Recovery method of tail gas light component in carbonylation production of acetic acid lanhydride

A recovery method and carbonylation technology are applied in the field of tail gas recovery in acetic acid production to achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

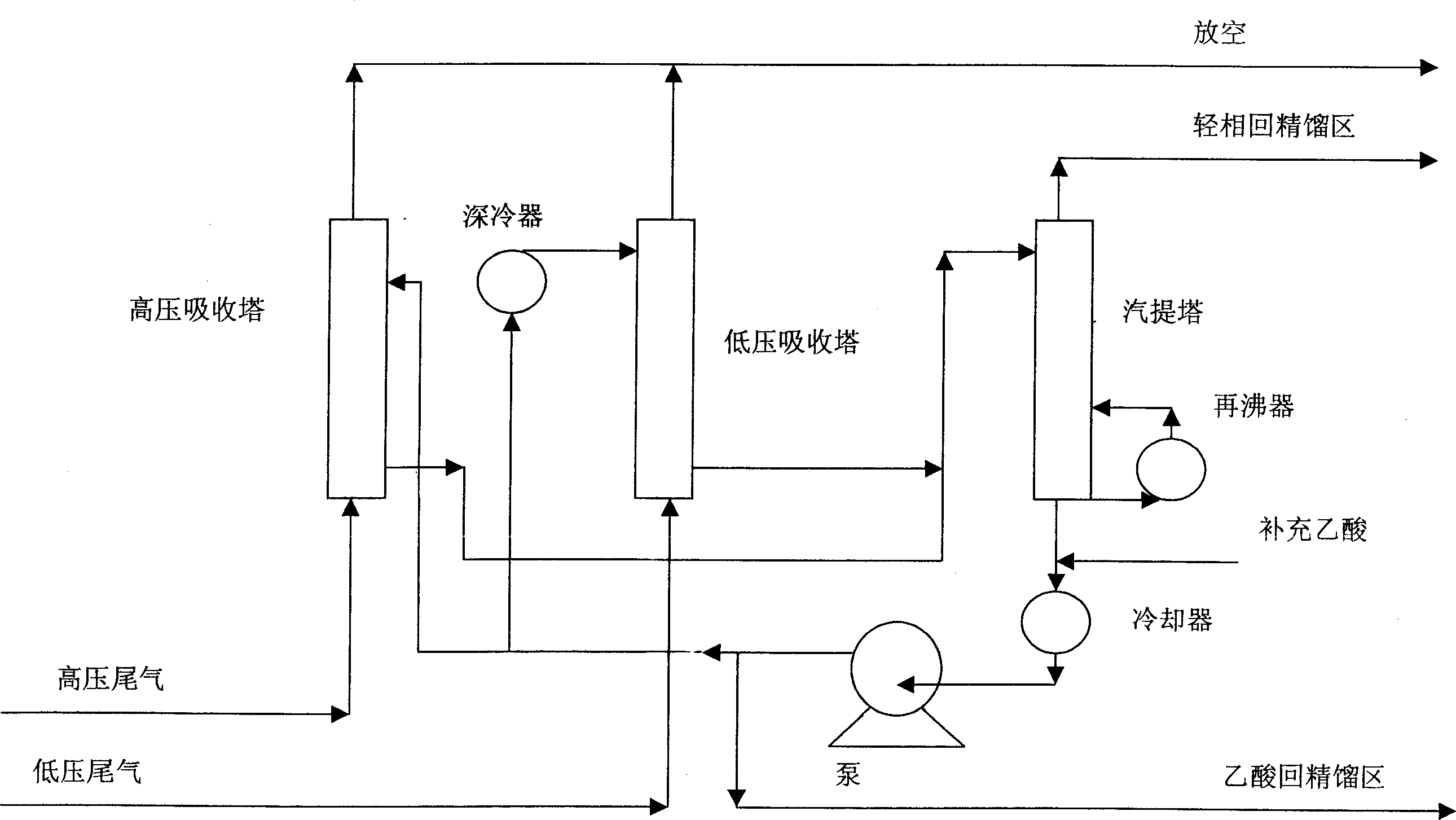

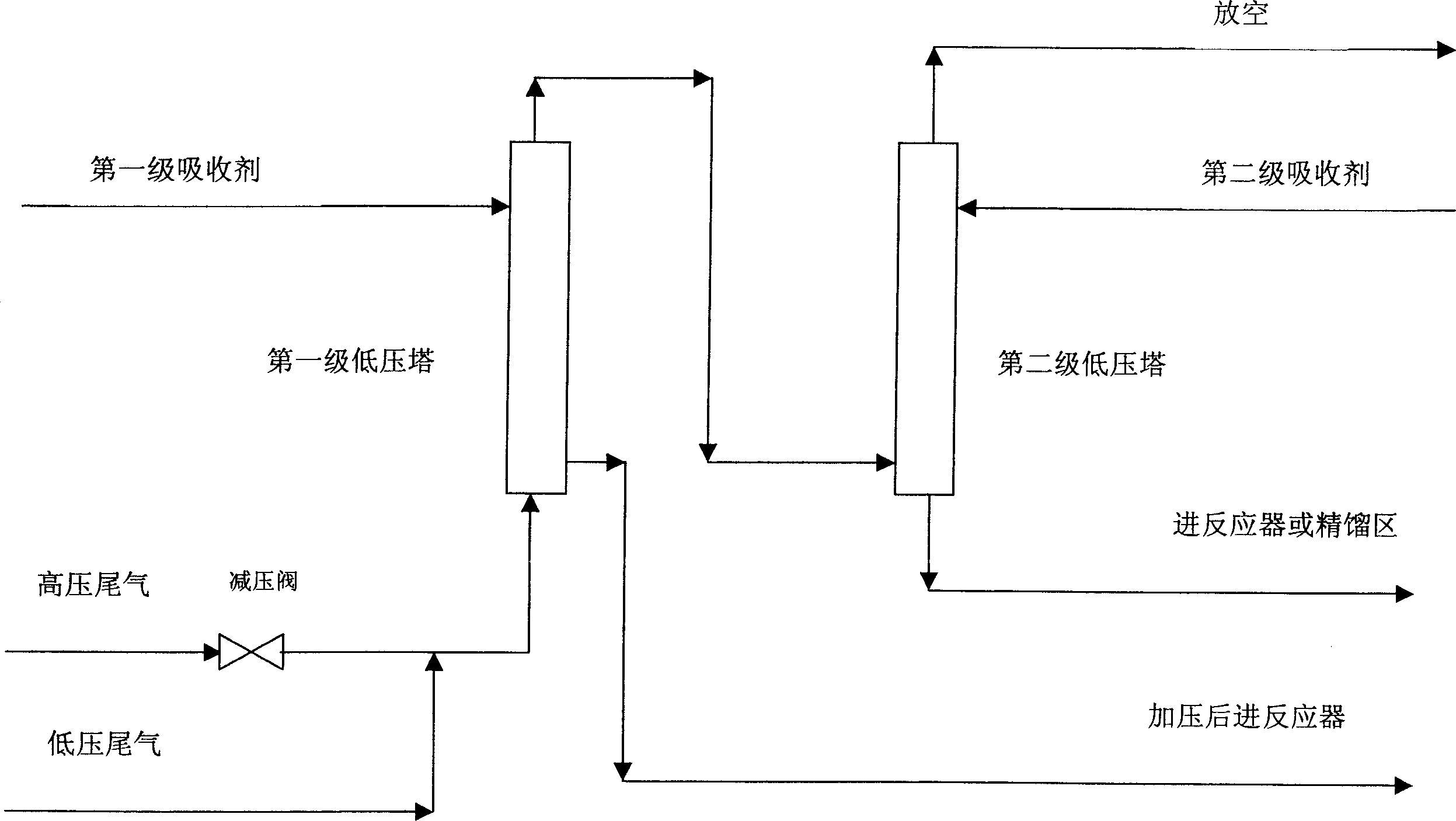

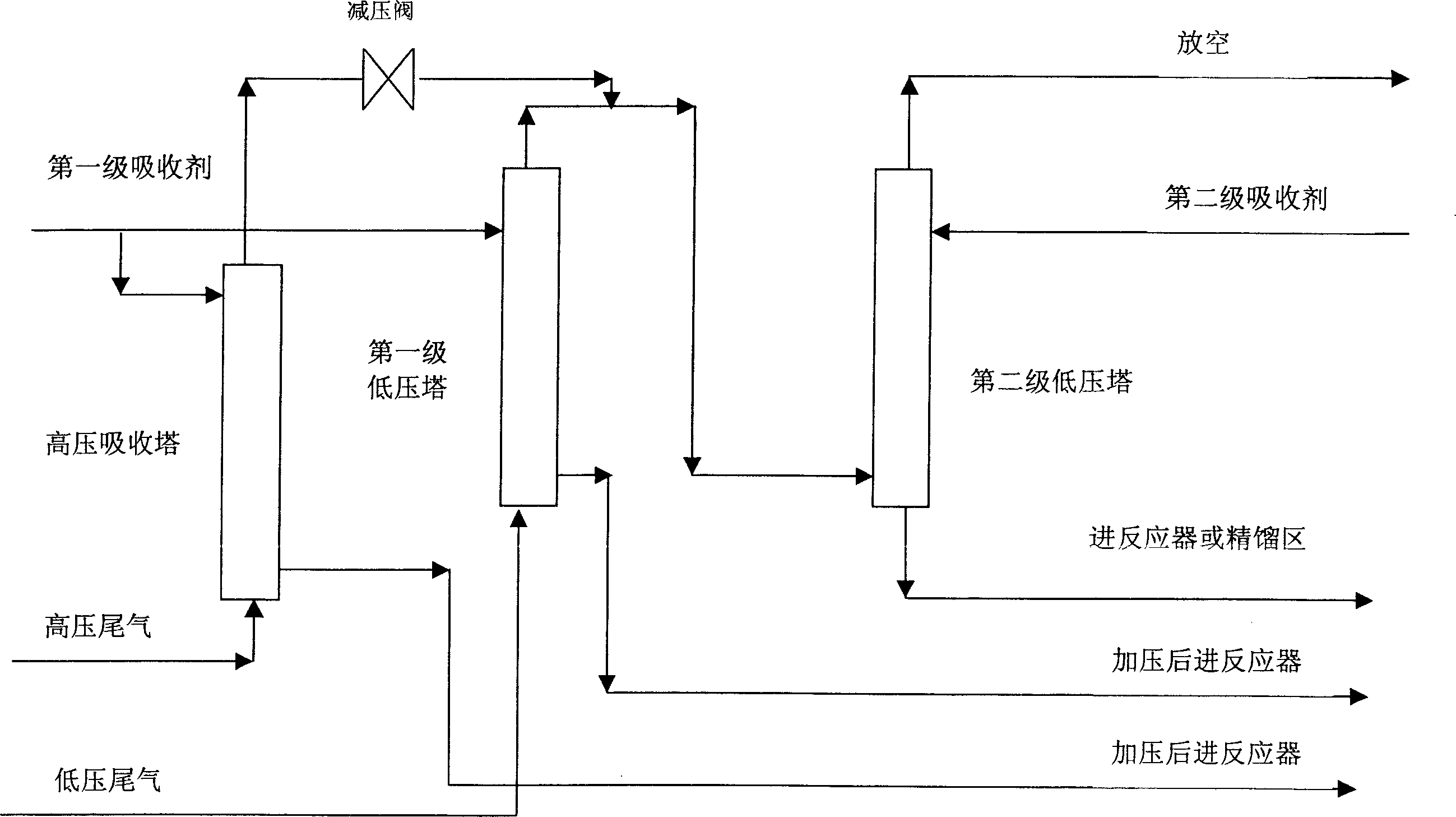

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, 2, 3, 4, 5, 6, 7, 8, 9:

[0030] Acetic acid is used as the first-stage absorption solution, and the first-stage absorption is carried out without the second-stage absorption test. with a certain amount of N 2 Through the methyl iodide and methyl acetate generator, the N containing methyl iodide and methyl acetate saturated gas 2 The gas passes through the first-stage low-pressure absorption tower and is absorbed with acetic acid. Experiments were carried out under different temperatures of methyl iodide and methyl acetate generators and different absorption temperatures of acetic acid. See Table 1 for the data.

[0031] Acetic acid freezes at 16.7°C, so the temperature cannot be lowered.

Embodiment 10~24

[0033] Examples 10-24 are examples in which methanol is absorbed in the first stage and acetic acid is absorbed in the second stage. 10 to 24 are data that vary according to the temperature of methyl iodide, methyl acetate generator, and absorbent. See Table 2.

Embodiment 25~28

[0035] Examples 25-28 are examples in which methyl acetate is used as the absorption solution for the first-stage absorption and acetic acid is used for the second-stage absorption. The data are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com