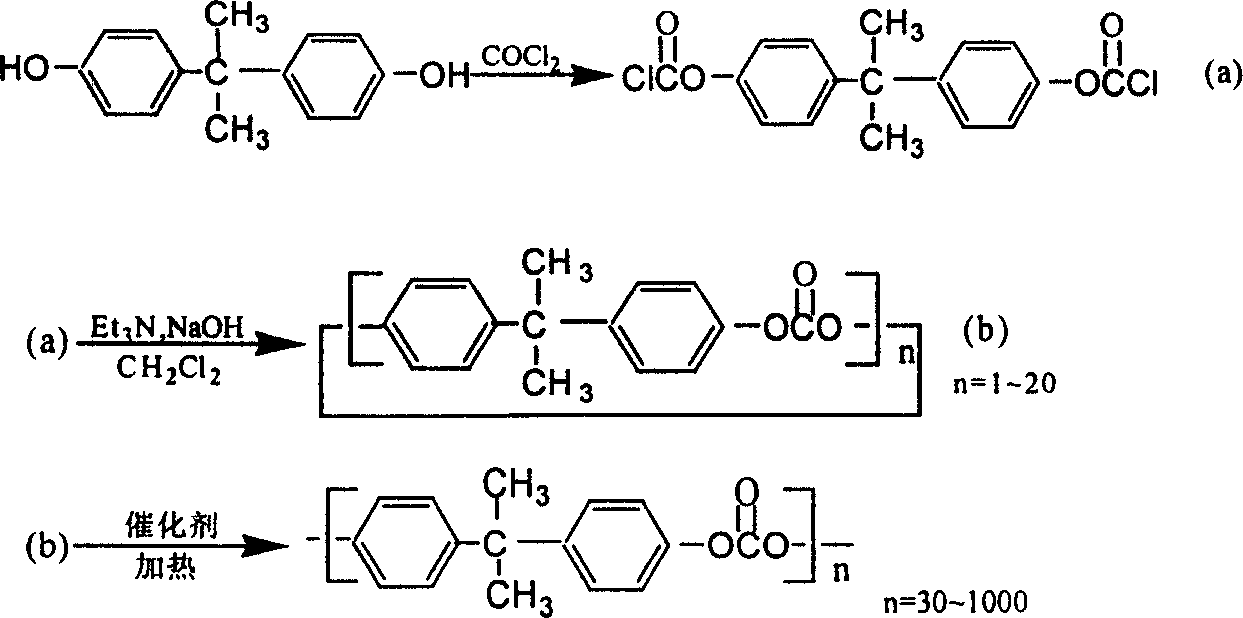

Synthesis process for polycarbonate with super high molecular weight

An ultra-high molecular weight, polycarbonate technology, applied in the field of organic high polymer preparation, can solve the problems of inability to carry out industrial production, the content cannot be too high, and the pretreatment procedure is long, and achieves convenient industrial production, simple reaction process, Avoid the effects of the use of phosgene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Non-limiting examples are described as follows:

[0028] 1. Add 20.326 grams of bisphenol A, 3.265 grams of sodium bisulfite, and 100 milliliters of 10% sodium hydroxide aqueous solution to a 250-milliliter four-neck flask equipped with a stirrer, a condenser, a dropping funnel, and a thermometer. Stir until the bisphenol A is completely dissolved, then maintain the temperature at 30-37°C, and start to add a saturated solution of triphosgene in methylene chloride (containing 9.881 g of triphosgene) dropwise. After about one hour, the addition of triphosgene is completed, and then add The phase transfer agent, tertiary amine, chain extender and 10 ml of 25% NaOH solution were reacted for another 2.5 hours, washed repeatedly with deionized water until the aqueous phase contained no chloride ions, added acetone and stirred quickly, and the precipitate was separated. The viscosity molecular weight of the product is 84033, and the yield is 98.4% based on bisphenol A, and 87....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com