Magnesium aluminum silicate structures for DPF applications

A technology of diesel engine and ceramic filter, which is applied in the direction of dispersed particle filtration, membrane filter, application, etc., can solve problems such as difficulty in engine work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Table 1 shows the raw materials used to prepare the samples. The comparative (non-invention) samples are shown in Table 2. The samples of the invention are shown in Tables 3 and 4. Table 5 shows a comparison of the pressure drop between the filter prepared according to the method of the present invention and two comparative cordierite DPFs.

[0042] When preparing the sample, weigh the inorganic powder and solid organic binder and lubricant into a Nalgene(R) jar, and mix on a Turbula(R) blender for 20 minutes. Transfer the dry ingredients to a grinder, gradually add liquid organics and water, and grind the mixture to a plastic consistency.

[0043] The ground batch was extruded three times into a hollow flour stick, and then a honeycomb body with a diameter of 1 or 2 inches, 200 holes per square inch, and a wall thickness of 0.019-0.022 inches was formed. For some compositions, it can also be extruded into a 5 / 16 inch rod or 0.020 inch ribbon. A 1-inch diameter honeycomb bo...

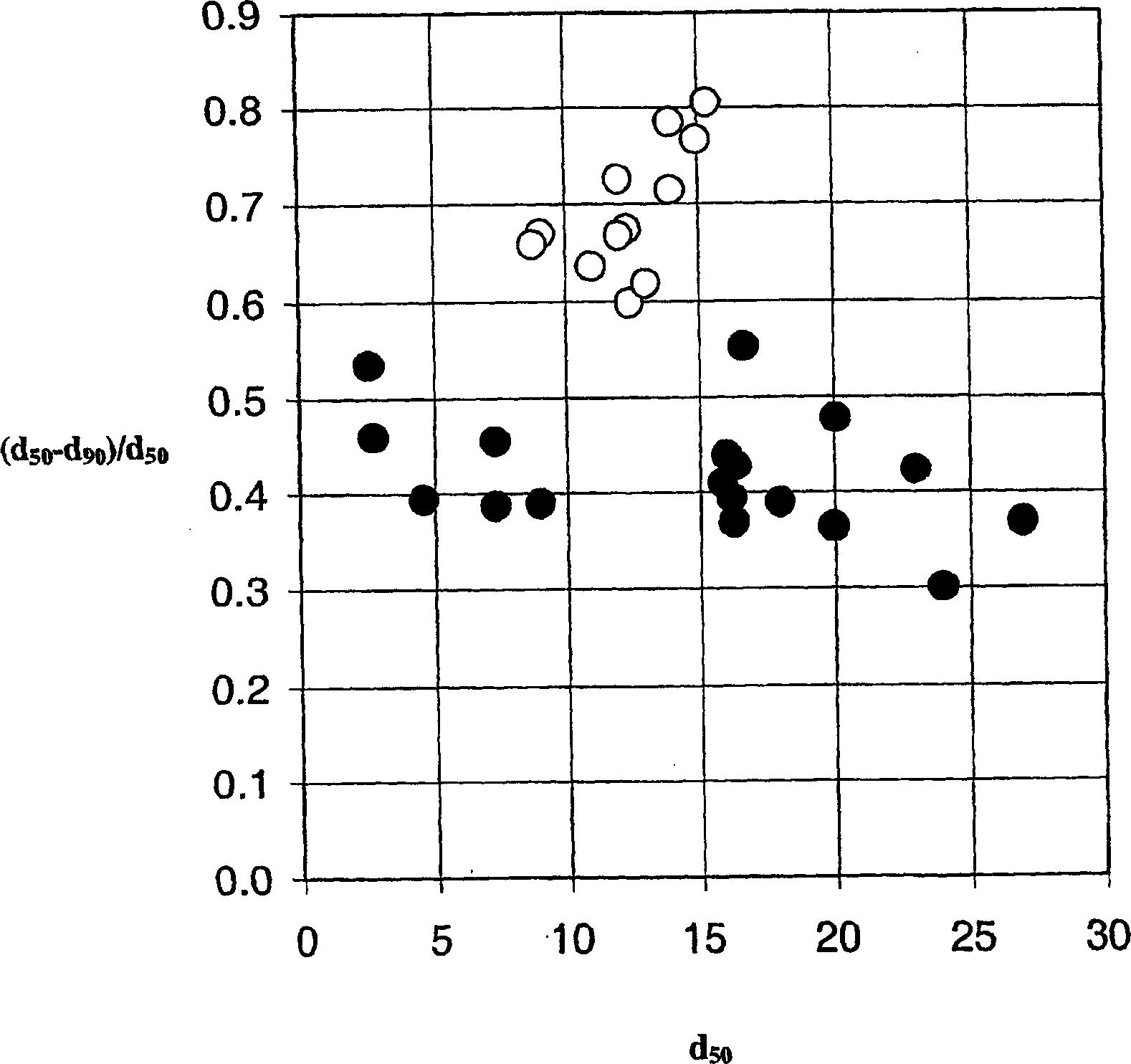

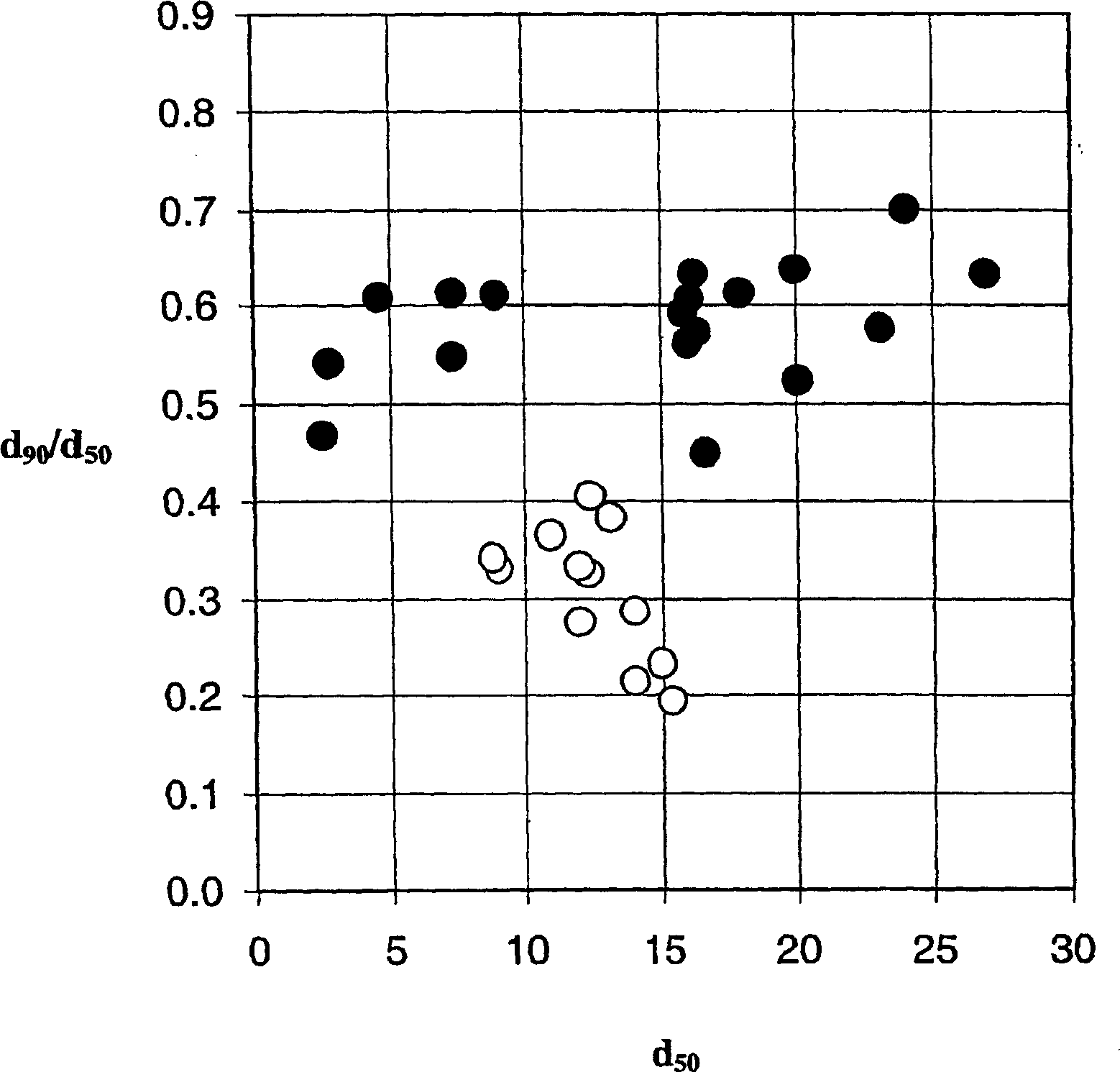

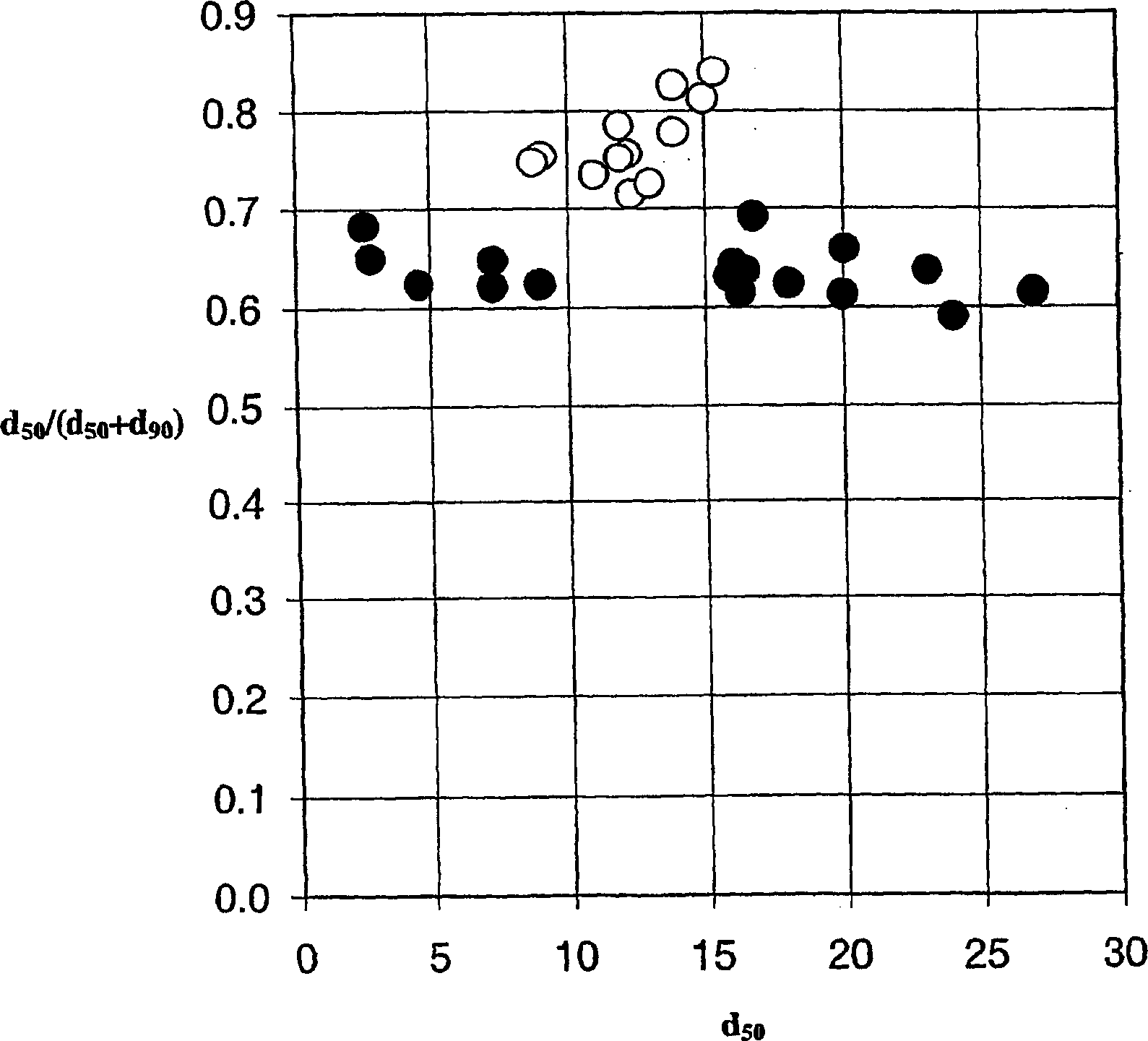

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com