Micro displacement variable cross-section uniform fine atomization combined type oil spout device

A micro-displacement and variable-section technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve the problems of increased fuel pump energy consumption, small spray penetration distance, and increased cost of high-pressure injection systems to reduce soot. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

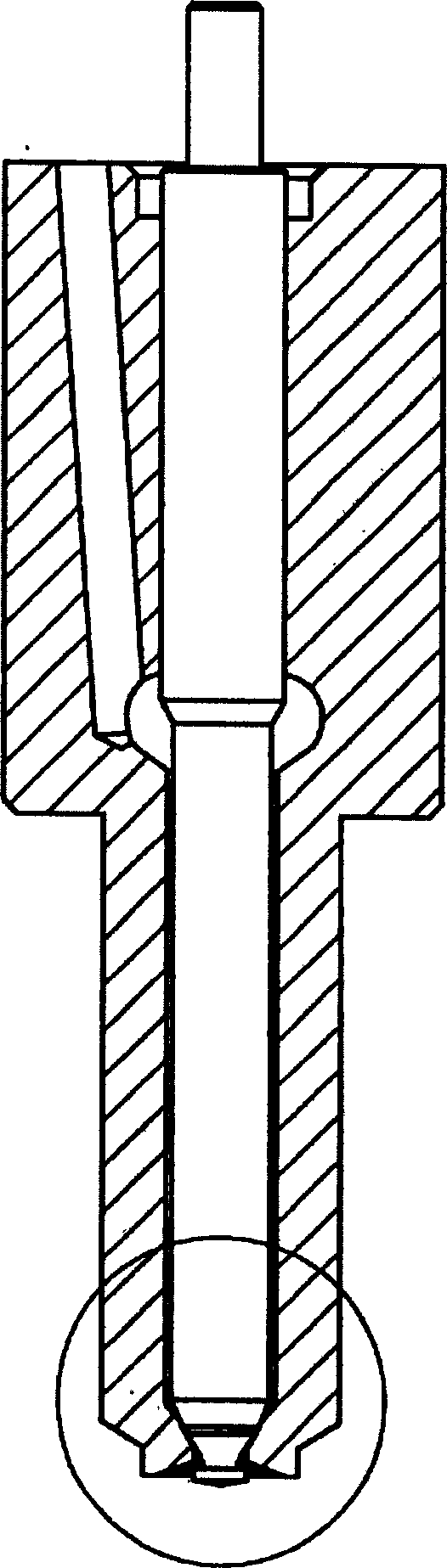

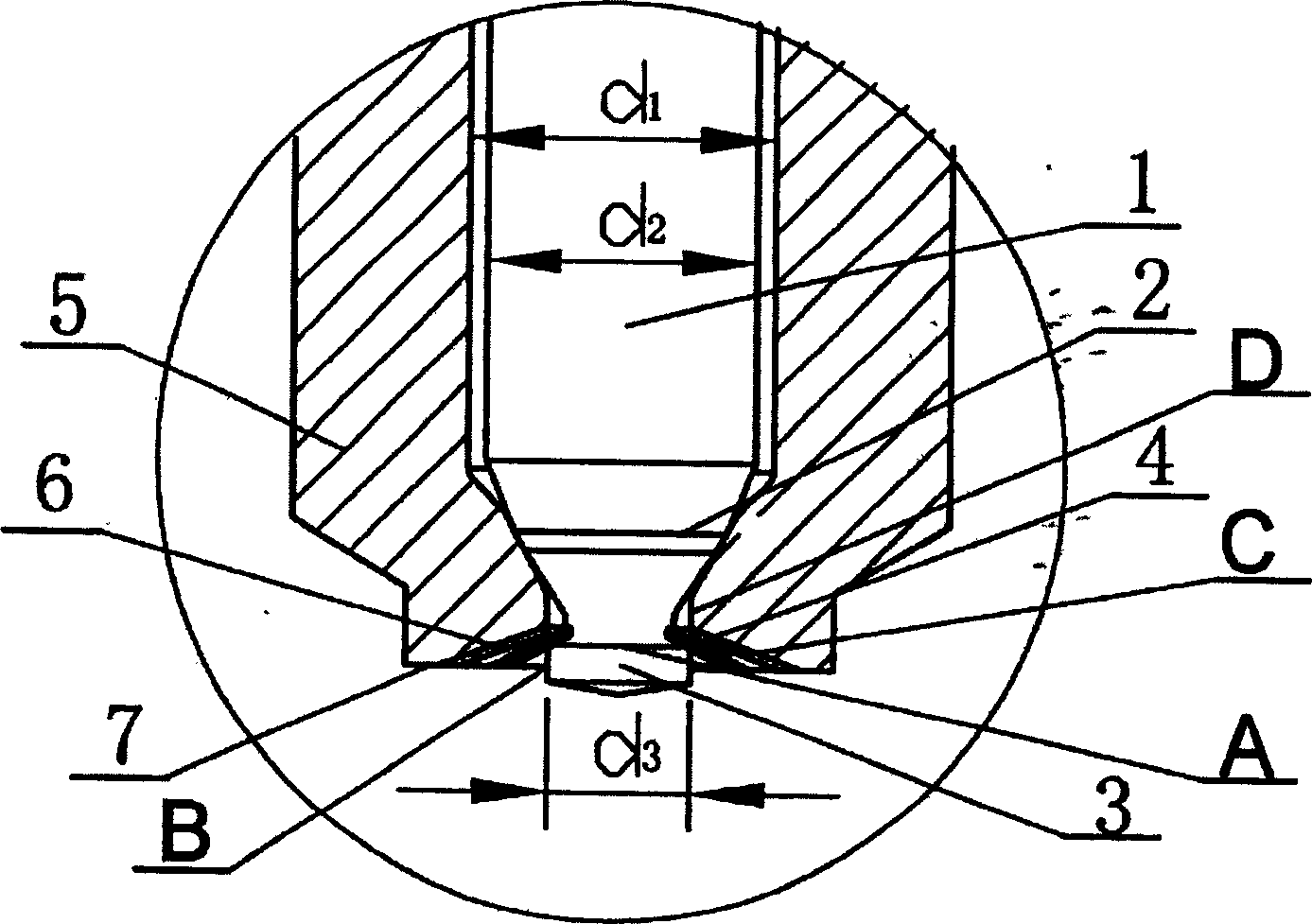

[0023] For vehicle diesel engines and other small diesel engines, micro-displacement variable cross-section uniform fine atomization compound injectors can be used figure 2 The scheme is characterized in that the size of the injector is:

[0024] d1=4~6mm; d1-d2=0.3~0.6mm; d3=1.0~2.5mm;

[0025] Needle valve body oil hole diameter -d3=10~20μm;

[0026] The included angle of the cone surface at the seal = 50-75 degrees; the lift of the needle valve = 75-200 μm;

[0027] The included angle of the inscribed cone surface on the end surface of the needle valve body = 120-150 degrees;

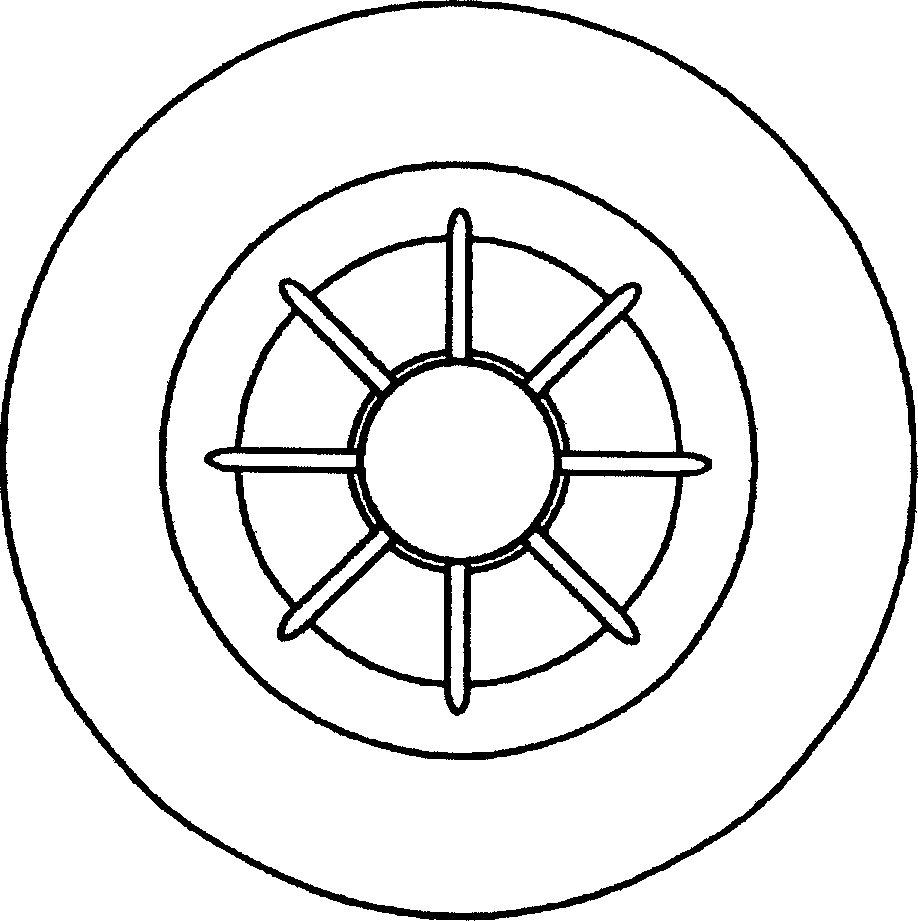

[0028] The number of oil holes / grooves on the inscribed tapered surface of the needle valve body = 6 to 12;

[0029] The diameter of the oil hole on the inscribed tapered surface of the needle valve body = 50-250 μm;

[0030] For medium-sized diesel engines, d1=5~6mm; d1-d2=0.4~0.6mm;

[0031] d3 = 1.5 ~ 3.0mm, other parameters can adopt the scheme similar to the above small diesel engine.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com