Pipe fitting type examination well

A technology for inspection wells and pipe fittings, applied in the field of inspection wells, can solve problems such as long construction period, shrubs and weeds, and poor water flow, and achieve the effects of shortening construction period, high degree of industrialization, and tight interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

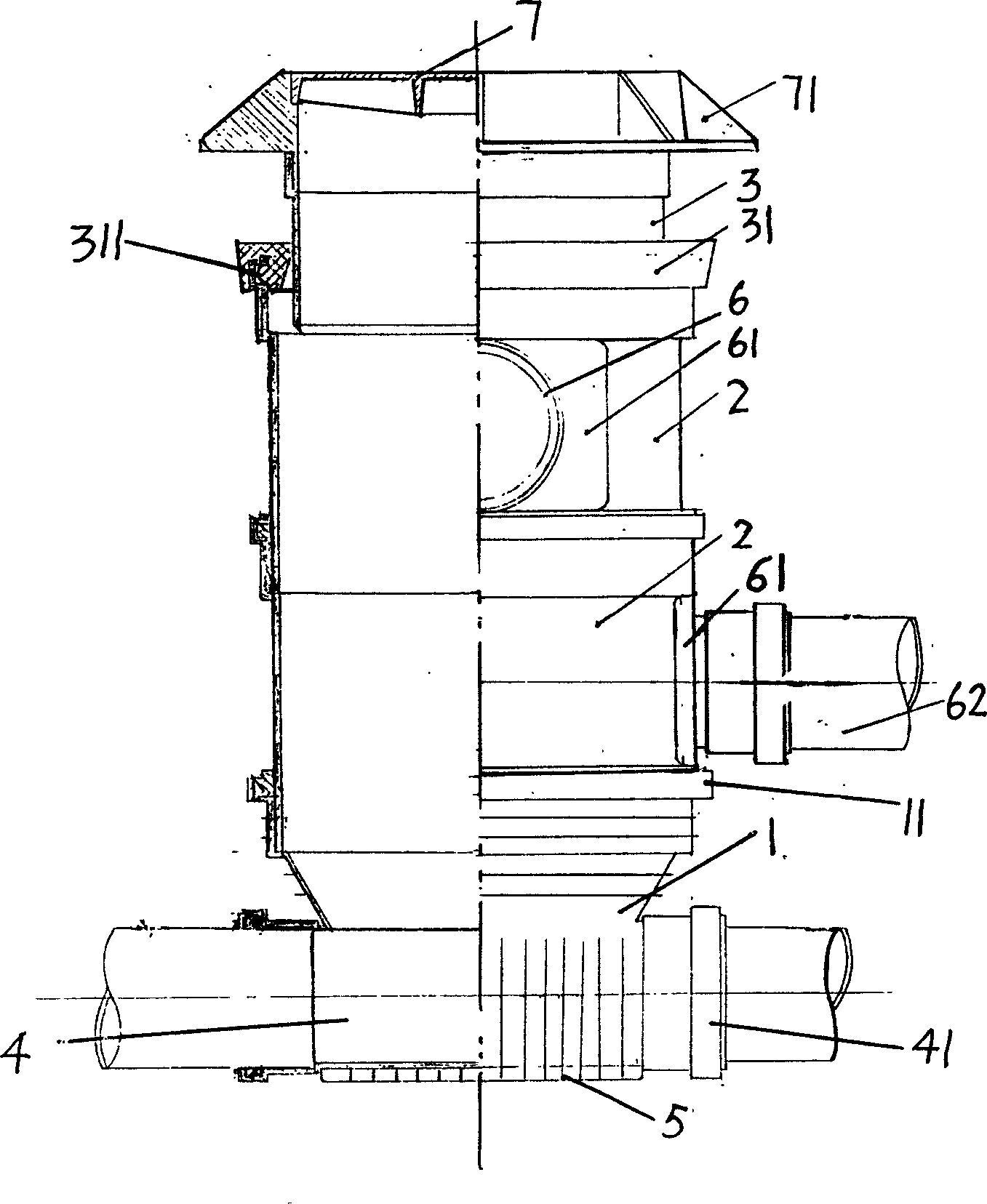

[0016] The inner hollow well body 1 is connected with a main flow pipe 4 , and the bottom of the main flow pipe 4 protrudes outward to form a collection chamber 5 . A well body socket 11 is arranged above the well body 1, a connecting pipe 2 is arranged close to the inner side wall of the well body socket 11, a telescopic tube 3 is arranged close to the inner side wall of the connecting pipe 2, and the telescopic pipe 3 is covered with a telescopic tube The ferrule 31 has an annular slot 311 , and the upper edge of the connecting pipe 2 below the telescopic tube 3 is embedded in the slot 311 . The main channel pipe 4 is located at the bottom of the well body 1, and has two main channel nozzles 41 communicating with the outside world and the inner cavity of the well body 1. The side wall of the connecting pipe 2 above the main channel pipe 4 is provided with two different heights. Branch port 6. The side wall of the connecting pipe 2 at the branch pipe opening 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com