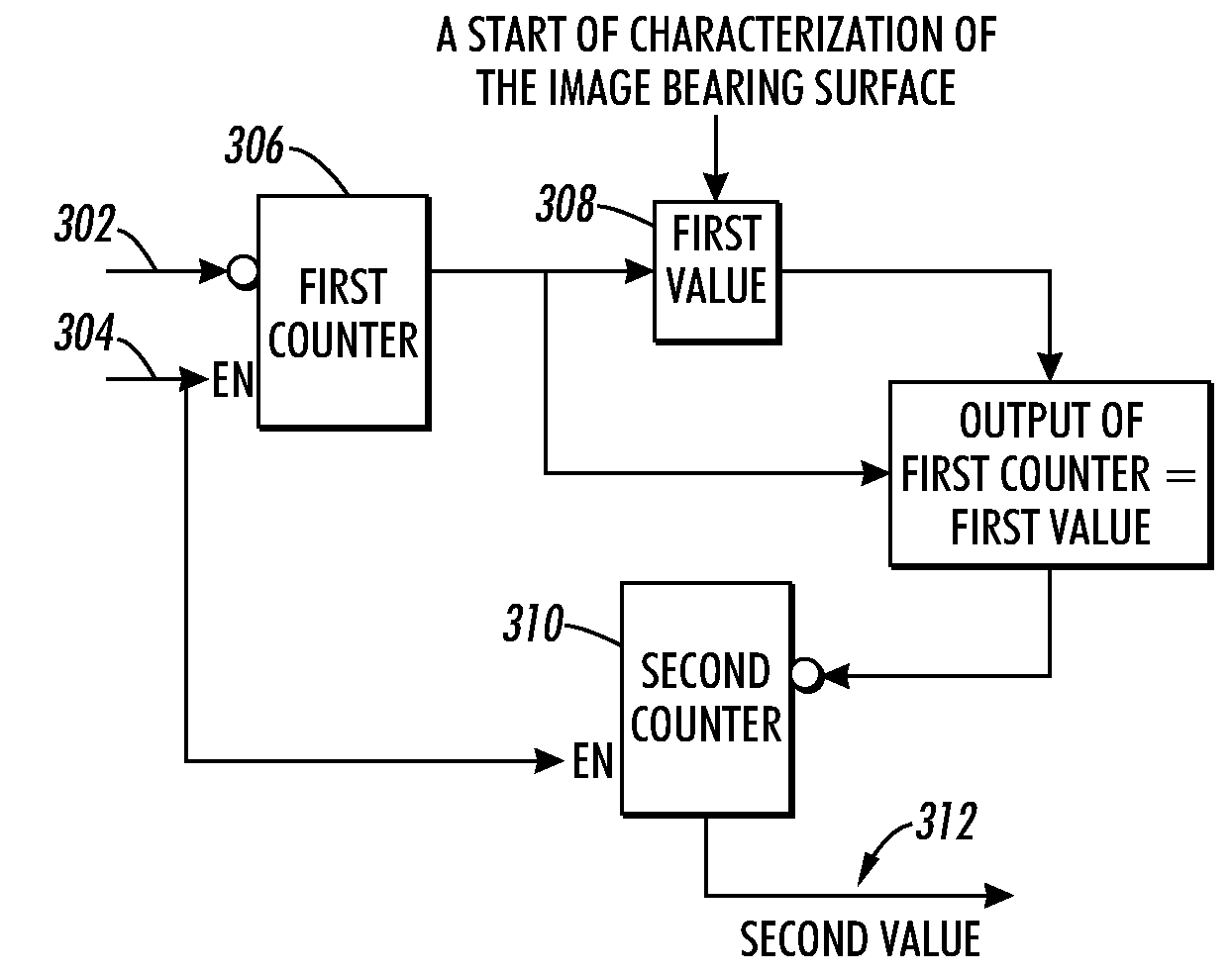

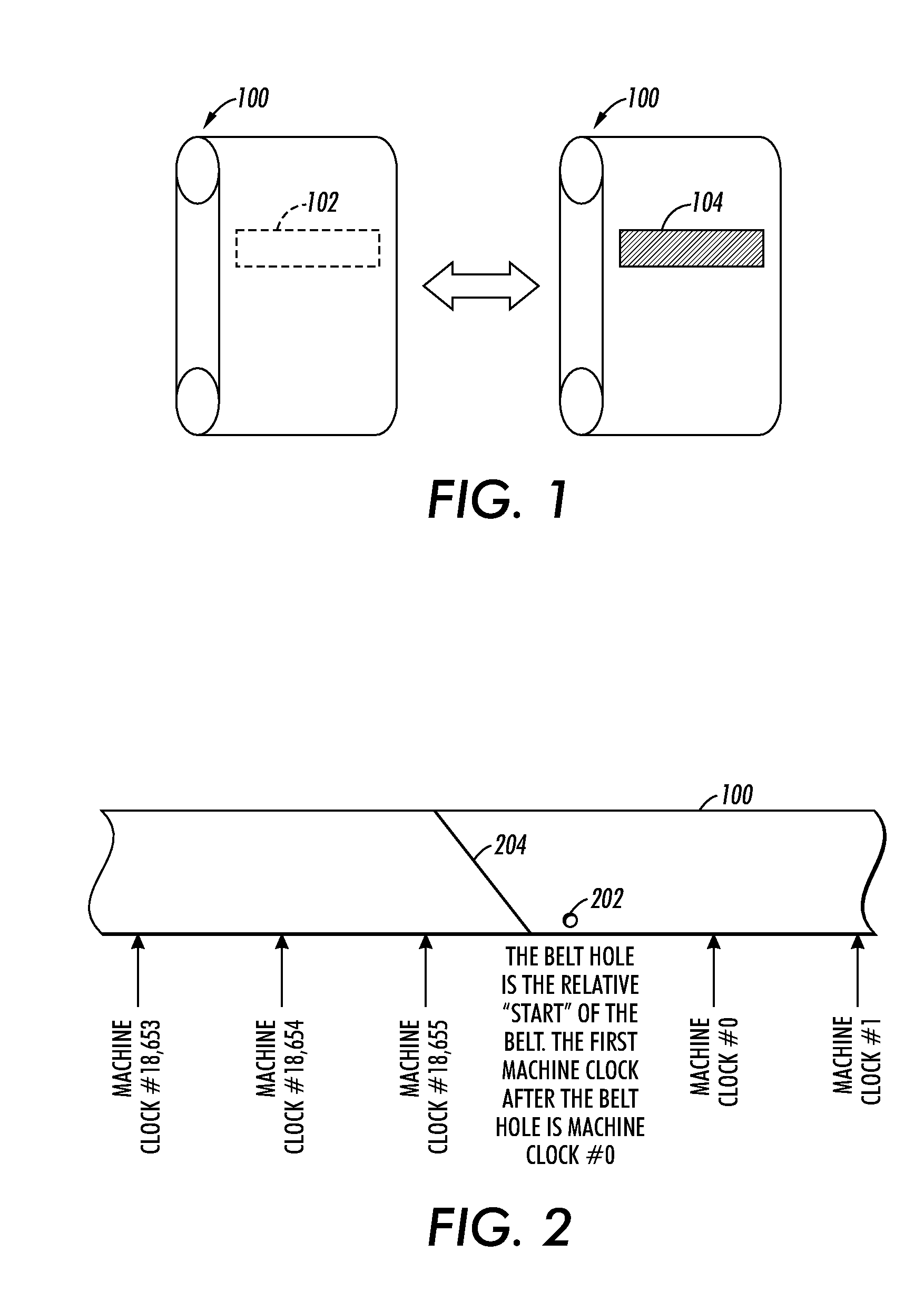

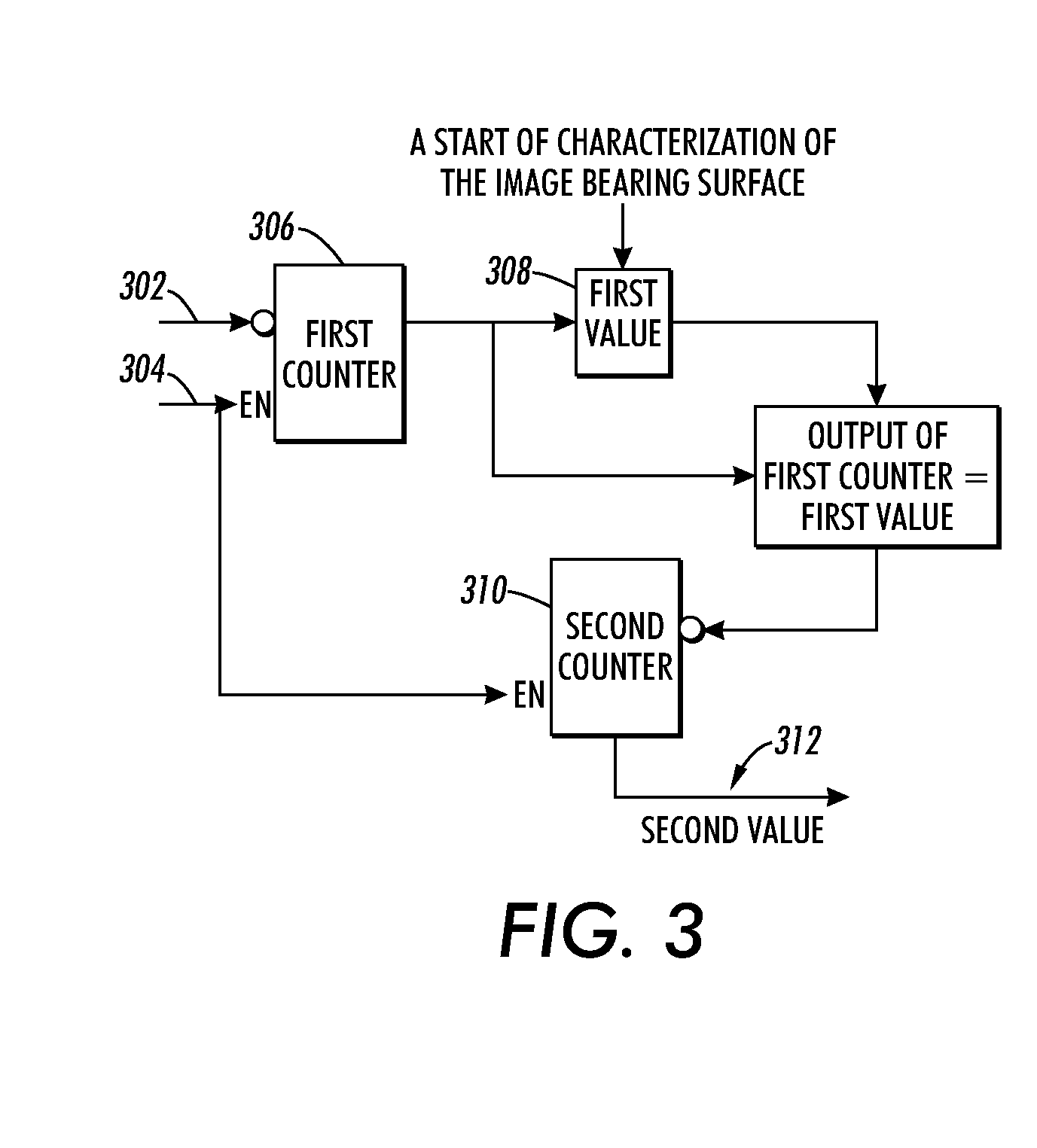

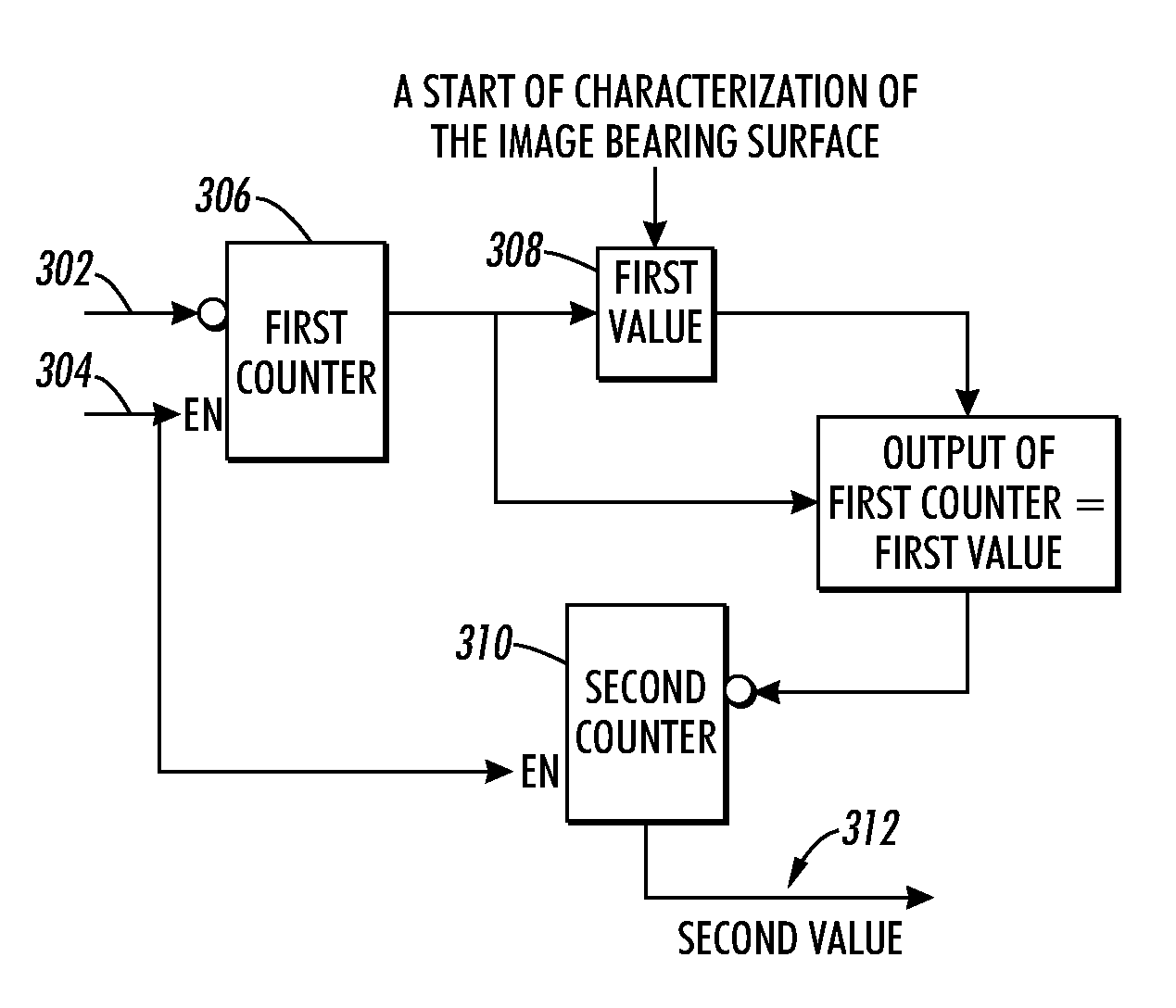

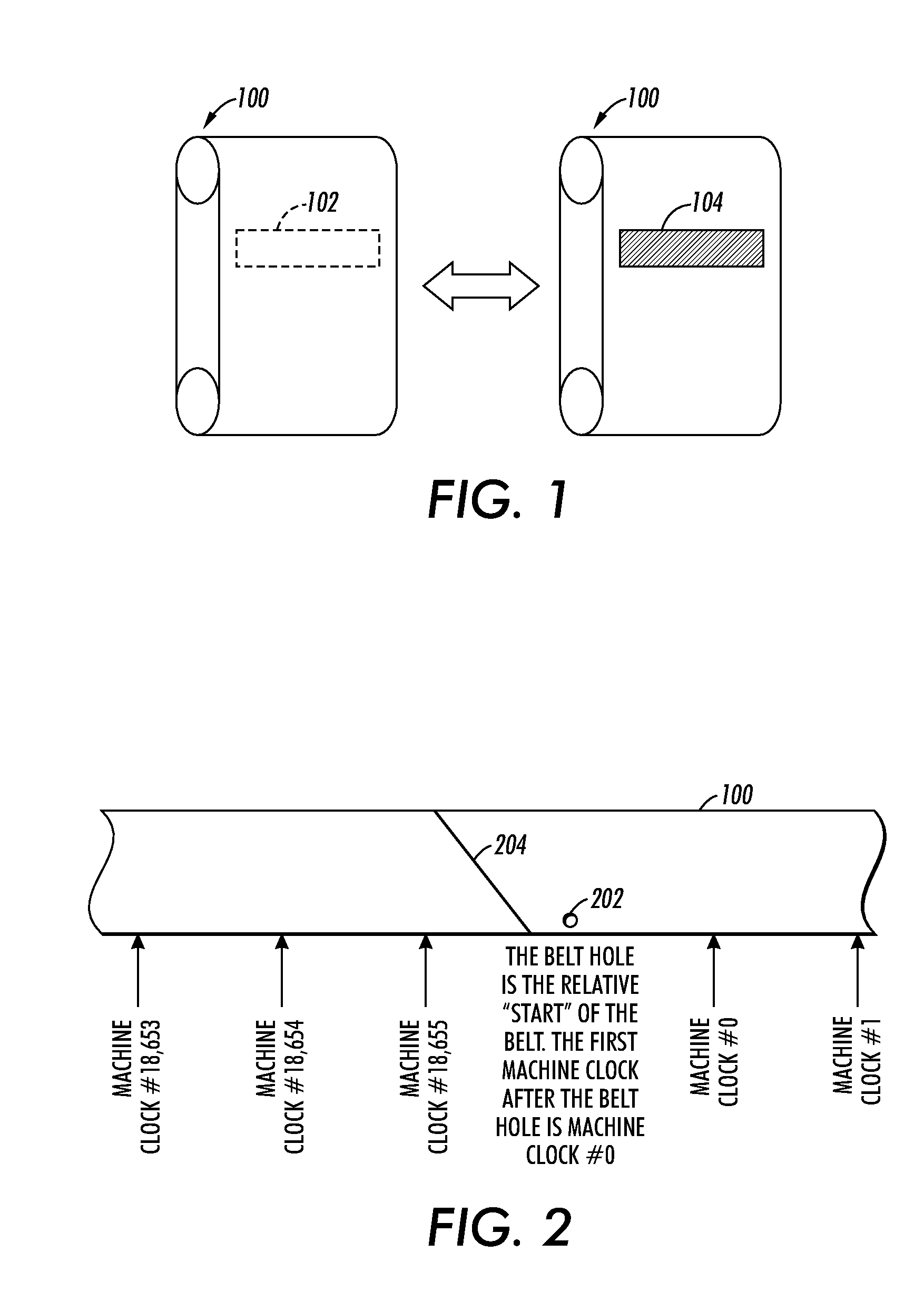

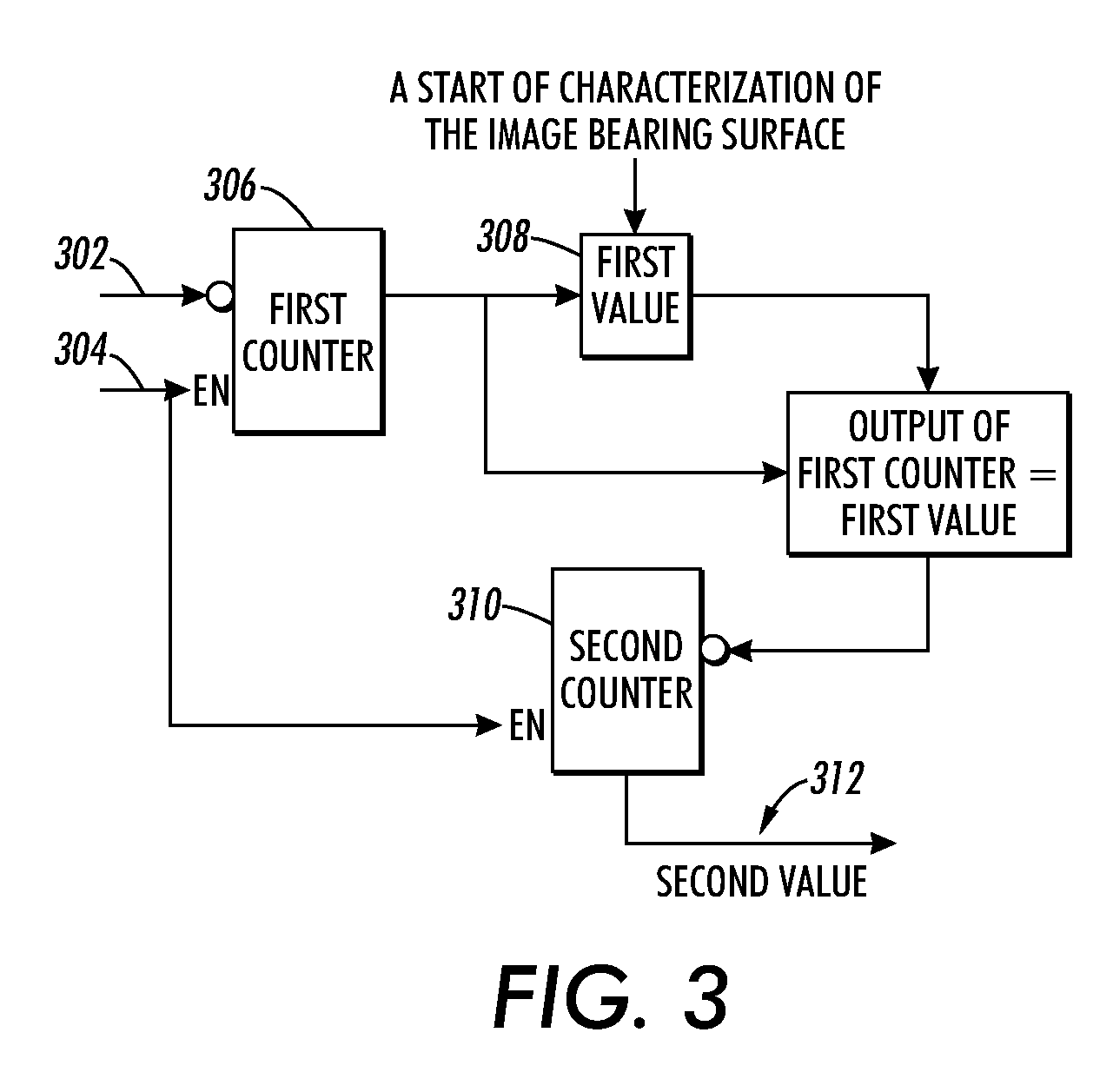

Method for accurately finding a physical location on an image bearing surface for toner images for optimal streak correction

A method for determining a location on an image bearing surface of an image printing system where a toner image is to be printed is provided. The method comprises generating a first signal from a detector that is configured to detect a reference mark on the image bearing surface, and a second signal from a clock system that counts. incremental movements of the image bearing surface, determining a first value that correlates the first signal and the second signal, where the first value corresponds to a value of the second signal at a start of characterization of the image bearing surface, and determining a second value using the first value, where the second value provides the location on the image bearing surface where the toner image is to be printed.

Owner:XEROX CORP

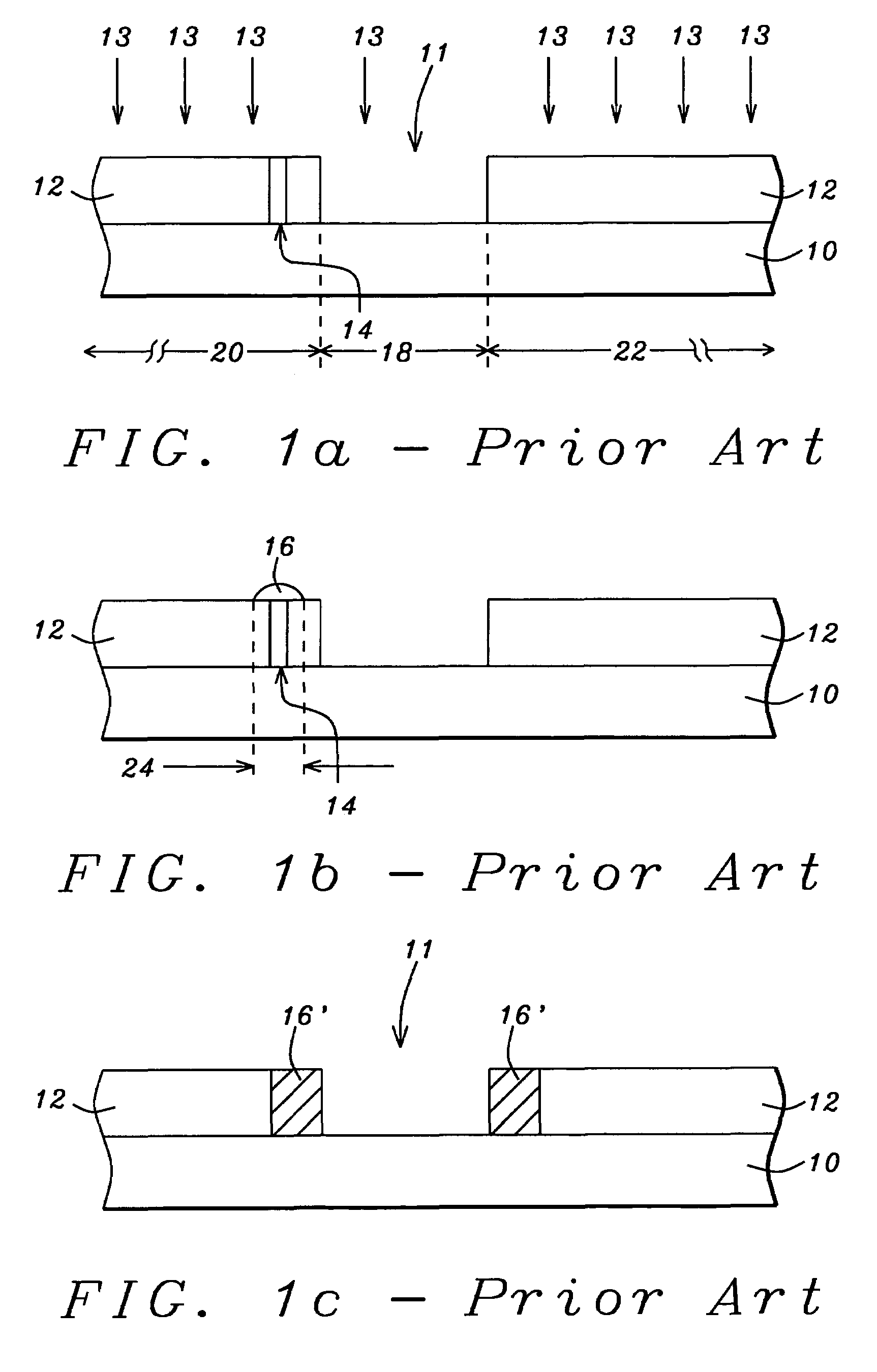

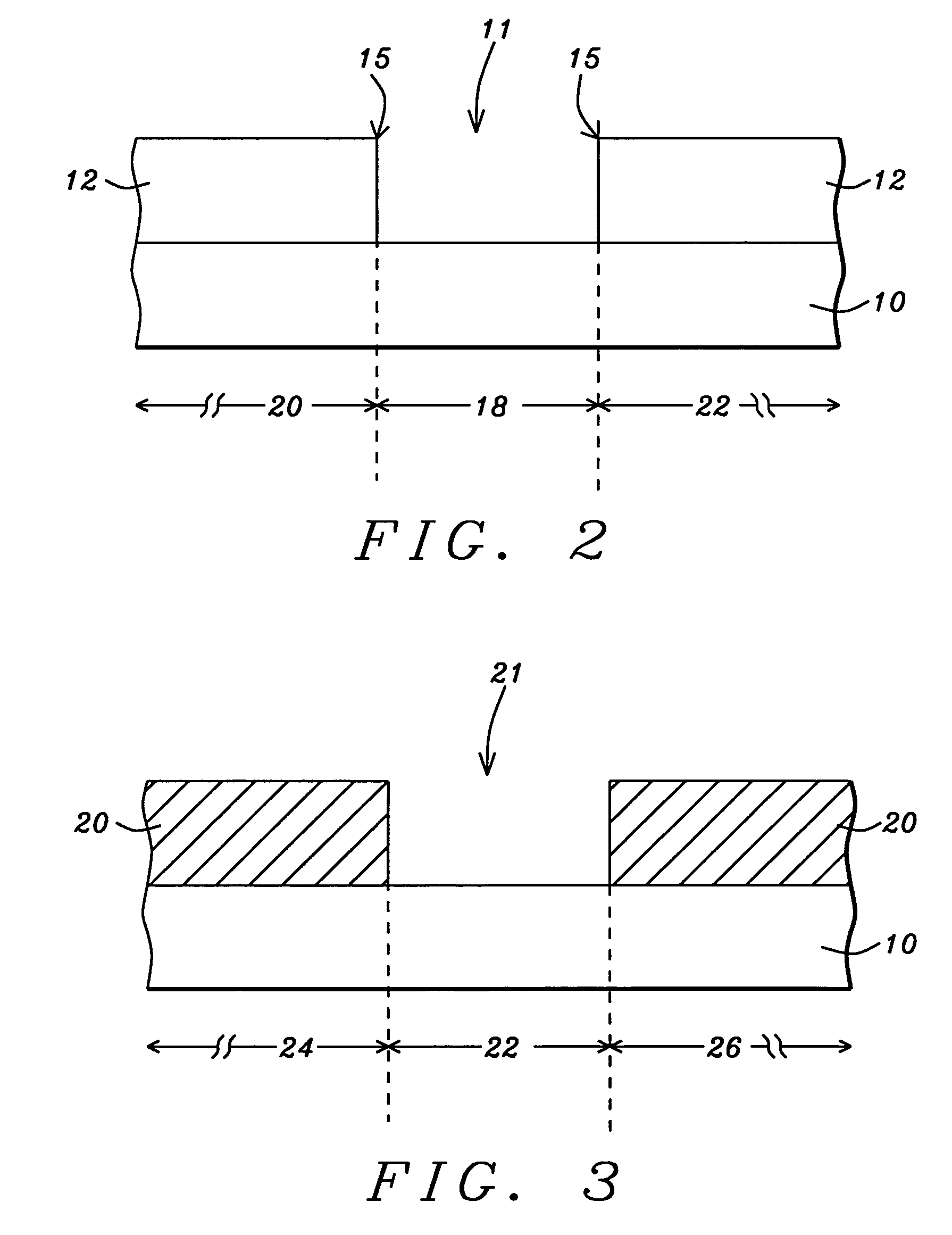

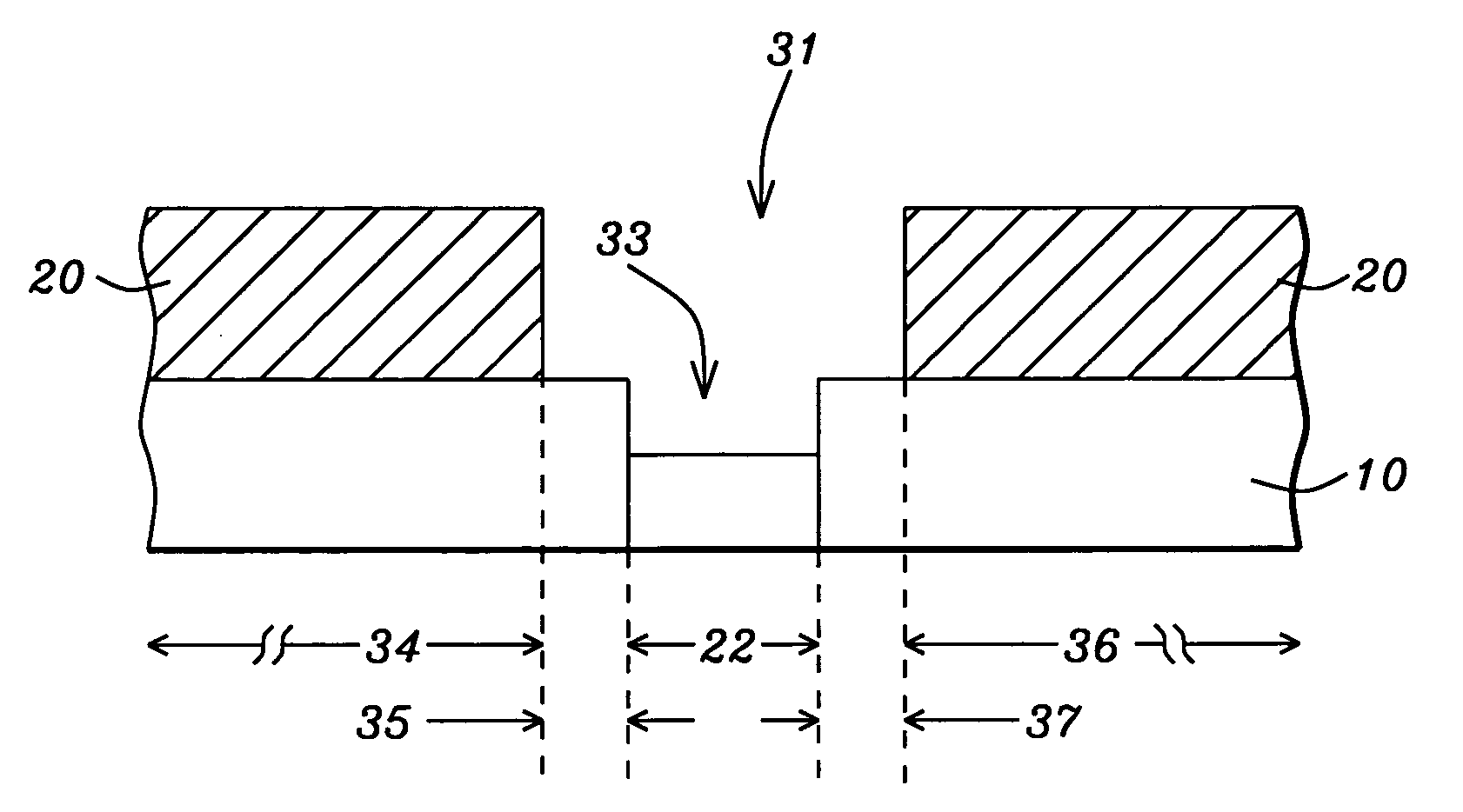

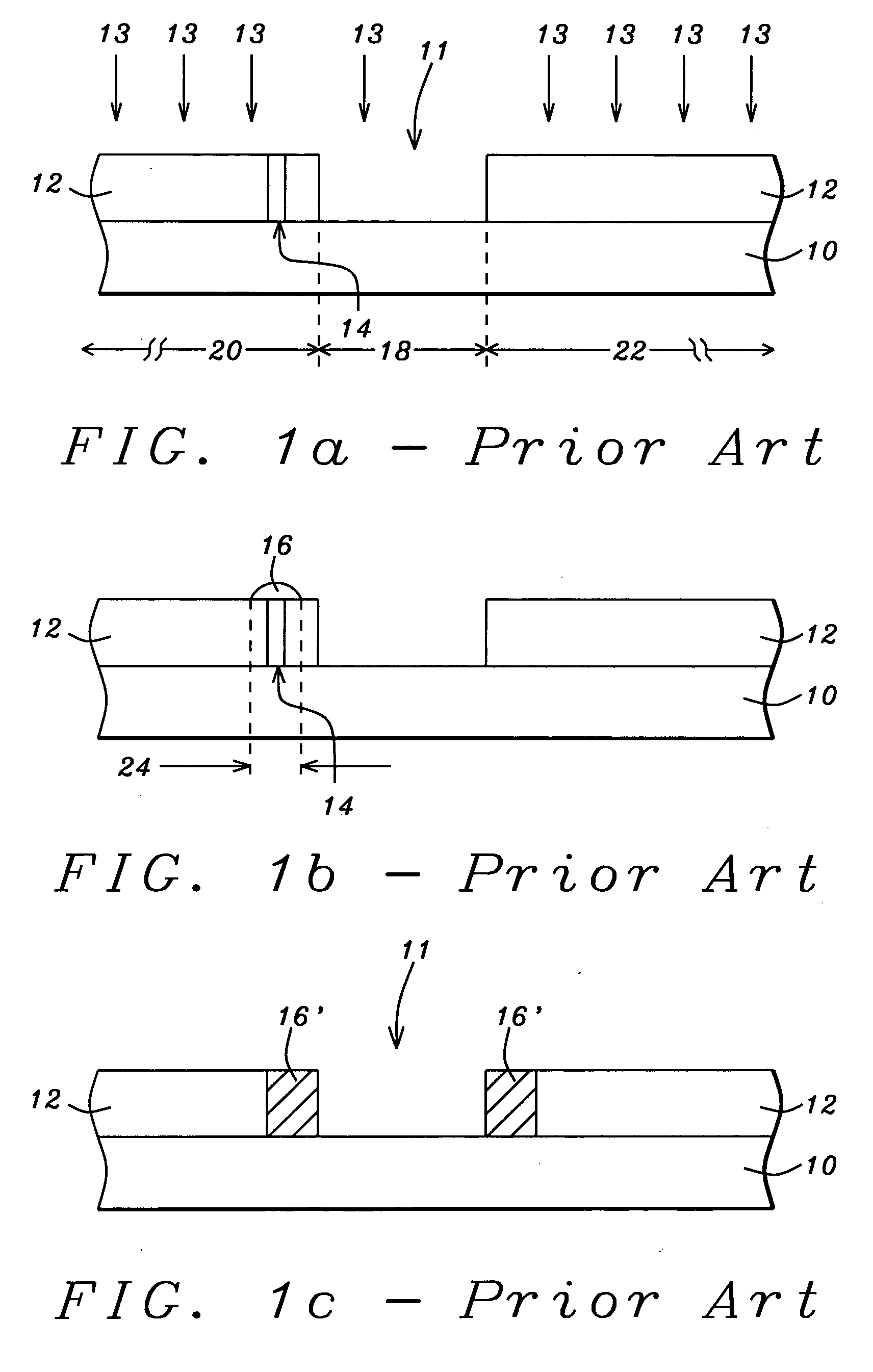

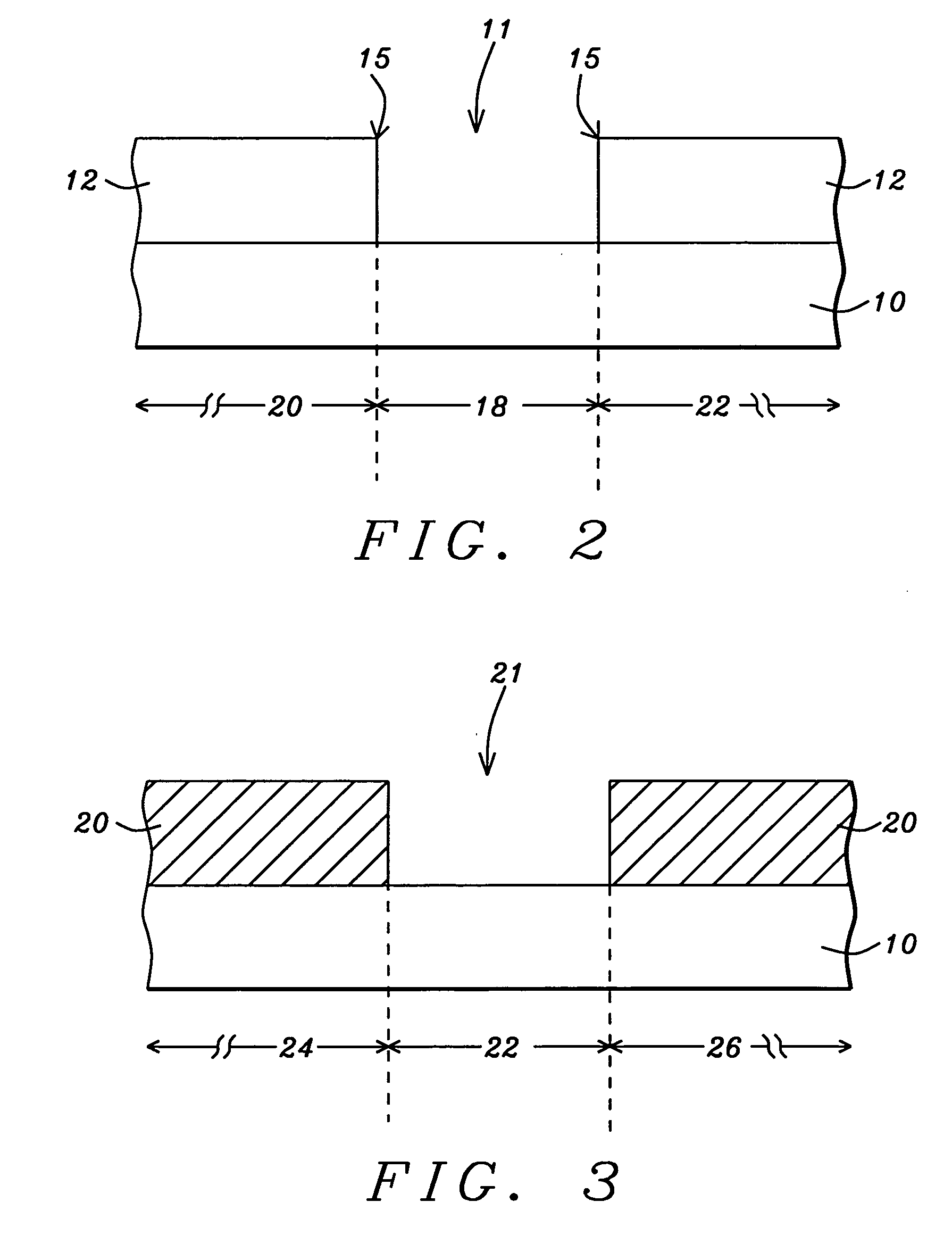

Single trench repair method with etched quartz for attenuated phase shifting mask

InactiveUS7157191B2Photomechanical apparatusOriginals for photomechanical treatmentEngineeringQuartz substrate

In accordance with the objectives of the invention a new method is provided for the repair of an attenuated phase shifting mask having a contact pattern. The invention etches a single trench in the quartz substrate of the phase shifter mask and removes the impact of a void in the phase shifter material. Alternatively, the invention provides for first conventionally restoring the original dimensions of a contact hole in which a pinhole is present and then etching a single or a double trench in the exposed substrate of the restored contact opening.

Owner:TAIWAN SEMICON MFG CO LTD

Single trench repair method with etched quartz for attenuated phase shifting mask

InactiveUS20050153214A1Photomechanical apparatusOriginals for photomechanical treatmentEngineeringQuartz substrate

In accordance with the objectives of the invention a new method is provided for the repair of an attenuated phase shifting mask having a contact pattern. The invention etches a single trench in the quartz substrate of the phase shifter mask and removes the impact of a void in the phase shifter material. Alternatively, the invention provides for first conventionally restoring the original dimensions of a contact hole in which a pinhole is present and then etching a single or a double trench in the exposed substrate of the restored contact opening.

Owner:TAIWAN SEMICON MFG CO LTD

Method for accurately finding a physical location on an image bearing surface for toner images for optimal streak correction

A method for determining a location on an image bearing surface of an image printing system where a toner image is to be printed is provided. The method comprises generating a first signal from a detector that is configured to detect a reference mark on the image bearing surface, and a second signal from a clock system that counts incremental movements of the image bearing surface, determining a first value that correlates the first signal and the second signal, where the first value corresponds to a value of the second signal at a start of characterization of the image bearing surface, and determining a second value using the first value, where the second value provides the location on the image bearing surface where the toner image is to be printed.

Owner:XEROX CORP

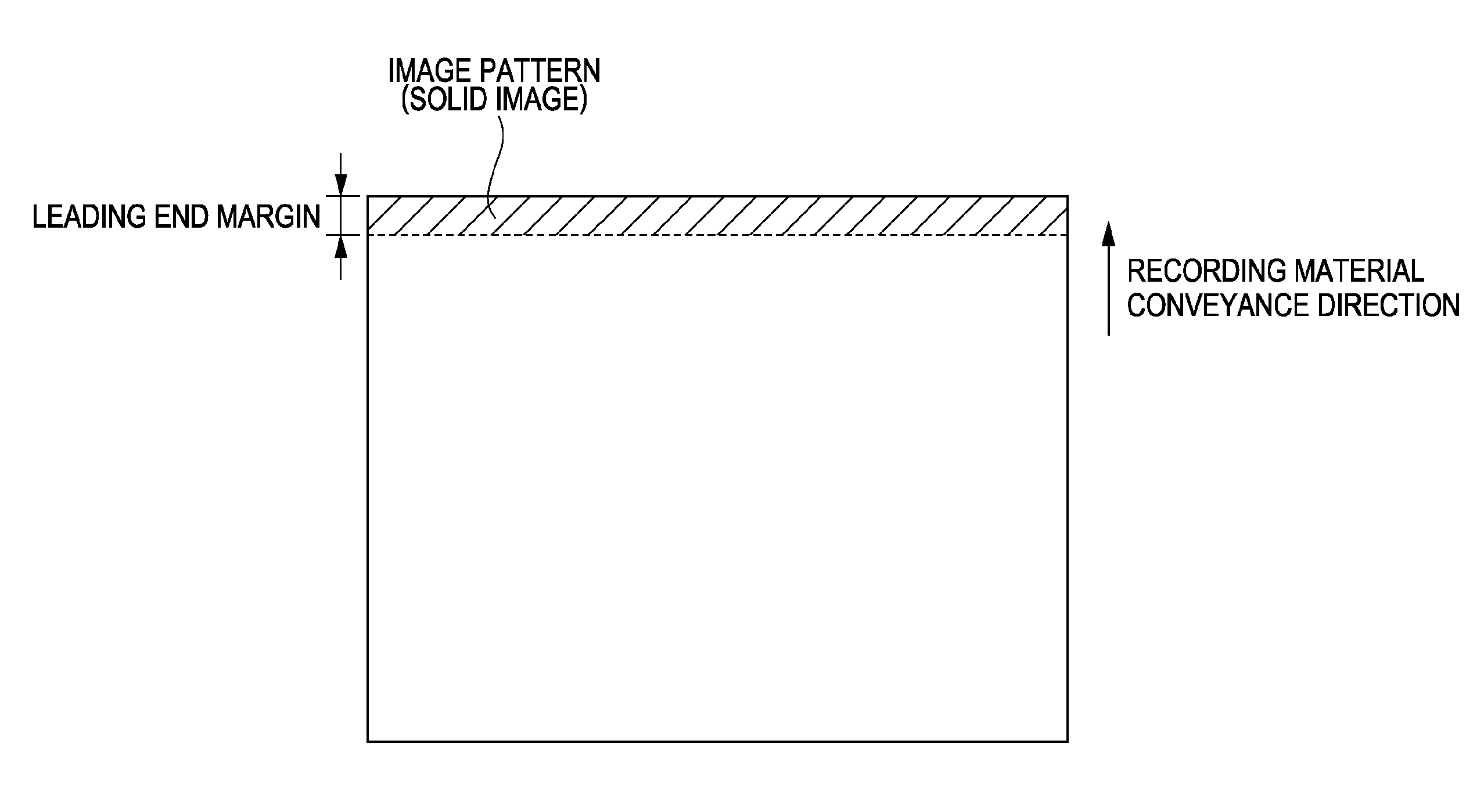

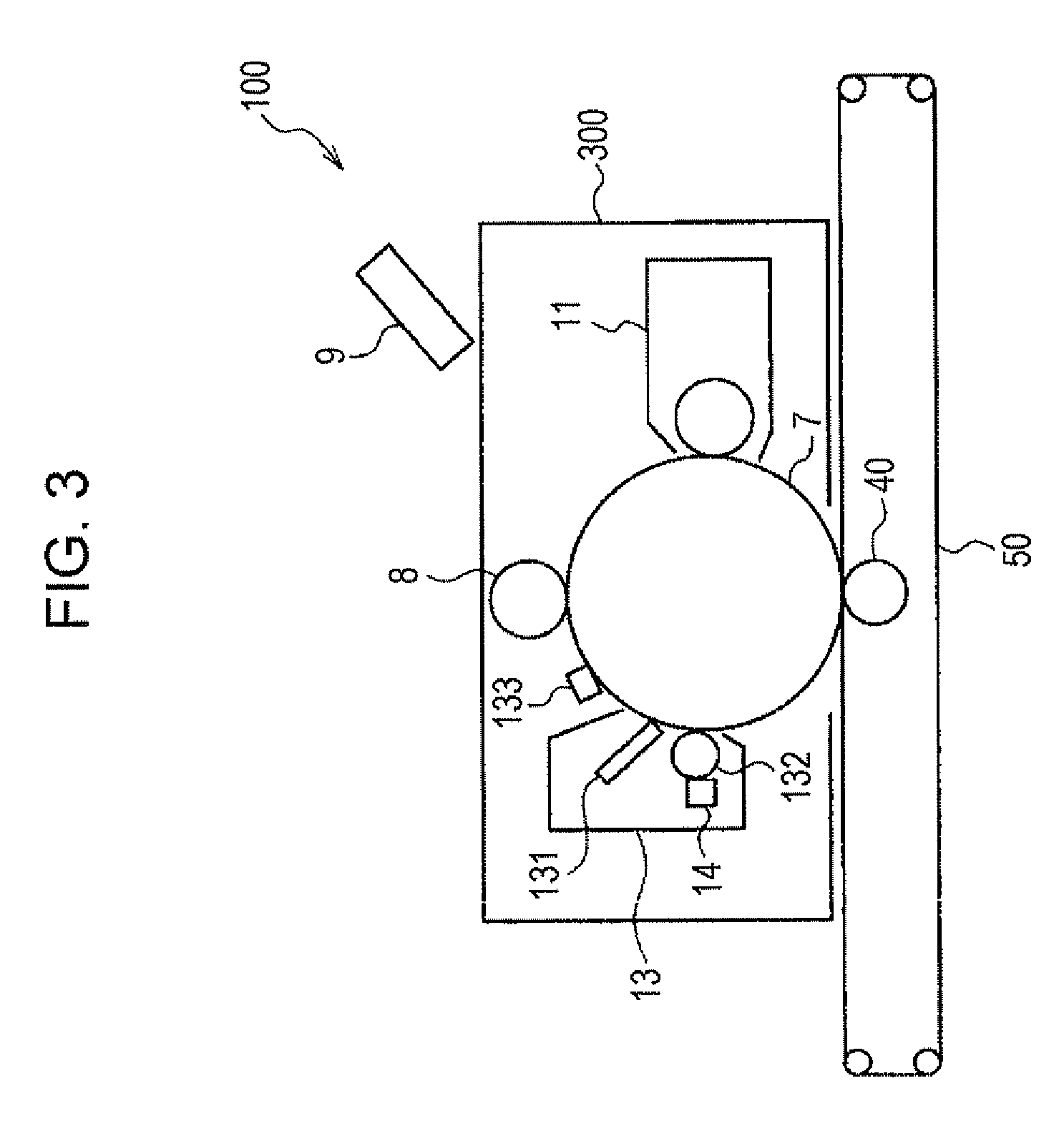

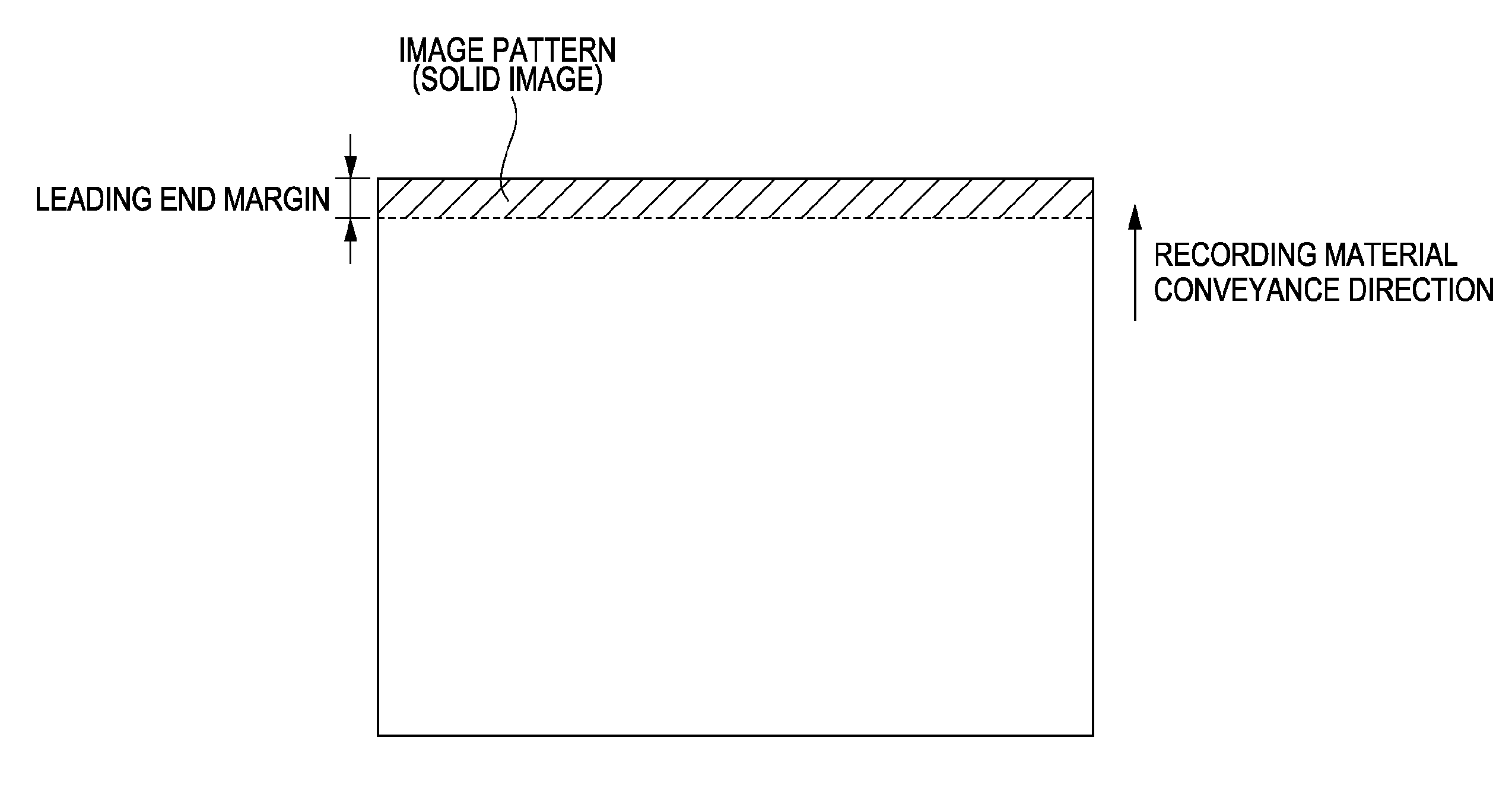

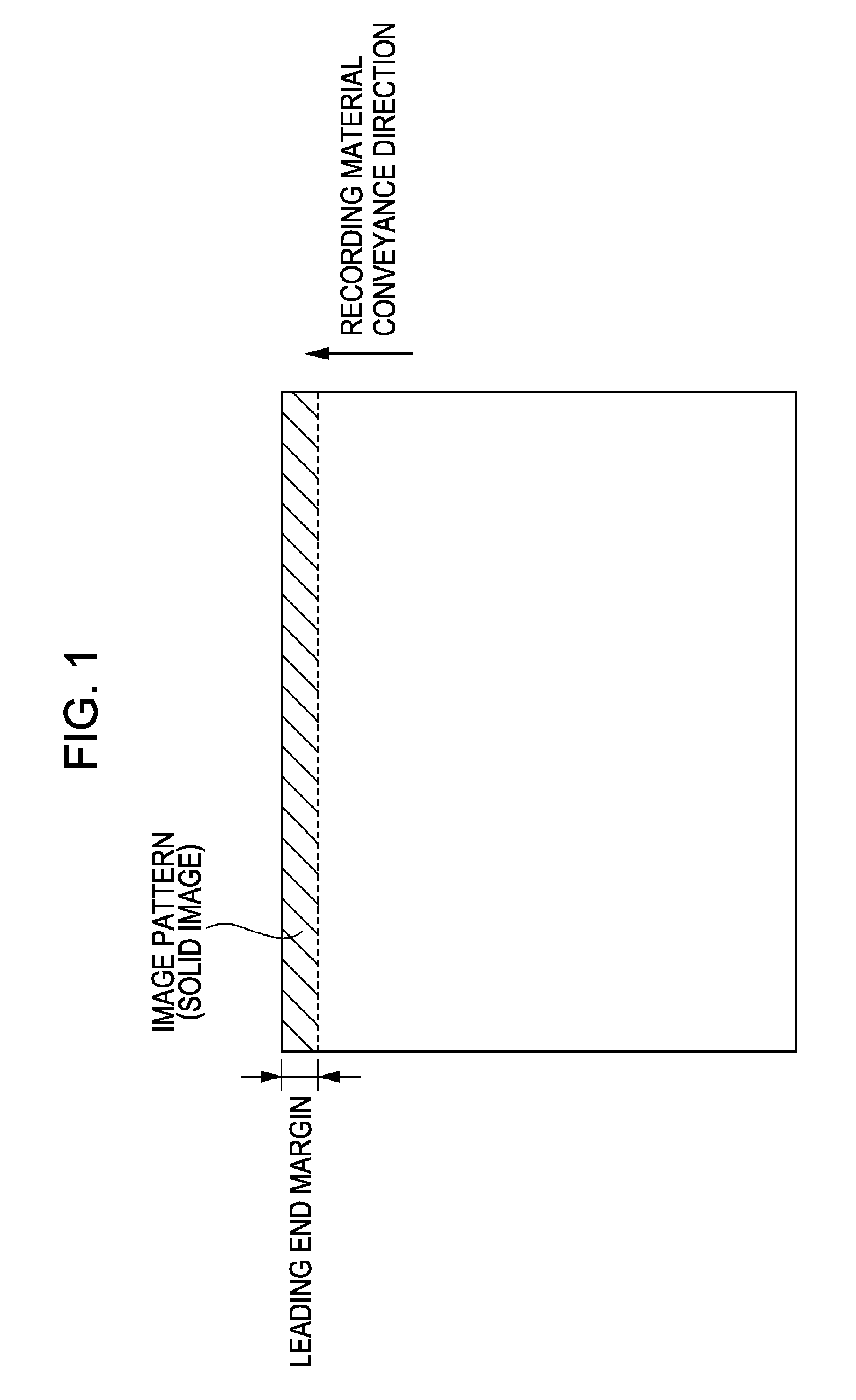

Image forming apparatus

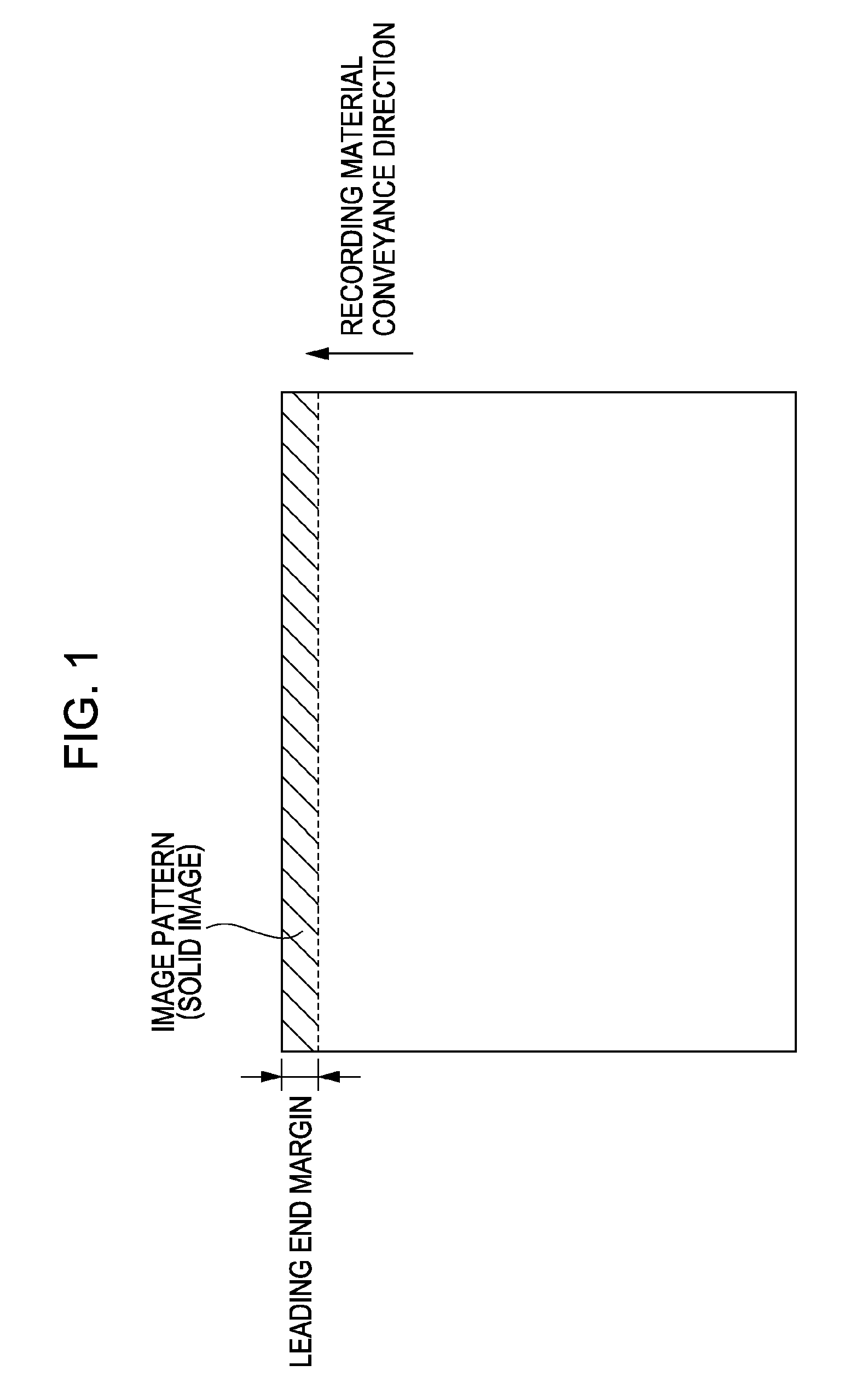

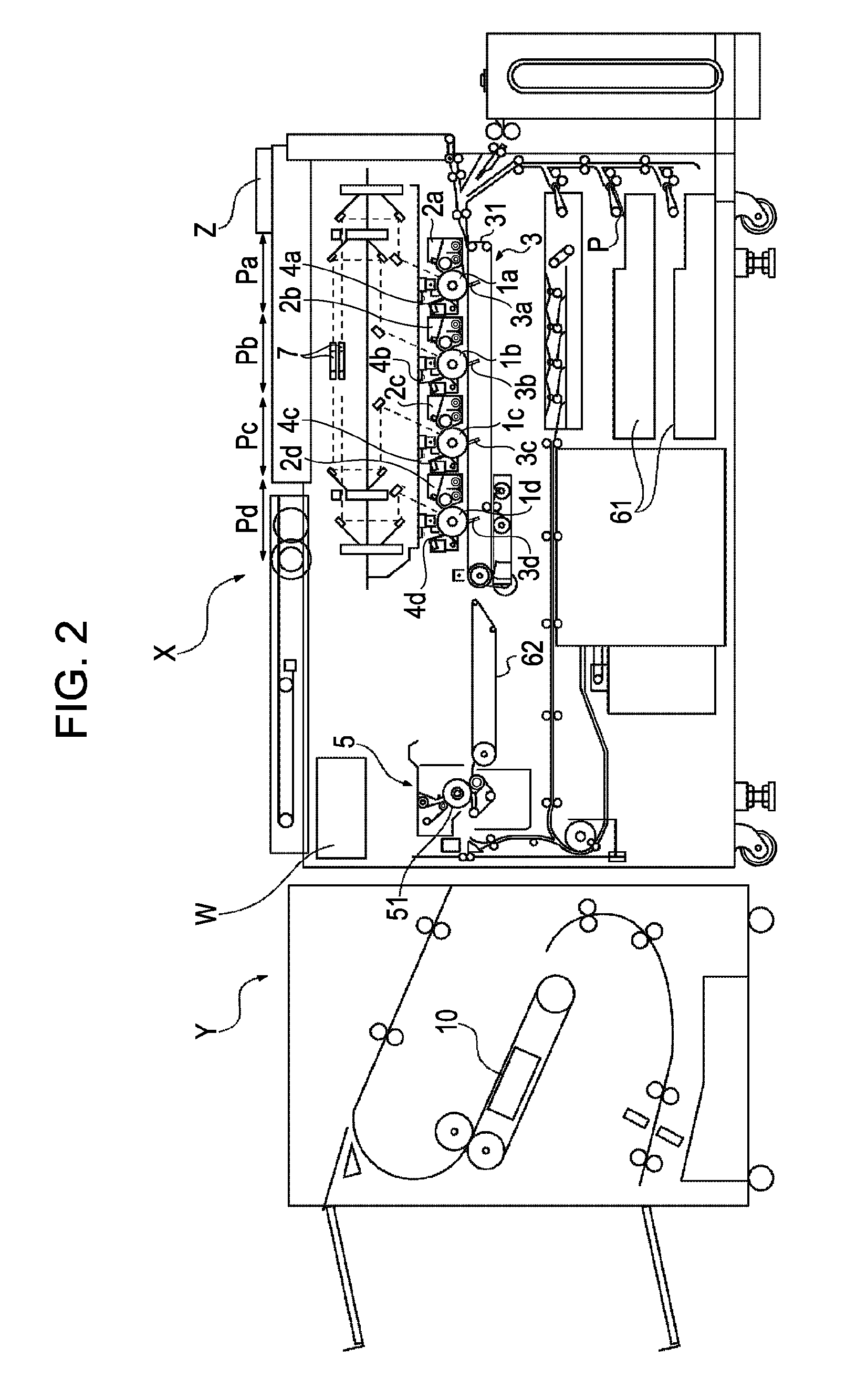

A fixing step before smoothing by a smoothing device causes the phenomenon that a photo-medium is not properly separated from a fixing device due to a toner receiving layer of the photo-medium. Therefore, in order to prevent the occurrence of defective separation in the fixing device, a predetermined image pattern is formed using a toner containing a wax component in a margin, i.e., a non-image forming region, at the leading end of the photo-medium.

Owner:CANON KK

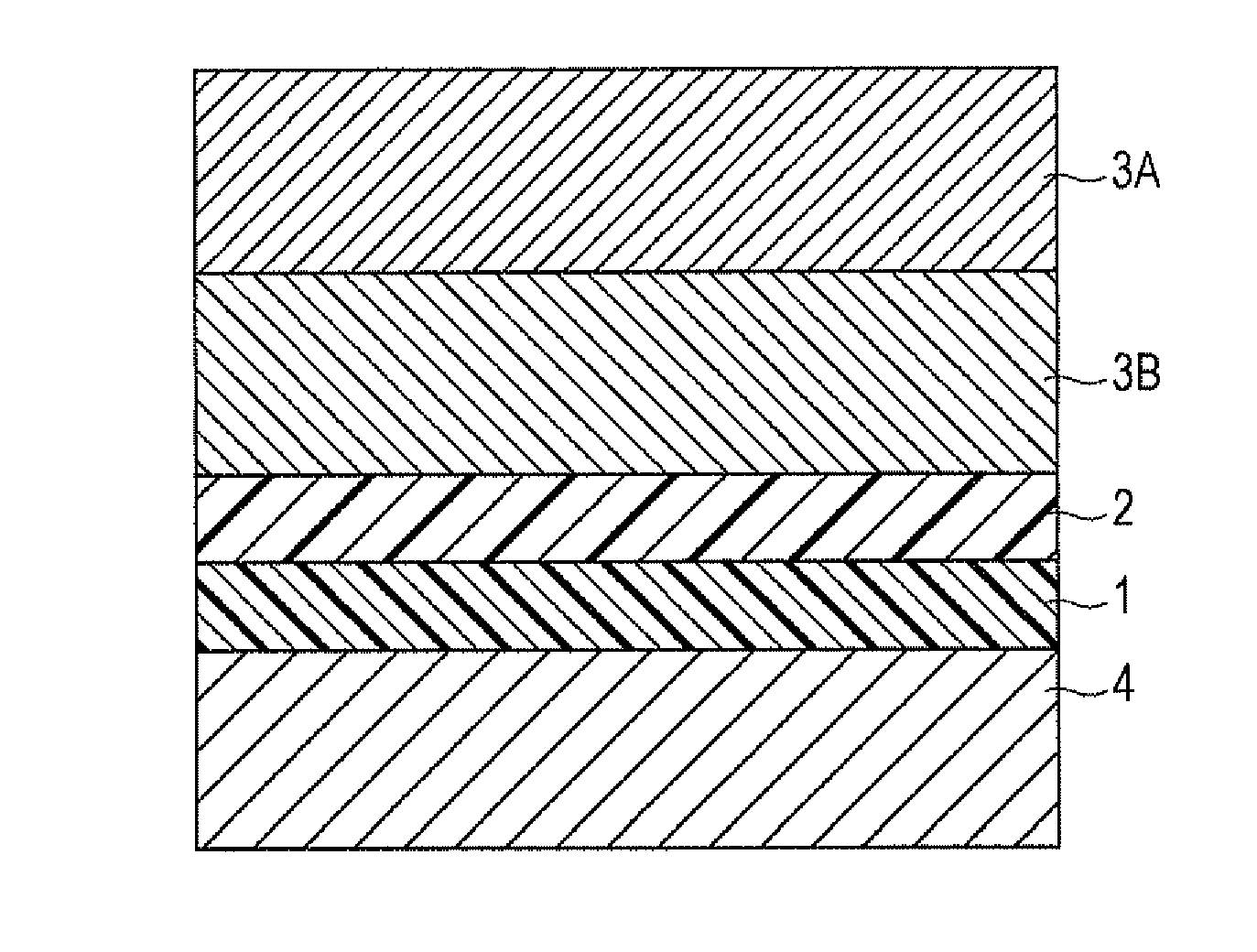

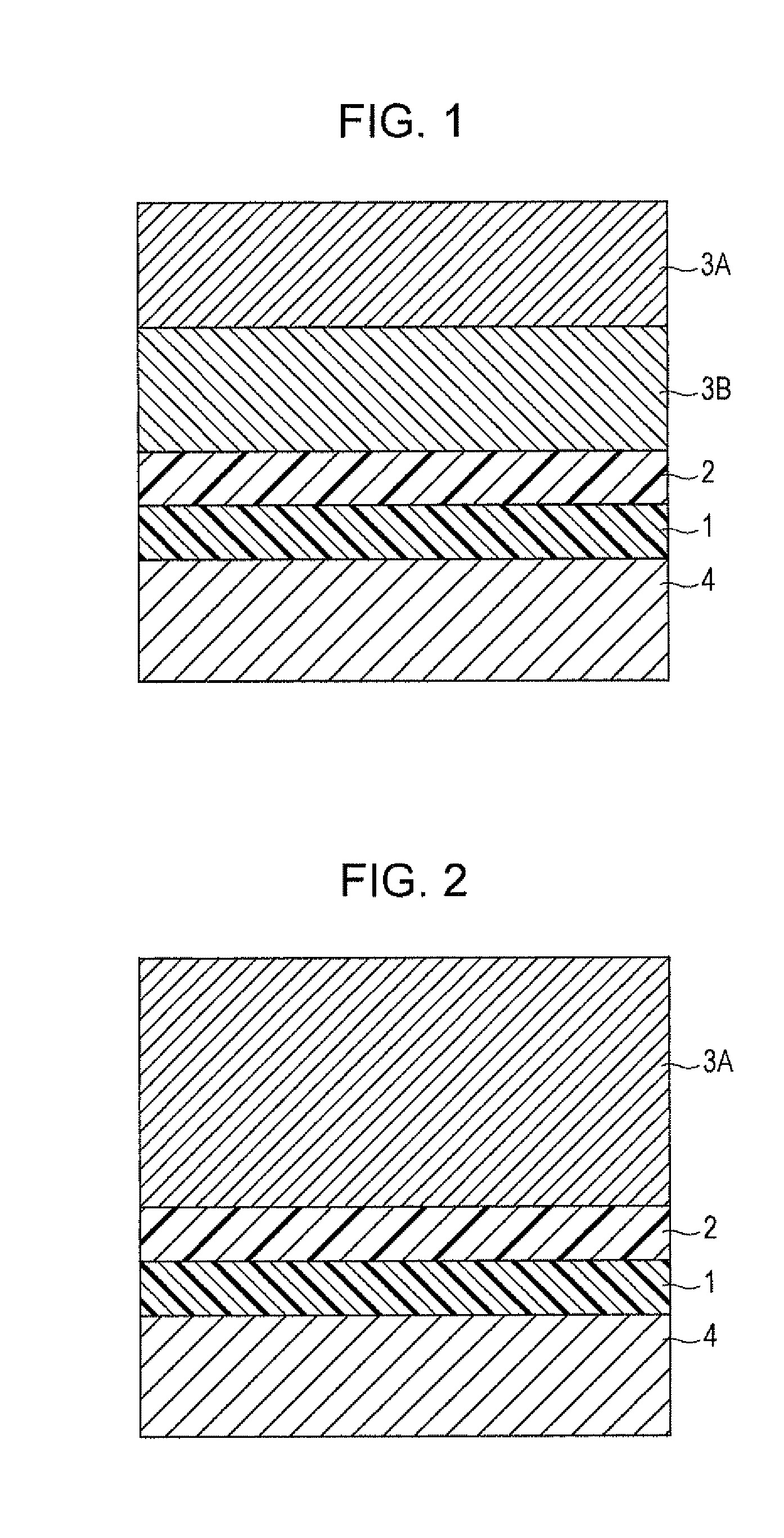

Electrophotographic photoconductor, method for preparing the same, process cartridge, and image forming apparatus

An electrophotographic photoconductor includes a conductive substrate and an outermost surface layer on the conductive substrate. The outermost surface layer contains a copolymer (a) derived from a reactive monomer having charge transport property and a reactive monomer having no charge transport property, and a polymer prepared by polymerizing, in the presence of the copolymer (a), a reactive monomer (b) that has a solubility parameter (SP value) different from a solubility parameter (SP value) of the reactive monomer having no charge transport property by about 2 (cal / cm3)1 / 2 or less.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Image forming apparatus

InactiveUS20090003879A1Ohmic-resistance heatingElectrographic process apparatusImage formationEngineering

A fixing step before smoothing by a smoothing device causes the phenomenon that a photo-medium is not properly separated from a fixing device due to a toner receiving layer of the photo-medium. Therefore, in order to prevent the occurrence of defective separation in the fixing device, a predetermined image pattern is formed using a toner containing a wax component in a margin, i.e., a non-image forming region, at the leading end of the photo-medium.

Owner:CANON KK

Reticle with antistatic coating

InactiveUS7514184B2Potential damageEliminate potential differencePicture framesLight effect designsEngineeringReticle

Owner:TAIWAN SEMICON MFG CO LTD

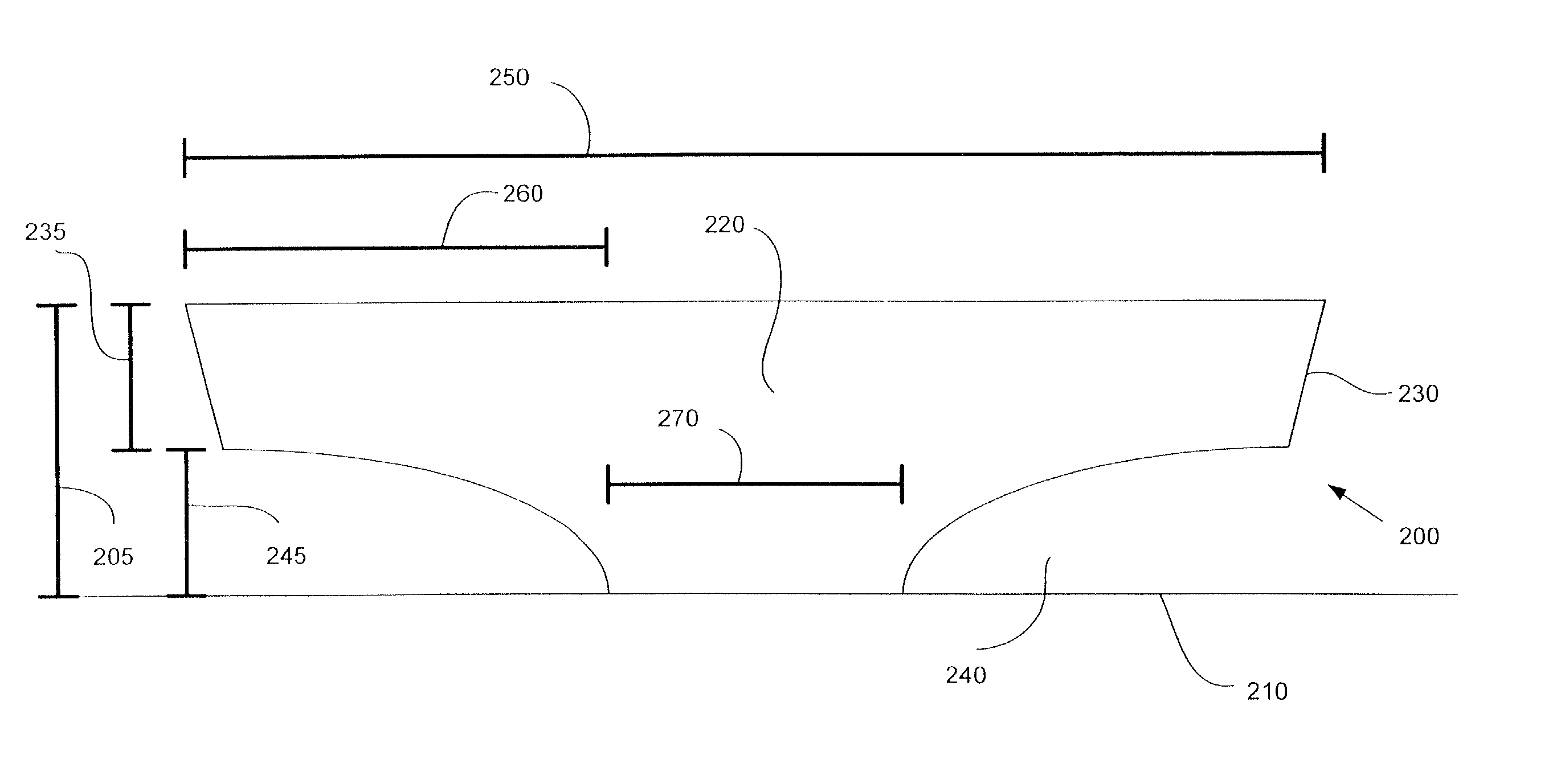

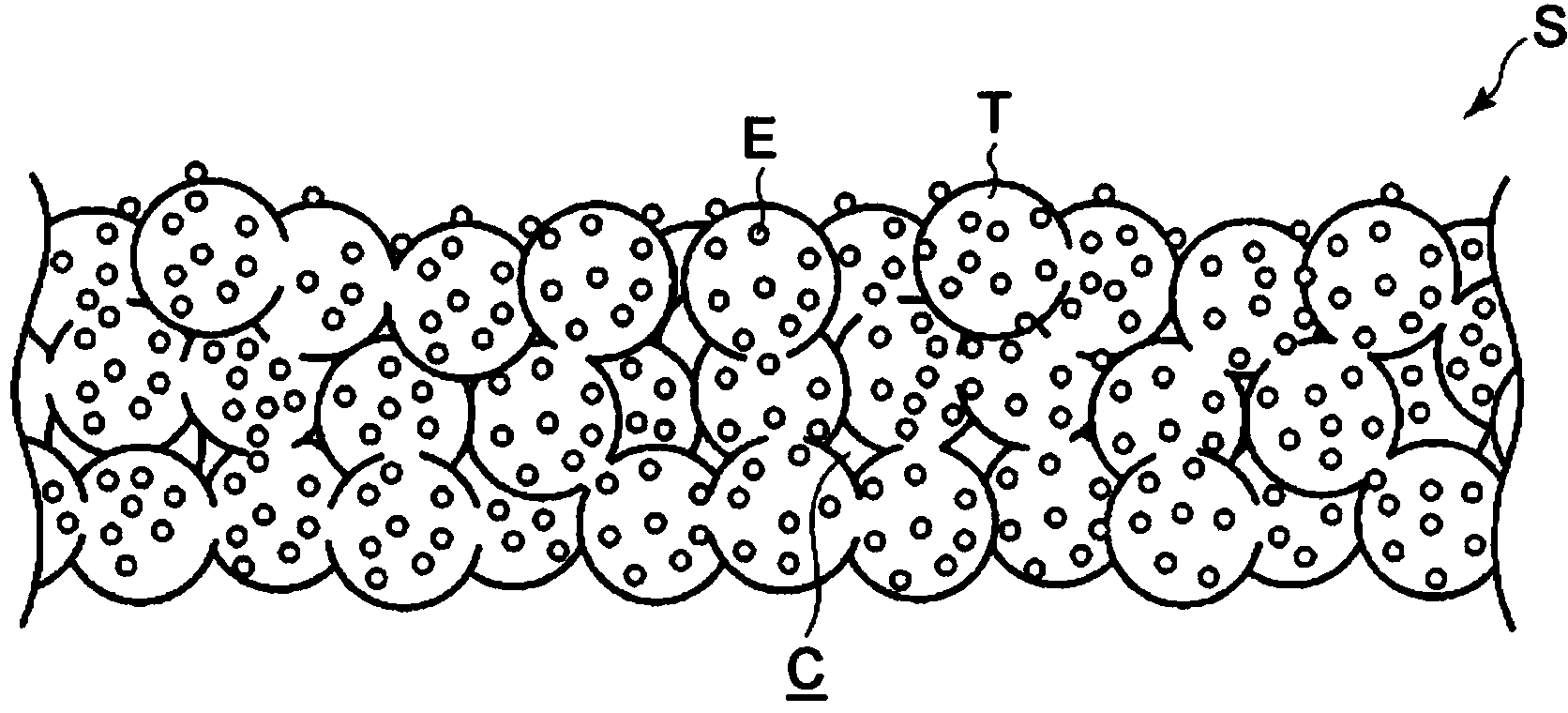

Porous Flexible Sheet And Method And Apparatus For Manufacturing Same

A method for manufacturing a porous flexible sheet according to the present disclosure includes forming a layer that includes a mixture including thermoplastic resin particles and inorganic particles and thermally fusing the thermoplastic particles to each other and to the inorganic particles while keeping at least a part of clearances between the particles.

Owner:CASIO COMPUTER CO LTD

Popular searches

Special data processing applications Beam/ray deflecting arrangements Material analysis by optical means Electrographic processes using charge pattern Radiation therapy Chemical conversion by chemical reaction Glass/slag layered products Microlithography exposure apparatus Photographic processes Metal layered products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com