Detection method for resonance frequency of resonant type piezoelectric microsensor

A resonant frequency, micro-sensor technology, applied in frequency measurement devices, measurement of force by measuring the frequency change of stressed vibration elements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

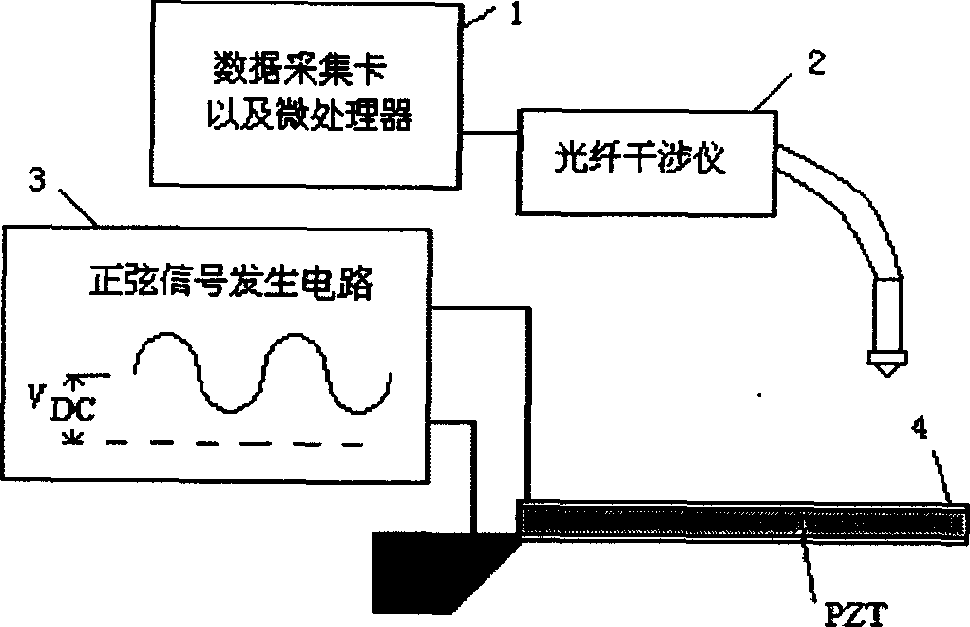

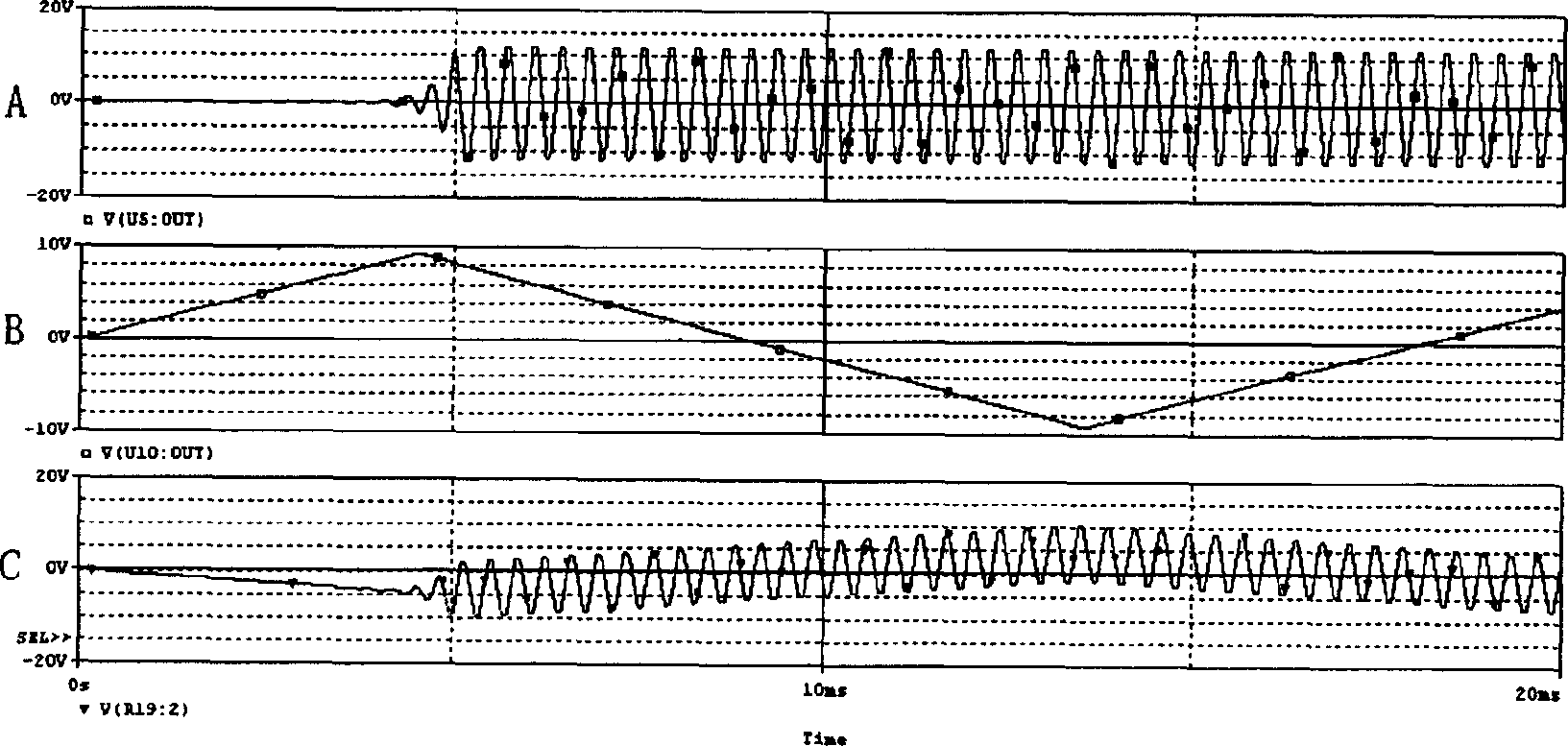

Method used

Image

Examples

Embodiment Construction

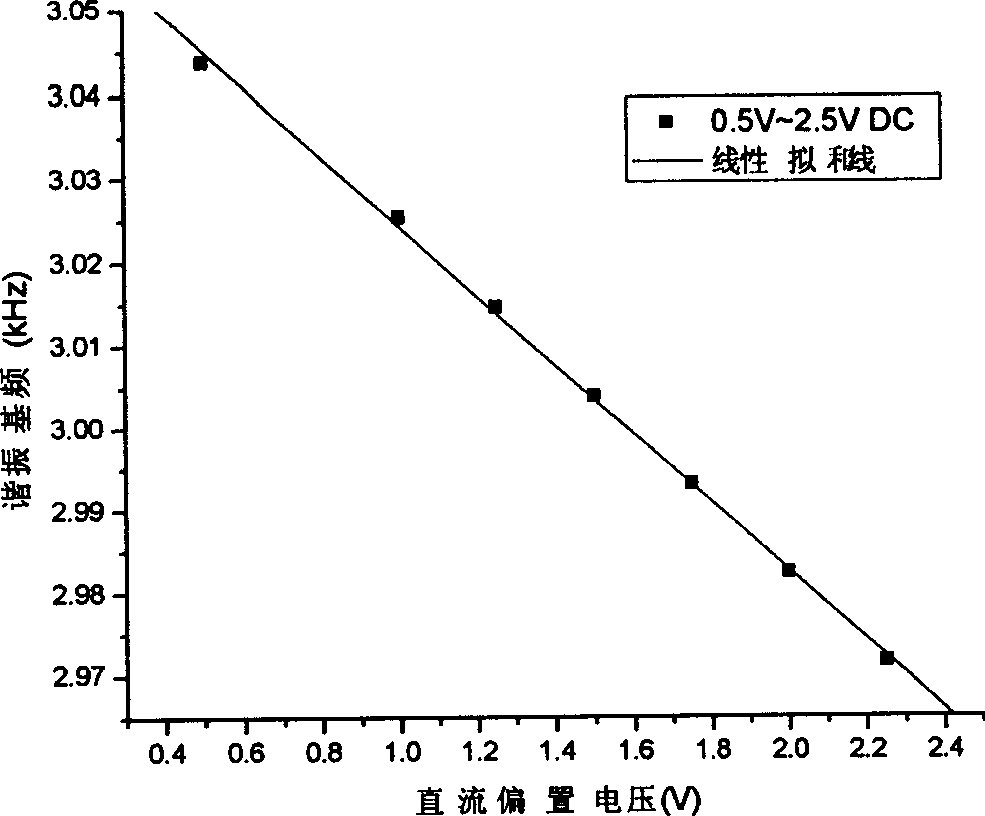

[0023] The self-developed resonant PZT micro-cantilever sensor is detected by using the method of the invention. The dimensions of the PZT microbeam structure are 860 microns long, 300 microns wide, and 2 microns thick. PZT material is made of Korean INOSTEK The company's commercial products are prepared by the sol-gel process, and the precise thickness of the PZT layer in the microbeams is 210nm. After scanning the DC bias voltage of the excitation signal, it is found that the DC bias voltage and the resonant frequency of the PZT microbeam are related by a second-order function. When the DC bias electric field is less than 1×10 7 At V / m, there is a linear region between the DC bias voltage and the resonant frequency of the PZT microbeam. See image 3.

[0024] The experimentally measured relationship between the two is:

[0025] f=3.06598-0.04167U

[0026] f is the resonant frequency (kHz), and U is the DC bias voltage (V) applied to the PZT. From this measurement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com