Refined catalyst for fraction oil hydrogenation and its preparing method

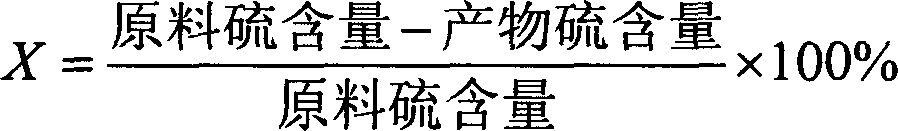

A hydrorefining and catalyst technology, which is applied in the direction of refining to remove heteroatoms, can solve the problems of low catalyst activity and complicated preparation process, and achieve the effect of high hydrodesulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Take by weighing 1000 grams of hydrated alumina (product name is Changling dry rubber powder, Changling Refinery Catalyst Factory product, dry basis is 73%, wherein gibbsite content is 68 weight percent, and gibbsite content is 5 weight percent %, the specific surface and pore distribution of the macroporous alumina Al-1 formed after 550 ° C roasting for 4 hours are listed in Table 1) mixed with 131 grams of sucrose, extruded into a clover-shaped strip with a circumscribed circle diameter of 1.4 mm, 120 After drying at ℃, put it in a tube furnace, and activate it at 580℃ for 3 hours under the condition of feeding water vapor. The weight ratio of water vapor to clover strips is 30:70, and the carrier S1 is obtained. The carbon content, specific surface area, number of pores, pore volume and pore distribution of support S1 are listed in Table 1. Carbon content is measured with RIPP-90 [petrochemical analysis method (RIPP test method), Science Press, 1990, 418-419] method,...

example 2

[0039] Take by weighing 678 grams of hydrated alumina (the name of the product is dry pseudoboehmite, a product from an aluminum factory in Shandong Province, with a dry basis of 64%, wherein the content of gibbsite is 80% by weight, and the content of gibbsite is 5% by weight , the specific surface and pore distribution of the small-pore alumina Al-2 formed after roasting at 550°C for 4 hours are listed in Table 1), the precursor of 203 grams of macroporous alumina (the product of the Changling Refinery Catalyst Factory, the specifications are the same Example 1) Mix evenly with 115 grams of methyl cellulose, extrude into a clover-shaped bar with a circumscribed circle diameter of 1.4 mm, dry at 120° C., place in a tube furnace, and pass through nitrogen conditions containing 1.5 volume percent oxygen at 450° C. Calcined at lower temperature for 2 hours, then changed the mixed gas of oxygen and nitrogen into nitrogen gas and raised the temperature to 630°C for 2 hours to obtai...

example 3

[0041] Take by weighing 678 grams of hydrated alumina (product of Shandong Aluminum Plant, specification is the same as example 2), 203 grams of hydrated alumina (product of Changling Oil Refinery Catalyst Factory, specification is the same as example 1) and mix evenly with 47 grams of edible starch, extrude into The clover-shaped bar with a circular diameter of 1.4 mm is dried at 120°C, placed in a tube furnace, and roasted for 2 hours at 450°C under the condition of nitrogen containing 1.5% oxygen by volume, and then the mixed gas of oxygen and nitrogen is replaced by nitrogen. And heated to 630 ° C for 2 hours to obtain carrier S3, wherein the weight ratio of small-pore alumina and macro-pore alumina is 74.6:25.4, the carbon content, specific surface, pore volume and pore distribution of S3 are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com