Waste heat driven double heat pipe generator

A generator and heat pipe technology, applied in the field of dual heat pipe generators driven by waste heat, can solve problems such as flue gas corrosion, achieve the effects of saving power consumption, avoiding low-temperature corrosion problems, and facilitating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

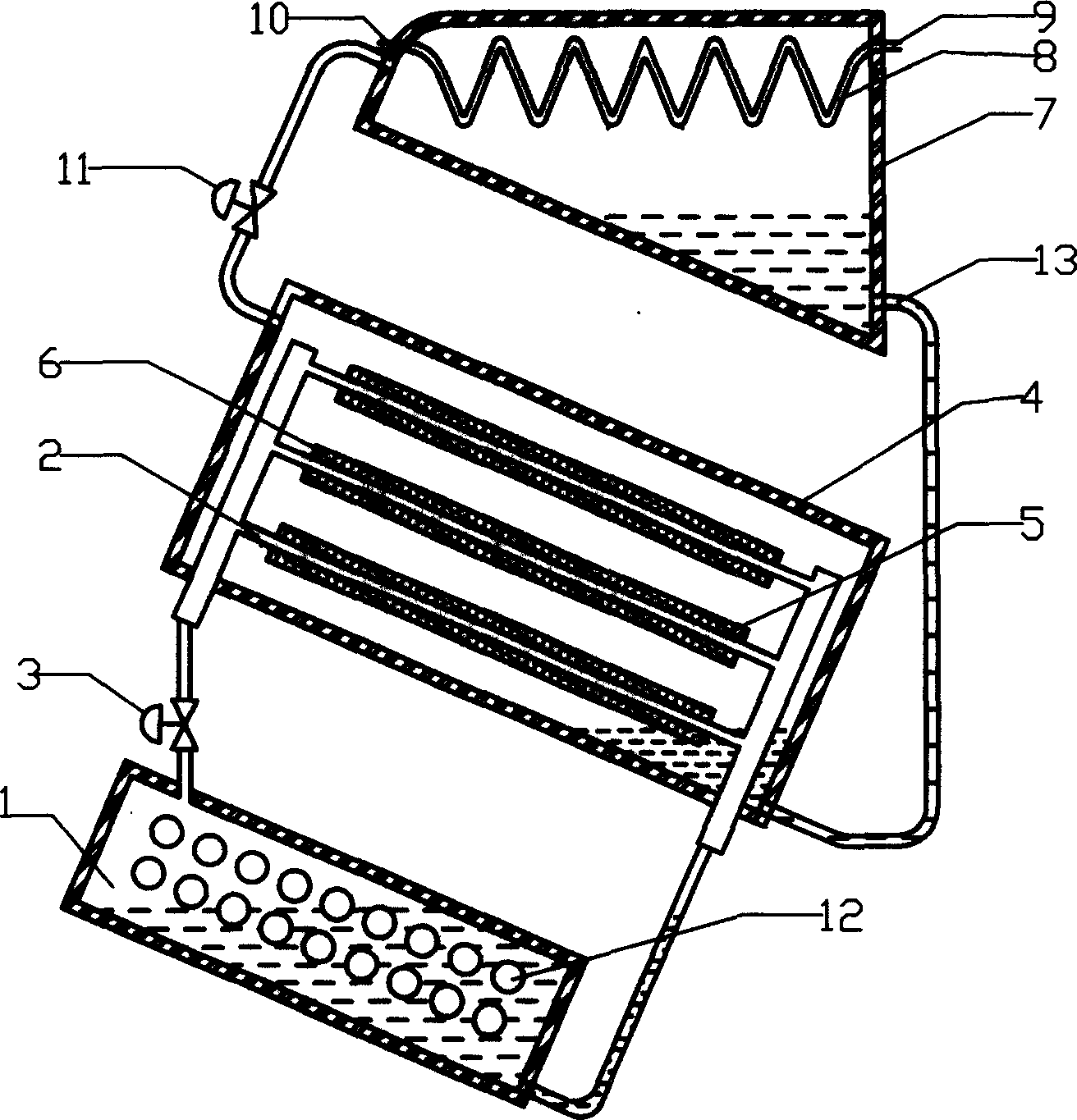

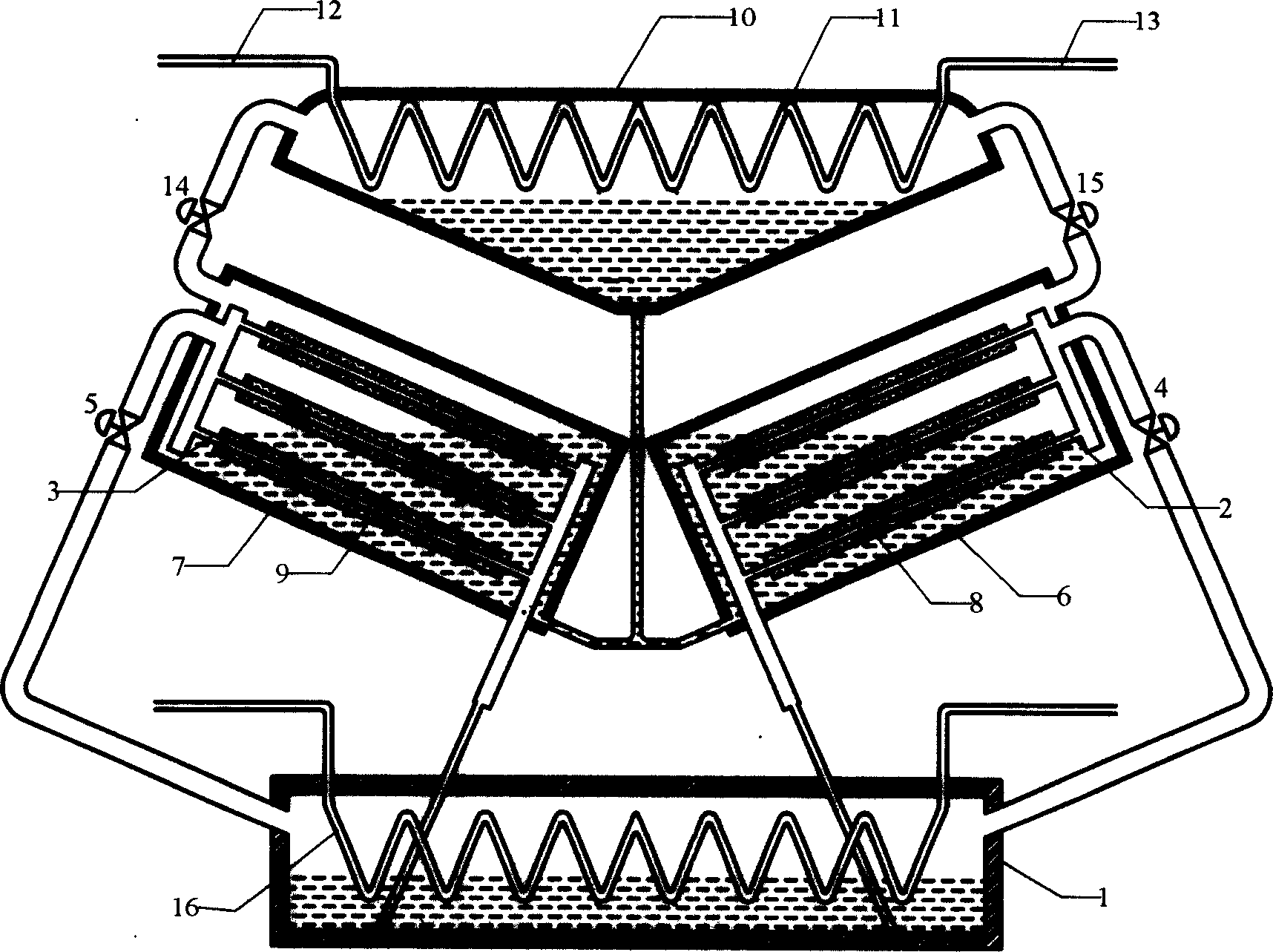

[0014] Such as figure 1 As shown, the present invention includes: flue gas heating type steam boiler 1, heat pipe heating pipeline 2, heat pipe pneumatic valve 3, adsorption bed 4, adsorption unit pipe 5, adsorbent 6, seawater condenser 7, seawater pipeline 8, seawater Inlet 9, seawater outlet 10, cooling valve 11. The connection method is: the flue gas heating pipeline 12 is located in the flue gas heating steam boiler 1, the flue gas is passed through the pipe, and water is used as the medium, and the upper part of the flue gas heating steam boiler 1 passes through the heat pipe pneumatic valve 3 and the heat pipe heating pipeline 2, and then through the outer wall of the adsorption bed 4 and then connected to the inner space in the middle of the adsorption unit tube 5. The adsorbent 6 is located inside the adsorption unit tube 5 . The seawater condenser 7 is located on the upper part of the adsorption bed 4 . The seawater pipeline 8 is connected to both ends of the seawa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com