Piezoelectric/electrostrictive material and process for production thereof

一种电致伸缩材料、压电的技术,应用在压电/电致伸缩器件的制造/组装、压电/电致伸缩/磁致伸缩器件、电路等方向,能够解决压电/电致伸缩特性差、很少执行元件或传感器使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Using BaCO 3 , TiO 2 , Nb 2 O 5 , SrCO 3 , CuO as the starting material, the composition in the porcelain, the replacement amount of strontium to barium, A / B=(barium + strontium) / titanium (molar ratio) and Nb 2 O 5 , CuO were weighed according to the ratios shown in Table 1, respectively. These raw materials, 150 grams of zirconia balls with a diameter of 2 mm, and 400 grams of solvent as a medium, were wet mixed with a ball mill for 64 hours, and the particle size of the primary particles of each raw material was 1 micrometer or less.

[0031] After the obtained mixture was dried, it was calcined at a temperature of 900° C. for 2 hours in an air atmosphere, and the obtained calcined product was pulverized with a ball mill. During the pulverization process, the amount of zirconia balls, the pulverization time, etc. were appropriately adjusted, and the specific surface area of the powder after the pulverization treatment (hereinafter referred to as pulverized pow...

Embodiment 2

[0038] Next, using the same starting materials as in Example 1, in the composition of the porcelain material, 1 mol% of barium was replaced by strontium, A / B=(barium+strontium) / titanium (molar ratio)=1.005, Nb 2 O 5 , CuO were weighed according to external preparation and addition of 0.1 wt % and 0.2 wt % components, respectively. These raw materials were mixed in the same manner as in Example 1

[0039] The obtained mixture was subjected to calcination treatment in the same manner as in Example 1, and the obtained calcined product was subjected to pulverization treatment, and the specific surface area of the powder after pulverization treatment was adjusted as shown in Table 2.

[0040] Thereafter, as in Example 1, the pulverized powder was molded, and the molded product was sintered at the sintering temperature shown in Table 2 to obtain a ceramic material.

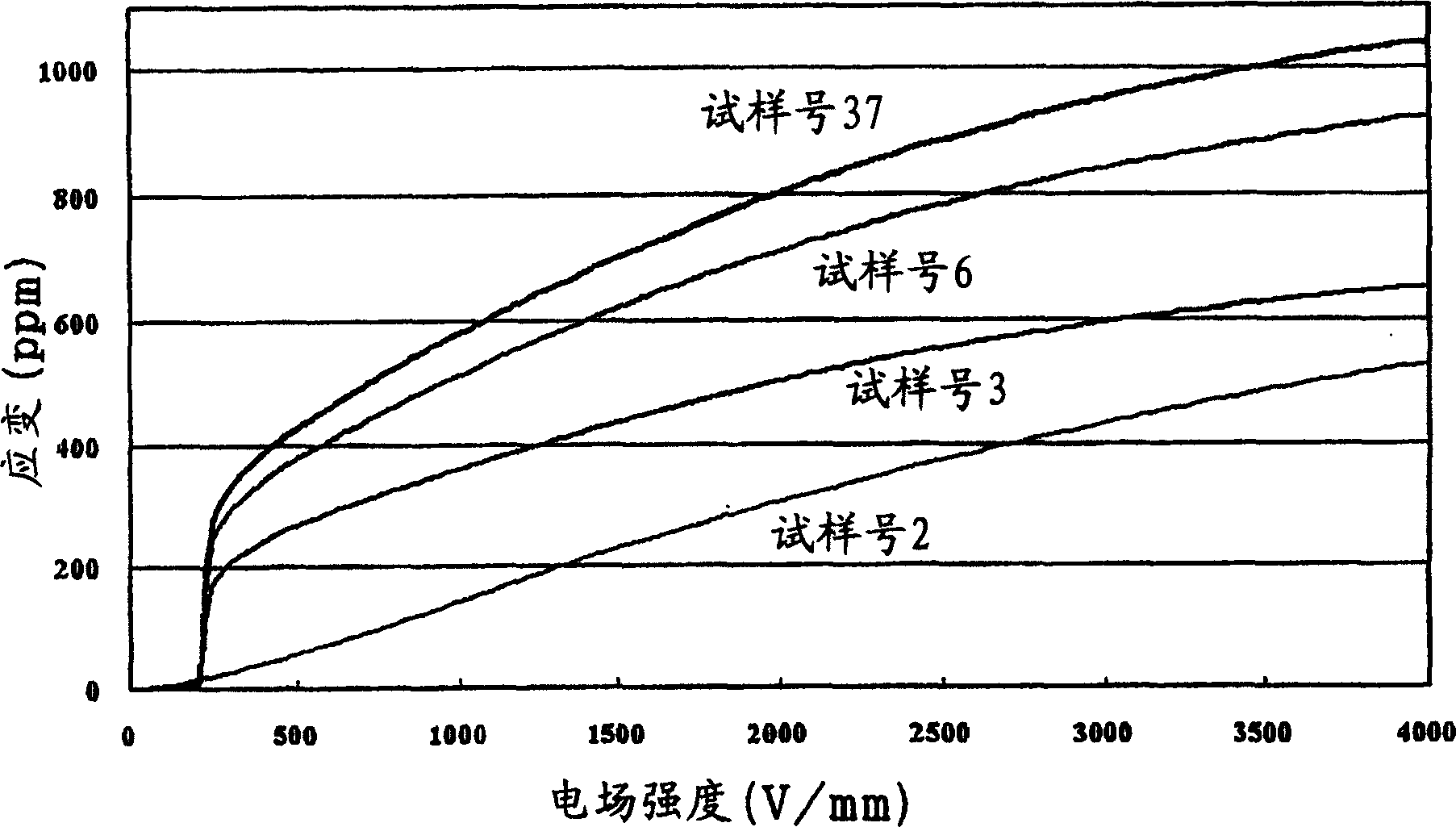

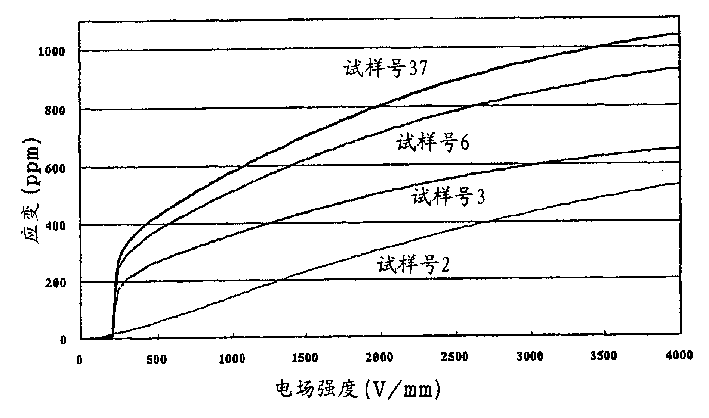

[0041] Next, after polarization treatment was carried out in the same manner as in Example 1, the strain in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com