III-V family high brilliancy composite coloured or white light luminous diode

A technology of light-emitting diodes and high brightness, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems that the brightness of white light needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

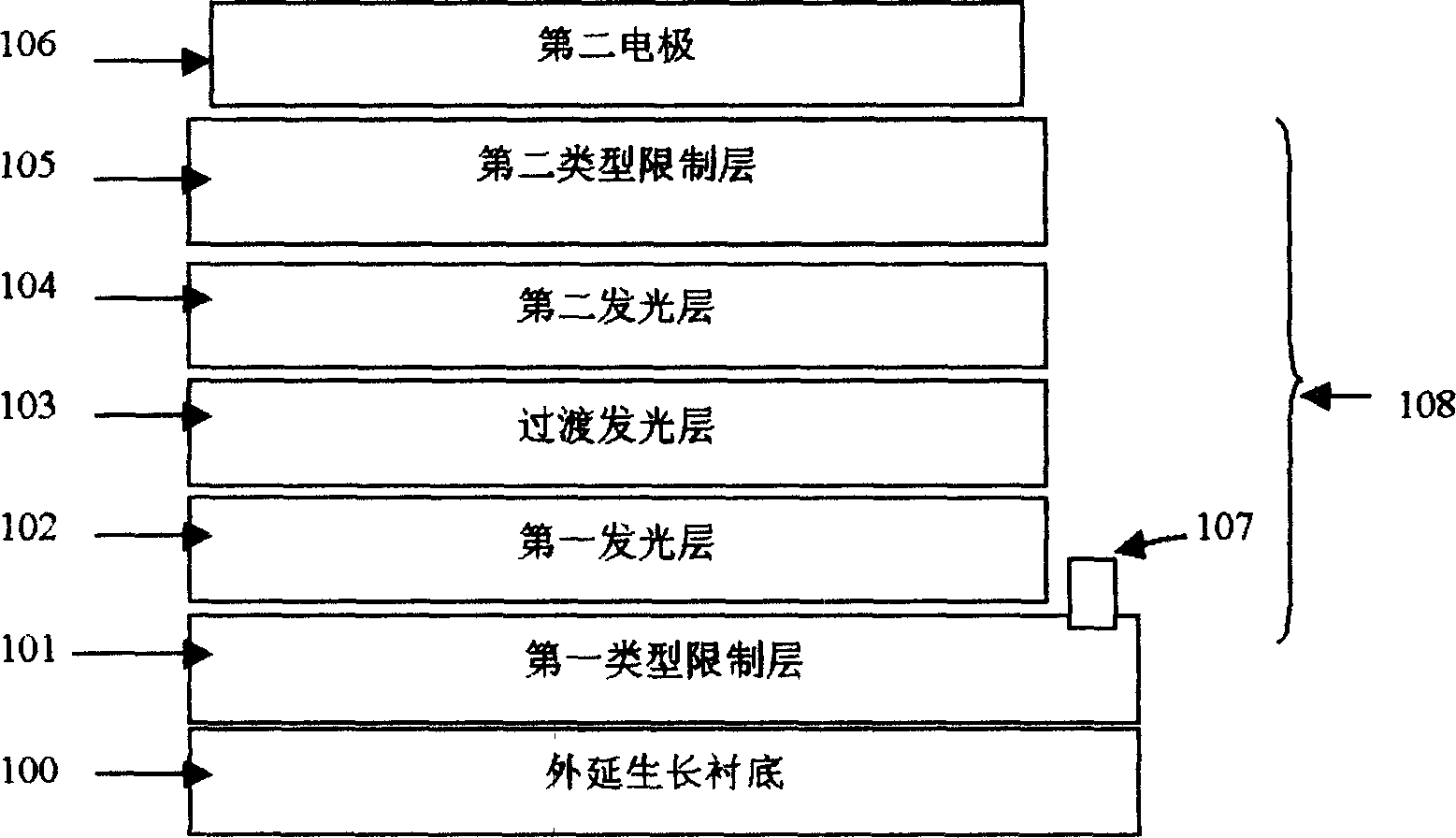

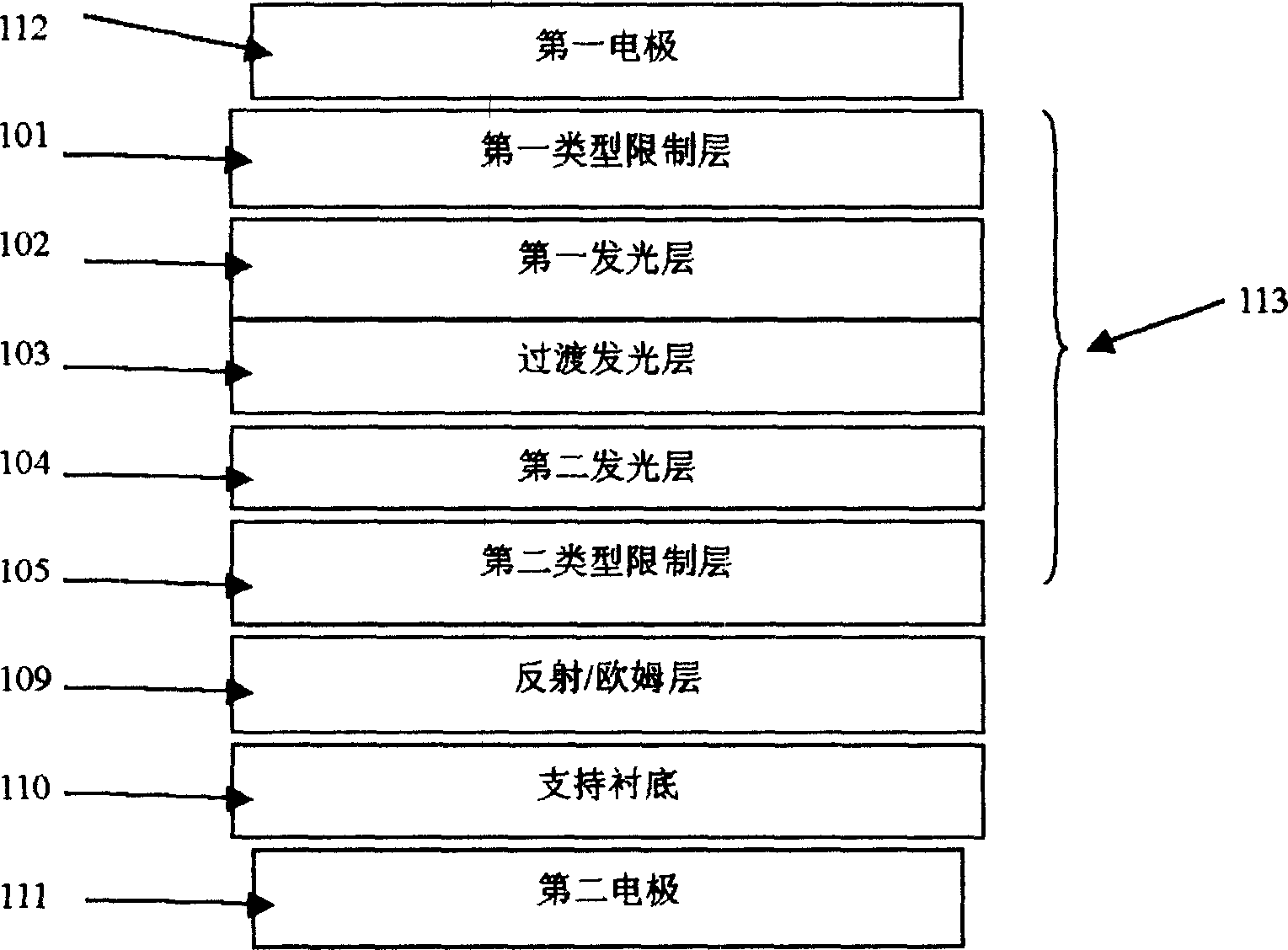

[0031] (A) The light-emitting layer material of the high-brightness composite color or white light-emitting diode of the present invention is selected from a group of materials, and the materials include, but are not limited to: (aluminum x gallium 1-x) y indium 1- y phosphorus z nitrogen 1-z, wherein 0≤x<1, 0<y≤1, 0≤z<1. The intensity and color of the emitted light can be controlled by adjusting the thickness of the different luminescent layers and the ratio of the constituents (i.e. the values of "x", "y", and "z" of the constituents of the luminescent layer), so that the composite light has color requested.

[0032] The first-type confinement layer is epitaxially grown on the growth substrate, the first light-emitting layer is epitaxially grown on the first-type confinement layer and emits light of the first wavelength, the transitional light-emitting layer is epitaxially grown on the first light-emitting layer, and the second light-emitting layer grows on the transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com