Brightness pearl for fireworks and its preparation method

A technology of bright beads and fireworks, which is applied in pyrotechnics, offensive equipment, explosives processing equipment, etc., can solve the problems of ineffective matching of smokeless powder and unsatisfactory use effect, and achieve obvious industrial promotion and application value, good viewing effect, and smoke Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

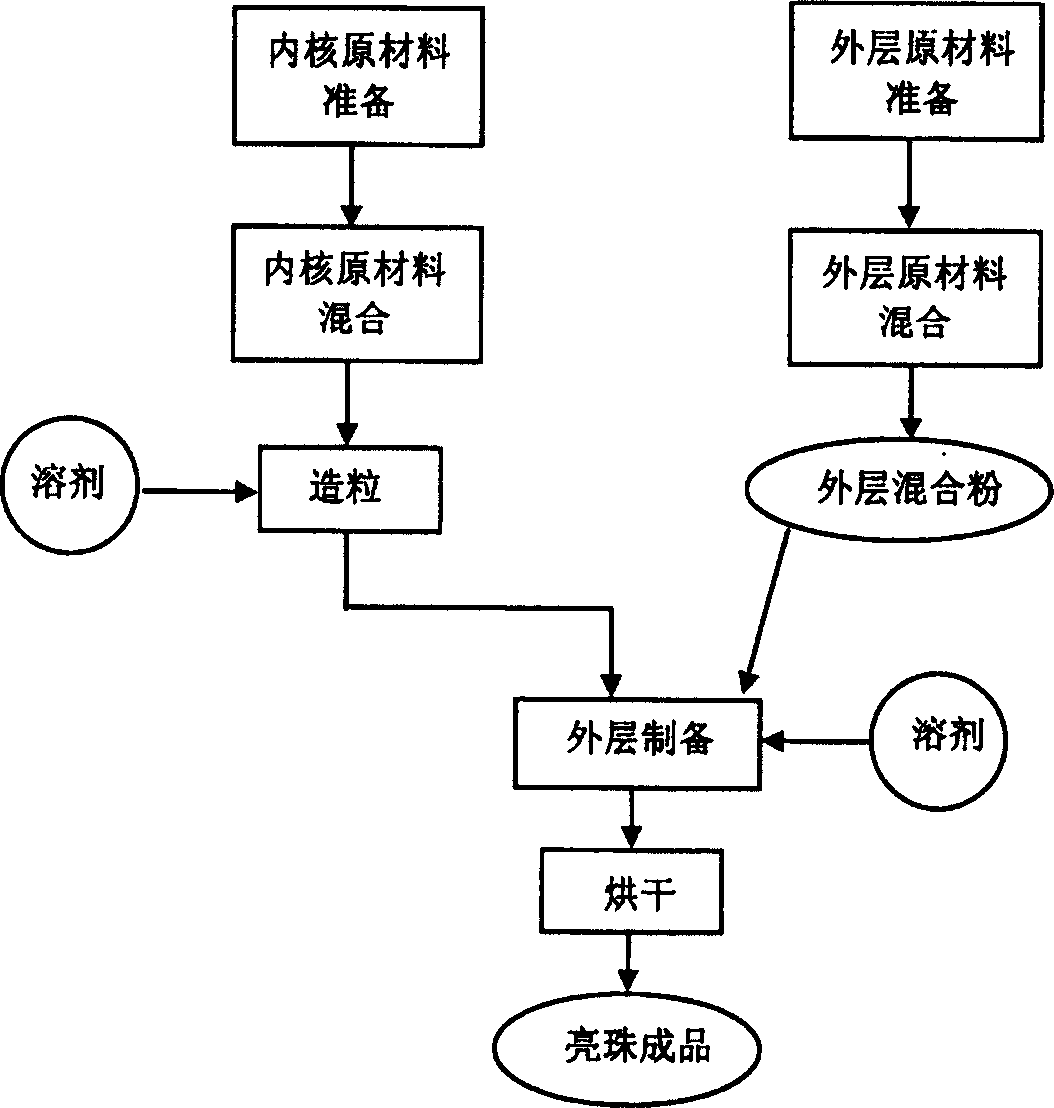

Method used

Image

Examples

Embodiment 1

[0027] 1. Bright pearl structure, composition and content

[0028] (1) Bright bead structure and core composition

[0029] Bright beads are composed of inner core and outer layer. When the inner core burns, it can provide sparks in three colors: red, green and purple. The inner core is composed of:

[0030] Red: KClO 4 SrCO 3 epoxy chip dextrin

[0031] 55% 24% 17% 4%

[0032] Green: Ba(NO 3 ) 2 Alloy powder Phenolic resin PVC KClO 4 Epoxy slice

[0033] 50% 20% 7% 7% 15% 1%

[0034] Purple: CuO KClO 4 PVC Phenolic resin Sulfur Alloy powder

[0035] 25% 45% 8% 8% 6% 8%

[0036] The outer layer is a flame retarding layer, which is formed by coating the surface of the inner core; the content of the outer layer accounts for 10% by weight in the effective medicine. The outer layer is designed for zero oxygen balance and consists of:

[0037] Potassium nitrate: 86.2%, phenolic resin: 13.8%.

[0038] 2. Preparation process and process con...

Embodiment 2

[0053]1. Bright pearl structure, composition and content

[0054] Outer layer accounts for 40% in bright pearl, and other is with embodiment one.

[0055] 2. Preparation process and process conditions

[0056] Same as Embodiment 1.

[0057] 3. The application effect of bright beads in flower spraying

[0058] Match the prepared red, green and purple beads with smokeless powder for flower spraying. Table 2 shows the charging conditions and spray discharge performance.

[0059]

Charging conditions

spout

the flame

spray

high

smoke volume

spray

time

Effective ejection

amount of pearls

GB10631-89

Requirements for spraying flowers

——

≤3 meters

——

——

——

Black powder: 11.0g

red beads # : 3.0g

green beads # : 3.0g

Purple beads # : 3.0g

end of blowing

flames ahead

<3 meters

many

...

Embodiment 3

[0065] 1. Bright pearl structure, composition and content

[0066] The formula for the outer layer is 84.2% of potassium perchlorate, 15.8% of phenolic 2123 resin, and the others are the same as in Example 1.

[0067] 2. Preparation process and process conditions

[0068] Same as Embodiment 1

[0069] 3. The application effect of bright beads in flower spraying

[0070] Match the prepared red, green and purple beads with smokeless powder for flower spraying. The charging conditions and spray discharge performance are shown in Table 3.

[0071]

Charging conditions

spout

the flame

spray

high

smoke volume

spray

time

Effective ejection

amount of pearls

GB10631-89

Requirements for spraying flowers

——

≤3 meters

——

——

——

Black powder: 11.0g

red beads # : 3.0g

green beads # : 3.0g

Purple beads # : 3.0g

end of blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com