Laser light generating device and method of fabricating the same

A technology of laser generation and manufacturing methods, which is applied to lasers, phonon exciters, laser components, etc., can solve problems such as manufacturing difficulties, temperature rise, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

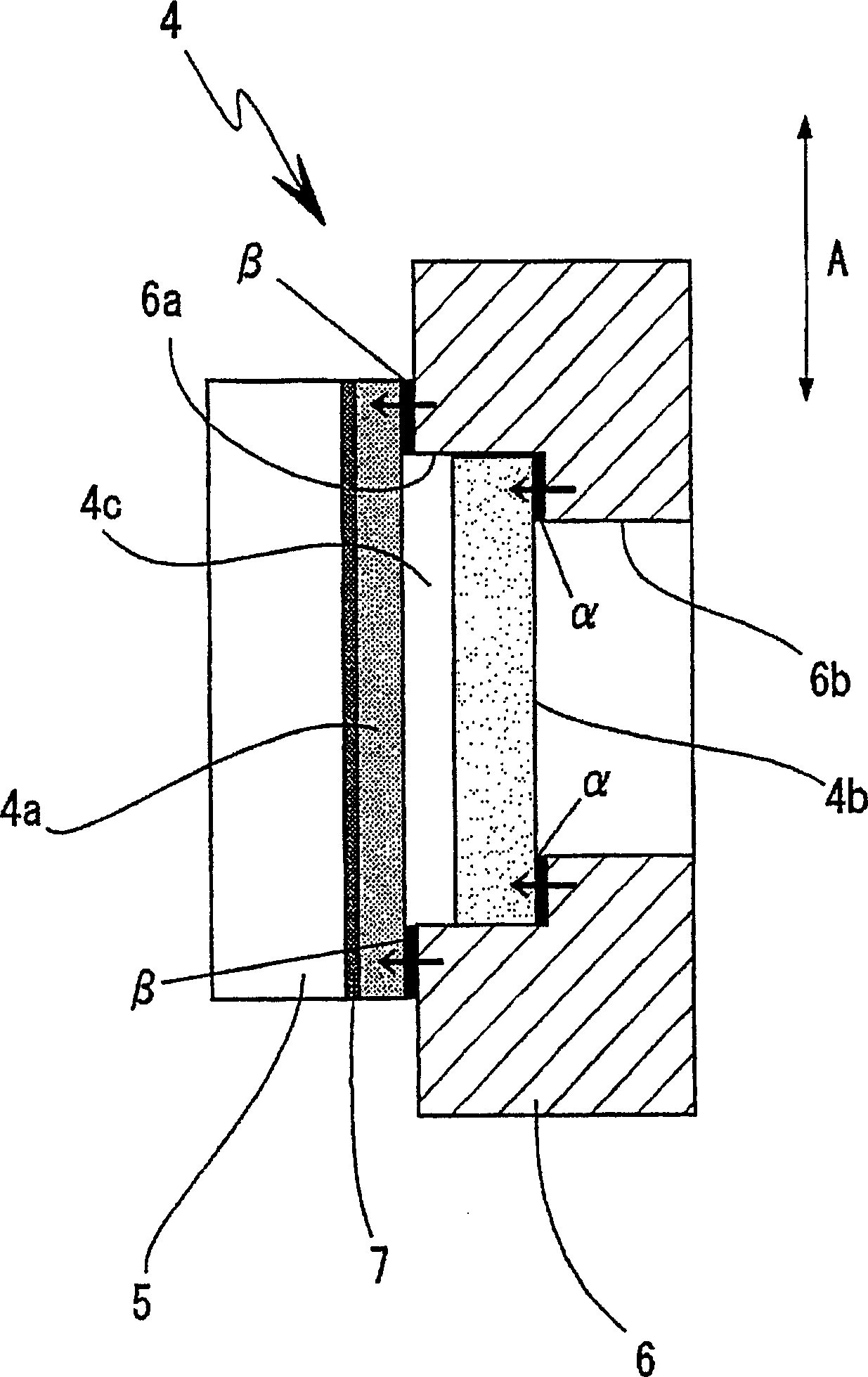

[0036] The present invention relates to the solid laser resonator that utilizes the thermal lens effect caused by continuous wave excitation light irradiation and the laser generating device equipped with the resonator, which can be applied to various light sources, such as GLV (Grating Light Valve : grating light valve) etc. as a light source for a display device (two-dimensional image display device) used as a linear optical modulation element.

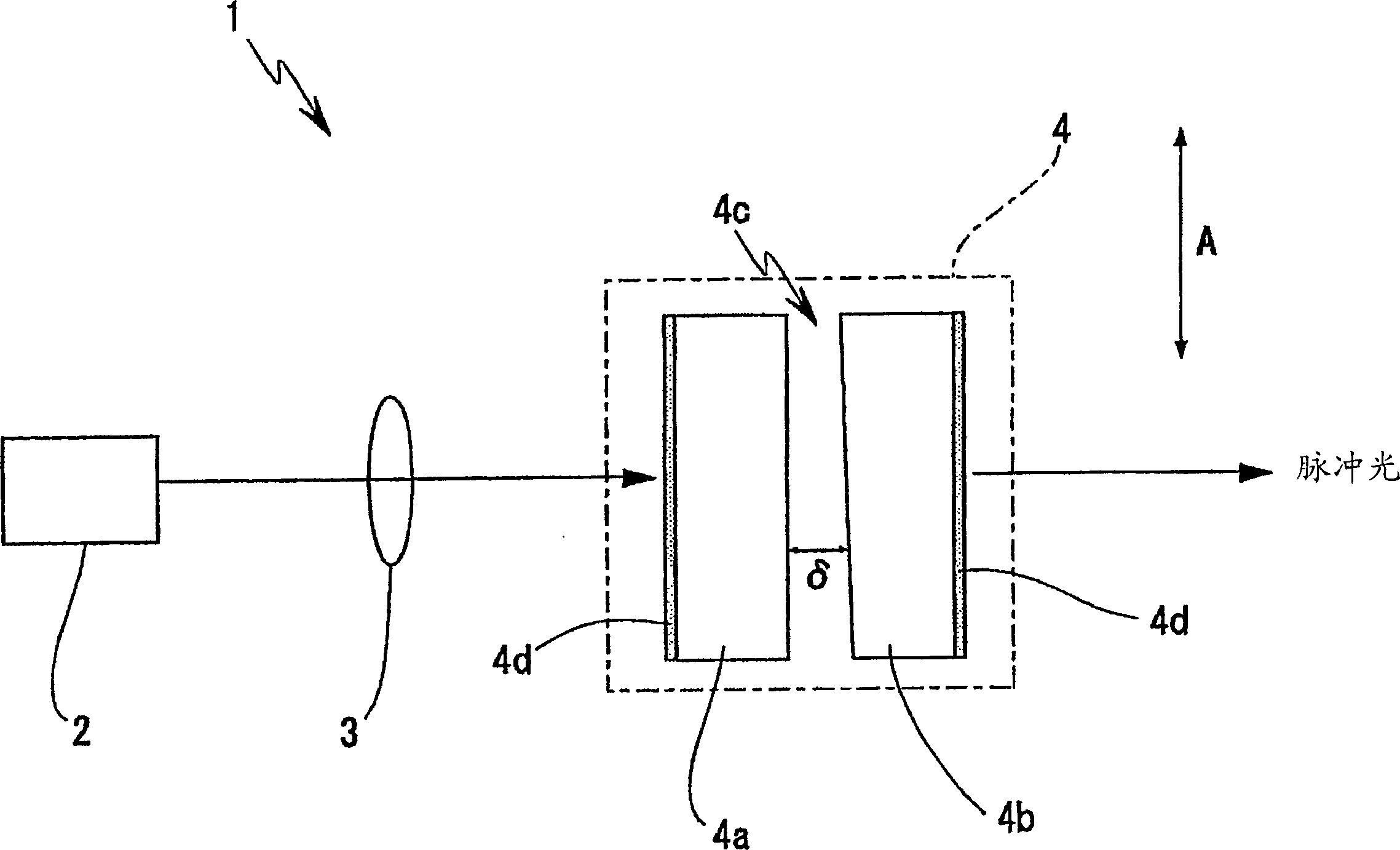

[0037] figure 1 It is a schematic diagram for explaining a basic configuration example of the laser light generator of the present invention, which is assumed to be applied to a passive Q-switched laser.

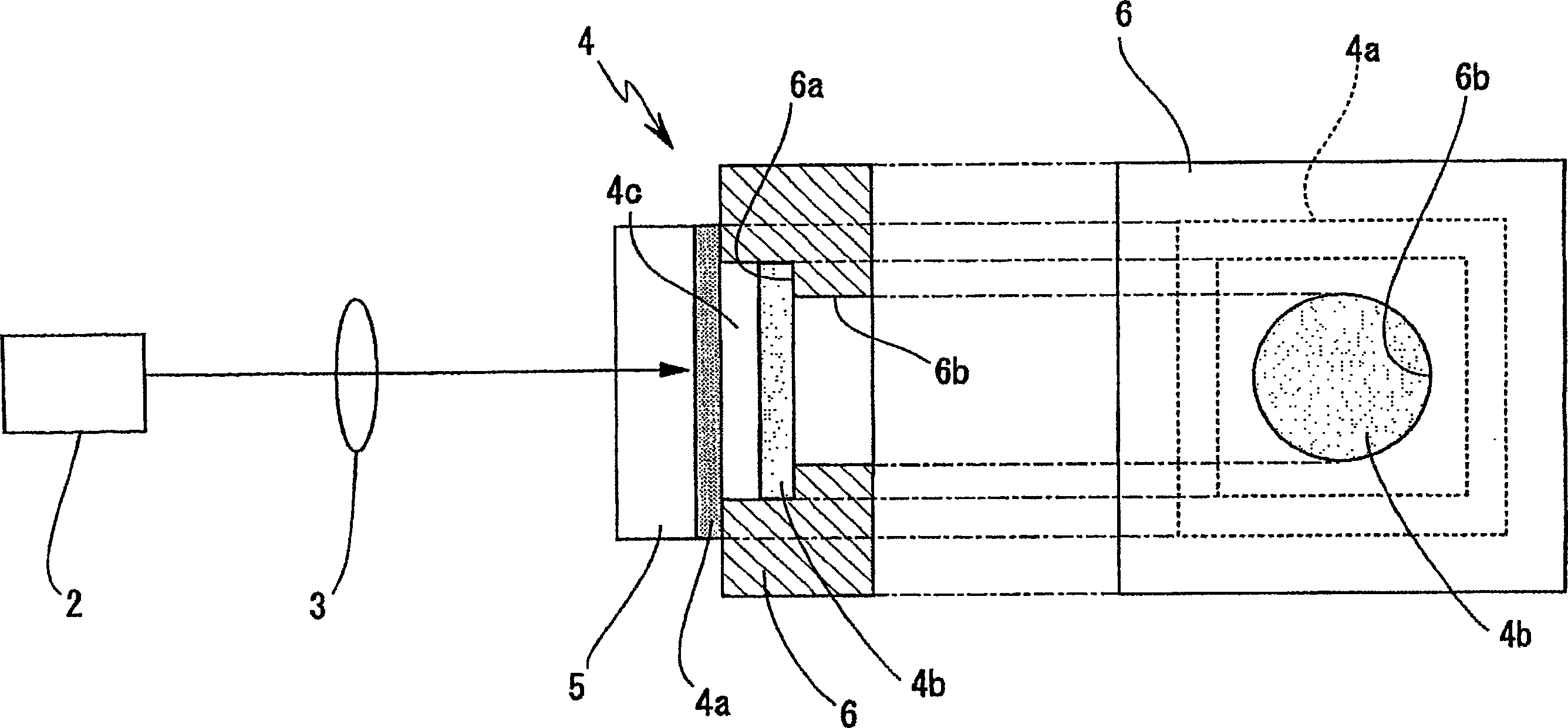

[0038] The laser generator 1 is equipped with an excitation light source 2 that generates continuous wave excitation light. The excitation light generated by the excitation light source 2 is irradiated onto the solid-state laser resonator 4 through an optical system 3 (simplified by a single lens in the figure). In addition, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com