Manufacturing method of concentrated aloe juice maintaining biological activity

An aloe vera concentrate and biological activity technology, which is applied in the directions of medical preparations containing active ingredients, food science, pharmaceutical formulations, etc. Highlights the effect of coolness, low sweetness, and a bland and astringent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

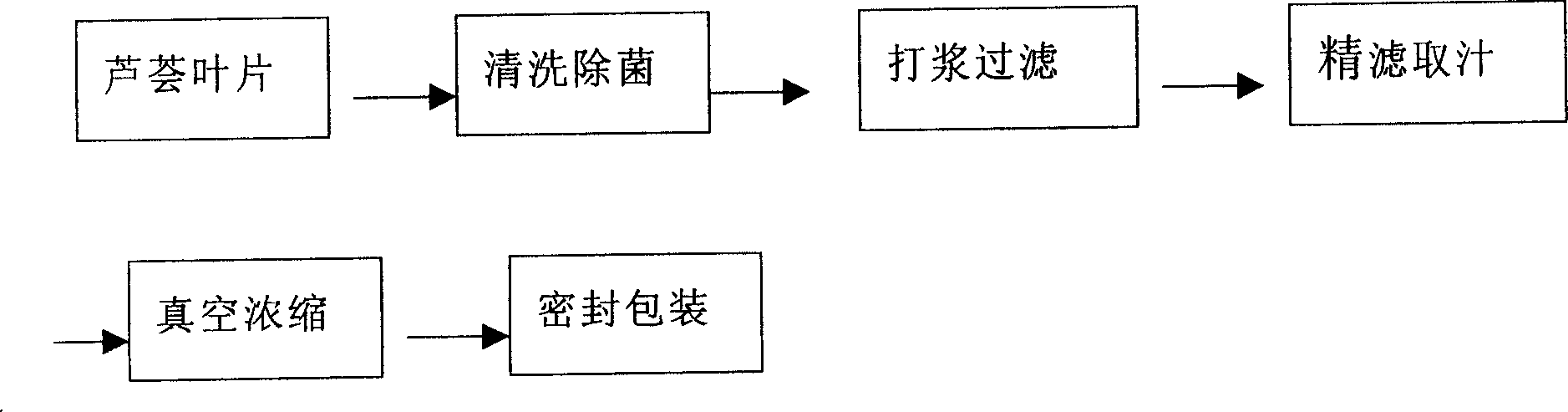

Image

Examples

Embodiment 1

[0018] 1. The invention first takes 30kg of fresh and intact aloe leaves within 2 hours of picking, and soaks them in an aqueous solution containing calcium hypochlorite 50-100ppm for 18 minutes to remove surface dirt and bacteria, and rinse them with clean water; 2. Use a beater After beating, filter the juice (liquid); 3. Use a fine filter with a pore size of 0.3μm to filter and remove bacteria and fiber fragments. The effective ingredients in aloe can pass through the filter holes but the bacteria cannot pass, so the bacteria are intercepted to achieve sterilization The purpose of; 4. Take 10Kg of aloe juice (liquid) into the vacuum concentrator, add 4Kg of sorbitol and 5g of cysteine at the same time, keep the temperature at a low temperature at 38℃, the vacuum degree is: 50-60mmHg under the column to concentrate and concentrate The time is: 16 hours; 5. When the concentrated solution reaches 5kg, the concentration is finished, and the concentrated solution is poured into a ...

Embodiment 2

[0020] 1. The present invention first takes 30 kg of fresh and intact aloe leaves within 2 hours of picking, and after peeling the aloe leaves first, soaks them in an aqueous solution containing 50-100 ppm calcium hypochlorite for 20 minutes to remove surface dirt and bacteria. Use clean water Rinse clean; 2. After beating with a beating machine, filter and extract the juice into aloe gel; 3. Use a 0.2μm fine filter to filter and remove bacteria and fiber fragments. The active ingredients in aloe can pass through the filter holes but the bacteria cannot After passing, the bacteria are intercepted and the purpose of sterilization is achieved; 4. Take 10Kg of aloe juice (liquid) into the vacuum concentrator, add 3.25Kg of sorbitol and 7.5g of cysteine at the same time, keep the temperature at 40℃, Vacuum degree: 50-60mmHg column concentration, concentration time: 10 hours; 5. When the concentrated solution reaches 5kg, finish the concentration, pour the concentrated solution into ...

Embodiment 3

[0022] 1. The invention first takes 30 kg of fresh and complete aloe leaves within 2 hours of picking, and soaks them in an aqueous solution containing calcium hypochlorite 50-100ppm for 30 minutes to remove surface dirt and bacteria, and rinse them with clean water; 2. Use a beater After beating, filter the juice; 3. Use a fine filter with a pore size of 0.1μm to filter to remove bacteria and fiber fragments; 4. Take 10Kg of aloe juice (liquid) into the vacuum concentrator, and add 2.5Kg of sorbitol and 10 cysteine at the same time G, keep the temperature at 42℃, the vacuum degree is: 50-60mmHg column concentration, the concentration time: 2 hours; 5. When the concentrated solution reaches 5kg, the concentration is finished, and the concentrated solution is poured into the sterilized container. Seal the package at low temperature. The 2:1 aloe juice concentrate is obtained. At this time, the aloe concentrate is: 50% by weight, sorbitol: 50% by weight, and cysteine: 0.2% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com