Optical proximity correcting method

An optical proximity correction, photomask technology, applied in optics, originals for optomechanical processing, special data processing applications, etc., to achieve the effect of improving exposure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

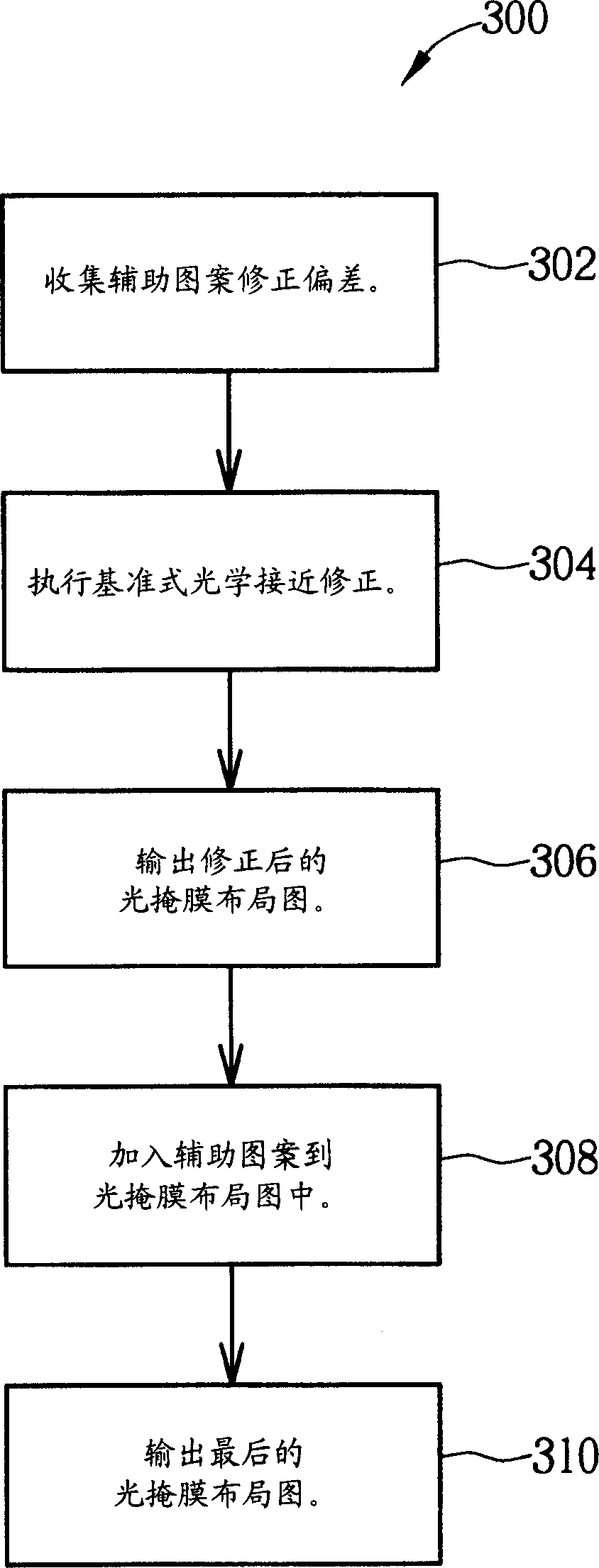

[0027] Please refer to image 3 , image 3 It is a schematic flowchart of a process 300 for modifying a photomask layout by the optical proximity correction method of the present invention, wherein the photomask layout includes at least one photomask pattern. The correction process 300 includes the following steps:

[0028] Step 302: Collect auxiliary pattern correction deviation values of the first auxiliary patterns scheduled to be added to the photomask layout pattern, establish an auxiliary pattern correction model similar to a database, and collect exposure deviation value data of the original photomask pattern at the same time. In this step, the first auxiliary pattern to be added may be a scattering strip. The implementation method of this step can use the test photomask to measure the deviation value of the photomask pattern that needs to be corrected, so as to obtain the proper adding position and size of the scattering strips.

[0029]Step 304: Combining with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com