Method of producing electrochemical device, and the electrochemical device

A manufacturing method and electrochemical technology, applied in the direction of electrode manufacturing, electrochemical generator, secondary battery manufacturing, etc., can solve the problems of impracticality, decline of charge and discharge characteristics, and lack of integration of laminated bodies, etc., and achieve the effect of reliable formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

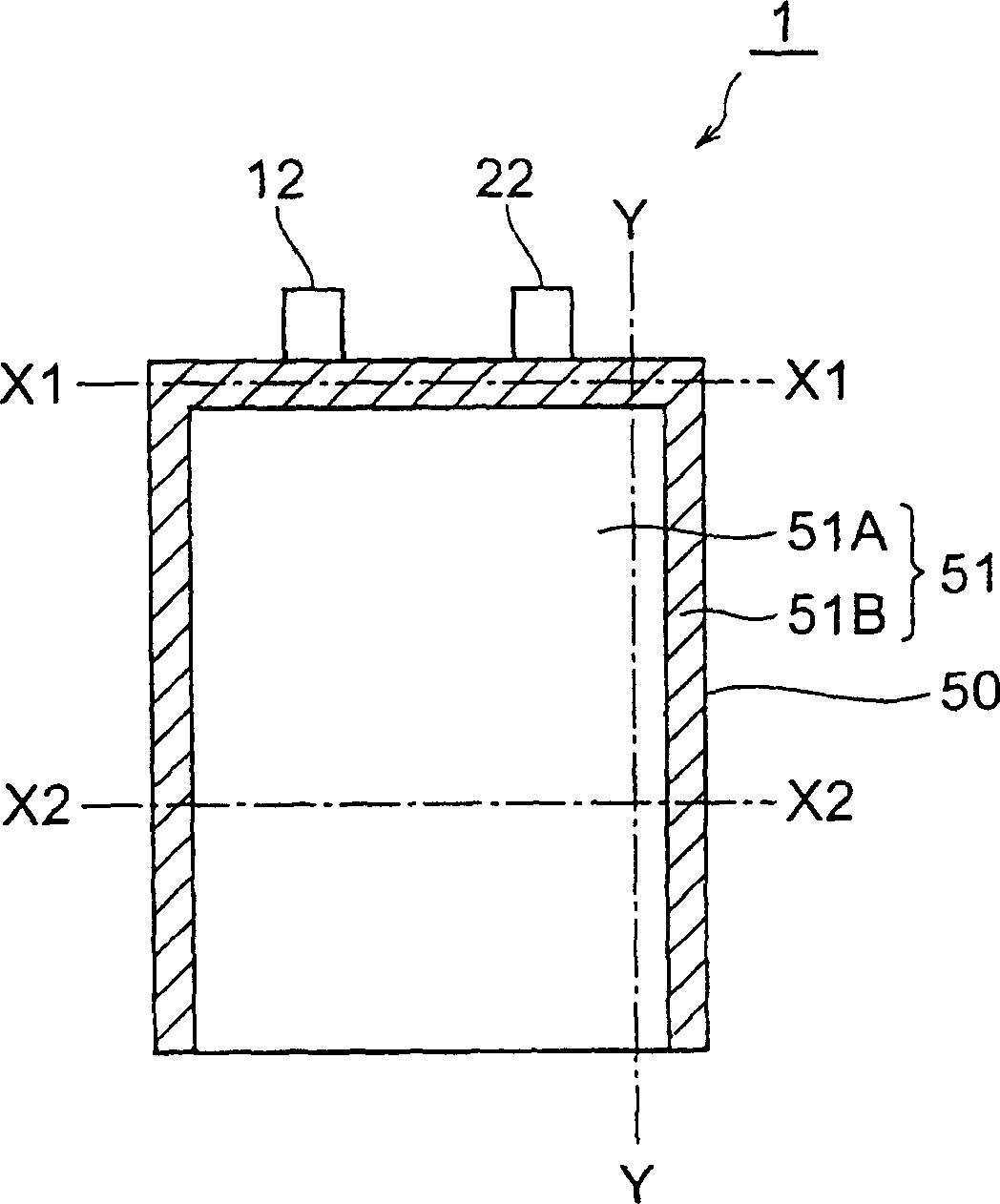

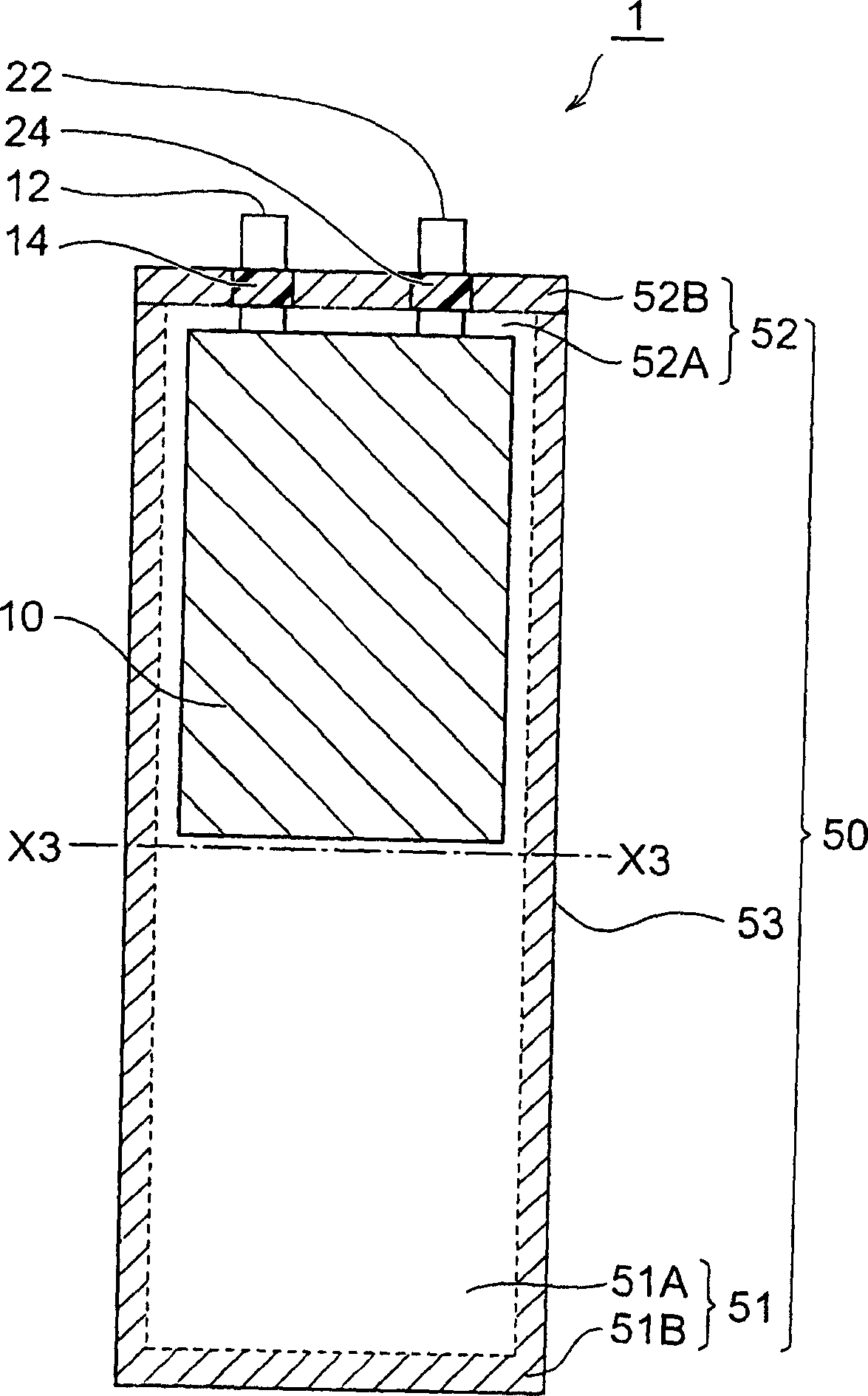

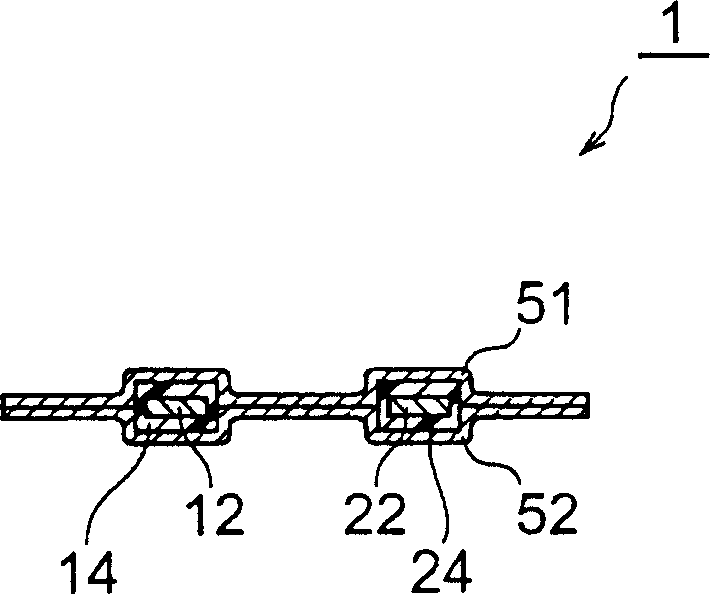

[0169] Through the following steps, the production with figure 1 The electrochemical device shown is an electrochemical device (electric double layer capacitor) of the same structure.

[0170] (1) Preparation of electrodes

[0171] The anode (polarizable electrode) and the negative electrode (polarizable electrode) were produced by the following procedure. First, the activated carbon material (activated carbon) that has been activated, the thermoplastic resin (fluororubber (T B=200°C) and conduction aid (carbon black) according to their mass ratio of carbon material: conduction aid: binder = 8:1:1 ratio, put it into MIBK (methyl isocyanate) as a solvent butanone) and then mixed to prepare a coating liquid for electrode formation (hereinafter referred to as "coating liquid L1")

[0172] Next, the coating liquid L1 was uniformly coated on one surface of a current collector (thickness: 50 μm) made of aluminum foil. Then, MIBK was removed from the coating film by drying treatm...

Embodiment 2

[0185] An electrochemical device was fabricated by the same procedures and conditions as the electrochemical device of Example 1 except that the heat treatment temperature T1 in the heat treatment step was set to 200°C.

Embodiment 3

[0187] In addition to making the pressure of the heat treatment process to 60kg / cm 2 Otherwise, an electrochemical device was produced by the same steps and conditions as the electrochemical device of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com