Process for preparing water-soluble chitosan oligosaccharide

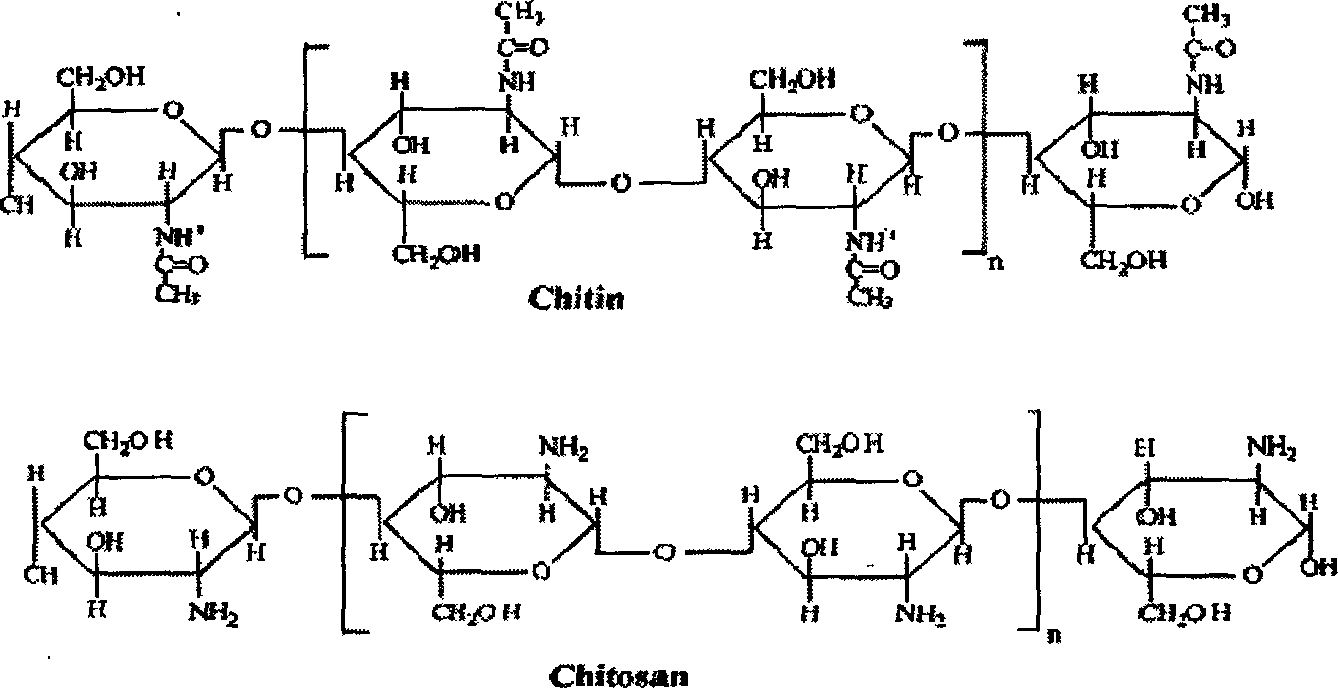

A technology for water-soluble chitosan oligosaccharide and chitosan is applied in the field of preparation of water-soluble chitosan oligosaccharide, and can solve the problems of low molecular weight, unsuitable application, unfavorable industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

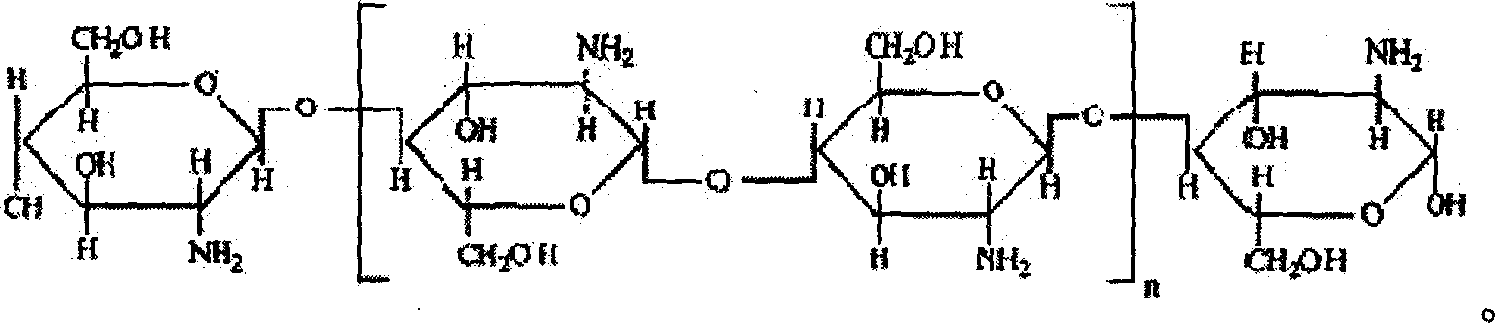

[0013] Specific Embodiment 1: In this embodiment, water-soluble oligochitosan is prepared according to the following steps: a. After drying and crushing the clean crab shells, soak them in an acidic solution for 5-8 hours; b. After washing, soak them in an alkaline solution Boil for 1-2 hours, wash until neutral to obtain chitin; c, then dissolve chitin in alkaline solution, heat at 100-110°C for 4-8 hours, wash once every 2 hours, and wash until the last time Neutral to obtain chitosan; d, chitosan is washed, dried and dissolved in acetic acid solution, according to the weight ratio of acetic acid solution: chitosan: hydrogen peroxide=20~30: 1: 2~4 Add hydrogen peroxide in an appropriate amount, hydrolyze for 80-100 minutes at a temperature of 60-80°C; e, then concentrate in a vacuum at a temperature of 30-50°C, filter with suction, and finally neutralize with an alkaline solution, vacuum freeze-dry, and seal , to obtain water-soluble chitosan oligosaccharides. Described aci...

specific Embodiment approach 2

[0014] Specific embodiment two: this embodiment prepares water-soluble chitosan oligosaccharides according to the following steps: a, after drying and pulverizing the clean crab shells, soak them in HCl with a volume concentration of 10% for 6 hours, and wash once every 3 hours; b, After washing, boil in a NaOH solution with a weight concentration of 10% for 1.5h, wash to neutrality, and obtain chitin; c, dissolve chitin in a sodium hydroxide solution with a weight concentration of 55%, and heat Heating under heating for 6 hours, washing once every 2 hours, and washing to neutrality for the last time to obtain chitosan; d, washing and drying chitosan and dissolving it in an acetic acid solution with a volume concentration of 2%, according to the weight ratio Add hydrogen peroxide in the amount of acetic acid solution: chitosan: hydrogen peroxide=25:1:3, and hydrolyze for 90min at a temperature of 70°C; NaOH solution neutralization, vacuum freeze-drying and sealing to obtain wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com