Relative humidity sensor compatible of CMOS process

A kind of relative humidity and sensor technology, applied in the direction of instruments, scientific instruments, material capacitance, etc., can solve problems such as circuit detection difficulties, and achieve the effect of being conducive to detection, small temperature drift, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

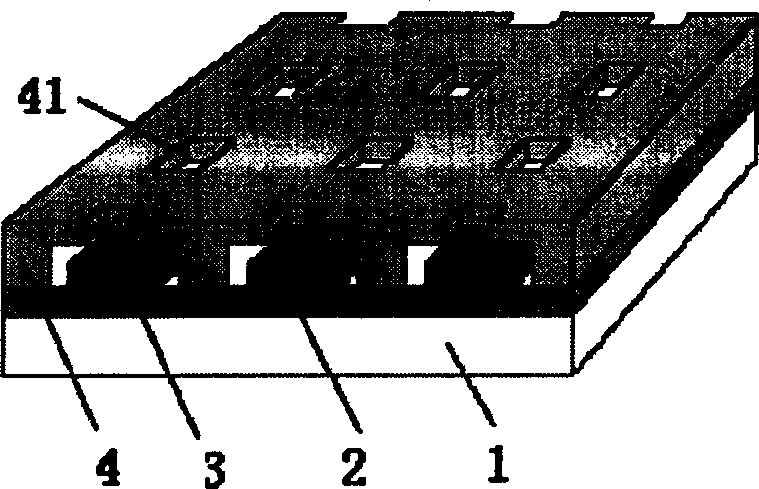

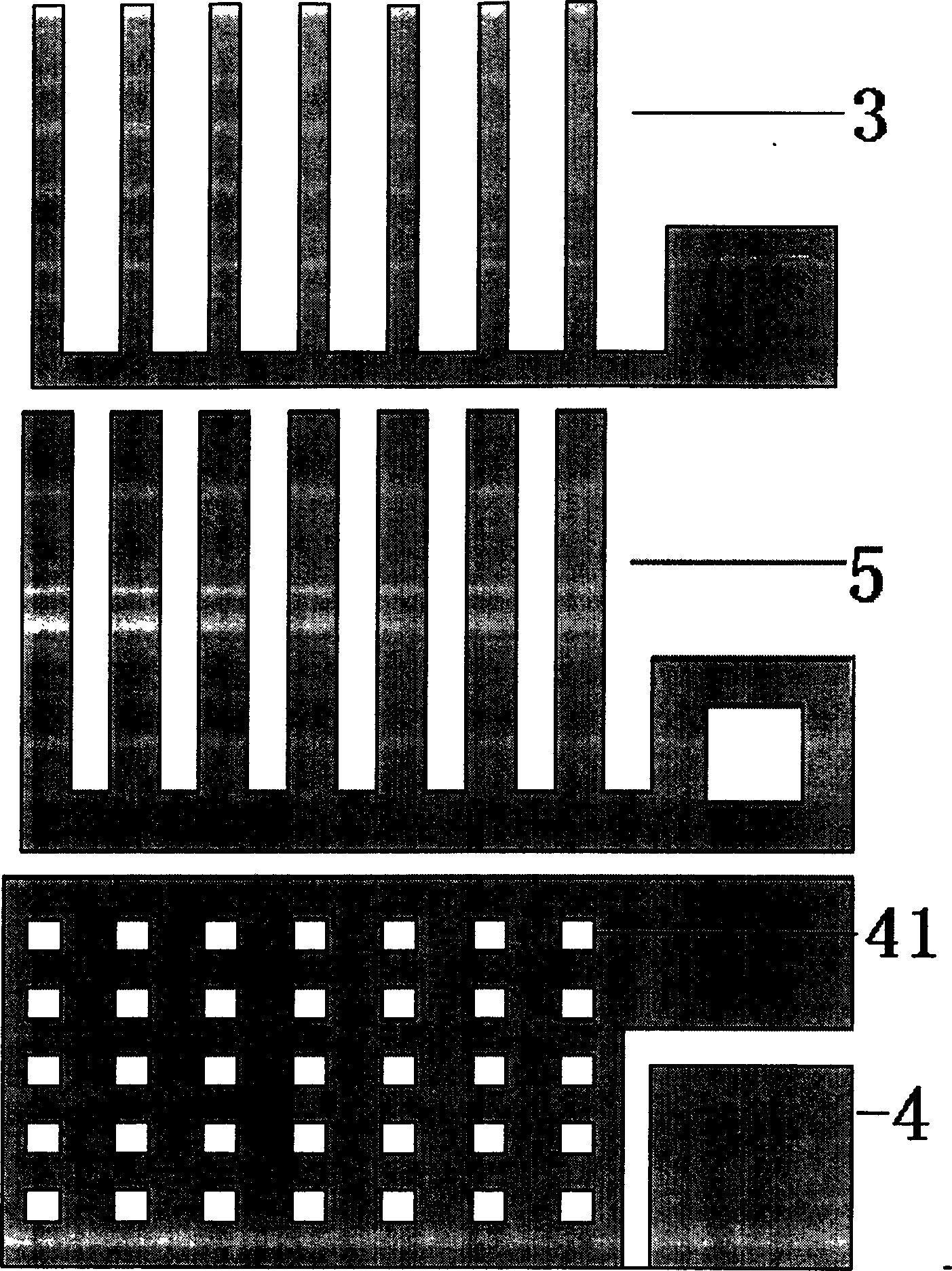

[0010] A CMOS process compatible relative humidity sensor for detecting humidity, which consists of a substrate 1, an oxide layer 2, a capacitor lower plate 3, and a capacitor upper plate 4, the oxide layer 2 is set on the substrate 1, and the capacitor lower plate 3 is spread on the oxide layer 2, and the upper plate 4 of the capacitor is located above the substrate 1 and the oxide layer 2. In this embodiment, the upper plate 4 of the capacitor is fixed on the oxide layer 2 through the anchor region. A hole 41 is provided on the region above the lower plate 3 of the capacitor on 4 .

[0011] The present invention is a capacitive relative humidity sensor using air as a humidity sensing medium, which consists of a substrate 1, an oxide layer 2, a capacitor lower plate 3 and a capacitor upper plate 4. The lower electrode plate 3 of the capacitor is located on the oxide layer 2, and is formed by sputtering aluminum and etching, and its top view is shown in the attached figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com