Power converter package with enhanced thermal management

A power converter and heat transfer technology, applied in circuit thermal devices, electric solid state devices, semiconductor devices, etc., can solve the problems of increasing power loss conduction paths of power consumption components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Although the present invention may have various embodiments in different forms, for the sake of simplicity of description, some preferred embodiments are listed in the present invention, and detailed description and explanation are given below. However, the content disclosed in this place exemplifies the principle of the present invention, but the scope of the present invention is not limited to the following specific embodiments.

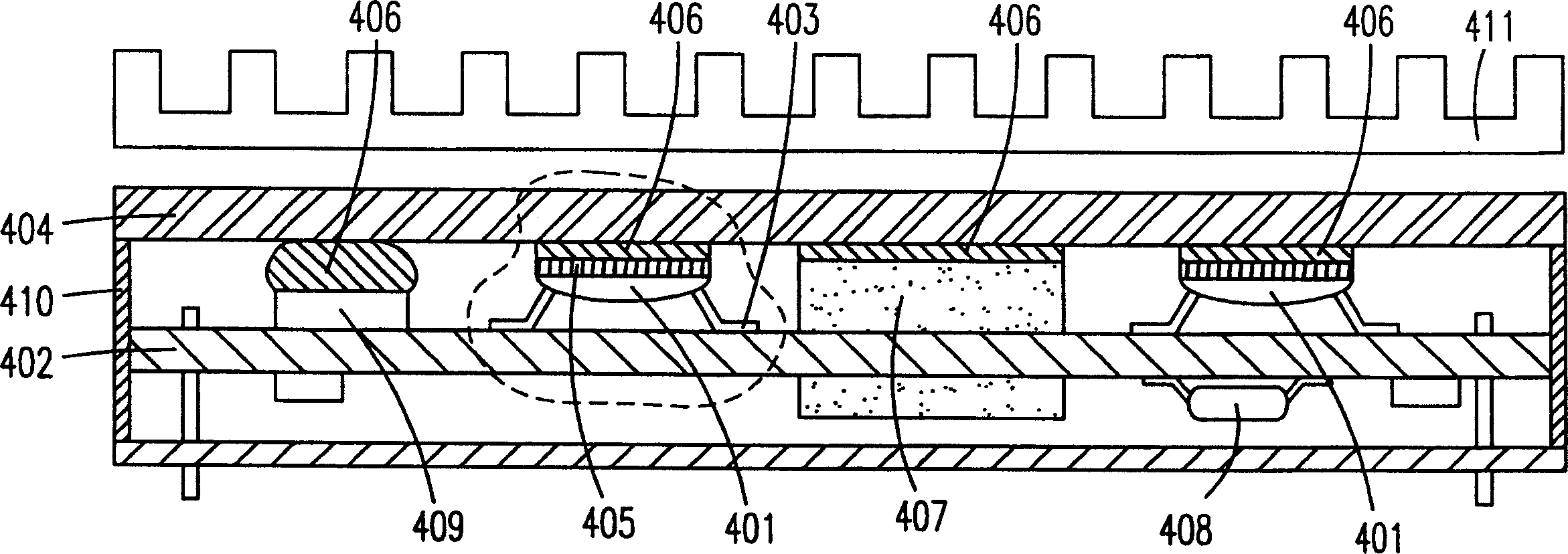

[0027] image 3 It is a cross-sectional side view of a preferred embodiment of the power conversion package of the present invention. As shown in the figure, all the electrical connections of the power converter are realized by mounting on the multilayer printed circuit board 402 so as to have a high interconnection density. A thermal diffusion element 404 is directly connected to the exposed top thermal block 405 and the magnetic element 407 of the sub-package 401 through the thermal insulator 406. The magnetic element 407 can be installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com