Integrated dehumidifier

A dehumidifier and integrated technology, which is applied in heating methods, household heating, lighting and heating equipment, etc., can solve the problems of increased energy consumption of dehumidifiers, poor cooling effect, and increased operating load of compressors. The structure design is simple and reasonable, and the dehumidification effect and the condensation effect are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

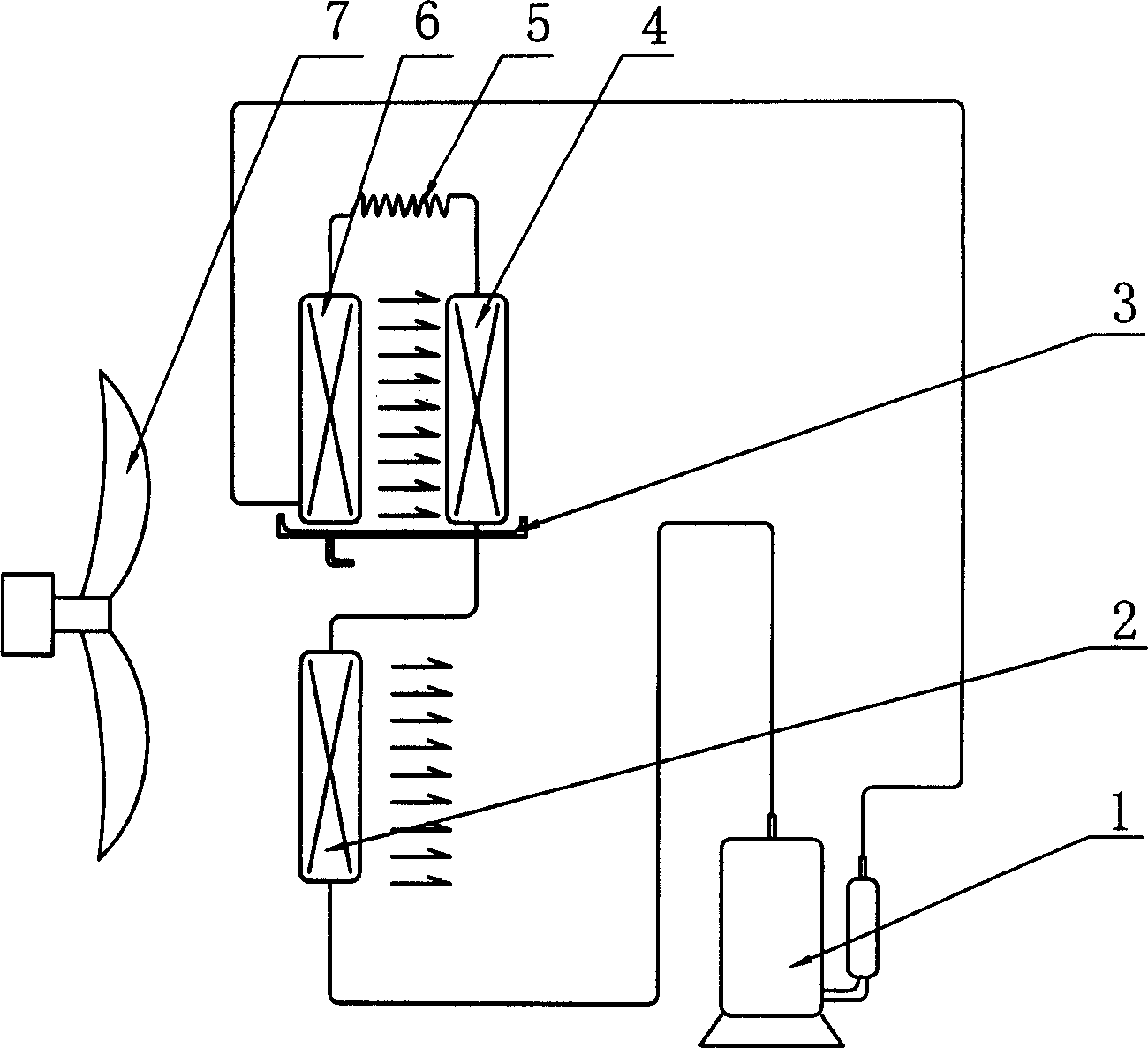

[0026] Embodiment 1, with reference to figure 1 . An integral dehumidifier, comprising a fan blade 7, a water tray 3, and a dehumidification device connected by a compressor 1, a condenser 4, an evaporator 6, and a throttling capillary 5, the exhaust port of the compressor 1 A pre-cooling condenser 2 is arranged between the air inlet of the condenser 4 . Fan blades 7 force a part of the indoor air to pass through the pre-cooling condenser 2, and the other part passes through the evaporator 6 and the condenser 4 for forced convection heat exchange.

[0027] The high-temperature, high-pressure gaseous refrigerant discharged after being compressed by the compressor 1 first enters the pre-cooling condenser 2 for pre-cooling, and then enters the condenser 4 for condensation. The refrigerant becomes a medium-temperature, high-pressure supercooled liquid refrigerant, and then enters the throttling capillary 5 After throttling, it becomes a low-temperature, low-pressure liquid refri...

Embodiment 2

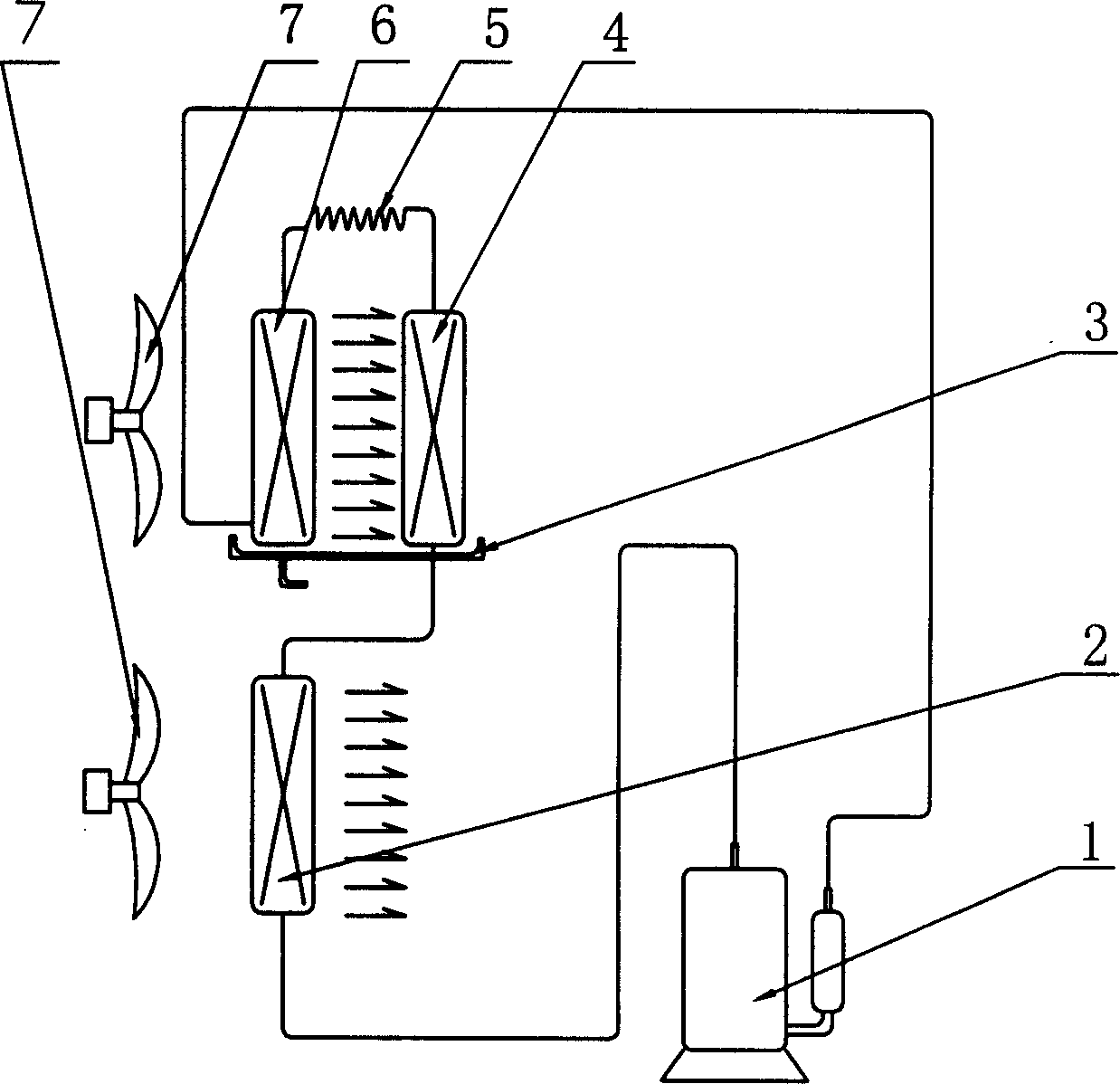

[0028] Embodiment 2, with reference to attached figure 2 . The difference between embodiment 2 and embodiment 1 is that the fan blade 7 is two fan blades, one fan blade 7 forces the indoor air to pass through the evaporator 6 and the condenser 4, and the other fan blade 7 makes the indoor air Forced through precooling condenser 2.

[0029] It is also possible to set the precooling condenser 2 and the fan blade 7 outdoors, and the outdoor air is forced to pass through the precooling condenser 2 by the fan blade 7. If you do not want to increase the indoor temperature, add a row corresponding to the air outlet of the precooling condenser 2 The air duct discharges the heat-exchanged air to the outside and does not enter the room.

Embodiment 3

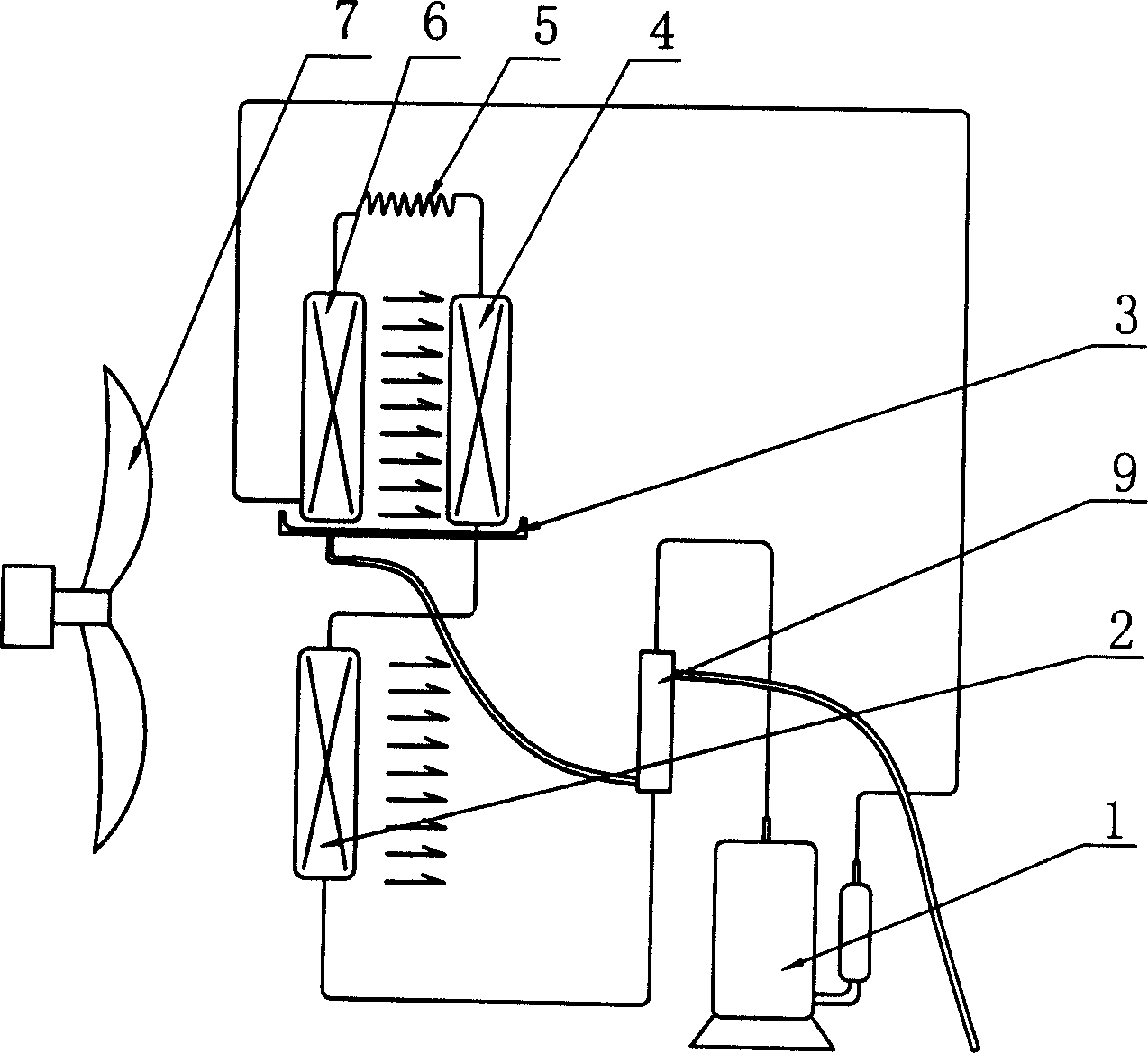

[0030] Embodiment 3, with reference to attached image 3 . The difference between embodiment 3 and embodiment 1 is that a condensed water regenerator 9 is provided between the exhaust port of the compressor 1 and the inlet of the pre-cooling condenser 2, and the condensed water regenerator 9 is connected to the water receiving device through a water pipe. The disks 3 are connected, and the water outlet of the condensed water regenerator 9 is provided with a drain pipe.

[0031] The low-temperature condensed water condensed and removed from the evaporator 6 is collected by the water receiving tray 3 and then enters the water inlet of the condensed water regenerator 9 through the drain pipe, and is then heated by the high-temperature and high-pressure gaseous refrigerant discharged after being compressed by the compressor 1. The water outlet pipe of the water outlet of the regenerator 9 is discharged; and the high-temperature, high-pressure gaseous refrigerant discharged after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com