Piezoelectric porcelain composition, laminated piezoelectric device therefrom and process for producing the same

A technology of piezoelectric ceramics and piezoelectric devices, applied in ceramic layered products, chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as poor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

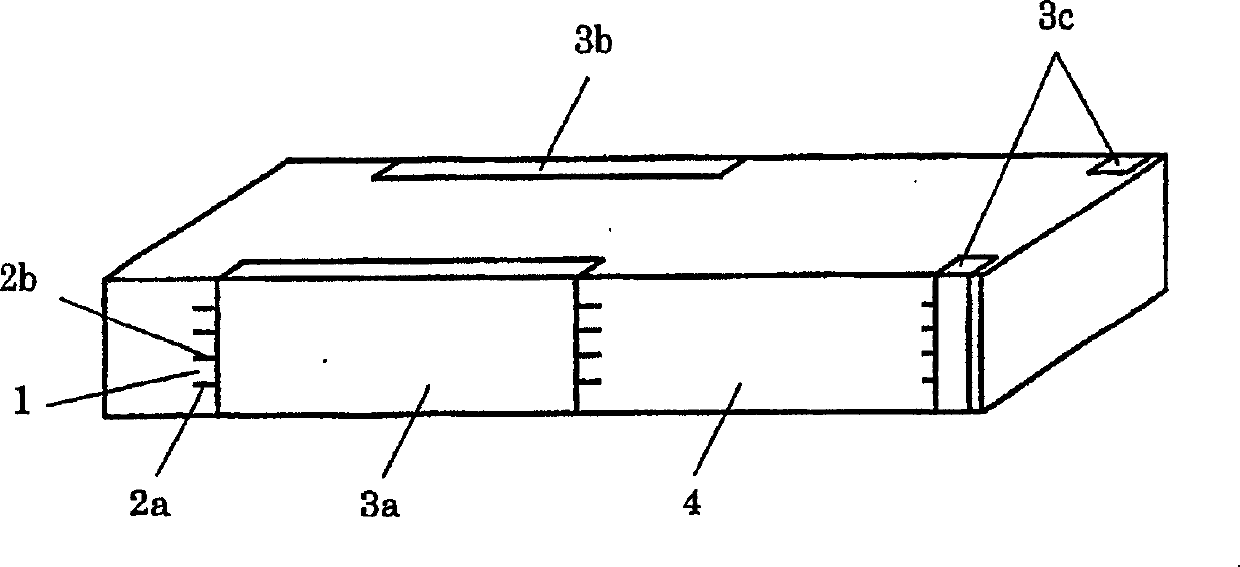

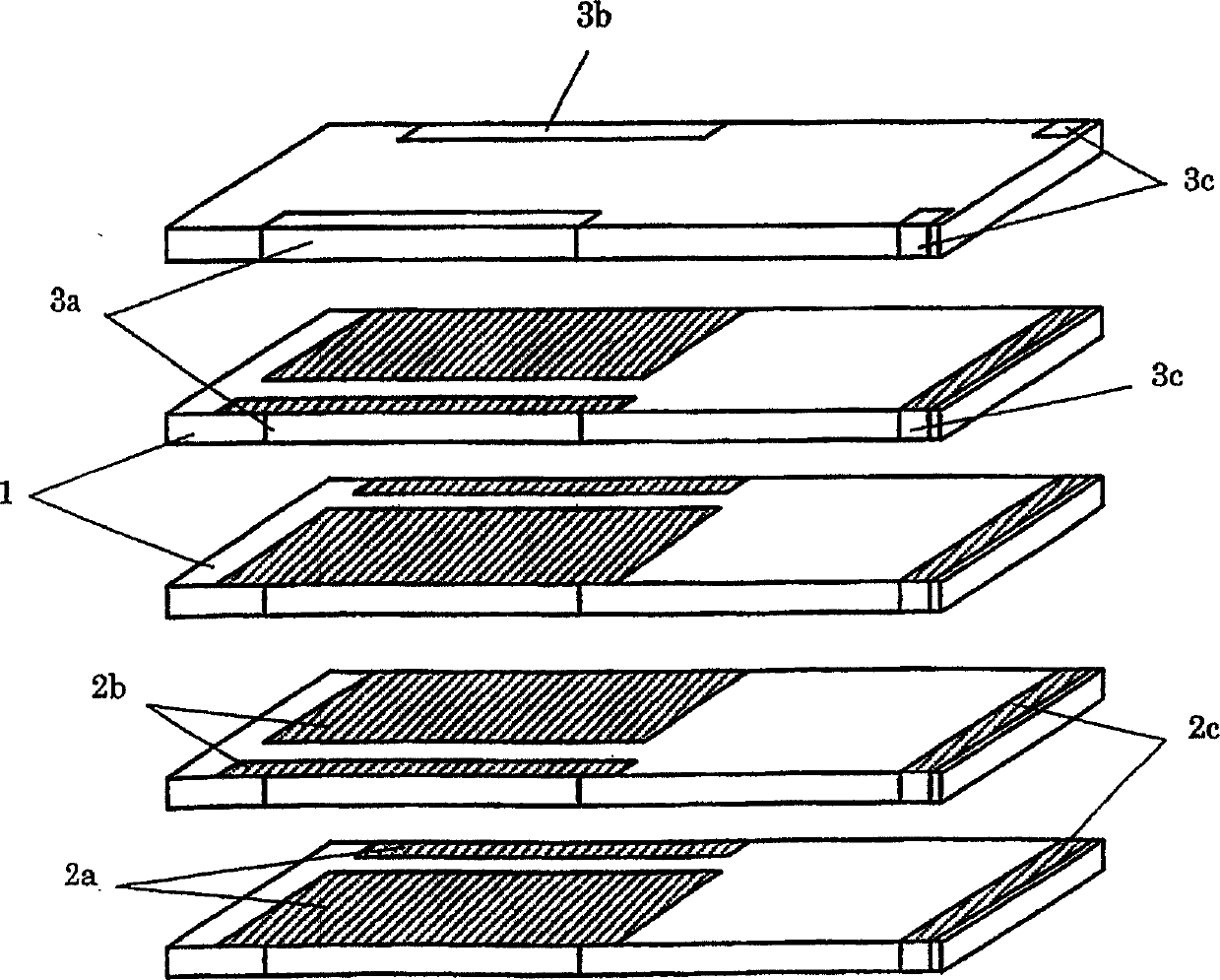

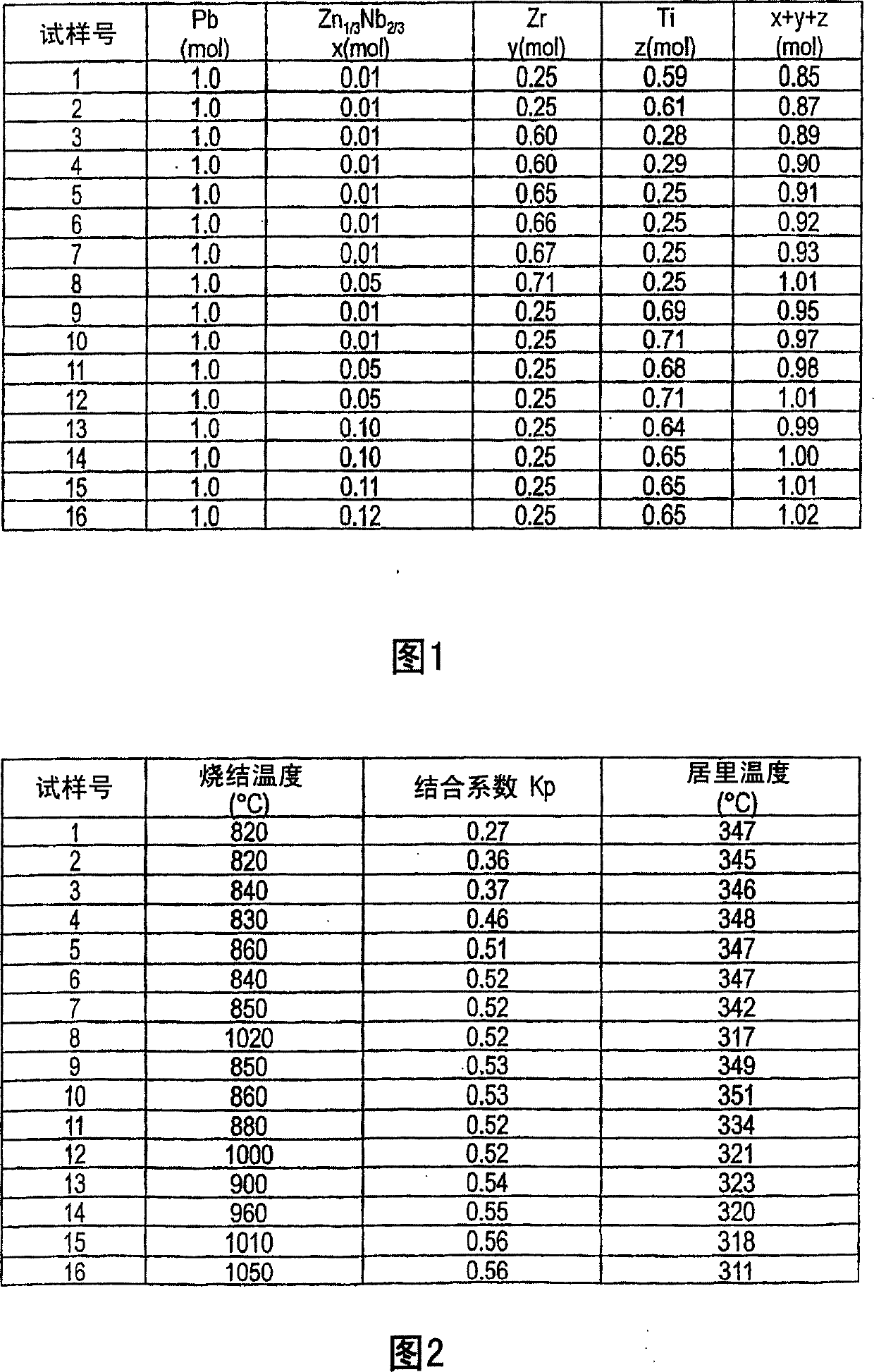

[0022] The piezoelectric ceramic composition and its production method in Example 1 of the present invention will be described.

[0023] First, lead oxide (PbO), titanium oxide (TiO 2 ), zirconia (ZrO 2 ), zinc oxide (ZnO), niobium oxide (Nb 2 o 5 ) powder as the raw material, each raw material was weighed and blended according to the molar ratio of the metal elements shown in Figure 1, and samples No.1 to No.16 were made.

[0024] Next, these raw materials were put into a porcelain pot ball mill together with water and a partially stabilized zirconia plate as a medium, and the porcelain pot ball mill was rotated and wet-mixed for 20 hours. At this time, the weight ratio of the raw material to water was 1:1, and a zirconia plate having a media diameter of 5 mm or less was used.

[0025] Next, the slurry obtained by the above-mentioned wet mixing was transferred to a stainless steel plate or the like, and dried in a dryer at 200° C. for a whole day and night. The dried pow...

Embodiment 2

[0037] The piezoelectric ceramic composition in Example 2 of the present invention will be described. The piezoelectric ceramic composition used in embodiment 2 is the same as embodiment 1, and its basic composition formula is Pb(Zn 1 / 3 Nb 2 / 3 ) x Zr y Ti z o 3 , when the metal element Pb is 1, the metal element Zn 1 / 3 Nb 2 / 3 The molar ratio of the metal element Zr is x, the molar ratio of the metal element Zr is y, and the molar ratio of the metal element Ti is z.

[0038] First, as in Example 1, with the composition shown in Figure 3, weigh and mix PbO and TiO 2 , ZrO 2 , ZnO, Nb 2 o 5 of each raw material. Then, piezoelectric ceramic elements of samples No. 17 to No. 62 were obtained by the same method as in Example 1, and their characteristics were measured. The measurement results of the properties are shown in Fig. 4 . In addition, the setting of the sintering temperature in Fig. 4 is the same as that in Example 1.

[0039] As shown by the results shown in ...

Embodiment 3

[0041] The piezoelectric ceramic composition in Example 3 of the present invention will be described.

[0042] First, in the same manner as in Example 1, PbO and TiO shown in FIG. 5 2 , ZrO 2 , ZnO, Nb 2 o 5 The composition, weighing, with each raw material. and add therein the SnO weighed as an additive with the composition shown in Figure 5 2 with MnO 2 . Then, piezoelectric ceramic elements of samples No. 63 to No. 88 were obtained by the same method as in Example 1, and their characteristics were measured. The measurement results are shown in Fig. 6 . In addition, the setting of the sintering temperature in FIG. 6 is the same as in Example 1.

[0043] As shown by the results shown in Figure 5 and Figure 6, the addition of SnO 2 with MnO 2 The piezoelectric ceramic composition shown in FIG. 5 in Example 3 has a Curie temperature of 300° C. or higher and a bonding coefficient Kp of almost 0.6 or higher, so superior piezoelectric characteristics are obtained compare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com