Rotating type compressor

A technology of rotary compressors and cylinders, applied to rotary piston/oscillating piston pump components, mechanical equipment, variable displacement pump components, etc., which can solve the problem of increased assembly workload, reduced productivity, and complex main bearing processing etc. to achieve the effects of easy processing, improved productivity, and reduced assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

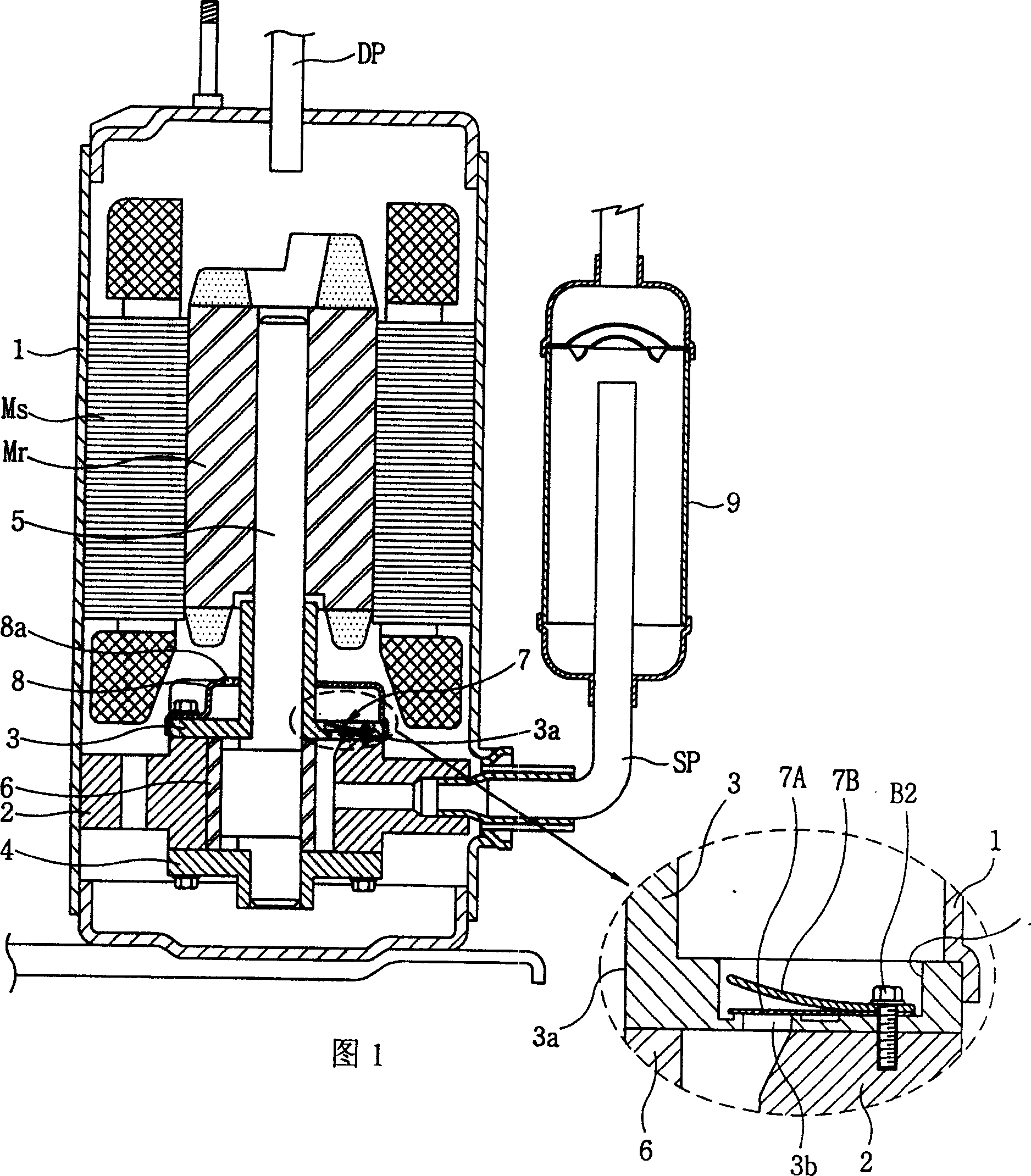

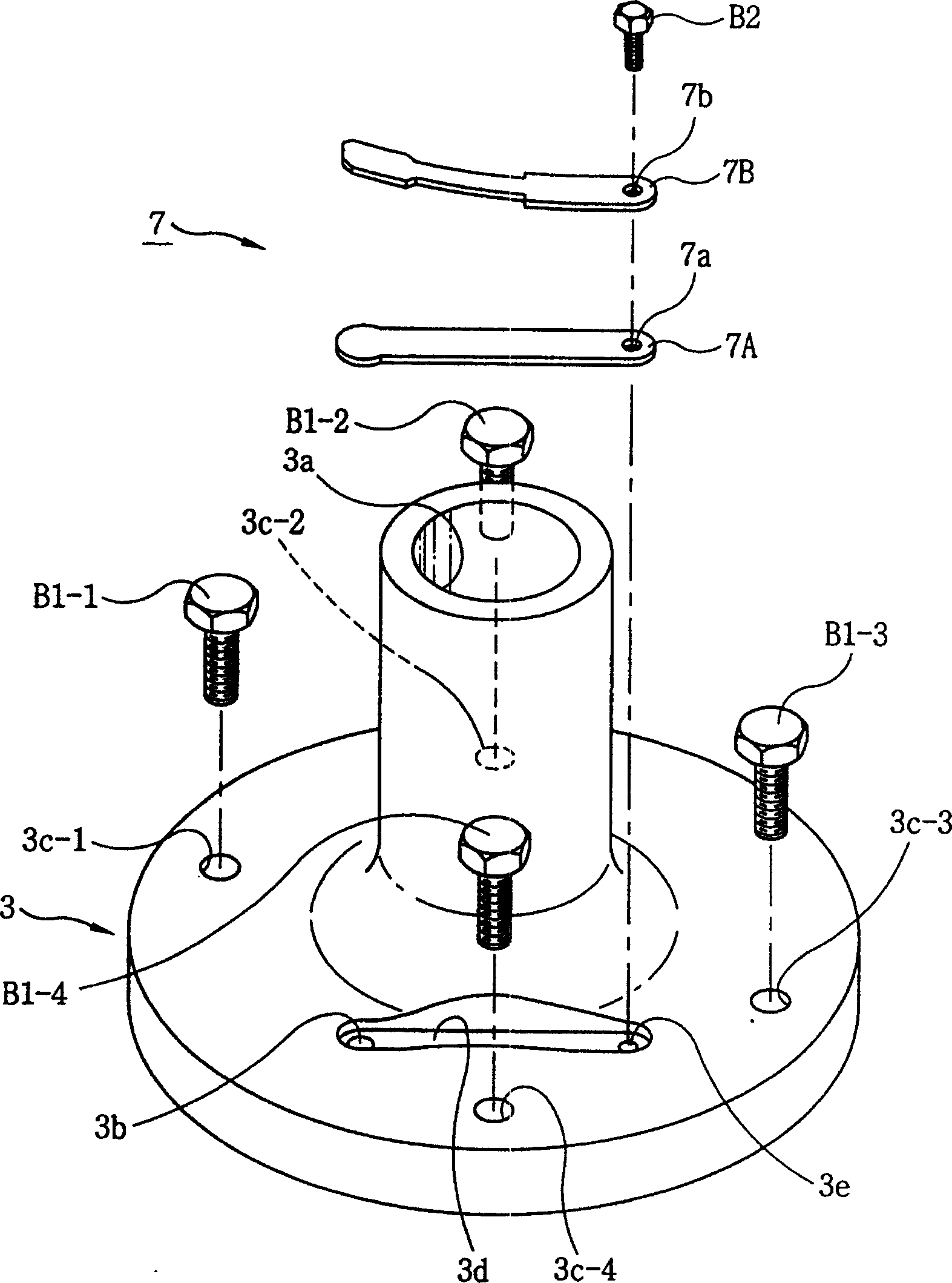

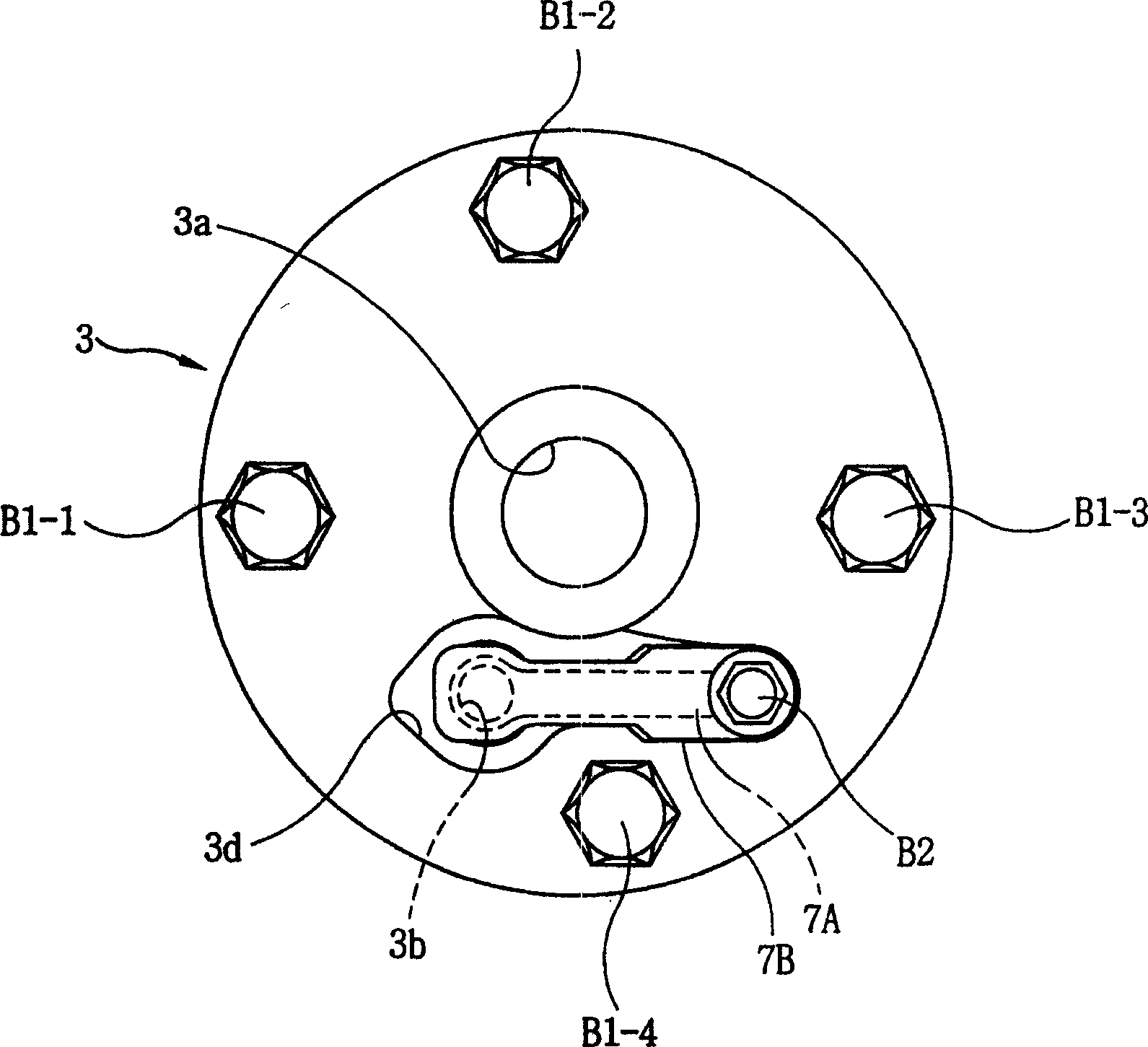

[0040] Hereinafter, a detailed description will be given with reference to the drawings of the rotary compressor according to the present invention.

[0041] 4 is a longitudinal sectional view of one example of a rotary compressor equipped with a reed type discharge valve according to the present invention, Figure 5 is an exploded oblique view of the reed type exhaust valve according to the present invention, Image 6 is a plan view of the assembled state of the reed type exhaust valve according to the present invention.

[0042] As shown in the figure, the rotary compressor with the reed type exhaust valve assembly according to the present invention is filled with a certain amount of refrigerated oil, and communicates with the casing where the gas suction pipe (SP) and the gas discharge pipe (DP) are arranged. (11); be arranged on the top of the casing (11) to generate the electric structure part of the rotating force; be arranged on the bottom of the casing (11), and utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com