Three freedom redundancy parallel mechanism for realizing two dimension translation and one dimension rotation

A degree of freedom and parallel technology, applied in the direction of manipulators, program-controlled manipulators, metal processing machinery parts, etc., can solve problems such as uncontrollable degrees of freedom, loss of control of parallel machine tools, and inability to balance the load force of dynamic platforms, etc., to improve mechanical properties, Effects that are not easy to interfere and have a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

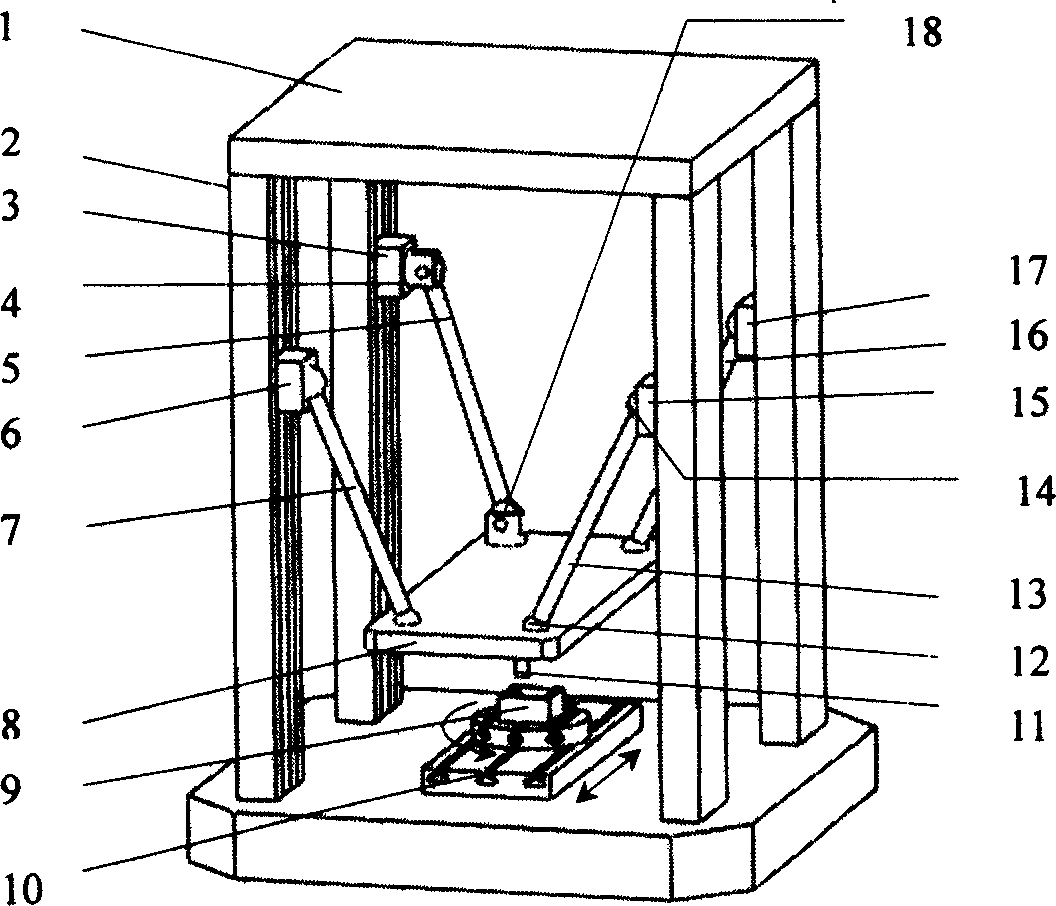

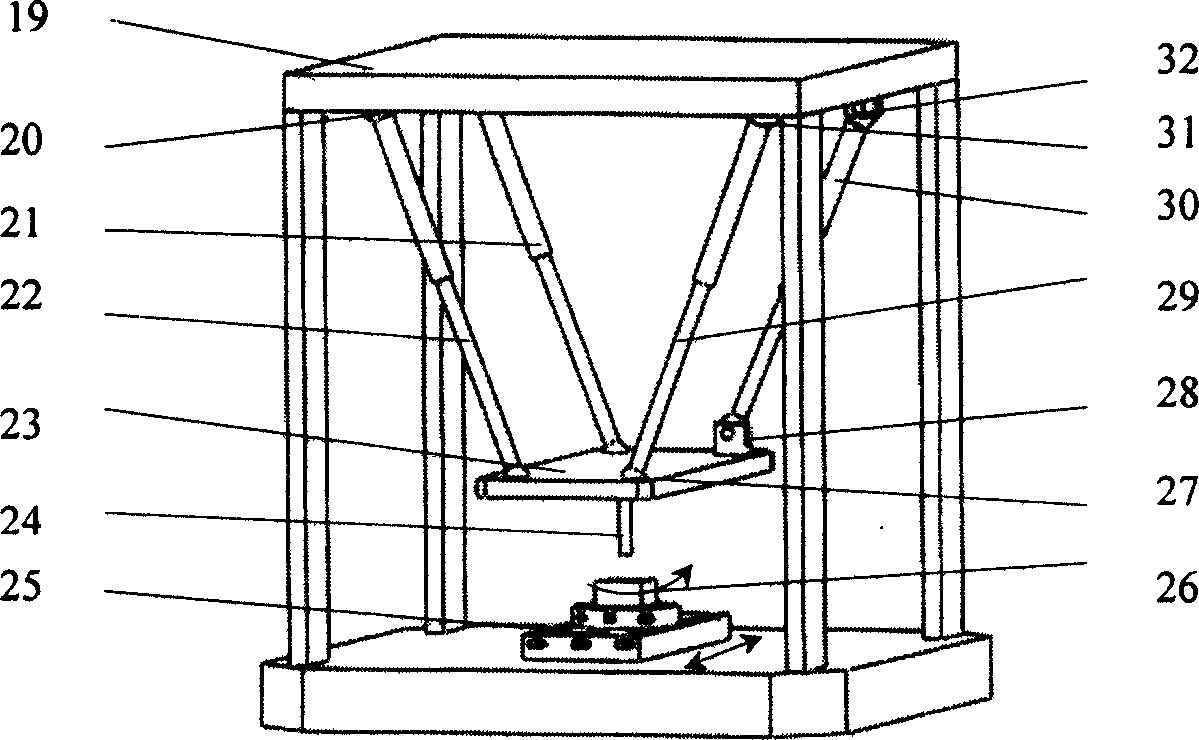

[0015] figure 1 Middle, 1 frame; 2 columns; 3, 6, 15, 17 sliders; 4, 18 rotating pairs; 5, 7, 13, 16 connecting rods; 8 moving platforms; 9 workpieces; 10 working tables; 11 cutting tools; 1214 Ball hinge. As shown in the figure, the figure is a vertical structure that realizes the single-degree-of-freedom motion input of each branch chain in the form of a slide rail slider. In the figure, the column 2 is equipped with slide rails, and the sliders 3, 6, 15, and 17 can slide on the column 2 respectively for motion input. The two ends of the branch chain 5 are respectively connected to the slider 3 and the moving platform 8 through parallel rotating pairs 4 and 18 . Both ends of the branch chains 7, 13, 16 are spherical hinges to connect the moving platform 8 and the corresponding slider. The moving platform can realize two-dimensional translation and one-dimensional rotation. In the figure, a worktable 9 with one-dimensional rotation and one-dimensional translation is attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com