Structure of king crab type light dyke-dam and method

A dam, lightweight technology, applied in the field of dam construction, which can solve the problems of water leakage, poor quality of anti-scour masonry, and reduction of effective stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

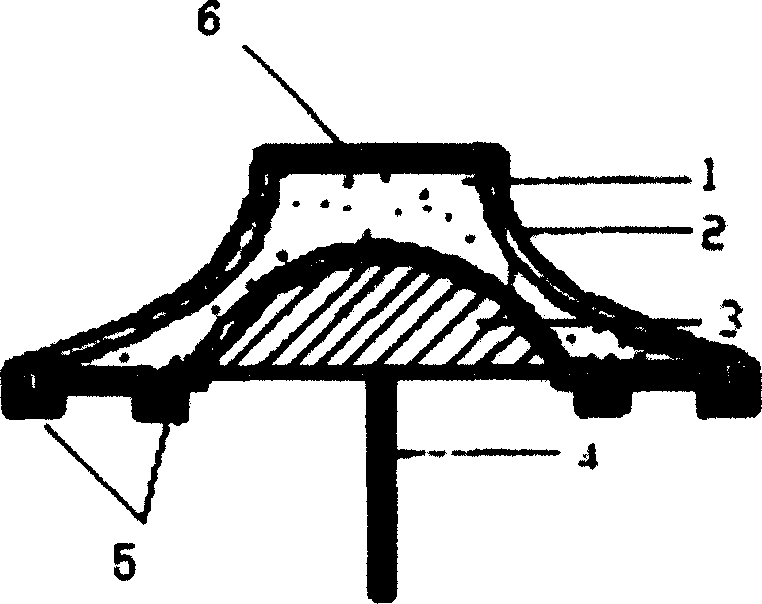

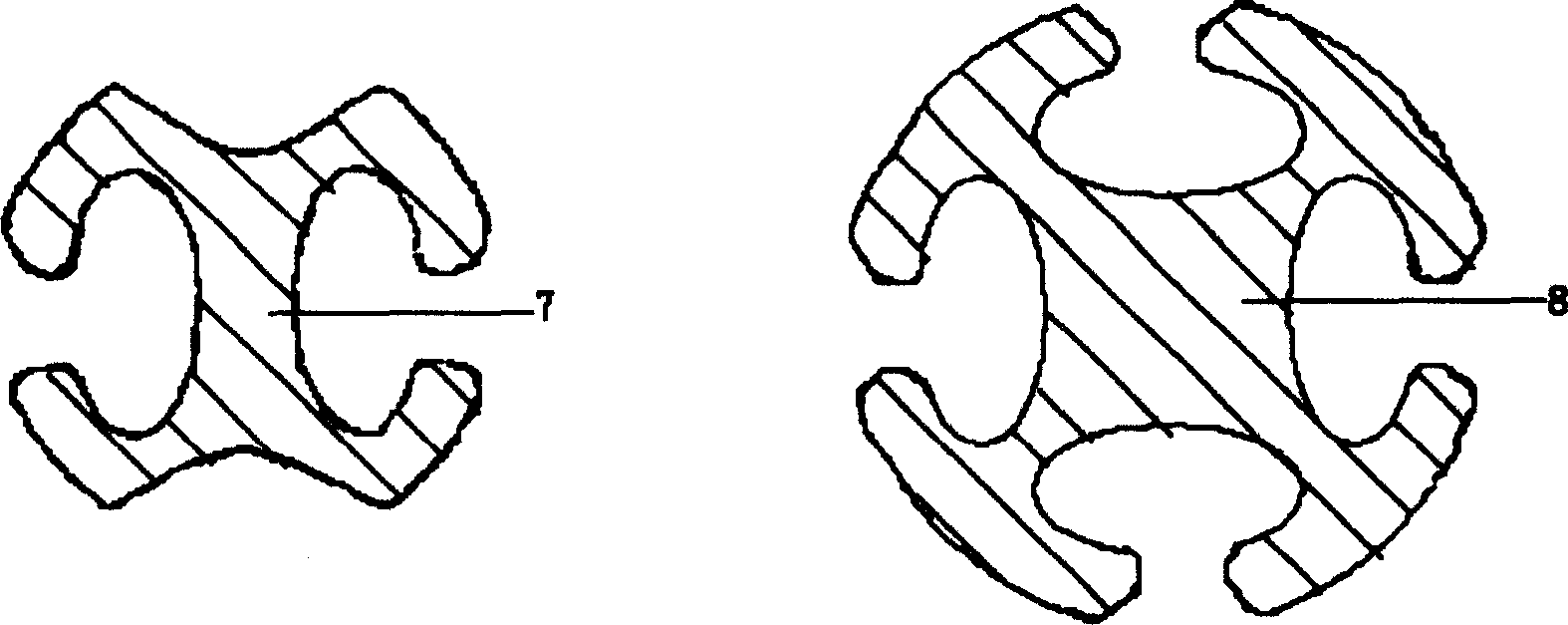

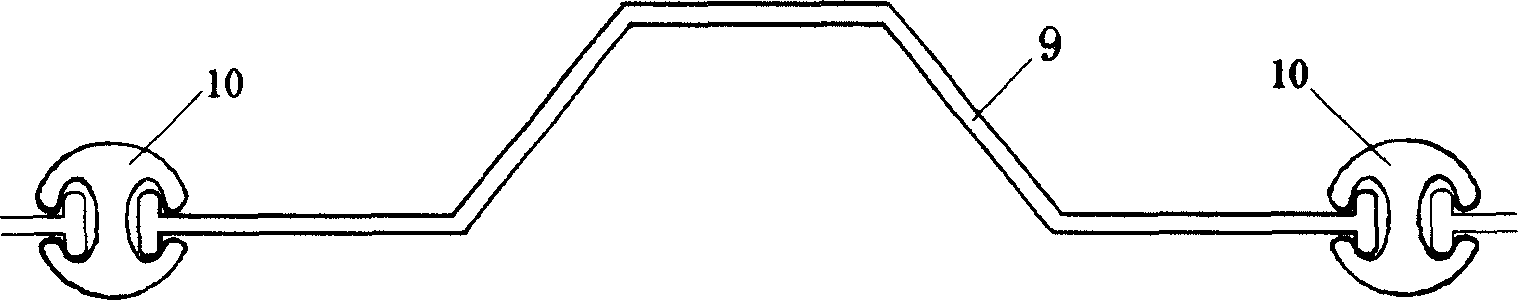

Embodiment 1

[0022] Embodiment 1, the beach oil exploration project of a certain oil field builds a drilling platform (artificial island) and a transportation channel (dam) in the intertidal zone. It takes several years when there is oil, and it is abandoned if there is no oil. It was originally built with stone cubes, but due to the weak foundation and the erosion of the tide, it sank within a few days, sinking and filling, filling and sinking. Not only the quantity is big but the cost is high, and it can't work normally. For this reason, according to foundation and actual conditions, the dam body type adopts the method of the present invention, and size is: dam height 5m, dam crest 5m, 17m at the bottom of the dam. Since the dam crest is required to be open to traffic, the outer shell is reinforced concrete, the dam crest cover plate is 15cm thick, and the other hard shell is 10cm; 3 ; The lightweight cushion is foam, with a bulk density of 0.4kN / m 3 . It is assumed that the dam crest...

Embodiment 2

[0023] Embodiment 2, a sluice reconstruction project.

[0024] Due to the low drainage standard of the originally designed 2×3m gate, it cannot meet the flood control and drainage requirements. In order to enhance the flood discharge capacity, the original two-hole sluice was abolished and a 5×5m five-hole sluice was rebuilt. The upstream of the project is the reservoir area, and the downstream is the sea surface, which is greatly affected by typhoons, rainstorms and tides. There are both floods and sea tides, and the hydrological changes are relatively large, which brings difficulties and risks to the construction and maintenance of the cofferdam. Moreover, according to the traditional cofferdam, the foot of the weir is wide, the amount of earthwork is large, the stability is poor, and the demolition is not complete. By adopting the structural method of the present invention, an arched steel plate hard shell structure with a height of 7m and a width of 17m is set, and 0.5m t...

Embodiment 3

[0025] Example 3, expansion project of water inlet of a water turning station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com