Single-purpose fluidal shortening for freezing flour dough and manufacturing method thereof

A technology of fluid shortening and frozen dough, which is applied in the directions of dough processing, application, baking, etc., can solve the problems of small specific volume of bread, damage to the gluten network structure of dough, increase in hardness of bread core, etc., and reduce the proofing time. , the production process is simple, the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

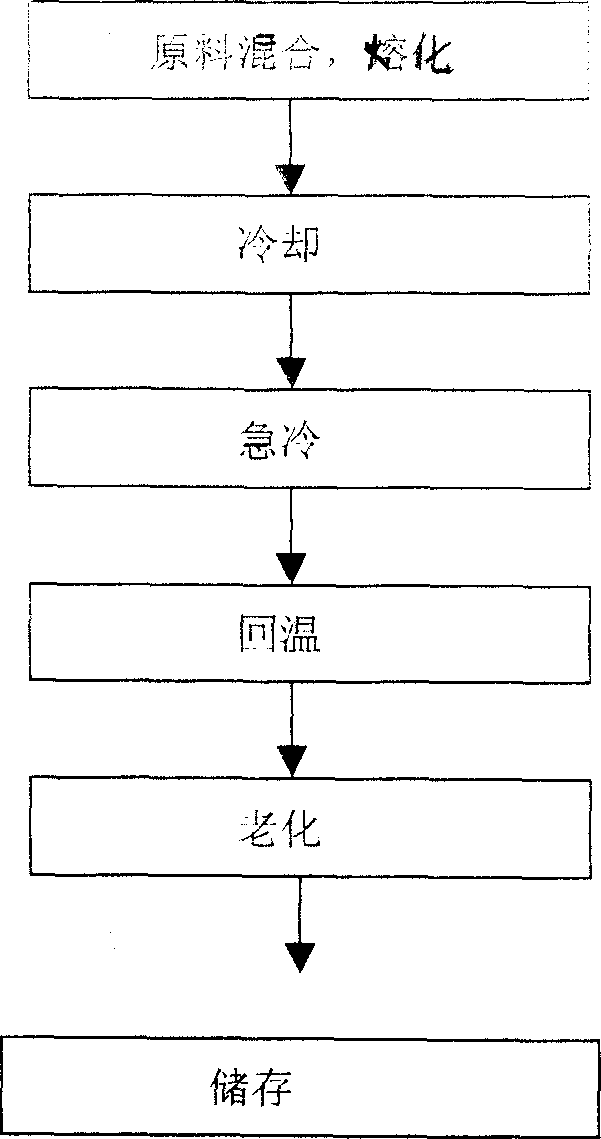

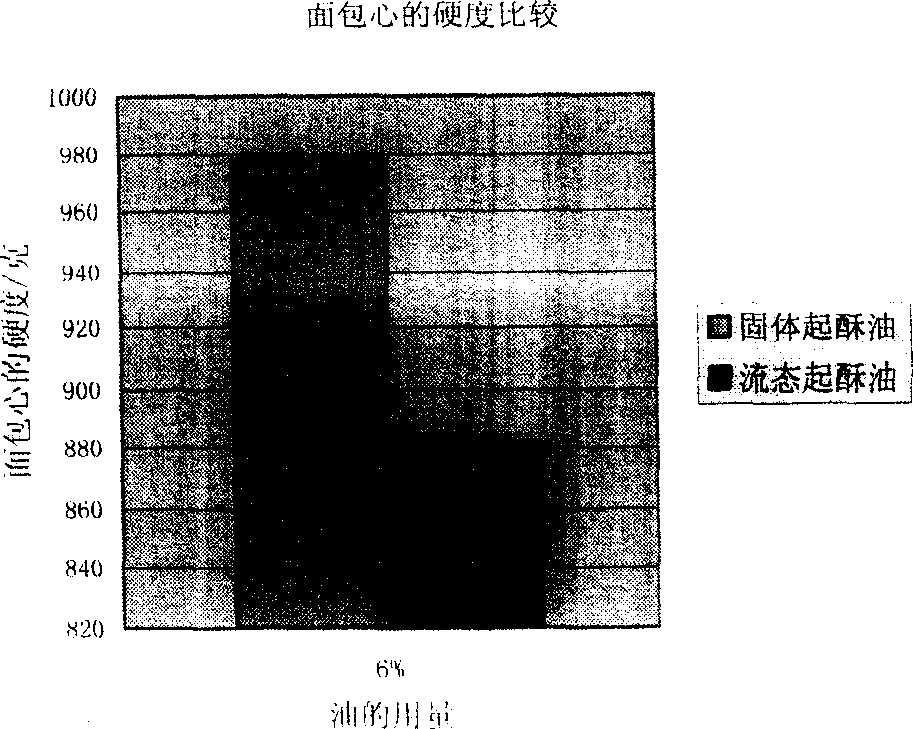

Embodiment 1

[0015] The present invention takes soybean salad oil as: 93% by weight, hydrogenated palm oil as solid fat: 6% by weight, emulsifier: adopts molecular distillation monoglyceride (MG) as: 2.5% by weight and sodium stearoyl lactylate (SSL) as: : 0.1% by weight, pour into the reactor and mix evenly. After melting the raw materials in a water bath at 75°C for 15 minutes, turn the reactor into a water bath at 50°C to cool for 20 minutes while stirring at a rate of 60rpm, and then The reactor was transferred to a water bath at 20°C for 30 minutes with stirring and quenching at a rate of 300rpm, then the temperature was raised to 45°C at a rate of 0.4°C / min, and aged at this temperature for two hours to obtain the product. Make the dough (120g / piece) according to the bread recipe, store the dough in a freezer for 3 days and thaw, freeze for 3 hours-after thawing once, the proofing time of the dough is 59 minutes, and the specific volume of the bread after baking is 6.10 ml / g. The bre...

Embodiment 2

[0017] The present invention takes soybean salad oil as: 94% by weight, hydrogenated palm oil as solid fat: 4.55% by weight, emulsifier: adopts molecular distillation monoglyceride (MG) as: 1% by weight and sodium stearoyl lactylate (SSL) as: : 0.05% by weight, poured into the reactor and mixed evenly, after melting the raw materials in a water bath of 70°C for 20 minutes, the reactor was transferred to a water bath of 55°C to cool for 15 minutes while stirring at a rate of 50rpm, and then the reaction The device was transferred to a water bath at 15°C and stirred and quenched at a rate of 250rpm for 25 minutes, then the temperature was raised to 40°C at a rate of 0.3°C / min, and then aged at this temperature for 1 hour to obtain the product. Make dough (120g / piece) according to the bread recipe, store the dough in the freezer for 5 days and thaw for 2 hours. Freeze and thaw twice. The specific volume of the dough can reach 6.51ml / g, and the proofing time is 75 minutes. The brea...

Embodiment 3

[0019] The present invention takes soybean salad oil as: 93.5% by weight, hydrogenated soybean oil as solid fat: 5.28% by weight, emulsifier: adopt molecular distillation monoglyceride (MG) as: 1.75% by weight and sodium stearoyl lactylate (SSL) as: : 0.08% by weight, poured into the reactor and mixed evenly, after melting the raw materials in a water bath at 73°C for 18 minutes, the reactor was transferred to a water bath at 53°C to cool for 18 minutes while stirring at a rate of 55rpm, and then the reaction The device was transferred to a water bath at 18°C for 28 minutes with stirring and quenching at a rate of 275rpm, then the temperature was raised to 43°C at a heating rate of 0.35°C / min, and then aged at this temperature for 1.5 hours to obtain the product. Make the dough (120g / piece) according to the bread recipe, then freeze and store the dough for 2 days, and thaw for 2 hours. The hardness of the bread core is 1423.94g when the freezing and thawing cycle is 1 time, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com