Technology for continuously making single-component mist-solidifying silicon-ketone composition

A moisture-curing silicone and manufacturing process technology, which is applied in the field of continuous manufacturing process of single-component moisture-curing silicone composition, can solve the problems of large production operation flexibility, and achieve large and adjustable production operation High efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

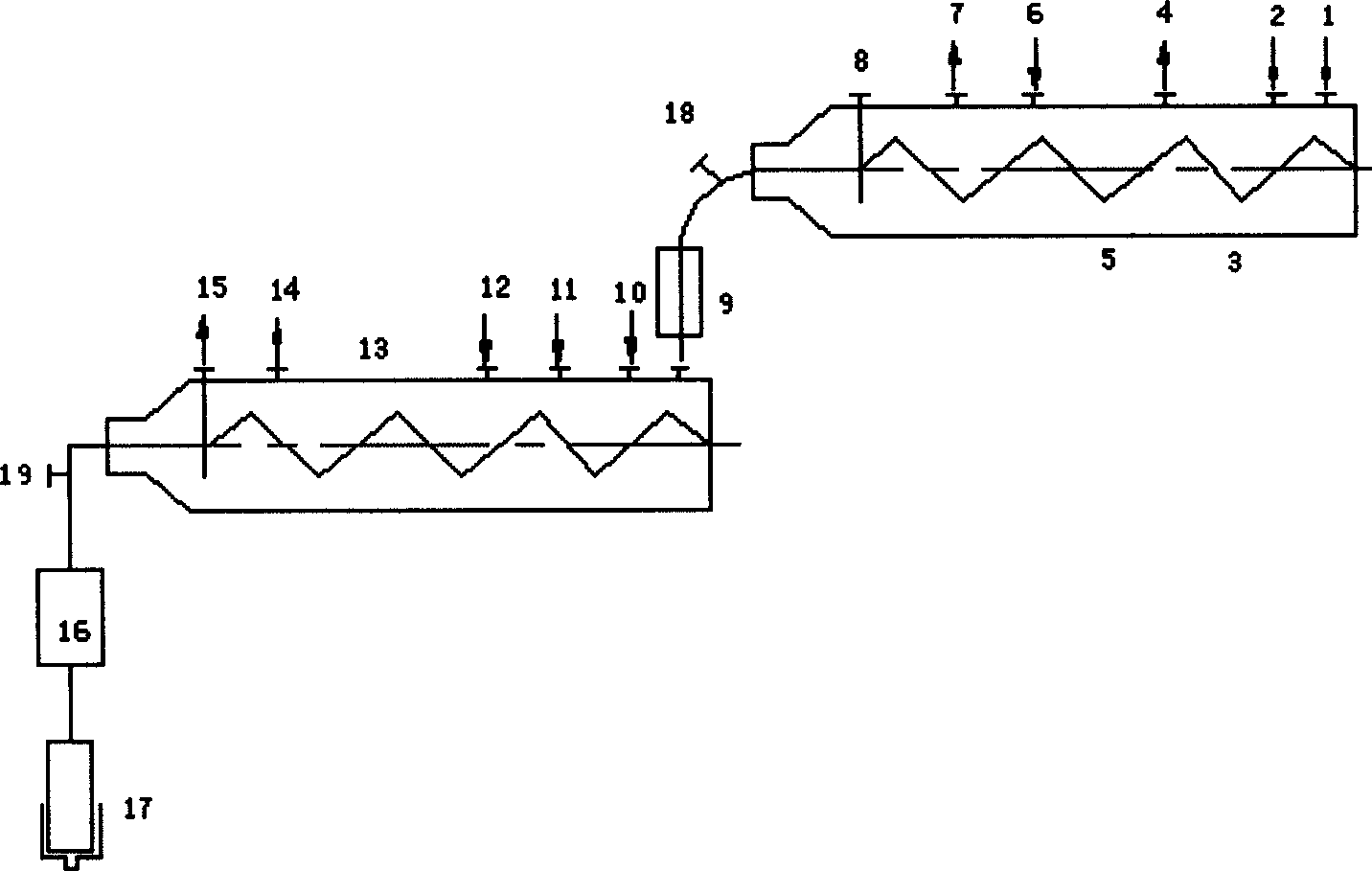

Method used

Image

Examples

Embodiment 1

[0030] The components and weight ratio of the one-component moisture-curing silicone composition are:

[0031] Hydroxy-terminated polysiloxane 100

[0032] Nano active calcium carbonate (40nm) 100

[0033] Dimethicone (0.1Pa.s) 3

[0034] Methyltrimethoxysilane 25

[0035] γ-Aminopropyltriethoxysilane 0.5

[0036] Ethyl acetoacetate titanium chelate 2

[0037] The hydroxyl-terminated polysiloxane is input into the first-stage machine at 500Kg / hr, 250Kg / hr at the 1 feed port, and 250Kg / hr at the 2 feed port, and other materials are added in proportion to the corresponding positions. Control the temperature of the material at the outlet of the first-stage machine to 150°C, the temperature of the material entering the second-stage machine is less than 25°C, the temperature of the material at the outlet of the second-stage machine is 3-5°C, and the vacuum degree of the 4, 7, and 14 vacuum ports is greater than -0.095MPa. The performance of the obtained product:

[0038] Surf...

Embodiment 2

[0043] The components and weight ratio of the one-component moisture-curing silicone composition are:

[0044] Hydroxy-terminated polysiloxane 100

[0045] Nano active calcium carbonate (40nm) 100

[0046] Dimethicone (0.1Pa.s) 3

[0047] Vinyl tributylketoximosilane 5

[0048] Methyltributanoximinosilane 30

[0049] γ-Aminopropyltriethoxysilane 0.5

[0050] Dibutyltin dilaurate 0.3

[0051] The hydroxyl-terminated polysiloxane is input into the first-stage machine at 500Kg / hr, 250Kg / hr at the 1 feed port, and 250Kg / hr at the 2 feed port, and other materials are added in proportion to the corresponding positions. Control the temperature of the material at the outlet of the first-stage machine to 150°C, the temperature of the material entering the second-stage machine is less than 50°C, the temperature of the material at the outlet of the second-stage machine is less than 45°C, and the vacuum degree of the 4, 7, and 14 vacuum ports is greater than -0.095MPa. The performan...

Embodiment 3

[0057] The components and weight ratio of the one-component moisture-curing silicone composition are:

[0058] Hydroxy-terminated polysiloxane 100

[0059] Fumed silica (H15, manufactured by Waker Co.) 10

[0060] Dimethicone (0.1Pa.s) 20

[0061] Ethyltriacetoxysilane 5

[0062] Methyltriacetoxysilane 15

[0063] γ-Aminopropyltriethoxysilane 0.5

[0064] Dibutyltin dilaurate 0.3

[0065] The hydroxyl-terminated polysiloxane is input into the first-stage machine at 500Kg / hr, 250Kg / hr at the 1 feed port, and 250Kg / hr at the 2 feed port, and other materials are added in proportion to the corresponding positions. Control the temperature of the material at the outlet of the first-stage machine to 150°C, the temperature of the material entering the second-stage machine is less than 50°C, the temperature of the material at the outlet of the second-stage machine is less than 45°C, and the vacuum degree of the 4, 7, and 14 vacuum ports is greater than -0.095MPa. The performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com