Rigid line product microscopic structure and mechanical property fore casting system

A technology of microstructure and prediction system, applied in the field of steel rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

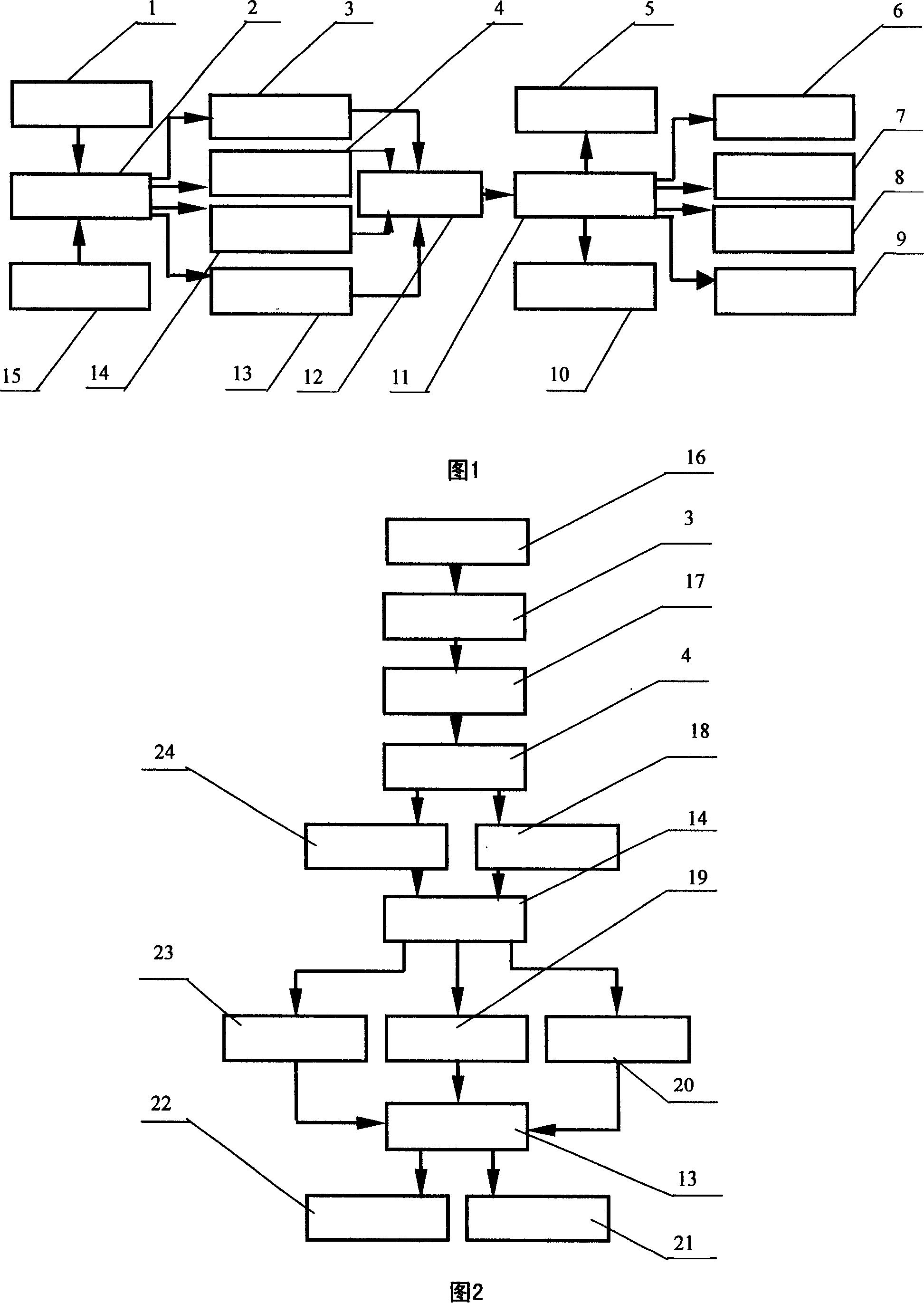

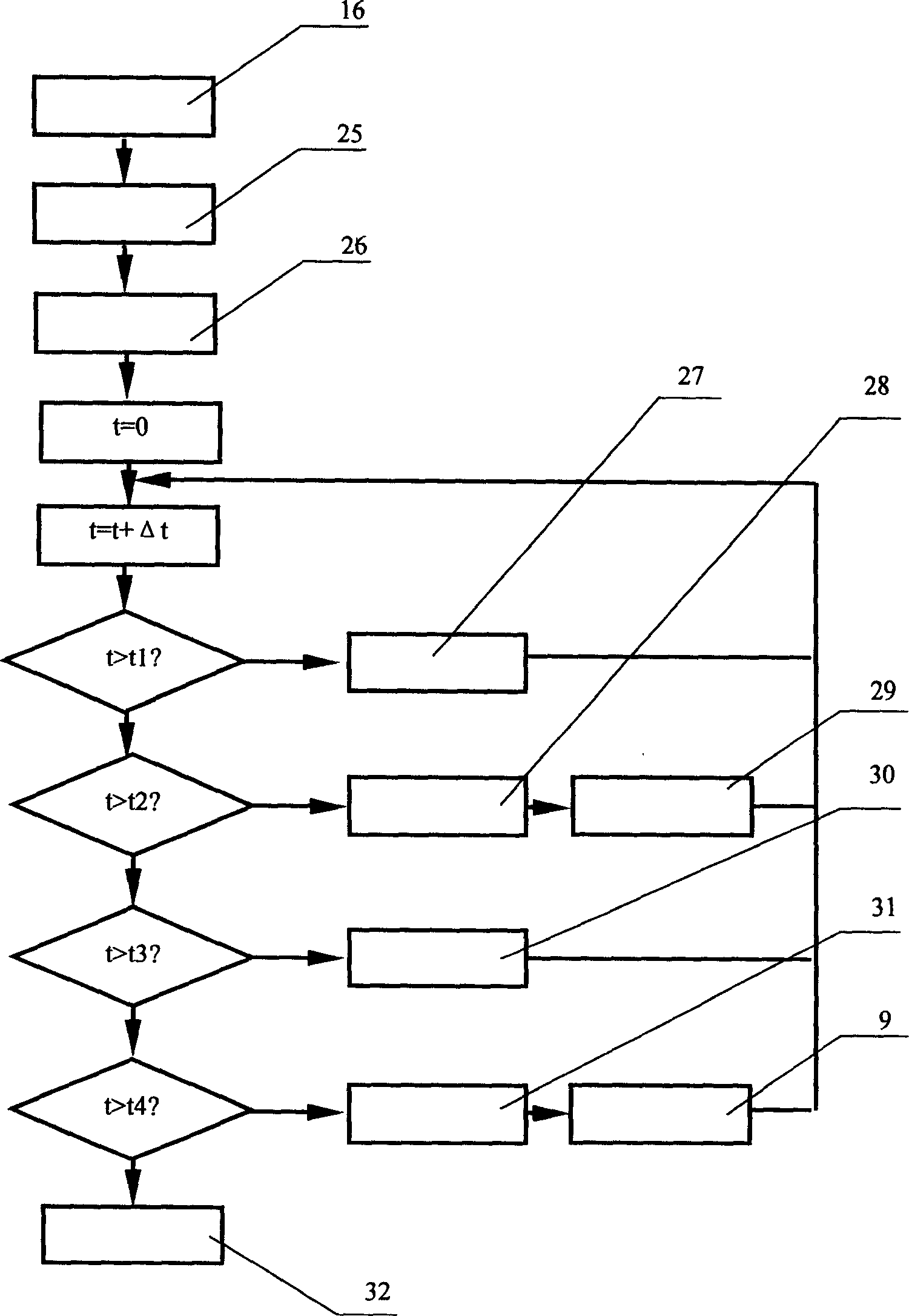

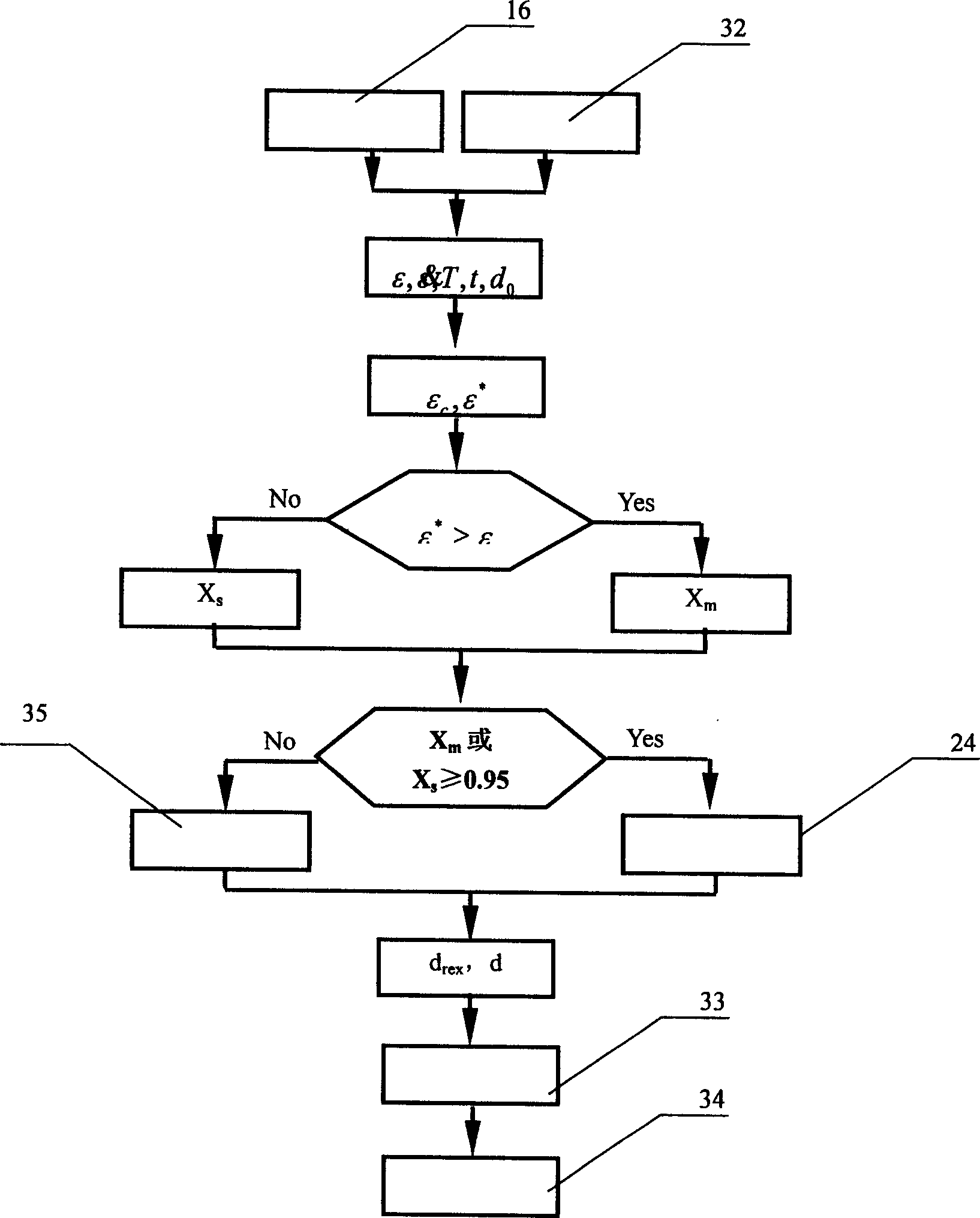

[0110] This embodiment is shown in Figure 1. The sample of the rolled piece is taken and analyzed by experiments on microstructure and mechanical properties [1], and the surface temperature of the rolled piece at the entrance of the finishing mill and the exit of the laying mill, and under various working conditions are measured. The surface temperature of the wire rod along the Stelmore line [15]; the establishment of a process mathematical model group for direct rolling of high-carbon steel wire rods using continuous casting slabs [2], including: the temperature model of the rolled piece [3], the austenite Microstructure evolution model [4], austenite decomposition model [14], wire mechanical properties and microstructure relationship model [13]; use VB language to write hard wire microstructure evolution and predict wire mechanical properties control program [12], Carry out rolling simulation [11]; then give all the temperature data of the rolled piece on the entire rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com