Method of preventing short circuiting in a lithium ion battery

A lithium-ion battery, charging process technology, applied in circuits, battery electrodes, secondary batteries, etc., can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

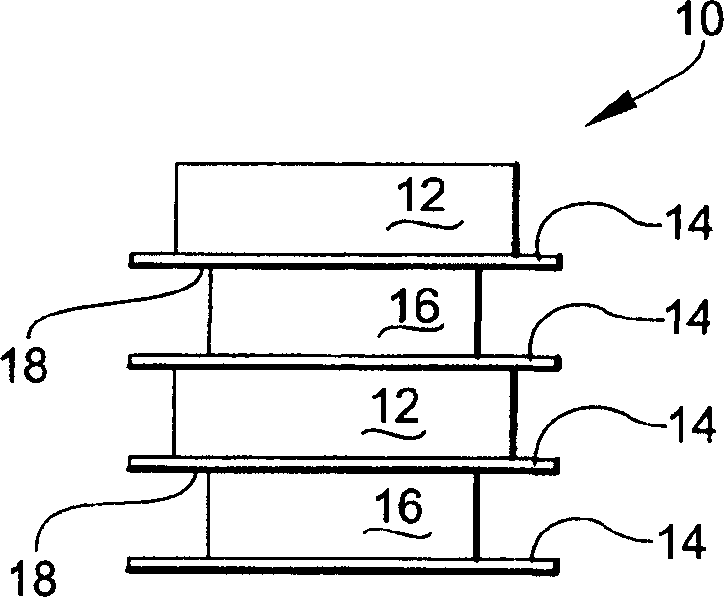

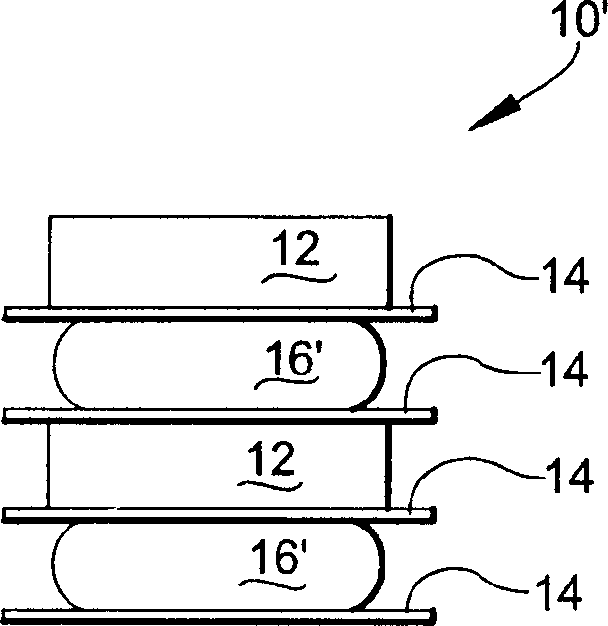

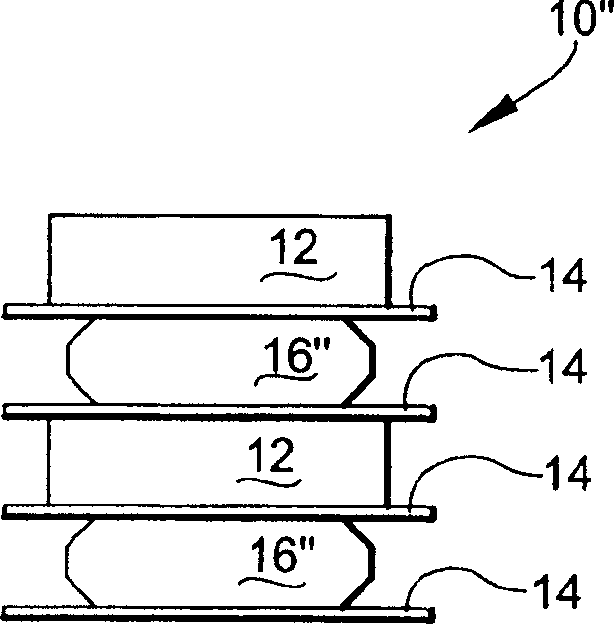

[0012] Referring to the drawings, wherein like numerals indicate like elements, FIG. 1 shows a prior art battery 10 .

[0013] The battery 10 is a conventional lithium-ion battery, cylindrical or prismatic. The anode is a lithiated intercalation compound (mostly carbon-based (e.g., coke and / or graphite), but can also be a metal oxide (e.g., WO 2 , MoO 2 , TiS 2 )). Preferably, the anode is a lithiated coke or graphite compound. The separator is a microporous polyolefin membrane preferably having a thickness of less than or equal to about 1 mil (25 microns). The separator can be a monolayer film made of polyolefins, including polyethylene (LDPE, LLDPE, HDPE, UHMWPE, and combinations thereof), or a polyolefin, including polyethylene (low density polyethylene (LDPE), Linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), ultra-high molecular weight polyethylene (UHMWPE) and their combinations), polypropylene, polybutene, polymethylpentene and their copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com