Light source module of power LED

A technology of light emitting diodes and light source modules, applied to light sources, electric light sources, lighting devices, etc., can solve the problems of low light source production efficiency, inability to achieve thermoelectric separation, and high cost of metal circuit boards, reducing design time and workload, reducing Application cost, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

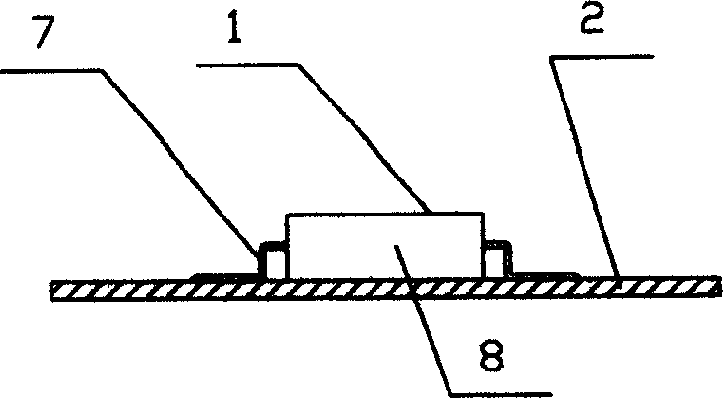

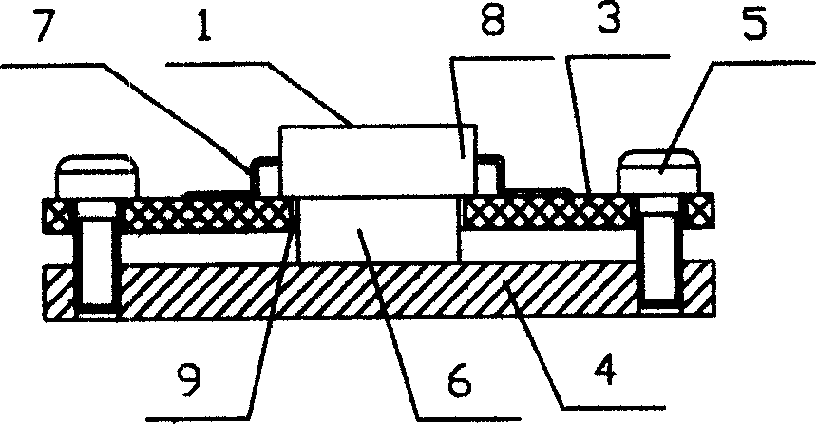

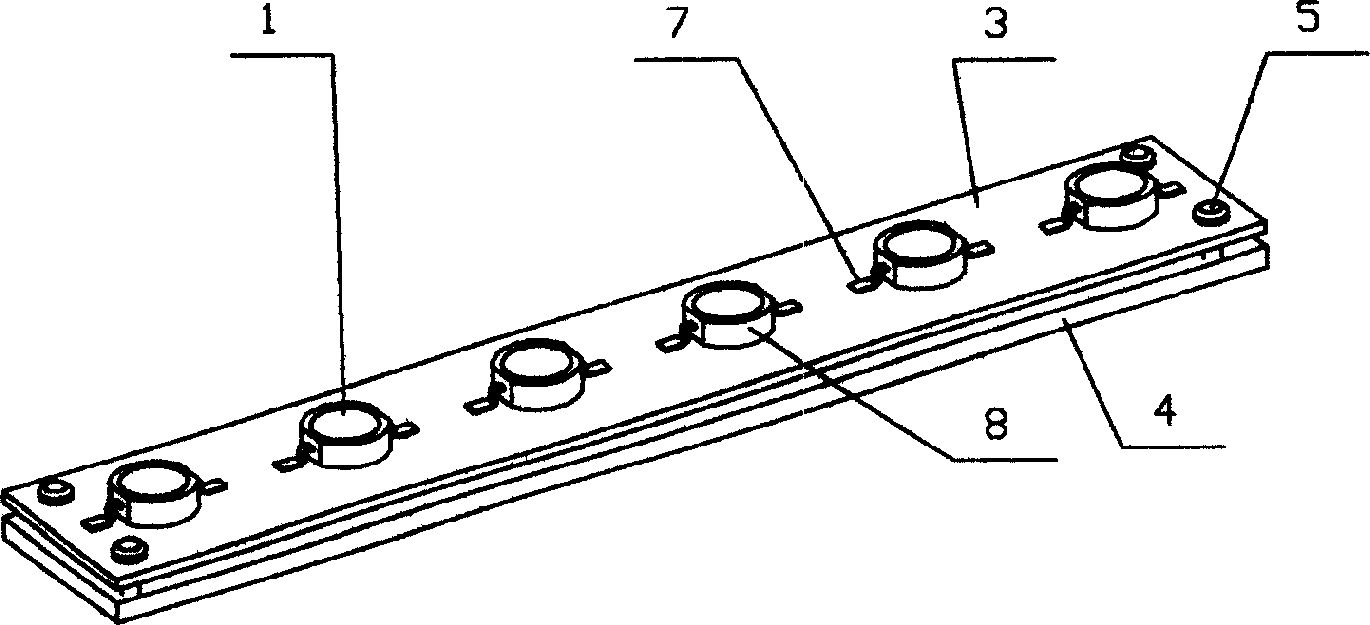

[0015] Such as figure 2 , the present invention includes a power light emitting diode 1, a circuit board 3, a heat sink 4, and a connector 5. The number of the power light emitting diode 1 is one, and has a heat sink 6, and the pin 7 is sheet-shaped, and the heat sink 6. The bottom surface is higher than its pin 7 and the bottom of the frame 8; the circuit board 3 is a fiber material circuit board, and the circuit board 3 is provided with an electric input and output circuit, a power LED drive circuit, and a socket for power supply input or for multiple For the quick connectors assembled by modules, the corresponding position on the circuit board 3 is provided with a through hole 9 suitable for the size of the heat sink of the power light emitting diode. The power light emitting diode 1 is also arranged on the circuit board, and its heat sink 6 passes through the aforementioned circuit board The through hole 9 on the 3 is in direct and close contact with the heat sink below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com