Process for producing an amino composition

A composition and amino technology, applied in amino compound purification/separation, condensation/addition reaction to prepare amino compounds, organic chemical methods, etc., can solve the problem of reduced commodity value, high device price, and reduced performance of epoxy resin cured products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

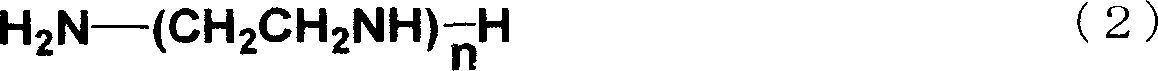

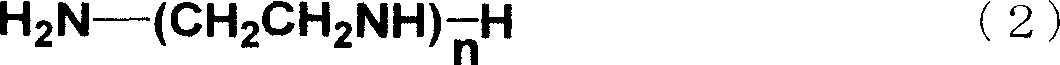

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] (Process 1)

[0109] In a 2-liter flask equipped with a stirring device, a thermometer, a nitrogen inlet tube, a dropping funnel, and a cooling tube, 817.2 g (6.0 mole ) and 2.9 g (0.13 mol) of lithium amide (manufactured by Merck Co., Ltd., reagent) were heated to 80° C. while stirring under a nitrogen stream. Thereafter, 625.2 g (6.0 mol) of styrene (manufactured by Wako Pure Chemical Industries, Ltd., reagent special grade) was continuously dripped over 2 hours while maintaining the temperature at 80°C. After the dropwise addition, keep it at 80°C for 30 minutes, then add 23.4g (1.3 moles) of distilled water equivalent to 10 times the molar amount of the added lithium amide, and 23.4g (1.3 moles) of distilled water equivalent to 10 times the weight of the added lithium amide as an alkali adsorption 2MgO 6 SiO 2 / xH 2 29 g of O (manufactured by Kyowa Chemical Industry Co., Ltd., キョ-ヮ-do 600s) was stirred for 1 hour, and the precipitate in the solution in the flask...

Embodiment 2

[0115] (Process 1)

[0116] In the same manner as in Example 1, 1453 g of a reaction solution containing an amino composition was obtained.

[0117] (Process 2)

[0118] 1453 g of the obtained solution was put into the same flask as in Example 1, and the inside of the apparatus was depressurized to 2.0 kPa and stirred, and then heated to 145°C. After reaching the predetermined temperature, 49 kPa steam was introduced into the apparatus, and an operation for removing unreacted polyamine was performed for 4 hours. Furthermore, the introduction of steam was stopped, and it was kept at a predetermined temperature and a reduced pressure for 30 minutes. Thus, amino composition B1175.4 g was obtained. Unreacted MXDA was 1.2% by weight. In addition, the mono-adduct was 53.0% by weight, the di-adduct was 41.6% by weight, the tri-adduct was 4.2% by weight, and the viscosity was 65 mPa·s. In addition, a storage stability test was performed on the obtained amino composition B. The r...

Embodiment 3

[0122] (Process 1)

[0123] In the same manner as in Example 1, 1453 g of a reaction solution containing an amino composition was obtained.

[0124] (Process 2)

[0125] 1453 g of the obtained solution was put into the same flask as in Example 1, and the inside of the apparatus was depressurized to 4.0 kPa and stirred, and then heated to 165°C. After reaching the predetermined temperature, 49 kPa steam was introduced into the apparatus, and an operation for removing unreacted polyamine was performed for 2.5 hours. Furthermore, the introduction of steam was stopped, and it was kept at a predetermined temperature and a reduced pressure for 30 minutes. Thus, 2.4 g of amino composition C118 was obtained. Unreacted MXDA was 1.9% by weight. In addition, the mono-adduct was 52.5% by weight, the di-adduct was 41.9% by weight, the tri-adduct was 3.7% by weight, and the viscosity was 66 mPa·s. In addition, a storage stability test was performed on the obtained amino composition C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com