Porous brickwalk laying method

A technology for permeable paving and pavement bricks, which is applied to roads, roads, paving surfaces paved with prefabricated blocks, etc., and can solve problems such as impermeability, uneven pavement, uneven paving of pavement bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

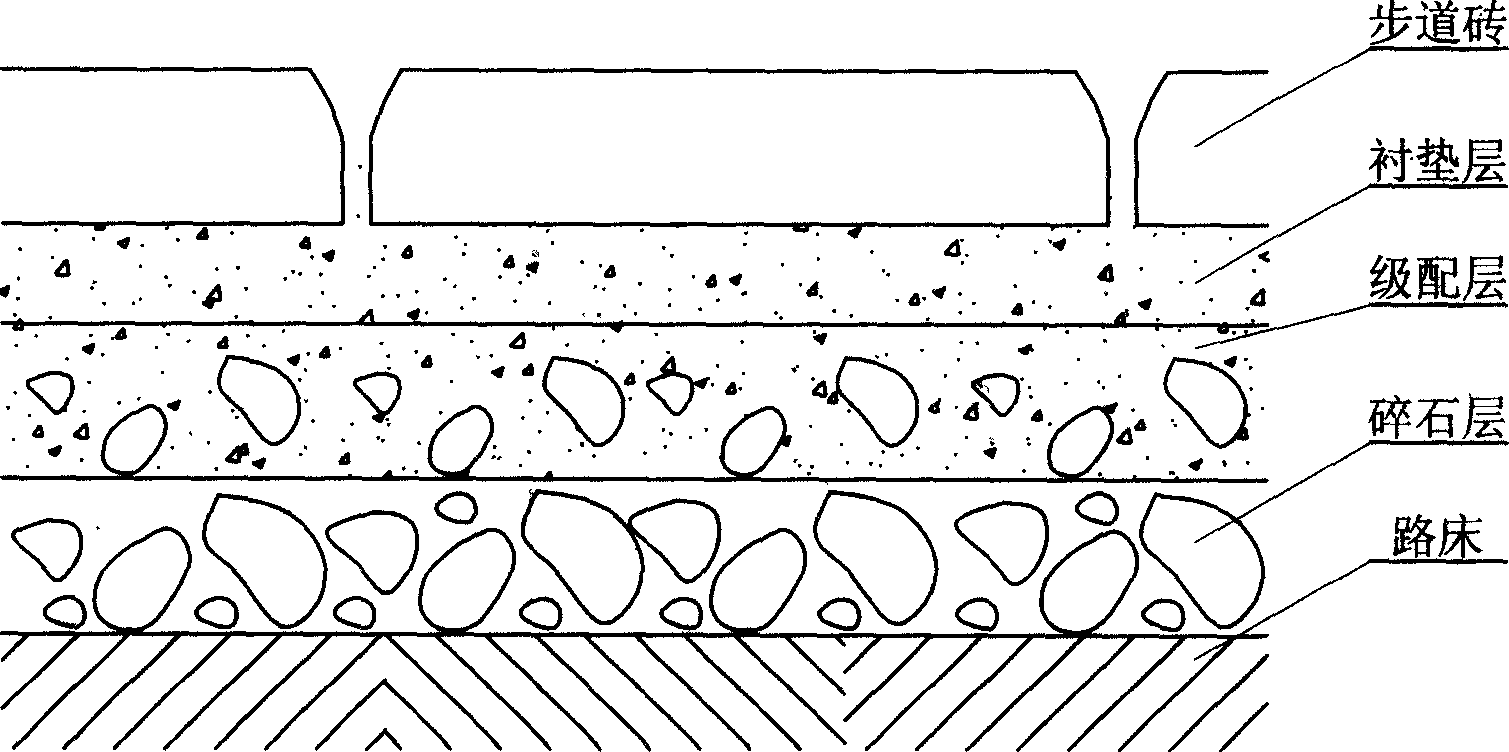

[0005] Specific implementation mode one: (see figure 1 ) This embodiment is achieved through the following steps: one, the original soil layer of the road bed is rammed or compacted with a rammer or a road roller; On the top, the paving thickness of the crushed stone is 30-200mm; 3. Laying the graded layer: lay the gravel and stone powder on the crushed stone layer, push it flat and then spray water for compaction, and the laying thickness of the graded layer is 10-200 mm. 100mm; 4. Laying the backing layer: After mixing the crushed stone and fine sand, spread it on the gradation layer, and sink it with water. The thickness of the backing layer is 10-50mm; The machine will tamp the backing layer, and then lay the pavement bricks, the thickness of the pavement bricks is 50-80mm. The average diameter of the gravel used in the crushed stone layer is 1-3cm or 2-4cm; the average diameter of the gravel in the graded layer is 0.1-2mm, and the particle size of the stone powder is 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com