Color adjustable plane color conversion organic device and producing method

A conversion device, an organic device technology, applied in the direction of lighting devices, light sources, electrical components, etc., can solve the problem of only blue light and other light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Regarding the technology, means and specific structural features adopted by the present invention to achieve the above-mentioned purpose, a preferred and feasible embodiment is given hereby, and it is further revealed by illustrations, as follows.

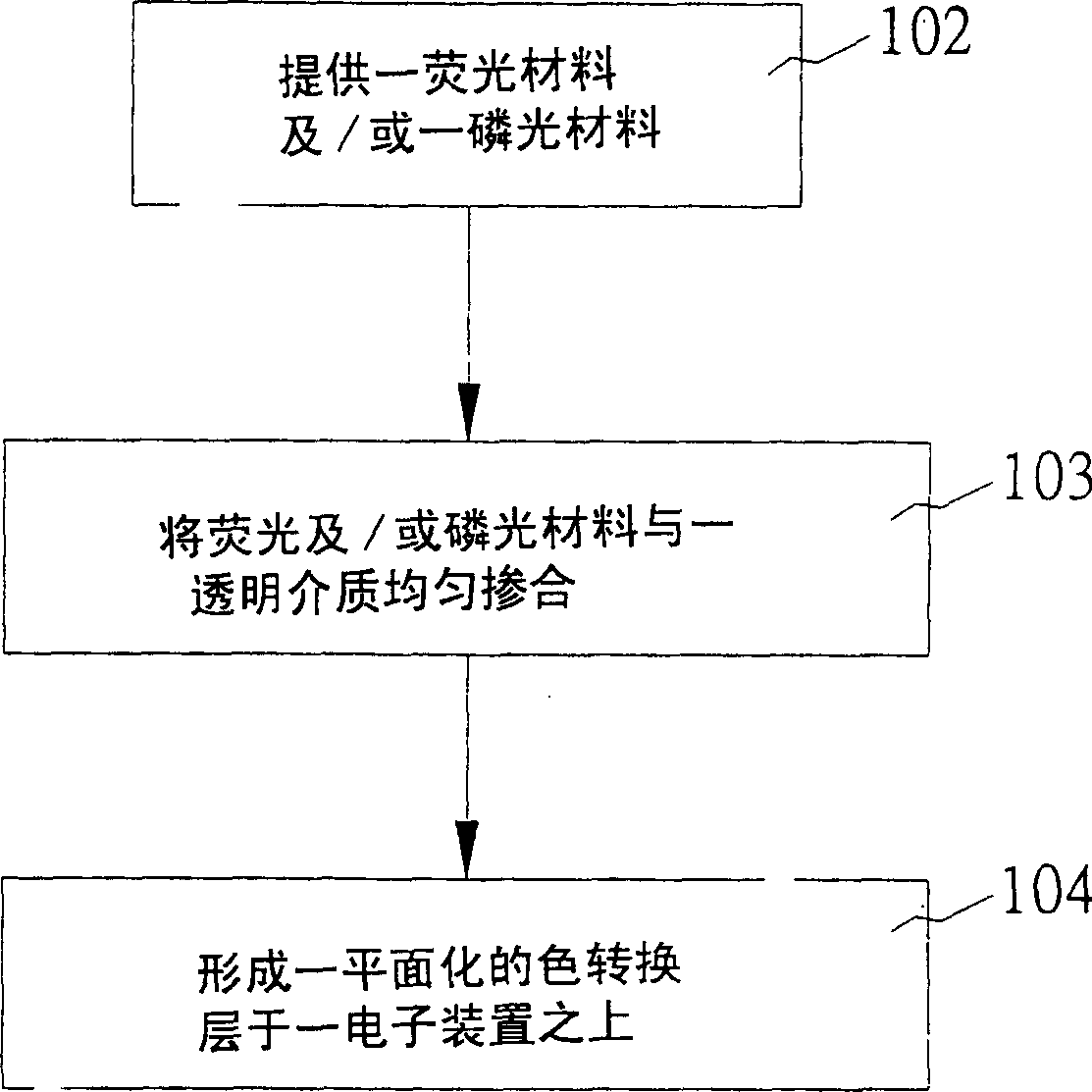

[0022] First, see figure 1 In the manufacturing method of the tunable flat color conversion device provided by the present invention, the first step 102 is to provide a fluorescent and / or a phosphorescent material; in a preferred embodiment, the fluorescent and / or phosphorescent material is made of at least one red, Blue, green three primary color fluorescent and / or phosphorescent materials are formed, and fluorescent and / or phosphorescent materials can be organic material or inorganic material; Furthermore, fluorescent material can be any existing fluorescent material (can refer to USP 5,869,929 , USP 3,172,862, USP5,935,720), the fluorescent substance contains more than one organic dye or more than one inorganic pigment, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com