Evaporative cooling electromagnetic iron eliminator

An electromagnetic iron remover and evaporative cooling technology, applied in high gradient magnetic separators, magnetic separations, indirect heat exchangers, etc., can solve the problems of low winding current density, affect heat dissipation, bulky and other problems, and achieve volume and weight reduction. , The effect of uniform temperature distribution and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

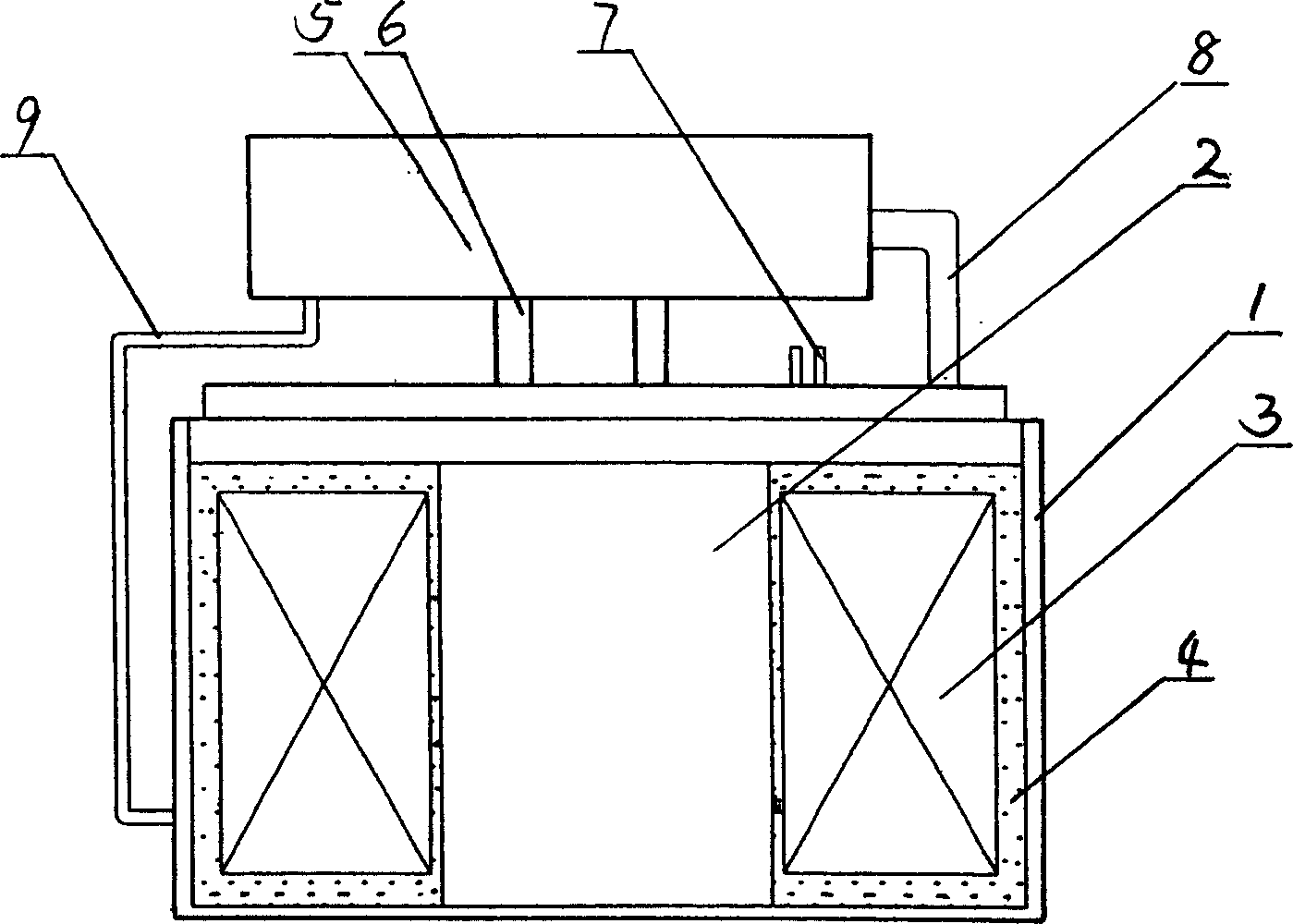

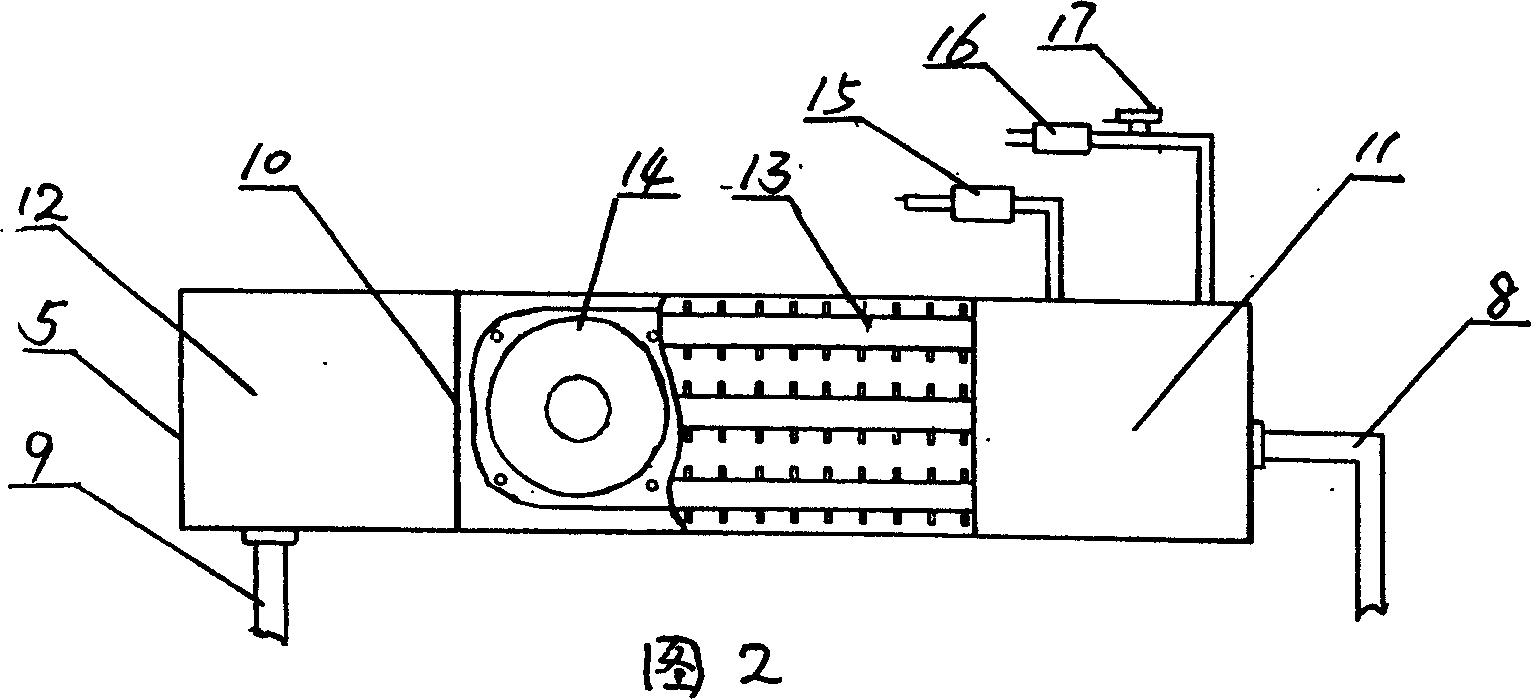

[0017] Embodiment 1: An evaporative cooling type electromagnetic iron remover, including a housing 1 and an iron core 2 arranged in the housing 1, a coil 3 is wound around the outer periphery of the iron core, and the coil lead wire 7 is drawn from the upper part of the housing 1, and the housing 1 An evaporative cooling medium 4 is installed in the inner cavity, and the evaporative cooling medium 4 adopts one of the evaporative cooling medium Fla, the evaporative cooling medium 4310 or the evaporative cooling medium 3000, and the coil 3 is completely immersed in the evaporative cooling medium. A condenser 5 is installed on the top of the housing 1 through a bracket 6, and one end of the condenser 5 is connected with a gas collecting pipe 8, and the lower end of the gas collecting pipe 8 communicates with the upper part of the housing 1, and the lower part of the condenser 5 is connected with a liquid return pipe 9, which returns The lower end of the liquid pipe 9 is connected ...

Embodiment 2

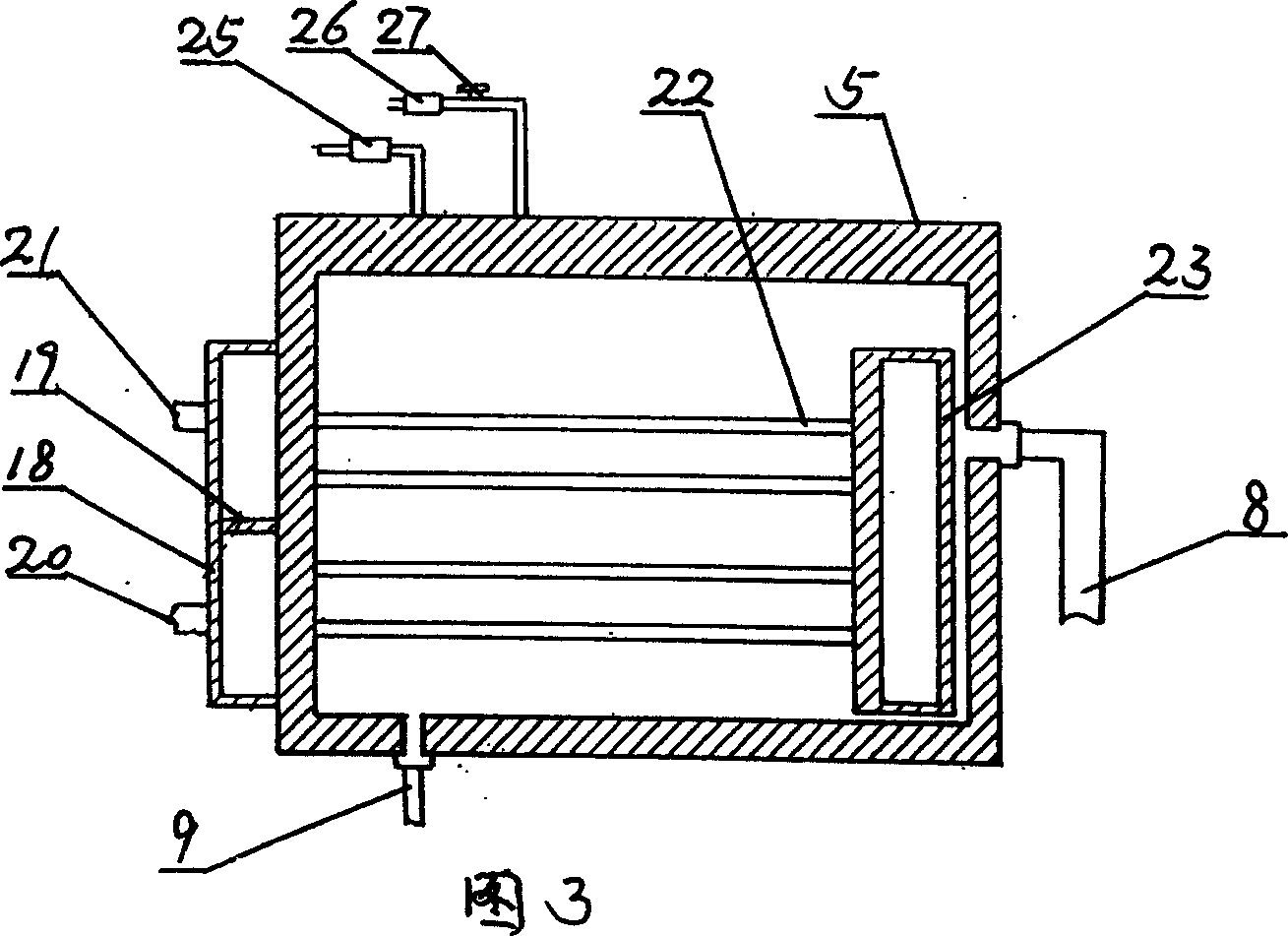

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a part of the coil 3 is immersed in the evaporative cooling medium, and the coil height of the immersed part is greater than 1 / 3 of the total coil height. The condenser 5 is water-cooled, and it has a cylindrical shell. The shell is equipped with a plurality of condenser pipes 22 through which secondary cooling water is passed inside. The inner end of the condenser pipe 22 is connected to an inner water box 23 installed in the shell. Connection, the outer end of the condensation pipe 22 is connected with the outer water box 18 installed on the outside of the shell, and there is a transverse partition 19 inside the outer water box 18, which divides the outer water box 18 into a lower water inlet chamber and an upper water outlet chamber, A cooling water inlet pipe 20 is connected to the water inlet chamber, and a cooling water outlet pipe 21 is connected to the water outlet chamber. A pressure ...

Embodiment 3

[0021] Embodiment 3: The difference between this embodiment and the above embodiment is that the cooling medium 4 is a mixture of evaporative cooling medium and transformer oil, the weight ratio of evaporative cooling medium and transformer oil is 1:2, and the coil 3 is completely immersed in the cooling medium. medium.

[0022] Due to the high current density of the electromagnetic separator of the present invention, the required coils are reduced, and the corresponding volume and weight are also reduced, and the boiling heat transfer coefficient of the heating surface is several times higher than that of the single-phase fluid convective heat transfer. Dozens of times, the cooling effect is good, and in the event of a failure, because the evaporative cooling medium is non-flammable, it will ensure that the electromagnetic separator will not fire. Therefore, the evaporative cooling electromagnetic iron remover has a high degree of safety and considerable economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com