Flexible metal foil-polyimide laminate and making method

A technology of polyimide layer and laminated material, applied in metal layered products, printed circuit manufacturing, circuit substrate materials, etc., can solve problems such as uneconomical, achieve low lamination temperature, high adhesive strength, low drying effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0031] Laminate Preparation

[0032] The polyamic acid varnish prepared above was coated on a rolled copper foil test piece with a thickness of 30 cm x 25 cm and a thickness of 35 microns by using an applicator, and the thickness of the wet coating was 30 microns. The coating was dried in a 120°C oven for 2 minutes. A 30 cm x 25 cm, 25 micron thick polyimide film as listed in Table 1 was laminated over the varnish coat. Pressure lamination was carried out using a test roll laminator (Nishimura Machinery Co., Ltd.) at 120°C and a pressure of 15 kg / cm at a rate of 4 m / min. The laminated coupons were heat treated continuously at 160°C for 4 hours, at 250°C for 1 hour, and then at 350°C for 1 hour in a nitrogen-filled oven. The resulting laminate consisted of a 35 micron thick copper foil and a 28 micron thick polyimide layer (adhesive layer + polyimide film).

[0033] DMAc transmittance of polyimide film

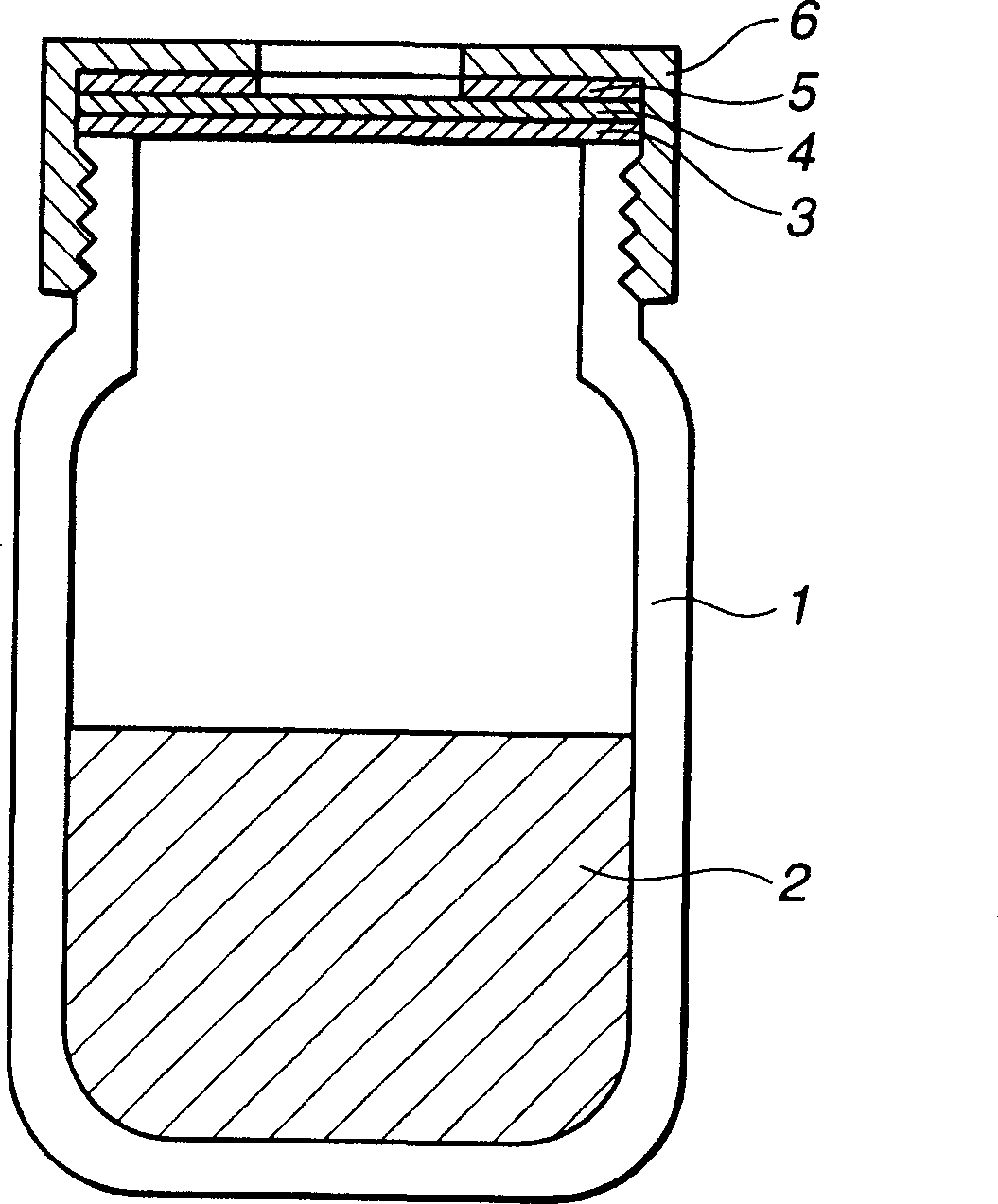

[0034] Such as figure 1 As shown, DMAc indicated by 2 has been poured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com