Water pricking non-woven fabric perforating mould and non-woven fabric production method

A technology of spunlace non-woven fabric and production method, which is applied in the directions of needle punching machine, non-woven fabric, textile and paper making, etc., can solve the problems of unreachable, high replacement cost, short service cycle, etc., and achieve product quality improvement and reduction. The effect of production cost and reduction of work flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

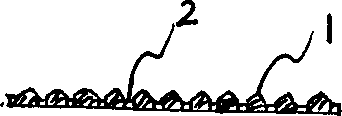

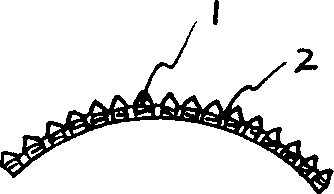

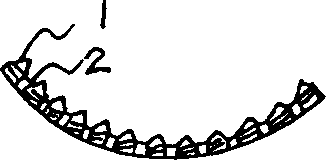

[0016] Embodiment 1: with reference to attached Figure 1~3 . The spunlace non-woven fabric punching die has a plurality of protruding bumps 1 on the template of the punching die 10, and a plurality of dehydrating small water holes 2 are distributed on the template between the multiple protruding bumps. Punching die 10 is sleeve shape (see attached Figure 4 Drum punching die 10 in the middle) or plate shape (see attached figure 1 ) or arc-shaped (see attached figure 2 and 3 ). The punching mold 10 is made mold earlier, then adopts metal material (copper, copper alloy, stainless steel, titanium alloy, zinc alloy, aluminum alloy etc.) Metal materials (such as plastics, nylon, etc.) are injection-molded or compression-molded, and its manufacturing process is a prior art, which will not be described here.

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, the protruding bumps 1 on the template of the punching die 10 are tapered.

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 1, the protruding bumps 1 on the template of the punching die 10 are arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com