Pressure release valve in electric water heater

An electric water heater and pressure relief valve technology, which is applied to safety valves, balance valves, valve devices, etc., can solve problems such as the inability to guarantee the uniformity of the internal pressure relief pressure, the difficulty in assembling and disassembling valve components, and the inability to adjust the balance pressure. Easy replacement, easy assembly and disassembly, and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

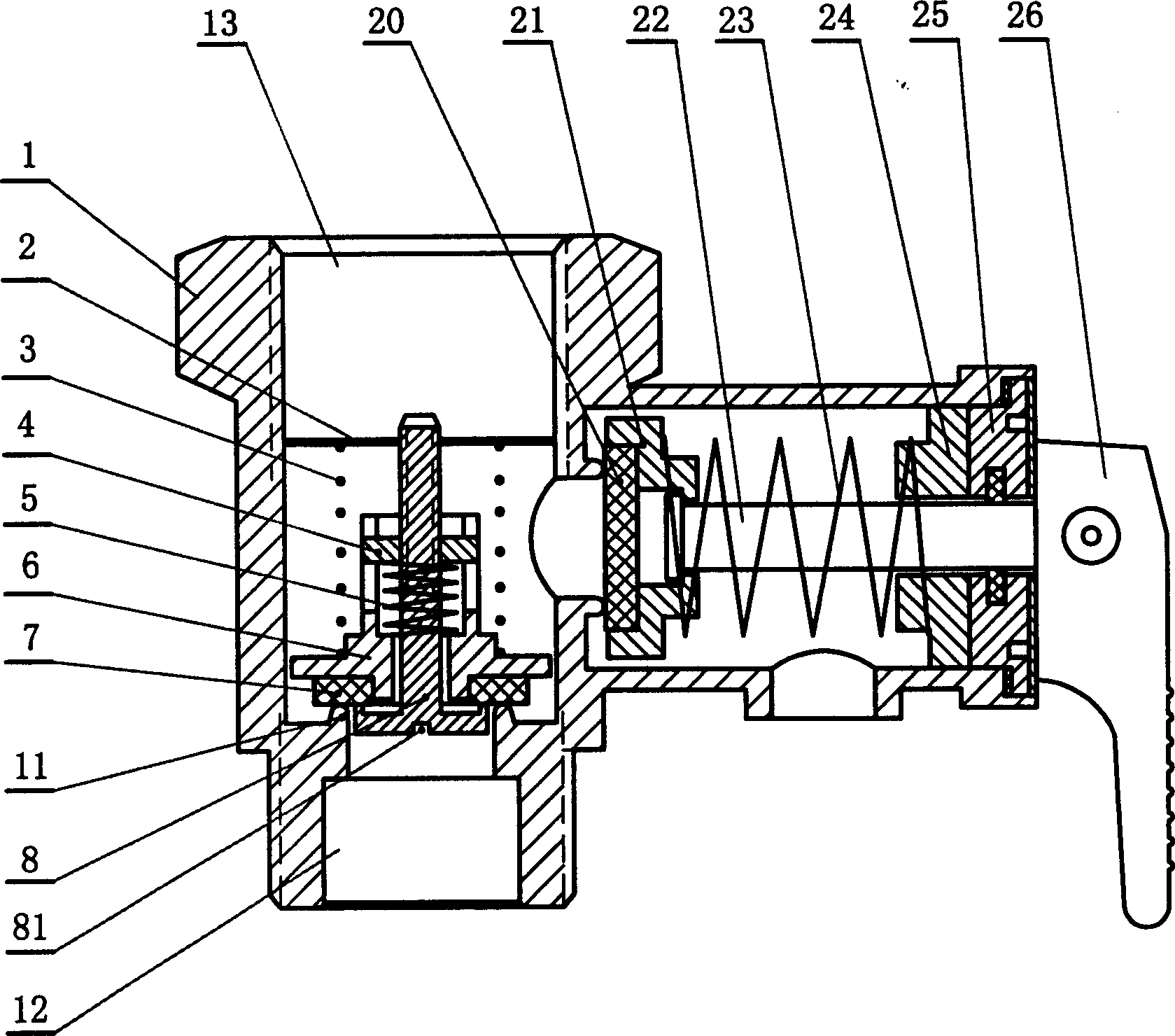

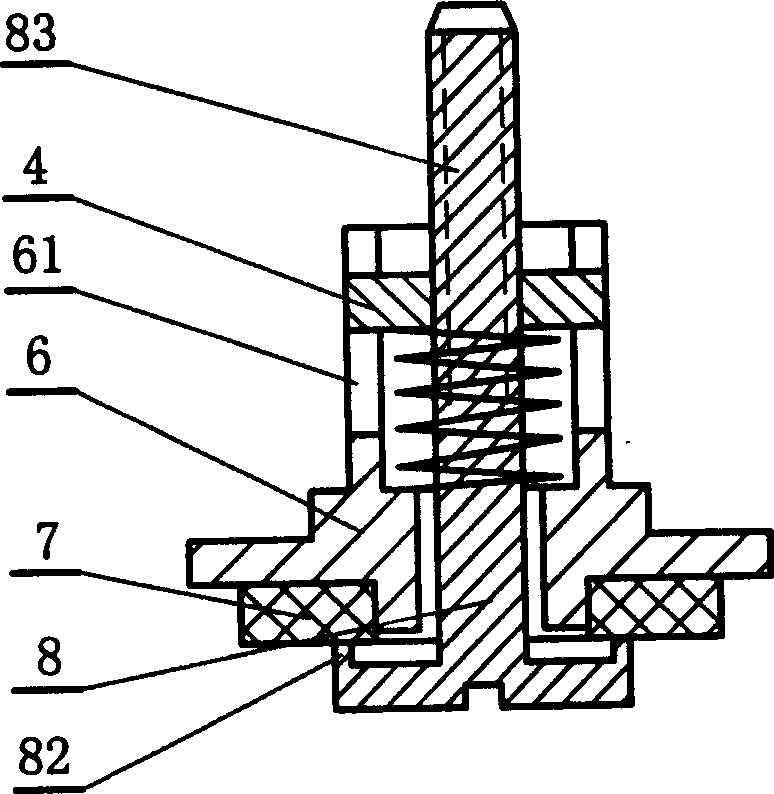

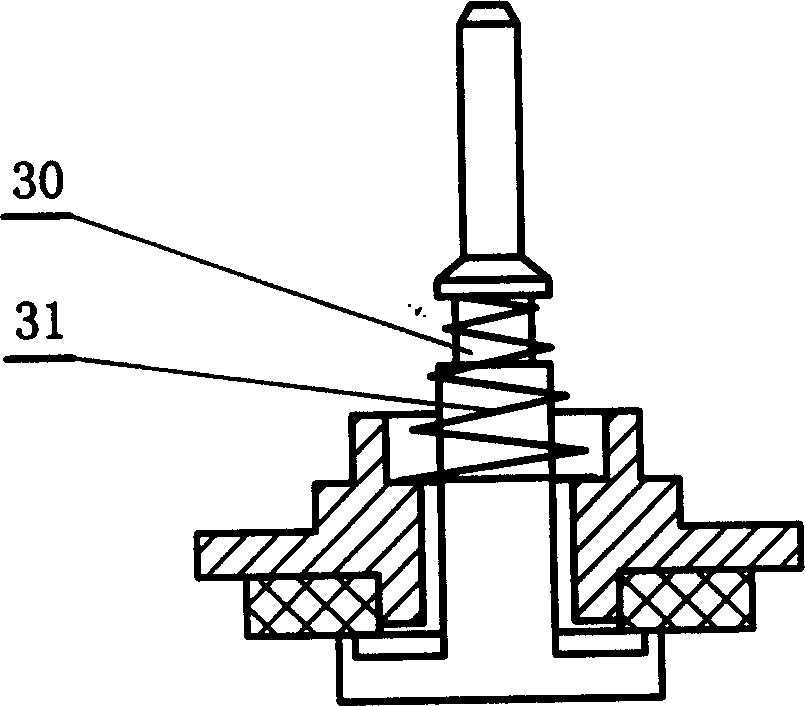

[0010] Electric water heater pressure relief valve, the water inlet channel of the valve body 1 is provided with an inner pressure relief valve seat 6 and a retaining ring 2, a spring I3 is arranged between the inner pressure relief valve seat and the retaining ring, and the inner pressure relief valve seat is embedded with The sealing gasket 7 corresponds to the water inlet valve seat 11, the inner pressure relief valve seat is pierced with an inner pressure relief valve core 8, and the outer pressure relief channel of the valve body 1 is provided with an outer pressure relief valve core 21 on which a seal Gasket 20, the outer pressure relief valve core 21 is connected with a pull rod 22, and the rear part is covered with an adjusting gland 24 and a female 25, which are built in and positioned at the rear end of the outer leak chamber of the valve body. The pull rod is covered with a spring III23, and the pull rod 22 The outer end is connected with a handle 26, and the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com